KR20120098632A - 레이저 삼각 측정을 이용한 층 두께의 측정 방법 및 장치 - Google Patents

레이저 삼각 측정을 이용한 층 두께의 측정 방법 및 장치 Download PDFInfo

- Publication number

- KR20120098632A KR20120098632A KR1020127009905A KR20127009905A KR20120098632A KR 20120098632 A KR20120098632 A KR 20120098632A KR 1020127009905 A KR1020127009905 A KR 1020127009905A KR 20127009905 A KR20127009905 A KR 20127009905A KR 20120098632 A KR20120098632 A KR 20120098632A

- Authority

- KR

- South Korea

- Prior art keywords

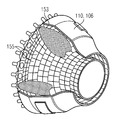

- layer thickness

- structural members

- coating

- blades

- laser triangulation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000000034 method Methods 0.000 title claims abstract description 29

- 238000000576 coating method Methods 0.000 claims abstract description 23

- 239000011248 coating agent Substances 0.000 claims abstract description 12

- 238000005259 measurement Methods 0.000 claims description 13

- 238000012544 monitoring process Methods 0.000 abstract 1

- 239000010410 layer Substances 0.000 description 37

- 238000002485 combustion reaction Methods 0.000 description 17

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 10

- 239000002245 particle Substances 0.000 description 7

- 239000013078 crystal Substances 0.000 description 6

- 238000009413 insulation Methods 0.000 description 5

- 239000000463 material Substances 0.000 description 5

- 229910000601 superalloy Inorganic materials 0.000 description 5

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 4

- 229910045601 alloy Inorganic materials 0.000 description 4

- 239000000956 alloy Substances 0.000 description 4

- 229910017052 cobalt Inorganic materials 0.000 description 4

- 239000010941 cobalt Substances 0.000 description 4

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 description 4

- 229910052759 nickel Inorganic materials 0.000 description 4

- 239000011241 protective layer Substances 0.000 description 4

- 238000005266 casting Methods 0.000 description 3

- 239000000919 ceramic Substances 0.000 description 3

- 238000001816 cooling Methods 0.000 description 3

- 238000007711 solidification Methods 0.000 description 3

- 230000008023 solidification Effects 0.000 description 3

- 229910052727 yttrium Inorganic materials 0.000 description 3

- VWQVUPCCIRVNHF-UHFFFAOYSA-N yttrium atom Chemical compound [Y] VWQVUPCCIRVNHF-UHFFFAOYSA-N 0.000 description 3

- 239000000292 calcium oxide Substances 0.000 description 2

- ODINCKMPIJJUCX-UHFFFAOYSA-N calcium oxide Inorganic materials [Ca]=O ODINCKMPIJJUCX-UHFFFAOYSA-N 0.000 description 2

- 239000011247 coating layer Substances 0.000 description 2

- 230000007797 corrosion Effects 0.000 description 2

- 238000005260 corrosion Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 238000000313 electron-beam-induced deposition Methods 0.000 description 2

- 229910052735 hafnium Inorganic materials 0.000 description 2

- VBJZVLUMGGDVMO-UHFFFAOYSA-N hafnium atom Chemical compound [Hf] VBJZVLUMGGDVMO-UHFFFAOYSA-N 0.000 description 2

- 239000000395 magnesium oxide Substances 0.000 description 2

- CPLXHLVBOLITMK-UHFFFAOYSA-N magnesium oxide Inorganic materials [Mg]=O CPLXHLVBOLITMK-UHFFFAOYSA-N 0.000 description 2

- AXZKOIWUVFPNLO-UHFFFAOYSA-N magnesium;oxygen(2-) Chemical compound [O-2].[Mg+2] AXZKOIWUVFPNLO-UHFFFAOYSA-N 0.000 description 2

- 238000005240 physical vapour deposition Methods 0.000 description 2

- 229910052761 rare earth metal Inorganic materials 0.000 description 2

- 150000002910 rare earth metals Chemical class 0.000 description 2

- 230000035939 shock Effects 0.000 description 2

- 229910052710 silicon Inorganic materials 0.000 description 2

- 239000010703 silicon Substances 0.000 description 2

- 239000007921 spray Substances 0.000 description 2

- 239000000758 substrate Substances 0.000 description 2

- OYPRJOBELJOOCE-UHFFFAOYSA-N Calcium Chemical compound [Ca] OYPRJOBELJOOCE-UHFFFAOYSA-N 0.000 description 1

- 241000397426 Centroberyx lineatus Species 0.000 description 1

- 239000008186 active pharmaceutical agent Substances 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- BRPQOXSCLDDYGP-UHFFFAOYSA-N calcium oxide Chemical compound [O-2].[Ca+2] BRPQOXSCLDDYGP-UHFFFAOYSA-N 0.000 description 1

- 238000005524 ceramic coating Methods 0.000 description 1

- 230000015271 coagulation Effects 0.000 description 1

- 238000005345 coagulation Methods 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 239000002826 coolant Substances 0.000 description 1

- 230000005611 electricity Effects 0.000 description 1

- 238000005242 forging Methods 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 238000007689 inspection Methods 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 229910001338 liquidmetal Inorganic materials 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000000155 melt Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 238000003801 milling Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 1

- SIWVEOZUMHYXCS-UHFFFAOYSA-N oxo(oxoyttriooxy)yttrium Chemical compound O=[Y]O[Y]=O SIWVEOZUMHYXCS-UHFFFAOYSA-N 0.000 description 1

- 239000011253 protective coating Substances 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 238000012797 qualification Methods 0.000 description 1

- 238000003908 quality control method Methods 0.000 description 1

- 238000013441 quality evaluation Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 238000012958 reprocessing Methods 0.000 description 1

- 238000005488 sandblasting Methods 0.000 description 1

- 239000004575 stone Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B11/00—Measuring arrangements characterised by the use of optical techniques

- G01B11/02—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness

- G01B11/06—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness for measuring thickness ; e.g. of sheet material

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B11/00—Measuring arrangements characterised by the use of optical techniques

- G01B11/02—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness

- G01B11/06—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness for measuring thickness ; e.g. of sheet material

- G01B11/0616—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness for measuring thickness ; e.g. of sheet material of coating

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B11/00—Measuring arrangements characterised by the use of optical techniques

- G01B11/02—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness

- G01B11/06—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness for measuring thickness ; e.g. of sheet material

- G01B11/0616—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness for measuring thickness ; e.g. of sheet material of coating

- G01B11/0683—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness for measuring thickness ; e.g. of sheet material of coating measurement during deposition or removal of the layer

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

- Length Measuring Devices By Optical Means (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP09013170A EP2312267A1 (de) | 2009-10-19 | 2009-10-19 | Verfahren zur Schichtdickenmessung mittels Lasertriangulation und Vorrichtung |

| EP09013170.7 | 2009-10-19 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20120098632A true KR20120098632A (ko) | 2012-09-05 |

Family

ID=41557637

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020127009905A Ceased KR20120098632A (ko) | 2009-10-19 | 2010-06-21 | 레이저 삼각 측정을 이용한 층 두께의 측정 방법 및 장치 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US20120263866A1 (enExample) |

| EP (2) | EP2312267A1 (enExample) |

| JP (1) | JP2013508696A (enExample) |

| KR (1) | KR20120098632A (enExample) |

| CN (1) | CN102575927A (enExample) |

| RU (1) | RU2541440C2 (enExample) |

| WO (1) | WO2011047890A1 (enExample) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9303983B2 (en) * | 2012-04-02 | 2016-04-05 | The Boeing Company | Sealant analysis system |

| DE102012217175A1 (de) | 2012-09-24 | 2014-03-27 | Evonik Litarion Gmbh | Verfahren zur Ausrichtung zweier Lasersensoren zueinander |

| DE102012217176A1 (de) | 2012-09-24 | 2014-03-27 | Evonik Litarion Gmbh | Verfahren zur Ausrichtung eines Lasersensors zu einem Messobjekt |

| CN103245291B (zh) * | 2013-04-24 | 2015-12-09 | 中国船舶重工集团公司第十二研究所 | 叶片类零件装配精度检测方法 |

| US9721044B2 (en) | 2013-05-10 | 2017-08-01 | General Electric Company | Systems and methods for non-destructive evaluation of molds and crucibles used in investment casting |

| DE102015217166A1 (de) * | 2015-09-09 | 2017-03-09 | Mtu Aero Engines Gmbh | Verfahren zur Bestimmung von mindestens einer Oberflächeneigenschaft |

| NL2016652B1 (en) | 2016-04-21 | 2017-11-16 | Innovative Mechanical Engineering Tech B V | Electrospinning device and method. |

| GB201808325D0 (en) * | 2018-05-21 | 2018-07-11 | 3D Automated Metrology Inspection Ltd | Apparatus For Monitoring A Coating |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6024A (en) * | 1849-01-09 | Cast-iron gar-wheel | ||

| US7027A (en) * | 1850-01-15 | Circulak | ||

| US10011A (en) * | 1853-09-13 | Improvement in the shape of scythes | ||

| US5013A (en) * | 1847-03-13 | Improvement in apparatus for the manufacture of malleable iron | ||

| DE10313888A1 (de) * | 2003-03-27 | 2004-10-28 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Verfahren und Vorrichtung zur online Materialschichtdickenbestimmung |

| US8315834B2 (en) * | 2003-12-17 | 2012-11-20 | Siemens Energy, Inc. | System and method for measuring coating thickness |

| EP1643209B1 (de) * | 2004-09-30 | 2020-11-04 | Ansaldo Energia IP UK Limited | Messverfahren zum Messen einer Dicke einer Beschichtung |

| WO2006116841A1 (en) * | 2005-04-29 | 2006-11-09 | National Research Council Of Canada | Method of on-line thickness measurement of applied coatings |

| EP1844892A1 (de) * | 2006-04-13 | 2007-10-17 | ALSTOM Technology Ltd | Verfahren zur Laserentfernung von Beschichtenmaterialen in Kühlenlöchern eines Turbinenbauteiles |

| JP2008202969A (ja) * | 2007-02-16 | 2008-09-04 | Toppan Printing Co Ltd | 膜厚測定装置及び膜厚測定方法 |

| RU82035U1 (ru) * | 2008-08-28 | 2009-04-10 | Юрий Андреевич Сазонов | Устройство для измерения толщины движущейся пленки (варианты) |

| US8031346B2 (en) * | 2008-10-31 | 2011-10-04 | Siemens Energy, Inc. | Coating evaluation process |

-

2009

- 2009-10-19 EP EP09013170A patent/EP2312267A1/de not_active Withdrawn

-

2010

- 2010-06-21 CN CN2010800472248A patent/CN102575927A/zh active Pending

- 2010-06-21 EP EP10728168A patent/EP2491338A1/de not_active Withdrawn

- 2010-06-21 JP JP2012534593A patent/JP2013508696A/ja active Pending

- 2010-06-21 WO PCT/EP2010/058722 patent/WO2011047890A1/de not_active Ceased

- 2010-06-21 KR KR1020127009905A patent/KR20120098632A/ko not_active Ceased

- 2010-06-21 US US13/502,381 patent/US20120263866A1/en not_active Abandoned

- 2010-06-21 RU RU2012120660/28A patent/RU2541440C2/ru not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| RU2012120660A (ru) | 2013-11-27 |

| WO2011047890A1 (de) | 2011-04-28 |

| CN102575927A (zh) | 2012-07-11 |

| JP2013508696A (ja) | 2013-03-07 |

| EP2491338A1 (de) | 2012-08-29 |

| EP2312267A1 (de) | 2011-04-20 |

| RU2541440C2 (ru) | 2015-02-10 |

| US20120263866A1 (en) | 2012-10-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8437010B2 (en) | Surface analysis for detecting closed holes, and device | |

| KR20120098632A (ko) | 레이저 삼각 측정을 이용한 층 두께의 측정 방법 및 장치 | |

| RU2490102C2 (ru) | Способ сварки и конструктивный элемент | |

| US8847106B2 (en) | Welding process with a controlled temperature profile and a device therefor | |

| US20130268107A1 (en) | Surface analysis for detecting closed holes and method for reopening | |

| US20130115479A1 (en) | Porous ceramic coating system | |

| US20110031226A1 (en) | Method for Welding Depending on a Preferred Direction of the Substrate | |

| CN102086503A (zh) | 掩蔽材料、掩蔽层、用于掩蔽基材的方法以及用于涂覆基材的方法 | |

| US9421639B2 (en) | Component having weld seam and method for producing a weld seam | |

| JP2015536406A (ja) | 孔周辺の改質表面 | |

| US8123105B2 (en) | Process for brazing wide gaps | |

| US20160312622A1 (en) | Thermal barrier coating of a turbine blade | |

| US20110020127A1 (en) | Component Comprising Overlapping Weld Seams and Method for the Production Thereof | |

| US20110293431A1 (en) | Component having varying structures and method for production | |

| US20100224600A1 (en) | Two-step welding process | |

| US20110056919A1 (en) | Method for Fusing Curved Surfaces, and a Device | |

| US8616764B2 (en) | Method for testing a thermography apparatus, designed for carrying out a thermography method, for its correct operation, test component therefor and method for its production | |

| US10975463B2 (en) | Monitoring and control of a coating process on the basis of a heat distribution on the workpiece | |

| US9957809B2 (en) | Modified interface around a hole | |

| US20110062120A1 (en) | Device for welding using a process chamber and welding method | |

| US8689731B2 (en) | Apparatus and process for coating a component with aligning device | |

| US20110159260A1 (en) | Multiple layer system comprising a metallic layer and a ceramic layer | |

| US8865255B2 (en) | Method for assessing the coolant consumption within actively cooled components | |

| US20120118524A1 (en) | Core die with variable pins and process for producing a core | |

| US20130213122A1 (en) | Component testing and method for operating a machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20120418 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| A201 | Request for examination | ||

| PA0201 | Request for examination |

Patent event code: PA02012R01D Patent event date: 20150119 Comment text: Request for Examination of Application |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20151106 Patent event code: PE09021S01D |

|

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20160219 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20151106 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |