KR20120026973A - 고 점도 물질의 중합화법 - Google Patents

고 점도 물질의 중합화법 Download PDFInfo

- Publication number

- KR20120026973A KR20120026973A KR1020110088972A KR20110088972A KR20120026973A KR 20120026973 A KR20120026973 A KR 20120026973A KR 1020110088972 A KR1020110088972 A KR 1020110088972A KR 20110088972 A KR20110088972 A KR 20110088972A KR 20120026973 A KR20120026973 A KR 20120026973A

- Authority

- KR

- South Korea

- Prior art keywords

- mixing means

- mixing

- high viscosity

- treated

- molecular weight

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G64/00—Macromolecular compounds obtained by reactions forming a carbonic ester link in the main chain of the macromolecule

- C08G64/20—General preparatory processes

- C08G64/205—General preparatory processes characterised by the apparatus used

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J3/00—Processes of treating or compounding macromolecular substances

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F23/00—Mixing according to the phases to be mixed, e.g. dispersing or emulsifying

- B01F23/40—Mixing liquids with liquids; Emulsifying

- B01F23/47—Mixing liquids with liquids; Emulsifying involving high-viscosity liquids, e.g. asphalt

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/70—Spray-mixers, e.g. for mixing intersecting sheets of material

- B01F25/74—Spray-mixers, e.g. for mixing intersecting sheets of material with rotating parts, e.g. discs

- B01F25/741—Spray-mixers, e.g. for mixing intersecting sheets of material with rotating parts, e.g. discs with a disc or a set of discs mounted on a shaft rotating about a vertical axis, on top of which the material to be thrown outwardly is fed

- B01F25/7411—Spray-mixers, e.g. for mixing intersecting sheets of material with rotating parts, e.g. discs with a disc or a set of discs mounted on a shaft rotating about a vertical axis, on top of which the material to be thrown outwardly is fed with repeated action, i.e. the material thrown outwardly being guided, by means provided on the surrounding casing or on top of the next lower disc

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

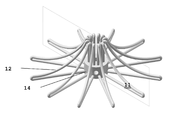

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/05—Stirrers

- B01F27/11—Stirrers characterised by the configuration of the stirrers

- B01F27/115—Stirrers characterised by the configuration of the stirrers comprising discs or disc-like elements essentially perpendicular to the stirrer shaft axis

- B01F27/1152—Stirrers characterised by the configuration of the stirrers comprising discs or disc-like elements essentially perpendicular to the stirrer shaft axis with separate elements other than discs fixed on the discs, e.g. vanes fixed on the discs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/05—Stirrers

- B01F27/11—Stirrers characterised by the configuration of the stirrers

- B01F27/119—Stirrers with rigid wires or flexible rods

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/05—Stirrers

- B01F27/11—Stirrers characterised by the configuration of the stirrers

- B01F27/13—Openwork frame or cage stirrers not provided for in other groups of this subclass

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

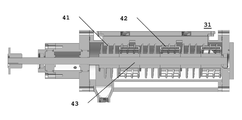

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/05—Stirrers

- B01F27/11—Stirrers characterised by the configuration of the stirrers

- B01F27/19—Stirrers with two or more mixing elements mounted in sequence on the same axis

- B01F27/192—Stirrers with two or more mixing elements mounted in sequence on the same axis with dissimilar elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

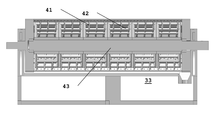

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

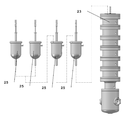

- B01F27/60—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a horizontal or inclined axis

- B01F27/625—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a horizontal or inclined axis the receptacle being divided into compartments, e.g. with porous divisions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/80—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis

- B01F27/87—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis the receptacle being divided into superimposed compartments

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J19/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J19/18—Stationary reactors having moving elements inside

- B01J19/20—Stationary reactors having moving elements inside in the form of helices, e.g. screw reactors

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F2/00—Processes of polymerisation

- C08F2/01—Processes of polymerisation characterised by special features of the polymerisation apparatus used

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G64/00—Macromolecular compounds obtained by reactions forming a carbonic ester link in the main chain of the macromolecule

- C08G64/20—General preparatory processes

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G64/00—Macromolecular compounds obtained by reactions forming a carbonic ester link in the main chain of the macromolecule

- C08G64/20—General preparatory processes

- C08G64/30—General preparatory processes using carbonates

- C08G64/307—General preparatory processes using carbonates and phenols

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F2101/00—Mixing characterised by the nature of the mixed materials or by the application field

- B01F2101/2805—Mixing plastics, polymer material ingredients, monomers or oligomers

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Organic Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Engineering & Computer Science (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Polyesters Or Polycarbonates (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP10176192.2A EP2428266B1 (en) | 2010-09-10 | 2010-09-10 | Process for preparation of high viscosity polymeric materials |

| EP10176192.2 | 2010-09-10 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20120026973A true KR20120026973A (ko) | 2012-03-20 |

Family

ID=43558342

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020110088972A Withdrawn KR20120026973A (ko) | 2010-09-10 | 2011-09-02 | 고 점도 물질의 중합화법 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US8796401B2 (enExample) |

| EP (1) | EP2428266B1 (enExample) |

| JP (1) | JP5829079B2 (enExample) |

| KR (1) | KR20120026973A (enExample) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102013019611A1 (de) * | 2013-11-25 | 2015-05-28 | Gneuss Gmbh | Vorrichtung zur Herstellung von Polymeren |

| CN112295492A (zh) * | 2020-11-16 | 2021-02-02 | 昆山全亚冠环保科技有限公司 | 一种靶材及应用该靶材的半导体器件加工设备 |

| CN115607501B (zh) * | 2022-09-22 | 2023-06-16 | 广东科盈科技有限公司 | 乳酸菌修护精华乳、乳化装置及制备方法 |

Family Cites Families (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3440019A (en) * | 1965-06-01 | 1969-04-22 | Vickers Zimmer Ag | Polycondensation reactor |

| DE1557063C2 (de) * | 1967-06-15 | 1974-04-25 | Feinpruef Feinmess U Pruefgera | Kontinuierlicher Laminarmischer fuer viscose,insbesondere hochviskose Medien |

| JPS5015738B1 (enExample) * | 1970-06-24 | 1975-06-07 | ||

| SU1187838A1 (ru) * | 1984-05-21 | 1985-10-30 | Днепродзержинский Ордена Трудового Красного Знамени Индустриальный Институт Им.М.И.Арсеничева | Устройство дл механической обработки эмульсии |

| JPH07330910A (ja) * | 1994-06-08 | 1995-12-19 | Hitachi Ltd | 重縮合系高分子の連続塊状重合方法及び装置 |

| JPH08311175A (ja) * | 1995-05-17 | 1996-11-26 | Shimadzu Corp | ポリ乳酸の製造法 |

| JPH093200A (ja) * | 1995-06-20 | 1997-01-07 | Hitachi Ltd | 重縮合系高分子の連続製造装置及び製造方法 |

| JPH09165455A (ja) * | 1995-12-18 | 1997-06-24 | Hitachi Ltd | 連続重縮合装置及び方法 |

| JPH09169852A (ja) * | 1995-12-20 | 1997-06-30 | Hitachi Ltd | 連続重縮合装置及び方法 |

| USRE38050E1 (en) | 1996-03-05 | 2003-03-25 | Asahi Kasei Kabushiki Kaisha | Polycarbonate comprising different kinds of bonding units and process for the preparation thereof |

| JPH11158262A (ja) * | 1997-11-28 | 1999-06-15 | Hitachi Ltd | ポリカーボネートの製造方法 |

| JPH11181068A (ja) * | 1997-12-22 | 1999-07-06 | Dainippon Ink & Chem Inc | ポリエーテルエステルの製造方法 |

| JPH11310632A (ja) * | 1998-04-28 | 1999-11-09 | Daicel Chem Ind Ltd | ポリカーボネートの製造方法 |

| JPH11310631A (ja) * | 1998-04-28 | 1999-11-09 | Daicel Chem Ind Ltd | ポリカーボネートの製造法 |

| DE10119851A1 (de) | 2001-04-24 | 2002-10-31 | Bayer Ag | Verfahren zur kontinuierlichen Herstellung von Polycarbonaten nach dem Schmelzumesterungsverfahren |

| DE10322106B4 (de) * | 2003-05-09 | 2006-05-11 | Aquafil Engineering Gmbh | Verfahren und Reaktor zur kontinuierlichen Herstellung von Polymeren |

| AU2005252556B2 (en) | 2004-06-14 | 2007-11-01 | Asahi Kasei Chemicals Corporation | Process for efficiently producing aromatic polycarbonate |

| ATE480577T1 (de) | 2004-06-14 | 2010-09-15 | Asahi Kasei Chemicals Corp | Verfahren zur stabilen herstellung von aromatischen polycarbonaten |

| AU2005252555B2 (en) | 2004-06-14 | 2007-11-01 | Asahi Kasei Chemicals Corporation | Improved process for producing aromatic polycarbonate |

| KR100785683B1 (ko) | 2004-06-14 | 2007-12-17 | 아사히 가세이 케미칼즈 가부시키가이샤 | 고품질 방향족 폴리카보네이트의 제조 방법 |

| CN100519621C (zh) | 2004-06-16 | 2009-07-29 | 旭化成化学株式会社 | 用于生产芳族聚碳酸酯的聚合装置 |

| KR100760159B1 (ko) * | 2006-01-12 | 2007-10-04 | 주식회사 엘지화학 | 점성물질 교반장치 |

| TWI284560B (en) * | 2006-01-26 | 2007-08-01 | Mao-Hsin Huang | Mixing device for beverage dispenser |

-

2010

- 2010-09-10 EP EP10176192.2A patent/EP2428266B1/en not_active Not-in-force

-

2011

- 2011-08-31 JP JP2011188886A patent/JP5829079B2/ja not_active Expired - Fee Related

- 2011-09-02 KR KR1020110088972A patent/KR20120026973A/ko not_active Withdrawn

- 2011-09-06 US US13/225,767 patent/US8796401B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2012057156A (ja) | 2012-03-22 |

| JP5829079B2 (ja) | 2015-12-09 |

| EP2428266A1 (en) | 2012-03-14 |

| US8796401B2 (en) | 2014-08-05 |

| EP2428266B1 (en) | 2013-07-10 |

| US20120065355A1 (en) | 2012-03-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR101134323B1 (ko) | 디올로 디카복실산을 에스테르화 및/또는 디카복실산을 트랜스에스테르화하여 고분자 폴리에스테르 및/또는 그 혼합물을 연속 제조하는 방법 및 이를 위한 장치 | |

| US7329723B2 (en) | Thermal crystallization of polyester pellets in liquid | |

| TW520381B (en) | Continuous process for producing poly(trimethylene terephthalate) | |

| KR101484353B1 (ko) | 중합 반응기, 중합 장치, 생분해성 폴리에스테르의 제조방법 및 용도 | |

| US6630563B2 (en) | Process for continuous production of polycarbonates and a reactor therefor | |

| KR20050035105A (ko) | 유체 중에서 용융된 폴리에스터 중합체를 열 결정화시키는방법 | |

| TWI282799B (en) | Polyester polymer particles having a small surface to center molecular weight gradient | |

| KR100684683B1 (ko) | 폴리트리메틸렌 테레프탈레이트 수지 | |

| KR20120026973A (ko) | 고 점도 물질의 중합화법 | |

| CN115770532B (zh) | 一种聚乳酸-乙醇酸嵌段共聚物的制备装置及方法 | |

| JP6230695B2 (ja) | 縮重合反応性ポリマー及びその製造装置 | |

| KR100805481B1 (ko) | 폴리카보네이트의 제조방법 | |

| KR100866301B1 (ko) | 공업적 증발 장치 | |

| TWI882210B (zh) | 芳香族分支聚碳酸酯、其製造方法、及芳香族分支聚碳酸酯的製造裝置 | |

| KR101148713B1 (ko) | 폴리에스테르 제조 방법 | |

| CN115427480B (zh) | 聚碳酸酯制造装置的组装方法和聚碳酸酯的制造装置 | |

| TWI838901B (zh) | 芳香族聚碳酸酯、芳香族聚碳酸酯的製造方法及容器 | |

| EA024379B1 (ru) | Способ получения ароматического поликарбоната реакцией поликонденсации и реактор полимеризации | |

| JP2004514772A (ja) | ポリカーボネートの製造方法 | |

| CN120021416A (zh) | 适合于高灵活且稳固的聚碳酸酯设施、特别是采用预酯交换技术的反应器及其特殊设计 | |

| JP2022155590A (ja) | ポリカーボネートの製造方法 | |

| CN120021421A (zh) | 用预酯交换反应技术提高聚碳酸酯装置的灵活性和稳健性的方法和装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0109 | Patent application |

Patent event code: PA01091R01D Comment text: Patent Application Patent event date: 20110902 |

|

| PG1501 | Laying open of application | ||

| N231 | Notification of change of applicant | ||

| PN2301 | Change of applicant |

Patent event date: 20150105 Comment text: Notification of Change of Applicant Patent event code: PN23011R01D |

|

| PC1203 | Withdrawal of no request for examination | ||

| WITN | Application deemed withdrawn, e.g. because no request for examination was filed or no examination fee was paid |