JP7033129B2 - エンボス加工押印パターンを有する接合表面を有する不織物を含む密封された接触領域を含むパッケージ - Google Patents

エンボス加工押印パターンを有する接合表面を有する不織物を含む密封された接触領域を含むパッケージ Download PDFInfo

- Publication number

- JP7033129B2 JP7033129B2 JP2019519694A JP2019519694A JP7033129B2 JP 7033129 B2 JP7033129 B2 JP 7033129B2 JP 2019519694 A JP2019519694 A JP 2019519694A JP 2019519694 A JP2019519694 A JP 2019519694A JP 7033129 B2 JP7033129 B2 JP 7033129B2

- Authority

- JP

- Japan

- Prior art keywords

- woven sheet

- package

- sheet structure

- woven

- embossed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000004745 nonwoven fabric Substances 0.000 title description 2

- 229920000642 polymer Polymers 0.000 claims description 39

- 238000007789 sealing Methods 0.000 claims description 39

- 238000004806 packaging method and process Methods 0.000 claims description 32

- 239000000758 substrate Substances 0.000 claims description 31

- 238000004049 embossing Methods 0.000 claims description 22

- 230000004888 barrier function Effects 0.000 claims description 13

- 239000002245 particle Substances 0.000 claims description 13

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 13

- 239000010410 layer Substances 0.000 description 35

- 239000000463 material Substances 0.000 description 33

- 239000000835 fiber Substances 0.000 description 30

- -1 polypropylene Polymers 0.000 description 29

- 239000007789 gas Substances 0.000 description 20

- 239000004698 Polyethylene Substances 0.000 description 18

- 238000000034 method Methods 0.000 description 18

- 229920000573 polyethylene Polymers 0.000 description 18

- 238000009987 spinning Methods 0.000 description 15

- 238000005259 measurement Methods 0.000 description 10

- 230000008569 process Effects 0.000 description 10

- 238000012360 testing method Methods 0.000 description 10

- 239000002657 fibrous material Substances 0.000 description 9

- 238000001816 cooling Methods 0.000 description 8

- 239000004743 Polypropylene Substances 0.000 description 7

- 230000035699 permeability Effects 0.000 description 7

- 229920001155 polypropylene Polymers 0.000 description 7

- 239000000047 product Substances 0.000 description 7

- 239000004952 Polyamide Substances 0.000 description 6

- 229920002647 polyamide Polymers 0.000 description 6

- 230000009467 reduction Effects 0.000 description 6

- 230000005540 biological transmission Effects 0.000 description 5

- 230000000052 comparative effect Effects 0.000 description 5

- 238000005304 joining Methods 0.000 description 5

- 239000004215 Carbon black (E152) Substances 0.000 description 4

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical compound [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 description 4

- 238000010438 heat treatment Methods 0.000 description 4

- 229930195733 hydrocarbon Natural products 0.000 description 4

- 238000002844 melting Methods 0.000 description 4

- 230000008018 melting Effects 0.000 description 4

- 239000003795 chemical substances by application Substances 0.000 description 3

- 238000000576 coating method Methods 0.000 description 3

- 239000000356 contaminant Substances 0.000 description 3

- 238000011109 contamination Methods 0.000 description 3

- 238000004299 exfoliation Methods 0.000 description 3

- 229920001903 high density polyethylene Polymers 0.000 description 3

- 239000004700 high-density polyethylene Substances 0.000 description 3

- 230000001965 increasing effect Effects 0.000 description 3

- 239000000155 melt Substances 0.000 description 3

- 229920000728 polyester Polymers 0.000 description 3

- 229920000098 polyolefin Polymers 0.000 description 3

- 230000000007 visual effect Effects 0.000 description 3

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 2

- 239000005977 Ethylene Substances 0.000 description 2

- IAYPIBMASNFSPL-UHFFFAOYSA-N Ethylene oxide Chemical compound C1CO1 IAYPIBMASNFSPL-UHFFFAOYSA-N 0.000 description 2

- 239000004677 Nylon Substances 0.000 description 2

- 239000004775 Tyvek Substances 0.000 description 2

- 229920000690 Tyvek Polymers 0.000 description 2

- 239000011230 binding agent Substances 0.000 description 2

- 229920001577 copolymer Polymers 0.000 description 2

- 238000011010 flushing procedure Methods 0.000 description 2

- 229920001519 homopolymer Polymers 0.000 description 2

- 150000002430 hydrocarbons Chemical class 0.000 description 2

- 230000006872 improvement Effects 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- OFBQJSOFQDEBGM-UHFFFAOYSA-N n-pentane Natural products CCCCC OFBQJSOFQDEBGM-UHFFFAOYSA-N 0.000 description 2

- 229920001778 nylon Polymers 0.000 description 2

- 229920000139 polyethylene terephthalate Polymers 0.000 description 2

- 239000005020 polyethylene terephthalate Substances 0.000 description 2

- 125000004805 propylene group Chemical group [H]C([H])([H])C([H])([*:1])C([H])([H])[*:2] 0.000 description 2

- 239000011780 sodium chloride Substances 0.000 description 2

- 230000001954 sterilising effect Effects 0.000 description 2

- 238000004659 sterilization and disinfection Methods 0.000 description 2

- 229920001059 synthetic polymer Polymers 0.000 description 2

- 241000894006 Bacteria Species 0.000 description 1

- 229920001474 Flashspun fabric Polymers 0.000 description 1

- XTXRWKRVRITETP-UHFFFAOYSA-N Vinyl acetate Chemical compound CC(=O)OC=C XTXRWKRVRITETP-UHFFFAOYSA-N 0.000 description 1

- 230000001464 adherent effect Effects 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 150000001336 alkenes Chemical class 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 210000000988 bone and bone Anatomy 0.000 description 1

- 239000004566 building material Substances 0.000 description 1

- 230000009172 bursting Effects 0.000 description 1

- 238000003490 calendering Methods 0.000 description 1

- 239000011247 coating layer Substances 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 239000002826 coolant Substances 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 239000005038 ethylene vinyl acetate Substances 0.000 description 1

- 201000004356 excessive tearing Diseases 0.000 description 1

- 238000001914 filtration Methods 0.000 description 1

- 239000004751 flashspun nonwoven Substances 0.000 description 1

- 230000036541 health Effects 0.000 description 1

- 230000002706 hydrostatic effect Effects 0.000 description 1

- 230000001939 inductive effect Effects 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- 229920004889 linear high-density polyethylene Polymers 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 229920001684 low density polyethylene Polymers 0.000 description 1

- 239000004702 low-density polyethylene Substances 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- JRZJOMJEPLMPRA-UHFFFAOYSA-N olefin Natural products CCCCCCCC=C JRZJOMJEPLMPRA-UHFFFAOYSA-N 0.000 description 1

- 239000005022 packaging material Substances 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 239000012466 permeate Substances 0.000 description 1

- 229920001200 poly(ethylene-vinyl acetate) Polymers 0.000 description 1

- 229920001748 polybutylene Polymers 0.000 description 1

- 239000011116 polymethylpentene Substances 0.000 description 1

- 229920000306 polymethylpentene Polymers 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- QQONPFPTGQHPMA-UHFFFAOYSA-N propylene Natural products CC=C QQONPFPTGQHPMA-UHFFFAOYSA-N 0.000 description 1

- 230000003134 recirculating effect Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 238000007655 standard test method Methods 0.000 description 1

- 238000010998 test method Methods 0.000 description 1

- 229920001169 thermoplastic Polymers 0.000 description 1

- 239000012780 transparent material Substances 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 238000011179 visual inspection Methods 0.000 description 1

- 230000004580 weight loss Effects 0.000 description 1

- 239000002759 woven fabric Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B9/00—Layered products comprising a layer of a particular substance not covered by groups B32B11/00 - B32B29/00

- B32B9/04—Layered products comprising a layer of a particular substance not covered by groups B32B11/00 - B32B29/00 comprising such particular substance as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B9/047—Layered products comprising a layer of a particular substance not covered by groups B32B11/00 - B32B29/00 comprising such particular substance as the main or only constituent of a layer, which is next to another layer of the same or of a different material made of fibres or filaments

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D65/00—Wrappers or flexible covers; Packaging materials of special type or form

- B65D65/38—Packaging materials of special type or form

- B65D65/40—Applications of laminates for particular packaging purposes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B27/08—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/12—Layered products comprising a layer of synthetic resin next to a fibrous or filamentary layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/306—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising vinyl acetate or vinyl alcohol (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/32—Layered products comprising a layer of synthetic resin comprising polyolefins

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/34—Layered products comprising a layer of synthetic resin comprising polyamides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/36—Layered products comprising a layer of synthetic resin comprising polyesters

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/26—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer

- B32B3/30—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer characterised by a layer formed with recesses or projections, e.g. hollows, grooves, protuberances, ribs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/022—Non-woven fabric

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B7/00—Layered products characterised by the relation between layers; Layered products characterised by the relative orientation of features between layers, or by the relative values of a measurable parameter between layers, i.e. products comprising layers having different physical, chemical or physicochemical properties; Layered products characterised by the interconnection of layers

- B32B7/02—Physical, chemical or physicochemical properties

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B7/00—Layered products characterised by the relation between layers; Layered products characterised by the relative orientation of features between layers, or by the relative values of a measurable parameter between layers, i.e. products comprising layers having different physical, chemical or physicochemical properties; Layered products characterised by the interconnection of layers

- B32B7/04—Interconnection of layers

- B32B7/06—Interconnection of layers permitting easy separation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B7/00—Layered products characterised by the relation between layers; Layered products characterised by the relative orientation of features between layers, or by the relative values of a measurable parameter between layers, i.e. products comprising layers having different physical, chemical or physicochemical properties; Layered products characterised by the interconnection of layers

- B32B7/04—Interconnection of layers

- B32B7/12—Interconnection of layers using interposed adhesives or interposed materials with bonding properties

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H27/00—Special paper not otherwise provided for, e.g. made by multi-step processes

- D21H27/02—Patterned paper

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0253—Polyolefin fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2305/00—Condition, form or state of the layers or laminate

- B32B2305/02—Cellular or porous

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2305/00—Condition, form or state of the layers or laminate

- B32B2305/02—Cellular or porous

- B32B2305/026—Porous

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/724—Permeability to gases, adsorption

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/724—Permeability to gases, adsorption

- B32B2307/7242—Non-permeable

- B32B2307/7246—Water vapor barrier

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/75—Printability

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2323/00—Polyalkenes

- B32B2323/04—Polyethylene

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2439/00—Containers; Receptacles

- B32B2439/40—Closed containers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2439/00—Containers; Receptacles

- B32B2439/40—Closed containers

- B32B2439/46—Bags

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2439/00—Containers; Receptacles

- B32B2439/80—Medical packaging

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2553/00—Packaging equipment or accessories not otherwise provided for

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Ceramic Engineering (AREA)

- Mechanical Engineering (AREA)

- Nonwoven Fabrics (AREA)

- Packages (AREA)

- Laminated Bodies (AREA)

- Wrappers (AREA)

- Apparatus For Disinfection Or Sterilisation (AREA)

Description

坪量。坪量は、ASTM D3776(2009)に従って測定される。

LRV-TSI 8130=-log10(透過[%]/100)

に基づく対数減少値として表現され得る。

さらなる結合およびエンボス加工のための未仕上げ繊維状不織シートを、紡糸溶液中のポリマー濃度が17重量%であり、紡糸温度が195℃であったこと以外には、Limらに付与された米国特許第6,034,008号明細書の実施例9~15に記載されたとおりの一般的フラッシュ紡糸プロセスを使用して、高密度ポリエチレンおよびn-ペンタン炭化水素紡糸剤を含む紡糸溶液から作製した。ポリエチレンは、約0.75g/10分の2.16kg/190℃でのメルトフローインデックス(ASTM D1238-13により測定して)を有した。2つの異なる坪量の不織シートを作製した。

さらなる結合およびエンボス加工のための未仕上げ繊維状不織シートを、紡糸溶液中のポリマー濃度が17重量%であり、紡糸温度が185℃であったこと以外には、Limらに付与された米国特許第6,034,008号明細書の実施例9~15に記載されたとおりの一般的フラッシュ紡糸プロセスを使用して、高密度ポリエチレンおよびn-ペンタン炭化水素紡糸剤を含む紡糸溶液から作製した。ポリエチレンは、約0.7g/10分の2.16kg/190℃でのメルトフローインデックス(ASTM D1238-13により測定して)を有した。

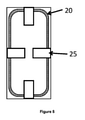

それらのそれぞれが44グラム/メートル2の坪量を有した実施例1および比較実施例Aからの得られた不織シートを、次いで、Multivac R535装置を使用して医療用パッケージを作製するために使用する。Multivac R535装置は、1つの基材に4つのパッケージを作製し、それぞれのパッケージは、縦方向に200mm、横方向に約95mmの長さおよび図3における寸法5として示されるとおりの約7.5mmの密封幅を有する。不織シートは、2つの異なるタイフィルム材料を使用して接触領域を密封する際にパッケージ基材に付着された。フィルム1は、Suedpack Verpackungen GmbH&Co.KG,Ochsenhausen,GermanyからのMultifol GA Tyvek(登録商標)、100μmのポリアミド/ポリエチレン剥離可能フィルムであった。フィルム2は、Wipak,Nastola,FinlandからのWipak(登録商標)ML E 135 TF PEEL、ポリエチレン/ポリアミド/ポリエチレンフィルムであった。

同じエンボス加工リネンパターンとともに47g/m2の坪量を有する不織シートを使用して実施例2を繰り返し、しかしながら、未仕上げシートは、表5に示されるエンボス加工条件を使用して接合した。得られた接合不織シートは、3.6秒のGurley多孔度を有した。

これらの実施例は、エンボス加工が不織シート接合後に別個の工程として不織シートに適用され得ることを例示する。不織シートが接合されるが、エンボス加工されない比較実施例Bを、2つの異なる不織シート坪量を使用して繰り返した。接合シートをロールに巻き上げた。次いで、接合不織シートのロールを、その後巻き戻し、シートを加熱カレンダロールの組でニップすることによって1つの表面にエンボス加工し、今回は、リネンパターンよりもむしろ図2に示されるとおりのドッグボーンパターンであるエンボス加工によるシートの1つの表面を提供した。接合およびその後のエンボス加工のための条件は、表7に示す。実施例4におけるとおり、タイフィルムと接触したエンボス加工表面を有する同じタイフィルムでパッケージを作製した。結果を表8に示す。

実施例1~実施例7で使用したエンボス加工押印パターンを有する不織シート構造をバリヤおよび機械的特性について試験した。これらの本発明のシート構造のすべては、2.0Nを超えるエルメンドルフ引裂き、500kPaを超えるミューレン破裂強度を有した。本発明のシート構造のすべては、2.3L/分の流量で動作されるTSI 8130装置を使用して10%未満の粒子バリヤ透過を有した。不織構造のそれぞれの非エンボス加工側は、良好な視覚的結果とともに線バーコードおよび2Dデータマトリックスの形態での印刷を許容する。

次に、本発明の好ましい態様を示す。

1.ガス透過性繊維状不織シート構造、ポリマータイ層およびパッケージ基材を含む、滅菌され得る閉囲内部環境を提供するためのパッケージであって、

前記不織シート構造は、第1の表面および第2の表面を有し、

前記閉囲内部環境は、前記不織シート構造の前記第1の表面と前記パッケージ構造との間の接触領域を密封することによって形成されており、前記密封された接触領域は、前記ポリマータイ層によって形成されており、

前記不織シート構造の前記第1の表面は、少なくとも前記密封された接触領域内において押印パターンで前接合されている、パッケージ。

2.前記ポリマータイ層は、前記パッケージ基材と一体である、上記1に記載のパッケージ。

3.前記ポリマータイ層およびパッケージ基材は、フィルムで組み合わされている、上記1に記載のパッケージ。

4.前記繊維状不織シート構造は、プレキシフィラメント状である、上記1~3のいずれか一つに記載のパッケージ。

5.前記繊維状不織シート構造は、ポリエチレンプレキシフィラメントを含む、上記4に記載のパッケージ。

6.ガス透過性であり、かつ第1の表面および第2の表面を有する、滅菌包装における使用に適した繊維状不織シート構造であって、

前記第1の表面は、エンボス加工押印パターンで接合されており、および前記第2の表面は、印刷を許容することができ、

前記シート構造は、10%未満の粒子バリヤ透過、40秒以下のGurley Hill多孔度および3500g/m 2 /日以上の水蒸気輸送率を有する、繊維状不織シート構造。

7.10秒以下のGurley Hill多孔度を有する、上記6に記載の繊維状不織シート構造。

8.7500g/m 2 /日以上の水蒸気輸送率を有する、上記6または7に記載の繊維状不織シート構造。

9.9000g/m 2 /日以上の水蒸気輸送率を有する、上記8に記載の繊維状不織シート構造。

10.プレキシフィラメント状である、上記6~9のいずれか一つに記載の繊維状不織シート構造。

11.ポリエチレンプレキシフィラメントを含む、上記10に記載の繊維状不織シート構造。

Claims (2)

- ガス透過性繊維状不織シート構造、ポリマータイ層およびパッケージ基材を含む、滅菌され得る閉囲内部環境を提供するためのパッケージであって、

前記不織シート構造は、第1の表面および第2の表面を有し、

前記閉囲内部環境は、前記不織シート構造の前記第1の表面と前記パッケージ基材との間の接触領域を密封することによって形成されており、前記密封された接触領域は、前記ポリマータイ層によって形成されており、

前記不織シート構造の前記第1の表面は、少なくとも前記密封された接触領域内においてエンボス加工押印パターンで前接合されており、

前記不織シート構造の前記第2の表面は、いかなるエンボス加工もない滑らかな表面を有する、パッケージ。 - ガス透過性であり、かつ第1の表面および第2の表面を有する、滅菌包装における使用に適した繊維状不織シート構造であって、

前記第1の表面は、エンボス加工押印パターンで接合されており、および前記第2の表面は、印刷を許容することができ、

前記第2の表面は、いかなるエンボス加工もない滑らかな表面を有し、

前記シート構造は、10%未満の粒子バリヤ透過、40秒以下のGurley Hill多孔度および3500g/m2/日以上の水蒸気輸送率を有する、繊維状不織シート構造。

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2022027583A JP2022079459A (ja) | 2016-10-11 | 2022-02-25 | エンボス加工押印パターンを有する接合表面を有する不織物を含む密封された接触領域を含むパッケージ |

| JP2024188229A JP2025026856A (ja) | 2016-10-11 | 2024-10-25 | エンボス加工押印パターンを有する結着表面を有する不織物を含む密封された接触領域を含むパッケージ |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201662406547P | 2016-10-11 | 2016-10-11 | |

| US62/406,547 | 2016-10-11 | ||

| PCT/US2017/051323 WO2018071124A1 (en) | 2016-10-11 | 2017-09-13 | Package comprising a sealed contact area including a nonwoven having a bonded surface with an embossed impression pattern |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2022027583A Division JP2022079459A (ja) | 2016-10-11 | 2022-02-25 | エンボス加工押印パターンを有する接合表面を有する不織物を含む密封された接触領域を含むパッケージ |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2020500125A JP2020500125A (ja) | 2020-01-09 |

| JP2020500125A5 JP2020500125A5 (ja) | 2020-10-15 |

| JP7033129B2 true JP7033129B2 (ja) | 2022-03-09 |

Family

ID=60117735

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2019519694A Active JP7033129B2 (ja) | 2016-10-11 | 2017-09-13 | エンボス加工押印パターンを有する接合表面を有する不織物を含む密封された接触領域を含むパッケージ |

| JP2022027583A Pending JP2022079459A (ja) | 2016-10-11 | 2022-02-25 | エンボス加工押印パターンを有する接合表面を有する不織物を含む密封された接触領域を含むパッケージ |

| JP2024188229A Pending JP2025026856A (ja) | 2016-10-11 | 2024-10-25 | エンボス加工押印パターンを有する結着表面を有する不織物を含む密封された接触領域を含むパッケージ |

Family Applications After (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2022027583A Pending JP2022079459A (ja) | 2016-10-11 | 2022-02-25 | エンボス加工押印パターンを有する接合表面を有する不織物を含む密封された接触領域を含むパッケージ |

| JP2024188229A Pending JP2025026856A (ja) | 2016-10-11 | 2024-10-25 | エンボス加工押印パターンを有する結着表面を有する不織物を含む密封された接触領域を含むパッケージ |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US11383489B2 (ja) |

| EP (3) | EP3526031B1 (ja) |

| JP (3) | JP7033129B2 (ja) |

| KR (3) | KR102479098B1 (ja) |

| CN (2) | CN109803818A (ja) |

| FI (1) | FI3736126T3 (ja) |

| WO (1) | WO2018071124A1 (ja) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USD848749S1 (en) * | 2017-06-09 | 2019-05-21 | Suominen Corporation | Material sheet with patterned surface |

| USD882276S1 (en) * | 2018-05-22 | 2020-04-28 | Berry Global, Inc. | Nonwoven fabric |

| USD899792S1 (en) * | 2018-08-09 | 2020-10-27 | Mayline Cordova | Changing table cover |

| WO2020196340A1 (ja) | 2019-03-22 | 2020-10-01 | 旭化成株式会社 | 滅菌用包装材用不織布 |

| USD1048729S1 (en) * | 2020-11-30 | 2024-10-29 | Chenbro Micom Co., Ltd. | Patterned board |

| EP4223504A1 (en) * | 2022-02-08 | 2023-08-09 | Danapak Flexibles A/S | Packaging materials |

| WO2023088713A1 (en) * | 2021-11-16 | 2023-05-25 | Danapak Flexibles A/S | Packaging materials |

| EP4481677A1 (de) * | 2023-06-21 | 2024-12-25 | SÜDPACK Medica AG | Verfahren zur qualitätsprüfung an einer siegelnaht |

| WO2025006920A1 (en) * | 2023-06-30 | 2025-01-02 | Dupont Safety & Construction, Inc. | Softened flash-spun sheet |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000510198A (ja) | 1996-04-23 | 2000-08-08 | イー・アイ・デユポン・ドウ・ヌムール・アンド・カンパニー | 接合されたポリオレフィンシート |

| US20020004351A1 (en) | 1997-03-05 | 2002-01-10 | Wazir Nobbee | Packaging product |

| JP2017522210A (ja) | 2014-07-18 | 2017-08-10 | イー・アイ・デュポン・ドウ・ヌムール・アンド・カンパニーE.I.Du Pont De Nemours And Company | 通気性防護衣 |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3081519A (en) | 1962-01-31 | 1963-03-19 | Fibrillated strand | |

| NL300881A (ja) | 1962-11-23 | |||

| US3532589A (en) | 1965-04-12 | 1970-10-06 | Du Pont | Differentially bonded non-woven sheet |

| US3860369A (en) | 1972-11-02 | 1975-01-14 | Du Pont | Apparatus for making non-woven fibrous sheet |

| JPH0443487Y2 (ja) * | 1986-12-26 | 1992-10-14 | ||

| JP3565822B2 (ja) | 1993-04-08 | 2004-09-15 | ユニチカ株式会社 | 網状構造の繊維からなる不織布およびその製造方法 |

| US6034008A (en) | 1996-08-19 | 2000-03-07 | E. I. Du Pont De Nemours And Company | Flash-spun sheet material |

| ES2165671T3 (es) | 1997-03-05 | 2002-03-16 | Du Pont | Material laminar mejorado fabricado por hilatura por evaporacion subita. |

| JPH11115127A (ja) * | 1997-10-17 | 1999-04-27 | Asahi Du Pont Flash Span Products Kk | 複合不織シート |

| JPH11292133A (ja) * | 1998-04-09 | 1999-10-26 | Asahi Chem Ind Co Ltd | 食品用包装シート |

| JP2003518202A (ja) | 1999-10-18 | 2003-06-03 | イー・アイ・デュポン・ドウ・ヌムール・アンド・カンパニー | フラッシュ紡糸されたシ−ト材料 |

| JP2003311051A (ja) * | 2002-04-19 | 2003-11-05 | Toyo Tire & Rubber Co Ltd | シートパッド |

| US7338916B2 (en) | 2004-03-31 | 2008-03-04 | E.I. Du Pont De Nemours And Company | Flash spun sheet material having improved breathability |

| US7660040B2 (en) * | 2005-05-17 | 2010-02-09 | E. I. Du Pont De Nemours And Company | Diffuse reflective article |

| JP4821202B2 (ja) * | 2005-07-20 | 2011-11-24 | 東レ株式会社 | 生分解性スパンボンド不織布の製造方法 |

| DE102007049031A1 (de) * | 2007-10-11 | 2009-04-16 | Fiberweb Corovin Gmbh | Polypropylenmischung |

| US20090173569A1 (en) * | 2007-12-20 | 2009-07-09 | E. I. Du Pont De Nemours And Company | Acoustic absorber with barrier facing |

| US20110127188A1 (en) * | 2009-12-01 | 2011-06-02 | Cryovac, Inc. | Method of Using Coextruded Film for Sterile Barrier System to Deliver Seal and Peel Characteristics |

| US20120227362A1 (en) * | 2011-03-11 | 2012-09-13 | Lima George Haase | Hydrophilic and hydrophobic sterile barrier system for use in sterilization of surgical implements |

-

2017

- 2017-09-13 FI FIEP20179350.2T patent/FI3736126T3/fi active

- 2017-09-13 CN CN201780063000.8A patent/CN109803818A/zh active Pending

- 2017-09-13 CN CN202410985247.7A patent/CN118723325A/zh active Pending

- 2017-09-13 JP JP2019519694A patent/JP7033129B2/ja active Active

- 2017-09-13 KR KR1020197012833A patent/KR102479098B1/ko active Active

- 2017-09-13 EP EP17784713.4A patent/EP3526031B1/en active Active

- 2017-09-13 WO PCT/US2017/051323 patent/WO2018071124A1/en unknown

- 2017-09-13 EP EP20179350.2A patent/EP3736126B1/en active Active

- 2017-09-13 KR KR1020247028651A patent/KR20240134237A/ko active Pending

- 2017-09-13 EP EP20179346.0A patent/EP3738763B1/en active Active

- 2017-09-13 KR KR1020227043974A patent/KR102700619B1/ko active Active

- 2017-09-18 US US15/706,817 patent/US11383489B2/en active Active

-

2022

- 2022-02-25 JP JP2022027583A patent/JP2022079459A/ja active Pending

-

2024

- 2024-10-25 JP JP2024188229A patent/JP2025026856A/ja active Pending

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000510198A (ja) | 1996-04-23 | 2000-08-08 | イー・アイ・デユポン・ドウ・ヌムール・アンド・カンパニー | 接合されたポリオレフィンシート |

| US20020004351A1 (en) | 1997-03-05 | 2002-01-10 | Wazir Nobbee | Packaging product |

| JP2017522210A (ja) | 2014-07-18 | 2017-08-10 | イー・アイ・デュポン・ドウ・ヌムール・アンド・カンパニーE.I.Du Pont De Nemours And Company | 通気性防護衣 |

Also Published As

| Publication number | Publication date |

|---|---|

| US11383489B2 (en) | 2022-07-12 |

| KR102700619B1 (ko) | 2024-08-30 |

| KR20230006593A (ko) | 2023-01-10 |

| EP3738763A1 (en) | 2020-11-18 |

| KR20240134237A (ko) | 2024-09-06 |

| CN118723325A (zh) | 2024-10-01 |

| JP2022079459A (ja) | 2022-05-26 |

| EP3736126A1 (en) | 2020-11-11 |

| KR20190059317A (ko) | 2019-05-30 |

| WO2018071124A1 (en) | 2018-04-19 |

| JP2025026856A (ja) | 2025-02-26 |

| EP3526031A1 (en) | 2019-08-21 |

| EP3738763B1 (en) | 2021-10-20 |

| FI3736126T3 (fi) | 2023-01-31 |

| US20180099483A1 (en) | 2018-04-12 |

| EP3736126B1 (en) | 2022-10-26 |

| KR102479098B1 (ko) | 2022-12-21 |

| CN109803818A (zh) | 2019-05-24 |

| JP2020500125A (ja) | 2020-01-09 |

| EP3526031B1 (en) | 2020-07-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP7033129B2 (ja) | エンボス加工押印パターンを有する接合表面を有する不織物を含む密封された接触領域を含むパッケージ | |

| JP2022079459A5 (ja) | ||

| AU2005292653B2 (en) | Multiple ply sterilization wrap | |

| US20100028575A1 (en) | High integrity composite bags adapted for steam sterilization | |

| RU2630973C2 (ru) | Способ использования стерилизационной упаковочной системы | |

| US12017442B2 (en) | Nonwoven fabric for sterilization packaging material | |

| US20220307174A1 (en) | Package comprising a sealed contact area including a nonwoven having a bonded surface with an embossed impression pattern | |

| EP3340950B1 (en) | Package seal having a fibrous breathable material | |

| JP2006008205A (ja) | 食品と同梱される非食品用の包装袋 | |

| AU2012200346B2 (en) | Multiple ply sterilization wrap | |

| AU2006200471B2 (en) | Single step sterilization wrap system | |

| AU715940B2 (en) | Single step sterilization wrap system |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20200901 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20200901 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20210802 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20211101 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20220202 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20220225 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 7033129 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |