JP6685914B2 - Rfプラズマ電界を使用したeuv光学部品のアクティブ洗浄装置および方法 - Google Patents

Rfプラズマ電界を使用したeuv光学部品のアクティブ洗浄装置および方法 Download PDFInfo

- Publication number

- JP6685914B2 JP6685914B2 JP2016551259A JP2016551259A JP6685914B2 JP 6685914 B2 JP6685914 B2 JP 6685914B2 JP 2016551259 A JP2016551259 A JP 2016551259A JP 2016551259 A JP2016551259 A JP 2016551259A JP 6685914 B2 JP6685914 B2 JP 6685914B2

- Authority

- JP

- Japan

- Prior art keywords

- conductive

- conductive member

- conductive surface

- euv

- electrically

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000004140 cleaning Methods 0.000 title claims description 12

- 238000000034 method Methods 0.000 title claims description 12

- 230000005684 electric field Effects 0.000 title description 2

- 230000005855 radiation Effects 0.000 claims description 36

- 230000003287 optical effect Effects 0.000 claims description 22

- 238000000059 patterning Methods 0.000 claims description 16

- 239000000758 substrate Substances 0.000 claims description 15

- 238000005286 illumination Methods 0.000 claims description 12

- 239000000356 contaminant Substances 0.000 claims description 8

- 239000013077 target material Substances 0.000 description 13

- 239000000463 material Substances 0.000 description 8

- 229910052718 tin Inorganic materials 0.000 description 7

- 235000012431 wafers Nutrition 0.000 description 7

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 6

- 238000001459 lithography Methods 0.000 description 5

- 239000004020 conductor Substances 0.000 description 3

- 238000009826 distribution Methods 0.000 description 3

- 239000007788 liquid Substances 0.000 description 3

- 229920002120 photoresistant polymer Polymers 0.000 description 3

- 229910052710 silicon Inorganic materials 0.000 description 3

- 229910000807 Ga alloy Inorganic materials 0.000 description 2

- WHXSMMKQMYFTQS-UHFFFAOYSA-N Lithium Chemical compound [Li] WHXSMMKQMYFTQS-UHFFFAOYSA-N 0.000 description 2

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 2

- 229910001128 Sn alloy Inorganic materials 0.000 description 2

- 230000003321 amplification Effects 0.000 description 2

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 230000005670 electromagnetic radiation Effects 0.000 description 2

- RHZWSUVWRRXEJF-UHFFFAOYSA-N indium tin Chemical compound [In].[Sn] RHZWSUVWRRXEJF-UHFFFAOYSA-N 0.000 description 2

- 239000010410 layer Substances 0.000 description 2

- 229910052744 lithium Inorganic materials 0.000 description 2

- 238000003199 nucleic acid amplification method Methods 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- 230000009467 reduction Effects 0.000 description 2

- 239000010703 silicon Substances 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 238000001228 spectrum Methods 0.000 description 2

- 229910052724 xenon Inorganic materials 0.000 description 2

- FHNFHKCVQCLJFQ-UHFFFAOYSA-N xenon atom Chemical compound [Xe] FHNFHKCVQCLJFQ-UHFFFAOYSA-N 0.000 description 2

- PXGOKWXKJXAPGV-UHFFFAOYSA-N Fluorine Chemical compound FF PXGOKWXKJXAPGV-UHFFFAOYSA-N 0.000 description 1

- YCKRFDGAMUMZLT-UHFFFAOYSA-N Fluorine atom Chemical compound [F] YCKRFDGAMUMZLT-UHFFFAOYSA-N 0.000 description 1

- 229910052688 Gadolinium Inorganic materials 0.000 description 1

- 229910000846 In alloy Inorganic materials 0.000 description 1

- 241000435574 Popa Species 0.000 description 1

- 230000004075 alteration Effects 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000003990 capacitor Substances 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 238000000151 deposition Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 239000003344 environmental pollutant Substances 0.000 description 1

- 230000003628 erosive effect Effects 0.000 description 1

- 230000005284 excitation Effects 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 239000010408 film Substances 0.000 description 1

- 229910052731 fluorine Inorganic materials 0.000 description 1

- 239000011737 fluorine Substances 0.000 description 1

- 238000011065 in-situ storage Methods 0.000 description 1

- 229910052738 indium Inorganic materials 0.000 description 1

- 239000011229 interlayer Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 229910052750 molybdenum Inorganic materials 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 238000000206 photolithography Methods 0.000 description 1

- 231100000719 pollutant Toxicity 0.000 description 1

- 230000036278 prepulse Effects 0.000 description 1

- 210000001747 pupil Anatomy 0.000 description 1

- 238000002310 reflectometry Methods 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 150000003606 tin compounds Chemical class 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 230000008016 vaporization Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B7/00—Cleaning by methods not provided for in a single other subclass or a single group in this subclass

- B08B7/0035—Cleaning by methods not provided for in a single other subclass or a single group in this subclass by radiant energy, e.g. UV, laser, light beam or the like

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B7/00—Cleaning by methods not provided for in a single other subclass or a single group in this subclass

- B08B7/0035—Cleaning by methods not provided for in a single other subclass or a single group in this subclass by radiant energy, e.g. UV, laser, light beam or the like

- B08B7/0057—Cleaning by methods not provided for in a single other subclass or a single group in this subclass by radiant energy, e.g. UV, laser, light beam or the like by ultraviolet radiation

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B1/00—Optical elements characterised by the material of which they are made; Optical coatings for optical elements

- G02B1/10—Optical coatings produced by application to, or surface treatment of, optical elements

- G02B1/18—Coatings for keeping optical surfaces clean, e.g. hydrophobic or photo-catalytic films

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B27/00—Optical systems or apparatus not provided for by any of the groups G02B1/00 - G02B26/00, G02B30/00

- G02B27/0006—Optical systems or apparatus not provided for by any of the groups G02B1/00 - G02B26/00, G02B30/00 with means to keep optical surfaces clean, e.g. by preventing or removing dirt, stains, contamination, condensation

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/70—Microphotolithographic exposure; Apparatus therefor

- G03F7/70008—Production of exposure light, i.e. light sources

- G03F7/70033—Production of exposure light, i.e. light sources by plasma extreme ultraviolet [EUV] sources

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/70—Microphotolithographic exposure; Apparatus therefor

- G03F7/708—Construction of apparatus, e.g. environment aspects, hygiene aspects or materials

- G03F7/70858—Environment aspects, e.g. pressure of beam-path gas, temperature

- G03F7/70883—Environment aspects, e.g. pressure of beam-path gas, temperature of optical system

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/70—Microphotolithographic exposure; Apparatus therefor

- G03F7/708—Construction of apparatus, e.g. environment aspects, hygiene aspects or materials

- G03F7/70908—Hygiene, e.g. preventing apparatus pollution, mitigating effect of pollution or removing pollutants from apparatus

- G03F7/70925—Cleaning, i.e. actively freeing apparatus from pollutants, e.g. using plasma cleaning

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32009—Arrangements for generation of plasma specially adapted for examination or treatment of objects, e.g. plasma sources

- H01J37/32082—Radio frequency generated discharge

- H01J37/32091—Radio frequency generated discharge the radio frequency energy being capacitively coupled to the plasma

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32009—Arrangements for generation of plasma specially adapted for examination or treatment of objects, e.g. plasma sources

- H01J37/32082—Radio frequency generated discharge

- H01J37/32174—Circuits specially adapted for controlling the RF discharge

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32009—Arrangements for generation of plasma specially adapted for examination or treatment of objects, e.g. plasma sources

- H01J37/32321—Discharge generated by other radiation

- H01J37/32339—Discharge generated by other radiation using electromagnetic radiation

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32431—Constructional details of the reactor

- H01J37/32623—Mechanical discharge control means

- H01J37/32651—Shields, e.g. dark space shields, Faraday shields

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32431—Constructional details of the reactor

- H01J37/32715—Workpiece holder

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05G—X-RAY TECHNIQUE

- H05G2/00—Apparatus or processes specially adapted for producing X-rays, not involving X-ray tubes, e.g. involving generation of a plasma

- H05G2/001—Production of X-ray radiation generated from plasma

- H05G2/008—Production of X-ray radiation generated from plasma involving an energy-carrying beam in the process of plasma generation

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J2237/00—Discharge tubes exposing object to beam, e.g. for analysis treatment, etching, imaging

- H01J2237/32—Processing objects by plasma generation

- H01J2237/327—Arrangements for generating the plasma

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J2237/00—Discharge tubes exposing object to beam, e.g. for analysis treatment, etching, imaging

- H01J2237/32—Processing objects by plasma generation

- H01J2237/33—Processing objects by plasma generation characterised by the type of processing

- H01J2237/335—Cleaning

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05G—X-RAY TECHNIQUE

- H05G2/00—Apparatus or processes specially adapted for producing X-rays, not involving X-ray tubes, e.g. involving generation of a plasma

- H05G2/001—Production of X-ray radiation generated from plasma

- H05G2/003—Production of X-ray radiation generated from plasma the plasma being generated from a material in a liquid or gas state

Landscapes

- Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Plasma & Fusion (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Optics & Photonics (AREA)

- General Physics & Mathematics (AREA)

- Public Health (AREA)

- Epidemiology (AREA)

- Environmental & Geological Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Atmospheric Sciences (AREA)

- Toxicology (AREA)

- Electromagnetism (AREA)

- Power Engineering (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Exposure And Positioning Against Photoresist Photosensitive Materials (AREA)

- Exposure Of Semiconductors, Excluding Electron Or Ion Beam Exposure (AREA)

- X-Ray Techniques (AREA)

- Plasma Technology (AREA)

- Cleaning In General (AREA)

- Lenses (AREA)

Description

[0001] 本出願は、2014年3月18日に出願された米国特許出願第14/218,707号に対する優先権を主張し、その全体が参照により本明細書に組み込まれる。

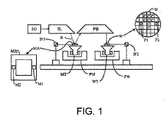

このリソグラフィ装置は、放射ビームBを調整するように構成された照明システム(照明システム)ILを備える。また、このリソグラフィ装置は、パターニングデバイス(例えば、マスク)MAを支持するように構築され、かつ特定のパラメータに従ってパターニングデバイスを正確に位置決めするように構成された第1ポジショナPMに連結されたサポート構造(例えば、マスクテーブル)MTと、基板(例えば、レジストコートウェーハ)Wを保持するように構築され、かつ特定のパラメータに従って基板を正確に位置決めするように構成された第2ポジショナPWに連結された基板テーブル(例えば、ウェーハテーブル)WTと、パターニングデバイスMAによって放射ビームBに付けられたパターンを基板Wのターゲット部分C(例えば、1つ以上のダイを含む)上に投影するように構成された投影システム(例えば、屈折または反射投影レンズシステム)PSと、を含む。

各RF供給路45は、それぞれの開口47を通って電極プレート42に接続される。電極プレート42は、Mo、Cu、またはAlといった好適な導電材料からなることが好ましい。また、電極プレート42は、EUV30の表面の形状に合致することが好ましく、EUV光学部品30の表面に接触することが好ましい。ただし、電極プレート42は、EUV光学部品30の導電性表面に実際に触れている必要はないことに留意されたい。電極プレート42は、EUV光学部品30の表面にRF出力を結合できるようにEUV光学部品30の導電性表面に十分近接していればよい。

Claims (9)

- 導電性表面を有するEUV光学要素と、

前記導電性表面に隣接して配置された導電性部材と、を備え、

前記導電性表面と前記導電性部材とは、RF出力が前記導電性部材に供給されると、前記導電性表面と前記導電性部材との間に、前記導電性表面の少なくとも一部分から汚染物質を取り除くことが可能なプラズマが生成されるように互いに近接して配置され、

前記導電性表面はオブスキュレーション領域を有し、前記導電性部材は、前記オブスキュレーション領域内に位置決めされる、極端紫外線生成装置。 - 前記導電性部材に電気的に接続された電源をさらに備え、前記電源は、無線周波数駆動回路を備える、請求項1に記載の極端紫外線生成装置。

- 前記導電性表面は、円形であり、かつ中央開口を有し、前記導電性部材は、前記中央開口を除く前記導電性表面の直径に沿って線状に形成される、請求項1に記載の極端紫外線生成装置。

- EUV光学要素は、電気絶縁性表面と導電性表面とを含む、請求項1に記載の極端紫外線生成装置。

- 前記EUV光学要素の導電性表面の背後のエリアをシールドするシールドをさらに備え、前記シールドは、前記導電性表面が前記シールドと前記導電性部材との間に置かれるように位置決めされる、請求項1に記載の極端紫外線生成装置。

- 前記シールドは、電気的に接地接続される、請求項5に記載の極端紫外線生成装置。

- 極端紫外線生成モジュールであって、

RF駆動回路と

EUV生成プラズマからの放射の焦点を合わせるように配置されたコレクタミラーの導電性表面を含むRF電極と、

前記導電性表面の一部分に隣接して配置された導電性部材であって、前記RF駆動回路と電気的に接続された導電性部材と、を備え、

前記導電性表面と前記導電性部材とは、RF出力が前記導電性部材に供給されると、前記導電性表面と前記導電性部材との間に、前記導電性表面の少なくとも一部分から汚染物質を取り除くことが可能なプラズマが生成されるように互いに近接して配置され、

前記導電性表面はオブスキュレーション領域を有し、前記導電性部材は、前記オブスキュレーション領域内に位置決めされる、

極端紫外線生成モジュール。 - EUV光源における導電性ミラー表面の洗浄方法であって、前記導電性ミラー表面に近接して導電性部材が配置されており、前記洗浄方法は、

前記導電性部材にRF出力を供給するステップと、

前記導電性部材と前記導電性ミラー表面との間に容量結合RFプラズマを生成することで前記導電性ミラー表面を洗浄するステップと、を含み、

前記導電性ミラー表面はオブスキュレーション領域を有し、前記導電性部材は、前記オブスキュレーション領域内に位置決めされる、

方法。 - 放射ビームを生成するための照明システムと、

前記放射ビームにパターンを付与するパターニングデバイスを前記放射ビームの経路内で支持するための支持構造と、

基板を支持するための支持テーブルと、

前記パターンを前記基板上に投影するように適合された投影システムと、を備え、

前記照明システムは、導電性表面と、前記導電性表面に隣接して配置された導電性部材とを有するEUV光学要素を備え、前記導電性表面と前記導電性部材とは、RF出力が前記導電性部材に供給されると、前記導電性表面と前記導電性部材との間に、前記導電性表面の少なくとも一部分から汚染物質を取り除くことが可能なプラズマが生成されるように互いに近接して配置され、

前記導電性表面はオブスキュレーション領域を有し、前記導電性部材は、前記オブスキュレーション領域内に位置決めされる、

装置。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020066317A JP6944565B2 (ja) | 2014-03-18 | 2020-04-01 | Rfプラズマ電界を使用したeuv光学部品のアクティブ洗浄装置および方法 |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US14/218,707 US9539622B2 (en) | 2014-03-18 | 2014-03-18 | Apparatus for and method of active cleaning of EUV optic with RF plasma field |

| US14/218,707 | 2014-03-18 | ||

| PCT/EP2015/054588 WO2015139964A1 (en) | 2014-03-18 | 2015-03-05 | Apparatus for and method of active cleaning of euv optic with rf plasma field |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2020066317A Division JP6944565B2 (ja) | 2014-03-18 | 2020-04-01 | Rfプラズマ電界を使用したeuv光学部品のアクティブ洗浄装置および方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2017515136A JP2017515136A (ja) | 2017-06-08 |

| JP2017515136A5 JP2017515136A5 (ja) | 2019-12-19 |

| JP6685914B2 true JP6685914B2 (ja) | 2020-04-22 |

Family

ID=52627218

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016551259A Active JP6685914B2 (ja) | 2014-03-18 | 2015-03-05 | Rfプラズマ電界を使用したeuv光学部品のアクティブ洗浄装置および方法 |

| JP2020066317A Active JP6944565B2 (ja) | 2014-03-18 | 2020-04-01 | Rfプラズマ電界を使用したeuv光学部品のアクティブ洗浄装置および方法 |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2020066317A Active JP6944565B2 (ja) | 2014-03-18 | 2020-04-01 | Rfプラズマ電界を使用したeuv光学部品のアクティブ洗浄装置および方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (2) | US9539622B2 (ja) |

| JP (2) | JP6685914B2 (ja) |

| KR (1) | KR102397027B1 (ja) |

| CN (2) | CN106104383B (ja) |

| WO (1) | WO2015139964A1 (ja) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111266368B (zh) * | 2020-01-20 | 2020-09-22 | 哈尔滨工业大学 | 一种聚焦离子束清理透射电子显微镜光阑的方法 |

| KR20220132731A (ko) | 2021-03-23 | 2022-10-04 | 삼성전자주식회사 | 극자외선 광원 시스템의 컬렉터 세정 방법 |

| KR20220132302A (ko) | 2021-03-23 | 2022-09-30 | 삼성전자주식회사 | Euv 컬렉터 검사 장치 및 검사 방법 |

| CN114200778A (zh) * | 2021-06-25 | 2022-03-18 | 四川大学 | 一种极紫外光刻机lpp光源收集镜的等离子体原位清洗结构 |

Family Cites Families (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7491954B2 (en) * | 2006-10-13 | 2009-02-17 | Cymer, Inc. | Drive laser delivery systems for EUV light source |

| EP1429189B1 (en) * | 2002-12-13 | 2008-10-08 | ASML Netherlands B.V. | Lithographic apparatus and device manufacturing method |

| US7116394B2 (en) * | 2002-12-20 | 2006-10-03 | Asml Netherlands B.V. | Method for cleaning a surface of a component of a lithographic projection apparatus, lithographic projection apparatus, device manufacturing method and cleaning system |

| US8075732B2 (en) * | 2004-11-01 | 2011-12-13 | Cymer, Inc. | EUV collector debris management |

| TWI305296B (en) * | 2004-07-27 | 2009-01-11 | Cymer Inc | Systems and methods for reducing the influence of plasma-generated debris on the internal components of an euv light source |

| US8317929B2 (en) * | 2005-09-16 | 2012-11-27 | Asml Netherlands B.V. | Lithographic apparatus comprising an electrical discharge generator and method for cleaning an element of a lithographic apparatus |

| US7989786B2 (en) * | 2006-03-31 | 2011-08-02 | Energetiq Technology, Inc. | Laser-driven light source |

| WO2008107166A1 (de) | 2007-03-07 | 2008-09-12 | Carl Zeiss Smt Ag | Verfahren zum reinigen einer euv-lithographievorrichtung, verfahren zur messung der restgasatmosphäre bzw. der kontamination sowie euv-lithographievorrichtung |

| JP5341071B2 (ja) * | 2007-06-12 | 2013-11-13 | コーニンクレッカ フィリップス エヌ ヴェ | Euv光学部品に低下した反射率を高めるための処理をその場で施す光学装置及び方法 |

| DE102007033701A1 (de) * | 2007-07-14 | 2009-01-22 | Xtreme Technologies Gmbh | Verfahren und Anordnung zur Reinigung von optischen Oberflächen in plasmabasierten Strahlungsquellen |

| US7894037B2 (en) * | 2007-07-30 | 2011-02-22 | Asml Netherlands B.V. | Lithographic apparatus and device manufacturing method |

| NL1036769A1 (nl) * | 2008-04-23 | 2009-10-26 | Asml Netherlands Bv | Lithographic apparatus, device manufacturing method, cleaning system and method for cleaning a patterning device. |

| JP2010123929A (ja) * | 2008-10-24 | 2010-06-03 | Gigaphoton Inc | 極端紫外光光源装置 |

| NL2003610A (en) * | 2008-12-22 | 2010-06-23 | Asml Netherlands Bv | A lithographic apparatus, a radiation system, a device manufacturing method and a radiation generating method. |

| US8173985B2 (en) * | 2009-12-15 | 2012-05-08 | Cymer, Inc. | Beam transport system for extreme ultraviolet light source |

| US8000212B2 (en) * | 2009-12-15 | 2011-08-16 | Cymer, Inc. | Metrology for extreme ultraviolet light source |

| JP5705592B2 (ja) * | 2010-03-18 | 2015-04-22 | ギガフォトン株式会社 | 極端紫外光生成装置 |

| WO2012031841A1 (en) * | 2010-09-08 | 2012-03-15 | Asml Netherlands B.V. | Lithographic apparatus, euv radiation generation apparatus and device manufacturing method |

| US8822949B2 (en) * | 2011-02-05 | 2014-09-02 | Ionsense Inc. | Apparatus and method for thermal assisted desorption ionization systems |

| US8399868B2 (en) * | 2011-02-15 | 2013-03-19 | Sematech Inc. | Tools, methods and devices for mitigating extreme ultraviolet optics contamination |

| US9516730B2 (en) * | 2011-06-08 | 2016-12-06 | Asml Netherlands B.V. | Systems and methods for buffer gas flow stabilization in a laser produced plasma light source |

| EP2732558B1 (en) * | 2011-07-13 | 2019-03-06 | USHIO Denki Kabushiki Kaisha | Power supply for a discharge produced plasma euv source |

| WO2013072154A1 (en) * | 2011-11-15 | 2013-05-23 | Asml Netherlands B.V. | Radiation source and method for operating the same, lithographic apparatus comprising the radiation source, and device manufacturing method |

| JP6170928B2 (ja) * | 2012-09-18 | 2017-07-26 | ギガフォトン株式会社 | スラブ型増幅器、それを含むレーザ装置および極短紫外光生成装置 |

-

2014

- 2014-03-18 US US14/218,707 patent/US9539622B2/en active Active

-

2015

- 2015-03-05 WO PCT/EP2015/054588 patent/WO2015139964A1/en active Application Filing

- 2015-03-05 CN CN201580013909.3A patent/CN106104383B/zh active Active

- 2015-03-05 CN CN201910125932.1A patent/CN110058494B/zh active Active

- 2015-03-05 KR KR1020167021861A patent/KR102397027B1/ko active IP Right Grant

- 2015-03-05 JP JP2016551259A patent/JP6685914B2/ja active Active

-

2016

- 2016-12-08 US US15/373,199 patent/US10493504B2/en active Active

-

2020

- 2020-04-01 JP JP2020066317A patent/JP6944565B2/ja active Active

Also Published As

| Publication number | Publication date |

|---|---|

| WO2015139964A1 (en) | 2015-09-24 |

| JP2017515136A (ja) | 2017-06-08 |

| CN110058494A (zh) | 2019-07-26 |

| JP2020122973A (ja) | 2020-08-13 |

| CN110058494B (zh) | 2021-09-03 |

| CN106104383B (zh) | 2019-03-19 |

| JP6944565B2 (ja) | 2021-10-06 |

| US20150266067A1 (en) | 2015-09-24 |

| CN106104383A (zh) | 2016-11-09 |

| KR102397027B1 (ko) | 2022-05-11 |

| US9539622B2 (en) | 2017-01-10 |

| US20170095843A1 (en) | 2017-04-06 |

| KR20160134648A (ko) | 2016-11-23 |

| US10493504B2 (en) | 2019-12-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6944565B2 (ja) | Rfプラズマ電界を使用したeuv光学部品のアクティブ洗浄装置および方法 | |

| EP1109427B1 (en) | Method for emitting radiation for use in lithographic projection apparatus | |

| KR100777414B1 (ko) | 방사선 발생 장치, 리소그래피 장치, 디바이스 제조방법 및그에 의해 제조되는 디바이스 | |

| US7528395B2 (en) | Radiation source, lithographic apparatus and device manufacturing method | |

| US8368032B2 (en) | Radiation source, lithographic apparatus, and device manufacturing method | |

| KR102709891B1 (ko) | 패싯형 euv 광학 요소 | |

| US7462851B2 (en) | Electromagnetic radiation source, lithographic apparatus, device manufacturing method and device manufactured thereby | |

| JP2013524525A (ja) | Euv放射源およびeuv放射生成方法 | |

| JP2017515136A5 (ja) | ||

| JP2023083302A (ja) | 極端紫外線光源のチャンバ内の光学系の表面の洗浄 | |

| NL2004816A (en) | Euv radiation generation apparatus. | |

| US10871647B2 (en) | Apparatus and method for prevention of contamination on collector of extreme ultraviolet light source | |

| JP4920741B2 (ja) | リソグラフィ装置およびデバイス製造方法 | |

| WO2013072154A1 (en) | Radiation source and method for operating the same, lithographic apparatus comprising the radiation source, and device manufacturing method | |

| JP2014533420A (ja) | 放射源デバイス、リソグラフィ装置、および、デバイス製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20180227 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20190124 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190418 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20190807 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20191105 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20200306 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20200401 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6685914 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |