JP6685224B2 - 複合構造材料及びそのための骨材 - Google Patents

複合構造材料及びそのための骨材 Download PDFInfo

- Publication number

- JP6685224B2 JP6685224B2 JP2016530270A JP2016530270A JP6685224B2 JP 6685224 B2 JP6685224 B2 JP 6685224B2 JP 2016530270 A JP2016530270 A JP 2016530270A JP 2016530270 A JP2016530270 A JP 2016530270A JP 6685224 B2 JP6685224 B2 JP 6685224B2

- Authority

- JP

- Japan

- Prior art keywords

- aggregate

- legs

- composite structural

- structural material

- concrete

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000463 material Substances 0.000 title claims description 46

- 239000002131 composite material Substances 0.000 title claims description 32

- 239000002245 particle Substances 0.000 claims description 50

- 239000000203 mixture Substances 0.000 claims description 26

- 239000004568 cement Substances 0.000 claims description 20

- 230000007423 decrease Effects 0.000 claims description 12

- 239000011159 matrix material Substances 0.000 claims description 12

- 239000004033 plastic Substances 0.000 claims description 11

- 229920003023 plastic Polymers 0.000 claims description 11

- 239000011230 binding agent Substances 0.000 claims description 6

- 239000011236 particulate material Substances 0.000 claims description 6

- 229920001903 high density polyethylene Polymers 0.000 claims description 5

- 239000004700 high-density polyethylene Substances 0.000 claims description 5

- -1 polyethylene terephthalate Polymers 0.000 claims description 5

- 229920000139 polyethylene terephthalate Polymers 0.000 claims description 4

- 239000005020 polyethylene terephthalate Substances 0.000 claims description 4

- 239000010881 fly ash Substances 0.000 claims description 3

- 239000004800 polyvinyl chloride Substances 0.000 claims description 3

- 239000004743 Polypropylene Substances 0.000 claims description 2

- 239000004793 Polystyrene Substances 0.000 claims description 2

- 229920000515 polycarbonate Polymers 0.000 claims description 2

- 239000004417 polycarbonate Substances 0.000 claims description 2

- 229920001155 polypropylene Polymers 0.000 claims description 2

- 229920002223 polystyrene Polymers 0.000 claims description 2

- 239000012615 aggregate Substances 0.000 description 76

- 239000004567 concrete Substances 0.000 description 68

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 16

- 238000012360 testing method Methods 0.000 description 7

- 239000004576 sand Substances 0.000 description 6

- 239000000047 product Substances 0.000 description 5

- 239000000126 substance Substances 0.000 description 5

- 239000000654 additive Substances 0.000 description 4

- 230000036571 hydration Effects 0.000 description 4

- 238000006703 hydration reaction Methods 0.000 description 4

- 239000007787 solid Substances 0.000 description 4

- 239000004575 stone Substances 0.000 description 4

- 239000011398 Portland cement Substances 0.000 description 3

- 238000005452 bending Methods 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 238000012986 modification Methods 0.000 description 3

- 230000004048 modification Effects 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 238000000926 separation method Methods 0.000 description 3

- 230000000740 bleeding effect Effects 0.000 description 2

- 238000005056 compaction Methods 0.000 description 2

- 239000013078 crystal Substances 0.000 description 2

- 239000012467 final product Substances 0.000 description 2

- 239000012530 fluid Substances 0.000 description 2

- 239000002994 raw material Substances 0.000 description 2

- 239000011150 reinforced concrete Substances 0.000 description 2

- 239000002893 slag Substances 0.000 description 2

- 235000019738 Limestone Nutrition 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 230000002745 absorbent Effects 0.000 description 1

- 239000002250 absorbent Substances 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 239000010426 asphalt Substances 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000001311 chemical methods and process Methods 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000007676 flexural strength test Methods 0.000 description 1

- 239000006260 foam Substances 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 239000010438 granite Substances 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 239000010440 gypsum Substances 0.000 description 1

- 229910052602 gypsum Inorganic materials 0.000 description 1

- 239000011372 high-strength concrete Substances 0.000 description 1

- 239000008240 homogeneous mixture Substances 0.000 description 1

- 239000004615 ingredient Substances 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 239000011499 joint compound Substances 0.000 description 1

- 239000006028 limestone Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000013508 migration Methods 0.000 description 1

- 230000005012 migration Effects 0.000 description 1

- 239000013502 plastic waste Substances 0.000 description 1

- 239000002952 polymeric resin Substances 0.000 description 1

- 229920000915 polyvinyl chloride Polymers 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 239000002352 surface water Substances 0.000 description 1

- 229920003002 synthetic resin Polymers 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B16/00—Use of organic materials as fillers, e.g. pigments, for mortars, concrete or artificial stone; Treatment of organic materials specially adapted to enhance their filling properties in mortars, concrete or artificial stone

- C04B16/04—Macromolecular compounds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28B—SHAPING CLAY OR OTHER CERAMIC COMPOSITIONS; SHAPING SLAG; SHAPING MIXTURES CONTAINING CEMENTITIOUS MATERIAL, e.g. PLASTER

- B28B1/00—Producing shaped prefabricated articles from the material

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B16/00—Use of organic materials as fillers, e.g. pigments, for mortars, concrete or artificial stone; Treatment of organic materials specially adapted to enhance their filling properties in mortars, concrete or artificial stone

- C04B16/12—Use of organic materials as fillers, e.g. pigments, for mortars, concrete or artificial stone; Treatment of organic materials specially adapted to enhance their filling properties in mortars, concrete or artificial stone characterised by the shape, e.g. perforated strips

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B14/00—Use of inorganic materials as fillers, e.g. pigments, for mortars, concrete or artificial stone; Treatment of inorganic materials specially adapted to enhance their filling properties in mortars, concrete or artificial stone

- C04B14/005—Inorganic fillers with a shape other than granular or fibrous

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B18/00—Use of agglomerated or waste materials or refuse as fillers for mortars, concrete or artificial stone; Treatment of agglomerated or waste materials or refuse, specially adapted to enhance their filling properties in mortars, concrete or artificial stone

- C04B18/04—Waste materials; Refuse

- C04B18/06—Combustion residues, e.g. purification products of smoke, fumes or exhaust gases

- C04B18/10—Burned or pyrolised refuse

- C04B18/105—Gaseous combustion products or dusts collected from waste incineration, e.g. sludge resulting from the purification of gaseous combustion products of waste incineration

- C04B18/106—Fly ash from waste incinerators

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B20/00—Use of materials as fillers for mortars, concrete or artificial stone according to more than one of groups C04B14/00 - C04B18/00 and characterised by shape or grain distribution; Treatment of materials according to more than one of the groups C04B14/00 - C04B18/00 specially adapted to enhance their filling properties in mortars, concrete or artificial stone; Expanding or defibrillating materials

- C04B20/0008—Materials specified by a shape not covered by C04B20/0016 - C04B20/0056, e.g. nanotubes

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B28/00—Compositions of mortars, concrete or artificial stone, containing inorganic binders or the reaction product of an inorganic and an organic binder, e.g. polycarboxylate cements

- C04B28/02—Compositions of mortars, concrete or artificial stone, containing inorganic binders or the reaction product of an inorganic and an organic binder, e.g. polycarboxylate cements containing hydraulic cements other than calcium sulfates

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B28/00—Compositions of mortars, concrete or artificial stone, containing inorganic binders or the reaction product of an inorganic and an organic binder, e.g. polycarboxylate cements

- C04B28/02—Compositions of mortars, concrete or artificial stone, containing inorganic binders or the reaction product of an inorganic and an organic binder, e.g. polycarboxylate cements containing hydraulic cements other than calcium sulfates

- C04B28/021—Ash cements, e.g. fly ash cements ; Cements based on incineration residues, e.g. alkali-activated slags from waste incineration ; Kiln dust cements

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B28/00—Compositions of mortars, concrete or artificial stone, containing inorganic binders or the reaction product of an inorganic and an organic binder, e.g. polycarboxylate cements

- C04B28/02—Compositions of mortars, concrete or artificial stone, containing inorganic binders or the reaction product of an inorganic and an organic binder, e.g. polycarboxylate cements containing hydraulic cements other than calcium sulfates

- C04B28/04—Portland cements

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B28/00—Compositions of mortars, concrete or artificial stone, containing inorganic binders or the reaction product of an inorganic and an organic binder, e.g. polycarboxylate cements

- C04B28/02—Compositions of mortars, concrete or artificial stone, containing inorganic binders or the reaction product of an inorganic and an organic binder, e.g. polycarboxylate cements containing hydraulic cements other than calcium sulfates

- C04B28/08—Slag cements

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C5/00—Reinforcing elements, e.g. for concrete; Auxiliary elements therefor

- E04C5/07—Reinforcing elements of material other than metal, e.g. of glass, of plastics, or not exclusively made of metal

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C5/00—Reinforcing elements, e.g. for concrete; Auxiliary elements therefor

- E04C5/07—Reinforcing elements of material other than metal, e.g. of glass, of plastics, or not exclusively made of metal

- E04C5/073—Discrete reinforcing elements, e.g. fibres

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W30/00—Technologies for solid waste management

- Y02W30/50—Reuse, recycling or recovery technologies

- Y02W30/91—Use of waste materials as fillers for mortars or concrete

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Ceramic Engineering (AREA)

- Structural Engineering (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Architecture (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Inorganic Chemistry (AREA)

- Civil Engineering (AREA)

- Nanotechnology (AREA)

- Combustion & Propulsion (AREA)

- Environmental & Geological Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Curing Cements, Concrete, And Artificial Stone (AREA)

- Porous Artificial Stone Or Porous Ceramic Products (AREA)

- Compositions Of Macromolecular Compounds (AREA)

Description

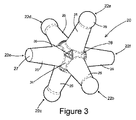

12、12a、12b、12c、12d、12e、12f 脚部

14 端部

16 平面

18 中央ハブ

20 粒子

22、22a、22b、22c、22d、22e、22f 脚部

24 中央ハブ

25 円錐形部分

26 端部

27 平面

28 表面部分

30 凹部

Claims (6)

- セメント質のバインダ、エネルギー的に改質されたセメント、又は、セメント混合物のいずれかの硬質なマトリックス内の骨材から形成された複合構造材料であって、前記骨材は粒状物質であり、各粒子は、3次元の骨材粒子を形成するように、中央ハブから外側に向かって、放射状に対称的に延在する少なくとも3つの放射状脚部を有しており、前記脚部が、前記中央ハブに最も近い位置において、前記中央ハブの直径/幅よりも小さい直径を有しており、前記中央ハブは、前記脚部の間に配置された、暴露される表面部分を有しており、前記表面部分は表面外形を含んでおり、前記複合構造材料は、2.0%v/vから7.5%v/vの量で前記骨材を含んでおり、前記脚部の1つ以上が、円錐形又は円錐台形であり、前記中央ハブから遠ざかるにつれて直径が減少する、複合構造材料。

- 前記骨材を、2.5%v/vから5.0%v/vの量で含んでいる、請求項1に記載の複合構造材料。

- 前記脚部の自由端が、平面を有しているか、又は、曲面(凸状若しくは凹状の表面)、球根状の球状端部を有しているか、又は、とがっている、請求項1又は2に記載の複合構造材料。

- 前記中央ハブが、概ね球状、概ね円筒状、又は、概ね立方体状の形を有している、請求項1から3のいずれか一項に記載の複合構造材料。

- 前記表面外形が凹部である、請求項1から4のいずれか一項に記載の複合構造材料。

- 前記骨材粒子が、ポリスチレン、高密度ポリエチレン(HDPE)、ポリエチレンテレフタレート(PET)、ポリ塩化ビニル(PVC)、ポリカーボネート、ポリプロピレン、又は、任意の高密度プラスチックから成る群から選択されるプラスチック材料であるか、成形可能若しくは鋳造可能な非プラスチック材料(フライアッシュ等)、またはこれらの材料の混合物である、請求項1から5のいずれか一項に記載の複合構造材料。

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AU2013101024A AU2013101024A4 (en) | 2013-07-29 | 2013-07-29 | plastic aggregate designed to add strength whist reducing the weight. |

| AU2013101024 | 2013-07-29 | ||

| AU2014901226 | 2014-04-04 | ||

| AU2014901226A AU2014901226A0 (en) | 2014-04-04 | Composite structural material and aggregate therefor | |

| PCT/AU2014/000758 WO2015013744A1 (en) | 2013-07-29 | 2014-07-29 | Composite structural material and aggregate therefor |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2019220441A Division JP2020045283A (ja) | 2013-07-29 | 2019-12-05 | 複合構造材料及びそのための骨材 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2016527175A JP2016527175A (ja) | 2016-09-08 |

| JP2016527175A5 JP2016527175A5 (ja) | 2017-08-10 |

| JP6685224B2 true JP6685224B2 (ja) | 2020-04-22 |

Family

ID=52430744

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016530270A Active JP6685224B2 (ja) | 2013-07-29 | 2014-07-29 | 複合構造材料及びそのための骨材 |

| JP2019220441A Withdrawn JP2020045283A (ja) | 2013-07-29 | 2019-12-05 | 複合構造材料及びそのための骨材 |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2019220441A Withdrawn JP2020045283A (ja) | 2013-07-29 | 2019-12-05 | 複合構造材料及びそのための骨材 |

Country Status (13)

| Country | Link |

|---|---|

| US (2) | US20160168027A1 (ja) |

| EP (1) | EP3024795B1 (ja) |

| JP (2) | JP6685224B2 (ja) |

| KR (1) | KR102321527B1 (ja) |

| CN (2) | CN111499239A (ja) |

| AU (1) | AU2014295893B2 (ja) |

| CA (1) | CA2919710C (ja) |

| DK (1) | DK3024795T3 (ja) |

| NZ (1) | NZ717315A (ja) |

| PH (1) | PH12016500385A1 (ja) |

| PL (1) | PL3024795T3 (ja) |

| RU (1) | RU2671984C2 (ja) |

| WO (1) | WO2015013744A1 (ja) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6697175B2 (ja) * | 2015-04-08 | 2020-05-20 | 株式会社大林組 | 補強用短繊維及びそれを用いた短繊維補強体 |

| AU2017285471A1 (en) * | 2016-06-16 | 2019-01-31 | Eaa Research Engineer Pty Ltd | Alternative reinforced concrete composite |

| CN107935426B (zh) * | 2017-10-31 | 2020-05-01 | 重庆工程职业技术学院 | 一种具有混凝土阻裂作用的金属结构 |

| CN107963821B (zh) * | 2017-12-08 | 2020-07-24 | 中水北方勘测设计研究有限责任公司 | 一种严寒地区坝体保温混凝土 |

| CN109734342A (zh) * | 2019-01-23 | 2019-05-10 | 东南大学 | 一种基于光固化3d打印的仿生混凝土粗骨料及其制备方法和应用 |

| IT201900003947A1 (it) * | 2019-03-19 | 2020-09-19 | Mt Ortho S R L | Granulo in materiale metallico biocompatibile per vertebroplastica. |

| RU2750501C2 (ru) * | 2019-07-30 | 2021-06-28 | Федеральное государственное бюджетное образовательное учреждение высшего образования "Череповецкий государственный университет" | Фибра из ПЭТ тары для полистиролбетона |

| CN111551407A (zh) * | 2020-04-14 | 2020-08-18 | 清华大学 | 胶结双球形颗粒材料及其制备方法 |

| CN113718581A (zh) * | 2021-08-04 | 2021-11-30 | 曾东升 | 一种沥青路面结构 |

| CN113584985A (zh) * | 2021-08-04 | 2021-11-02 | 黄鹏宇 | 用于沥青路面的嵌挤型结构层 |

| CN113622245A (zh) * | 2021-08-04 | 2021-11-09 | 杨庆国 | 用于与集料配合嵌挤的沥青路面人造增强骨料 |

| CN113718578A (zh) * | 2021-08-04 | 2021-11-30 | 郑佳艳 | 一种旧水泥混凝土加铺改造方法 |

| CN113605168A (zh) * | 2021-08-04 | 2021-11-05 | 黄鹏宇 | 一种旧水泥混凝土加铺改造结构 |

| DE102022101163A1 (de) | 2022-01-19 | 2023-07-20 | Hochschule Schmalkalden | Armierungsbauteil zur Betonarmierung sowie Betonbauteil |

Family Cites Families (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3846085A (en) * | 1972-01-27 | 1974-11-05 | Versatile Structures Inc | Ferrous aggregate for concrete |

| US4033781A (en) * | 1976-01-09 | 1977-07-05 | Amtech, Inc. | Fiber reinforced structural material |

| GB1506615A (en) * | 1976-06-08 | 1978-04-05 | Initial Plastics Ltd | Concrete or cement mortar |

| JPS5420034A (en) * | 1977-07-15 | 1979-02-15 | Toshiba Jiyuutaku Sangiyou Kk | Mixed mortar reinforced with steel fiber |

| US4370390A (en) * | 1981-06-15 | 1983-01-25 | Mcdonnell Douglas Corporation | 3-D Chopped-fiber composites |

| EP0126167A1 (de) * | 1983-05-18 | 1984-11-28 | BM Chemie Kunststoff GmbH | Faserförmiger Zuschlag |

| US4778718A (en) | 1987-03-26 | 1988-10-18 | University Of Delaware | Fabric-reinforced cementitious sheet-like structures and their production |

| JPS6480668A (en) * | 1987-09-21 | 1989-03-27 | Shimizu Construction Co Ltd | Method of light-weight prepacked concrete construction |

| CA2005746C (en) * | 1988-12-19 | 1994-05-31 | Minoru Yoshinaka | Soundproofing materials |

| US5209968A (en) * | 1991-07-22 | 1993-05-11 | Diversitech Corporation | Composite structure with waste plastic core and method of making same |

| WO1994008912A2 (en) * | 1992-10-13 | 1994-04-28 | Ushers Inc. | Improved aggregates, and apparatus and method for making same |

| JPH07115898B2 (ja) * | 1992-12-14 | 1995-12-13 | 晃 葛西 | 舗装材 |

| JP2000512609A (ja) * | 1993-10-13 | 2000-09-26 | アッシャーズ インコーポレイテッド | 改良した骨材及びその製造装置及び製造方法 |

| JPH11278894A (ja) * | 1998-03-30 | 1999-10-12 | Ando Kensetsu Kk | 多針状構造繊維及びその製造方法 |

| JP2001089210A (ja) * | 1999-09-27 | 2001-04-03 | Michio Hirata | コンクリートの骨材の形状 |

| EP1259196A2 (en) * | 2000-03-03 | 2002-11-27 | Smith & Nephew, Inc. | Shaped particle and composition for bone deficiency and method of making the particle |

| CN2527560Y (zh) * | 2002-02-19 | 2002-12-25 | 胡向赤 | 混凝土专用粗骨料 |

| CN100467809C (zh) * | 2005-01-19 | 2009-03-11 | 谢铋年 | 轻骨料钢丝网增强混凝土预制件及其制备方法 |

| RU2474542C2 (ru) * | 2011-03-21 | 2013-02-10 | федеральное государственное бюджетное образовательное учреждение высшего профессионального образования "Волгоградский государственный архитектурно-строительный университет" (ВолгГАСУ) | Крупный заполнитель для бетона |

| AU2013101024A4 (en) | 2013-07-29 | 2013-10-03 | Seels Technology Pty Ltd | plastic aggregate designed to add strength whist reducing the weight. |

| US10046090B2 (en) * | 2013-10-08 | 2018-08-14 | Vivorte, Inc. | Processed bone particle compositions and related methods |

-

2014

- 2014-07-29 PL PL14832660T patent/PL3024795T3/pl unknown

- 2014-07-29 NZ NZ717315A patent/NZ717315A/en unknown

- 2014-07-29 DK DK14832660.6T patent/DK3024795T3/da active

- 2014-07-29 US US14/908,566 patent/US20160168027A1/en not_active Abandoned

- 2014-07-29 KR KR1020167005413A patent/KR102321527B1/ko active IP Right Grant

- 2014-07-29 JP JP2016530270A patent/JP6685224B2/ja active Active

- 2014-07-29 EP EP14832660.6A patent/EP3024795B1/en active Active

- 2014-07-29 WO PCT/AU2014/000758 patent/WO2015013744A1/en active Application Filing

- 2014-07-29 AU AU2014295893A patent/AU2014295893B2/en active Active

- 2014-07-29 RU RU2016106918A patent/RU2671984C2/ru active

- 2014-07-29 CN CN202010146639.6A patent/CN111499239A/zh active Pending

- 2014-07-29 CN CN201480053761.1A patent/CN105593189A/zh active Pending

- 2014-07-29 CA CA2919710A patent/CA2919710C/en active Active

-

2016

- 2016-02-26 PH PH12016500385A patent/PH12016500385A1/en unknown

-

2019

- 2019-12-05 JP JP2019220441A patent/JP2020045283A/ja not_active Withdrawn

-

2021

- 2021-11-29 US US17/536,825 patent/US11718560B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2020045283A (ja) | 2020-03-26 |

| US20160168027A1 (en) | 2016-06-16 |

| JP2016527175A (ja) | 2016-09-08 |

| PL3024795T3 (pl) | 2021-08-09 |

| AU2014295893A1 (en) | 2016-03-10 |

| PH12016500385A1 (en) | 2016-05-16 |

| KR102321527B1 (ko) | 2021-11-08 |

| DK3024795T3 (da) | 2021-02-15 |

| EP3024795A1 (en) | 2016-06-01 |

| EP3024795B1 (en) | 2020-11-11 |

| RU2016106918A (ru) | 2017-08-31 |

| RU2671984C2 (ru) | 2018-11-08 |

| RU2016106918A3 (ja) | 2018-04-25 |

| CA2919710C (en) | 2022-11-01 |

| US11718560B2 (en) | 2023-08-08 |

| NZ717315A (en) | 2019-04-26 |

| US20220081361A1 (en) | 2022-03-17 |

| AU2014295893B2 (en) | 2017-09-07 |

| CN105593189A (zh) | 2016-05-18 |

| CN111499239A (zh) | 2020-08-07 |

| WO2015013744A1 (en) | 2015-02-05 |

| KR20160064078A (ko) | 2016-06-07 |

| EP3024795A4 (en) | 2017-04-12 |

| CA2919710A1 (en) | 2015-02-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6685224B2 (ja) | 複合構造材料及びそのための骨材 | |

| Nepomuceno et al. | Mechanical performance evaluation of concrete made with recycled ceramic coarse aggregates from industrial brick waste | |

| Kan et al. | A novel material for lightweight concrete production | |

| Ling | Effects of compaction method and rubber content on the properties of concrete paving blocks | |

| RU2410486C2 (ru) | Асфальт сверхвысокой прочности | |

| Sasah et al. | Study of brick mortar using sawdust as partial replacement for sand | |

| Winarno | Comparative strength and cost of rice husk concrete block | |

| EP3129201B1 (en) | Process for the preparation of masonry composite materials | |

| Atoyebi et al. | Evaluation of laterized earth moist concrete in construction works | |

| JP5969426B2 (ja) | 軽量充填モルタル組成物 | |

| WO2007049136A2 (en) | Method of making constructional elements | |

| Lomboy et al. | Semi-flowable self-consolidating concrete and its application | |

| Han et al. | Self-compacting concrete | |

| Corinaldesi | Influence of lightweight aggregates and GRP by-product powders on the properties of self-compacting concretes | |

| Al-Zboon et al. | Utilization of volcanic tuffs as construction materials | |

| US5702651A (en) | Use of oriented tabular aggregate in manufacture of high-flexural-strength concrete | |

| Ismail et al. | Evaluation on the Mechanical Properties of Concrete Using Clay Brick as Sand Substitution | |

| Ling et al. | The effect of cement and water cement ratio on concrete paving block | |

| Musau et al. | Use of Rice Husks as partial replacement of coarse aggregates in concrete paving blocks | |

| AL-Ridha et al. | Research Article Assessment of the Effect of Replacing Normal Aggregate by Porcelinite on the Behaviour of Layered Steel Fibrous Self-Compacting Reinforced Concrete Slabs under Uniform Load | |

| Wang et al. | A Novel Self-consolidating Concrete for Slip-form Application | |

| RU2002129225A (ru) | Цементобетонная смесь, способ её приготовления и способ производства изделий для устроения тротуаров из цементобетонной смеси | |

| PRASAD et al. | Experimental Studies On Steel Fiber Reinforced Self Compacting Concrete By Partial Replacement Of Cement With Marble Dust. | |

| JP2004224633A (ja) | プレストレストコンクリート舗装版 | |

| Saravanan et al. | Fine Aggregate Replacement with China Clay-Based Concrete: A Strength and Durability Study |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170629 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20170629 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20180326 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20180409 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20180601 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20181105 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190204 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20190805 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20191205 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20200123 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20200302 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20200331 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6685224 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |