JP6450910B2 - 溶接ハイブリッドリングを備えるシリンダヘッドガスケット - Google Patents

溶接ハイブリッドリングを備えるシリンダヘッドガスケットInfo

- Publication number

- JP6450910B2 JP6450910B2 JP2016500529A JP2016500529A JP6450910B2 JP 6450910 B2 JP6450910 B2 JP 6450910B2 JP 2016500529 A JP2016500529 A JP 2016500529A JP 2016500529 A JP2016500529 A JP 2016500529A JP 6450910 B2 JP6450910 B2 JP 6450910B2

- Authority

- JP

- Japan

- Prior art keywords

- cylinder head

- head gasket

- opening

- tab

- sealing ring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000007789 sealing Methods 0.000 claims description 41

- 239000011241 protective layer Substances 0.000 claims description 13

- 239000002346 layers by function Substances 0.000 claims description 6

- 239000002356 single layer Substances 0.000 claims description 3

- 239000010410 layer Substances 0.000 description 19

- 239000002826 coolant Substances 0.000 description 5

- 239000000463 material Substances 0.000 description 4

- 239000011324 bead Substances 0.000 description 3

- 239000003921 oil Substances 0.000 description 3

- 239000010935 stainless steel Substances 0.000 description 3

- 229910001220 stainless steel Inorganic materials 0.000 description 3

- 239000010960 cold rolled steel Substances 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 229920001971 elastomer Polymers 0.000 description 2

- 239000000806 elastomer Substances 0.000 description 2

- 239000010705 motor oil Substances 0.000 description 2

- 230000001681 protective effect Effects 0.000 description 2

- 239000003566 sealing material Substances 0.000 description 2

- 239000000567 combustion gas Substances 0.000 description 1

- 238000002485 combustion reaction Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 238000013021 overheating Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F11/00—Arrangements of sealings in combustion engines

- F02F11/002—Arrangements of sealings in combustion engines involving cylinder heads

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16J—PISTONS; CYLINDERS; SEALINGS

- F16J15/00—Sealings

- F16J15/02—Sealings between relatively-stationary surfaces

- F16J15/06—Sealings between relatively-stationary surfaces with solid packing compressed between sealing surfaces

- F16J15/064—Sealings between relatively-stationary surfaces with solid packing compressed between sealing surfaces the packing combining the sealing function with other functions

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16J—PISTONS; CYLINDERS; SEALINGS

- F16J15/00—Sealings

- F16J15/02—Sealings between relatively-stationary surfaces

- F16J15/06—Sealings between relatively-stationary surfaces with solid packing compressed between sealing surfaces

- F16J15/08—Sealings between relatively-stationary surfaces with solid packing compressed between sealing surfaces with exclusively metal packing

- F16J15/0818—Flat gaskets

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16J—PISTONS; CYLINDERS; SEALINGS

- F16J15/00—Sealings

- F16J15/02—Sealings between relatively-stationary surfaces

- F16J15/06—Sealings between relatively-stationary surfaces with solid packing compressed between sealing surfaces

- F16J15/10—Sealings between relatively-stationary surfaces with solid packing compressed between sealing surfaces with non-metallic packing

- F16J15/12—Sealings between relatively-stationary surfaces with solid packing compressed between sealing surfaces with non-metallic packing with metal reinforcement or covering

- F16J15/121—Sealings between relatively-stationary surfaces with solid packing compressed between sealing surfaces with non-metallic packing with metal reinforcement or covering with metal reinforcement

- F16J15/122—Sealings between relatively-stationary surfaces with solid packing compressed between sealing surfaces with non-metallic packing with metal reinforcement or covering with metal reinforcement generally parallel to the surfaces

- F16J15/123—Details relating to the edges of the packing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16J—PISTONS; CYLINDERS; SEALINGS

- F16J15/00—Sealings

- F16J15/02—Sealings between relatively-stationary surfaces

- F16J15/06—Sealings between relatively-stationary surfaces with solid packing compressed between sealing surfaces

- F16J15/08—Sealings between relatively-stationary surfaces with solid packing compressed between sealing surfaces with exclusively metal packing

- F16J15/0818—Flat gaskets

- F16J2015/0862—Flat gaskets with a bore ring

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16J—PISTONS; CYLINDERS; SEALINGS

- F16J15/00—Sealings

- F16J15/02—Sealings between relatively-stationary surfaces

- F16J15/06—Sealings between relatively-stationary surfaces with solid packing compressed between sealing surfaces

- F16J15/08—Sealings between relatively-stationary surfaces with solid packing compressed between sealing surfaces with exclusively metal packing

- F16J15/0818—Flat gaskets

- F16J2015/0868—Aspects not related to the edges of the gasket

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Gasket Seals (AREA)

Description

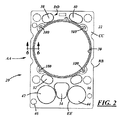

本発明の好ましい実施形態に係るシリンダヘッドガスケットの斜視図は、図1に示され、その正面図は、図2に示される。

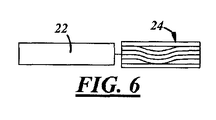

図6は、封止リング部材24および保護層26を示す断面図である。この断面は、図2のA−A線に沿って切断したものである。図示のように、封止リング24の層からなる環状体は、シリンダ開口30の内側に配置され、キャリア部材の平面と同一平面に整列されている。

Claims (9)

- シリンダヘッドガスケットであって、

単層のキャリア部材を備え、前記キャリア部材は、シリンダ開口および複数の他の開口を有し、

シリンダ開口に配置された環状の封止リングを備え、前記封止リングは、複数の環状の機能層および1対の環状の保護層を含み、前記保護層の1つは、前記封止リングの一方側に配置され、

前記機能層に位置する複数の第1タブ部材と、前記保護層に位置する複数の第2タブ部材とをさらに備え、

前記第1タブ部材は内部に開口を有し、前記第1および第2タブ部材は、前記開口を介して互いにスポット溶接されている、シリンダヘッドガスケット。 - 前記シリンダヘッドガスケットは、前記キャリア部材に設けられ、前記シリンダ開口の周囲に配置された複数の凹部部材をさらに備え、

前記第1タブ部材と第2タブ部材とは、前記凹部部材に配置されている、請求項1に記載のシリンダヘッドガスケット。 - 前記第1タブ部材と第2タブ部材とは、前記凹部部材に確実に連接されている、請求項2に記載のシリンダヘッドガスケット。

- 前記第1および第2タブ部材は、互いにスポット溶接され、前記封止リングと前記保護層とを前記キャリア部材に固定する、請求項3に記載のシリンダヘッドガスケット。

- 前記キャリア部材の一部は、前記第1タブ部材の開口内に受入れられる、請求項1に記載のシリンダヘッドガスケット。

- 3つの機能層が設けられている、請求項1に記載のシリンダヘッドガスケット。

- 前記キャリア部材に設けられた追加の開口と、前記追加の開口の各々の周囲に配置されたエラストマー封止部材とをさらに備える、請求項1に記載のシリンダヘッドガスケット。

- 前記封止部材は、径方向に沿って前記開口の内側に延在し、横方向に沿って前記キャリア部材の両側から外側に突出する、請求項7記載のシリンダヘッドガスケット。

- 前記環状の保護層は、前記環状の封止リングと実質的に同様のサイズおよび形状を有する、請求項1に記載のシリンダヘッドガスケット。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US13/828,024 US8960682B2 (en) | 2013-03-14 | 2013-03-14 | Hybrid ring welded cylinder head gasket |

| US13/828,024 | 2013-03-14 | ||

| PCT/US2014/019715 WO2014158735A1 (en) | 2013-03-14 | 2014-03-01 | Hybrid ring welded cylinder head gasket |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2016512310A JP2016512310A (ja) | 2016-04-25 |

| JP2016512310A5 JP2016512310A5 (ja) | 2017-03-09 |

| JP6450910B2 true JP6450910B2 (ja) | 2019-01-16 |

Family

ID=50336539

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016500529A Expired - Fee Related JP6450910B2 (ja) | 2013-03-14 | 2014-03-01 | 溶接ハイブリッドリングを備えるシリンダヘッドガスケット |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US8960682B2 (ja) |

| EP (1) | EP2971876B1 (ja) |

| JP (1) | JP6450910B2 (ja) |

| KR (1) | KR20150130518A (ja) |

| CN (1) | CN105190130B (ja) |

| WO (1) | WO2014158735A1 (ja) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5723846B2 (ja) * | 2012-10-04 | 2015-05-27 | 内山工業株式会社 | ガスケット |

| USD747445S1 (en) * | 2014-02-10 | 2016-01-12 | Evoqua Water Technologies Llc | One piece gasket assembly |

| DE202019104931U1 (de) * | 2019-09-06 | 2020-12-08 | Reinz-Dichtungs-Gmbh | Zylinderkopfdichtung mit einer Trägerlage und zumindest einem Einsatzdichtelement |

Family Cites Families (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE8102660U1 (de) * | 1981-07-09 | Elring Dichtungswerke Gmbh, 7012 Fellbach | Flachdichtung, insbesondere Zylinderkopfdichtung für Verbrennungskraftmaschinen | |

| US1782870A (en) | 1928-09-10 | 1930-11-25 | James G Dickson | Gasket |

| US2034610A (en) | 1934-01-22 | 1936-03-17 | Dickson Gasket Company | Gasket |

| DE1248397B (de) | 1966-06-15 | 1967-08-24 | Goetzewerke | Flanschdichtung |

| FR1592635A (ja) | 1967-11-21 | 1970-05-19 | ||

| GB1305366A (ja) | 1971-05-28 | 1973-01-31 | ||

| JPS51144646U (ja) * | 1975-05-16 | 1976-11-20 | ||

| FR2446970A1 (fr) * | 1979-01-18 | 1980-08-14 | Renault Vehicules Ind | Joint de culasse perfectionne pour les moteurs a combustion interne |

| JPS5851041U (ja) * | 1981-10-01 | 1983-04-06 | 鎌苅 良太 | 金属ガスケツト |

| US4518168A (en) | 1984-03-02 | 1985-05-21 | Dana Corporation | Multi-thickness fire ring assembly |

| IT1186800B (it) | 1985-06-03 | 1987-12-16 | Tako Spa | Guarnizione per testa cilindri di motore a combustione interna esente da amianto |

| US4645217A (en) * | 1985-11-29 | 1987-02-24 | United Technologies Corporation | Finger seal assembly |

| DE3903918A1 (de) * | 1989-02-10 | 1990-08-16 | Goetze Ag | Flachdichtung, insbesondere zylinderkopfdichtung fuer verbrennungskraftmaschinen |

| US5338046A (en) * | 1992-12-18 | 1994-08-16 | Dana Corporation | Composite powdered metal retaining ring |

| US5505466A (en) | 1992-12-18 | 1996-04-09 | Dana Corporation | Cylinder head gasket with retaining ring and spring seal |

| US5890719A (en) | 1996-08-27 | 1999-04-06 | Parker-Hannifin Corporation | Combination metal and elastomer cylinder head gasket |

| DE19654283A1 (de) * | 1996-12-24 | 1998-06-25 | Reinz Dichtungs Gmbh | Metallische Flachdichtung |

| US5921558A (en) | 1997-04-15 | 1999-07-13 | Dana Corporation | High recovery combustion seal gasket |

| US6093467A (en) | 1997-08-29 | 2000-07-25 | Interface Solutions, Inc. | High sealing gaskets |

| US6241253B1 (en) | 1998-06-08 | 2001-06-05 | Interface Solutions, Inc. | Edge coated soft gasket |

| JP3792934B2 (ja) * | 1999-05-12 | 2006-07-05 | 内山工業株式会社 | ガスケットとその製造方法 |

| FR2827638B1 (fr) * | 2001-07-23 | 2003-09-19 | Meillor Sa | Joint de culasse comprenant un stoppeur bord a bord |

| WO2005012769A2 (en) * | 2003-07-28 | 2005-02-10 | Coltec Industries, Inc. | Head gasket assembly |

| CA2477342A1 (en) * | 2003-08-28 | 2005-02-28 | Freudenberg-Nok General Partnership | Improved sealing gasket with flexible stopper |

| US7726662B2 (en) * | 2006-07-10 | 2010-06-01 | Dana Automotive Systems Group, Llc | Stopped-active type cylinder head gasket |

| CN101910688A (zh) | 2008-06-21 | 2010-12-08 | 菲特尔莫古密封系统有限公司 | 平面密封件 |

| WO2011022530A2 (en) | 2009-08-19 | 2011-02-24 | Federal-Mogul Corporation | Cylinder head gasket assembly |

| JP5425954B2 (ja) | 2012-03-14 | 2014-02-26 | 石川ガスケット株式会社 | ガスケット用ラバーリング |

-

2013

- 2013-03-14 US US13/828,024 patent/US8960682B2/en not_active Expired - Fee Related

-

2014

- 2014-03-01 KR KR1020157029228A patent/KR20150130518A/ko not_active Application Discontinuation

- 2014-03-01 WO PCT/US2014/019715 patent/WO2014158735A1/en active Application Filing

- 2014-03-01 JP JP2016500529A patent/JP6450910B2/ja not_active Expired - Fee Related

- 2014-03-01 EP EP14711381.5A patent/EP2971876B1/en active Active

- 2014-03-01 CN CN201480025251.3A patent/CN105190130B/zh not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| US8960682B2 (en) | 2015-02-24 |

| CN105190130A (zh) | 2015-12-23 |

| EP2971876A1 (en) | 2016-01-20 |

| KR20150130518A (ko) | 2015-11-23 |

| WO2014158735A1 (en) | 2014-10-02 |

| EP2971876B1 (en) | 2019-07-31 |

| US20140265153A1 (en) | 2014-09-18 |

| JP2016512310A (ja) | 2016-04-25 |

| CN105190130B (zh) | 2017-08-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US20140090619A1 (en) | Cylinder liner seal arrangement and method of providing the same | |

| JP2019505742A (ja) | 往復機械のためのクランクケースアセンブリ | |

| KR20130008027A (ko) | 래버린스 스토퍼를 구비한 다층 개스킷 | |

| JP2018200104A (ja) | 主燃焼封止型押しの内部の小型弾性封止特徴 | |

| JP6450910B2 (ja) | 溶接ハイブリッドリングを備えるシリンダヘッドガスケット | |

| EP3315830B1 (en) | Reciprocating cylinder liner seal assembly | |

| US9732698B2 (en) | Temperature reducing channel | |

| JP5136808B2 (ja) | シリンダヘッドガスケットとその製造方法 | |

| US9528466B2 (en) | Cylinder head gasket | |

| JP2017519166A (ja) | 圧縮リミッタおよびフルビード荷重を有するシリンダヘッドガスケット | |

| US10082103B2 (en) | Method of making engine spacer plate gasket | |

| CN104763529A (zh) | 可变压缩比发动机用防护罩 | |

| KR20150127629A (ko) | 멀티-레이어 개스킷 | |

| CN211008808U (zh) | 一种带有限位套结构的油底壳密封垫 | |

| US10634251B2 (en) | Multi-layer gasket assembly | |

| JP2005155713A (ja) | 金属ガスケット | |

| US20170191445A1 (en) | Multi-Layer Gasket Assembly | |

| US10119494B2 (en) | Multi-layer gasket assembly | |

| KR20110003044A (ko) | 실린더 헤드 개스킷 | |

| JPH072672U (ja) | 金属積層形シリンダヘッドガスケット | |

| CN104265896A (zh) | 一种密封型排气管接口垫片 | |

| TWM468569U (zh) | 汽缸墊片之改良 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170202 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20170202 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20171214 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20180116 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20180413 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20181002 |

|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A712 Effective date: 20181031 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20181101 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6450910 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |