JP6151578B2 - Wastewater treatment equipment - Google Patents

Wastewater treatment equipment Download PDFInfo

- Publication number

- JP6151578B2 JP6151578B2 JP2013117285A JP2013117285A JP6151578B2 JP 6151578 B2 JP6151578 B2 JP 6151578B2 JP 2013117285 A JP2013117285 A JP 2013117285A JP 2013117285 A JP2013117285 A JP 2013117285A JP 6151578 B2 JP6151578 B2 JP 6151578B2

- Authority

- JP

- Japan

- Prior art keywords

- carrier

- waste water

- hard

- filtration membrane

- filtration

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D61/00—Processes of separation using semi-permeable membranes, e.g. dialysis, osmosis or ultrafiltration; Apparatus, accessories or auxiliary operations specially adapted therefor

- B01D61/14—Ultrafiltration; Microfiltration

- B01D61/18—Apparatus therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D65/00—Accessories or auxiliary operations, in general, for separation processes or apparatus using semi-permeable membranes

- B01D65/08—Prevention of membrane fouling or of concentration polarisation

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F3/00—Biological treatment of water, waste water, or sewage

- C02F3/02—Aerobic processes

- C02F3/08—Aerobic processes using moving contact bodies

- C02F3/085—Fluidized beds

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F3/00—Biological treatment of water, waste water, or sewage

- C02F3/02—Aerobic processes

- C02F3/12—Activated sludge processes

- C02F3/1236—Particular type of activated sludge installations

- C02F3/1268—Membrane bioreactor systems

- C02F3/1273—Submerged membrane bioreactors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2315/00—Details relating to the membrane module operation

- B01D2315/06—Submerged-type; Immersion type

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2321/00—Details relating to membrane cleaning, regeneration, sterilization or to the prevention of fouling

- B01D2321/18—Use of gases

- B01D2321/185—Aeration

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D65/00—Accessories or auxiliary operations, in general, for separation processes or apparatus using semi-permeable membranes

- B01D65/02—Membrane cleaning or sterilisation ; Membrane regeneration

- B01D65/04—Membrane cleaning or sterilisation ; Membrane regeneration with movable bodies, e.g. foam balls

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F3/00—Biological treatment of water, waste water, or sewage

- C02F2003/001—Biological treatment of water, waste water, or sewage using granular carriers or supports for the microorganisms

- C02F2003/003—Biological treatment of water, waste water, or sewage using granular carriers or supports for the microorganisms using activated carbon or the like

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F3/00—Biological treatment of water, waste water, or sewage

- C02F3/02—Aerobic processes

- C02F3/12—Activated sludge processes

- C02F3/20—Activated sludge processes using diffusers

- C02F3/201—Perforated, resilient plastic diffusers, e.g. membranes, sheets, foils, tubes, hoses

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W10/00—Technologies for wastewater treatment

- Y02W10/10—Biological treatment of water, waste water, or sewage

Description

本発明は、担体に担持された活性汚泥を用いて有機性排水を処理する排水処理装置に関する。 The present invention relates to a wastewater treatment apparatus that treats organic wastewater using activated sludge supported on a carrier.

汚水処理装置として、活性汚泥を用いたものが従来から知られている。具体的には、この種の装置は、汚水に曝気を施して活性汚泥処理を行わせる曝気槽と、この曝気槽に設けられ槽内の活性汚泥混合液を濾過により固液分離する濾過膜装置と、この濾過膜装置に接続されて同部材による濾液を吸引して外部へ流出させるための吸引ポンプと、濾過膜装置と吸引ポンプとを結ぶ吸引経路に設けられ濾過膜装置にかかる吸引ポンプの吸引負圧を測定するための圧力計とを備えている。 As a sewage treatment apparatus, one using activated sludge has been conventionally known. Specifically, this type of apparatus includes an aeration tank that aerates sludge to perform activated sludge treatment, and a filtration membrane apparatus that is provided in the aeration tank and separates the activated sludge mixed liquid in the tank by solid-liquid separation by filtration. A suction pump connected to the filtration membrane device for sucking the filtrate from the same member and flowing it out, and a suction pump connected to the filtration membrane device and provided in a suction path connecting the filtration membrane device and the suction pump. And a pressure gauge for measuring the suction negative pressure.

また、活性汚泥による排水処理の効率を高めるために、処理槽に貯留された排水に活性炭等の担体を添加し、この担体に各種有機物やバクテリアを担持させる技術が知られている(下記特許文献1、特許文献2、特許文献3)。 In addition, in order to increase the efficiency of wastewater treatment with activated sludge, a technique is known in which a carrier such as activated carbon is added to the wastewater stored in the treatment tank and various organic substances and bacteria are carried on this carrier (the following patent document). 1, Patent Document 2, Patent Document 3).

特許文献1では、排水に粉末炭素系吸着剤を添加することにより、生物処理による下水処理に加えて、排水の脱臭処理等も可能としている。 In Patent Document 1, by adding a powdered carbon-based adsorbent to the wastewater, in addition to sewage treatment by biological treatment, deodorization treatment of the wastewater and the like are also possible.

特許文献2では、処理槽の内部にて排水に粒状活性炭を添加し、この活性炭の表面に好気性微生物を吸着させ、これにより排水の生物処理を行なっている。 In Patent Document 2, granular activated carbon is added to the waste water inside the treatment tank, and aerobic microorganisms are adsorbed on the surface of the activated carbon, thereby biologically treating the waste water.

特許文献3では、活性汚泥を用いた生物処理に際し、粉末活性炭を排水に添加することで、色度やCODを分解している。 In Patent Document 3, chromaticity and COD are decomposed by adding powdered activated carbon to wastewater during biological treatment using activated sludge.

しかしながら、上記した特許文献に記載された発明では、濾過膜としてポリオレフィン等の樹脂材料から成る樹脂製濾過膜が採用されており、担体として比重の大きい硬質のものを採用した場合、担体が濾過膜に接触することで濾過膜が破壊されてしまう恐れがあった。 However, in the invention described in the above-mentioned patent document, a resin filtration membrane made of a resin material such as polyolefin is adopted as the filtration membrane. When a hard material having a large specific gravity is adopted as the carrier, the carrier is a filtration membrane. There was a risk that the membrane would be destroyed by contact with the filter.

また、活性汚泥処理を行う処理槽にて濾過処理を行う場合、粉末状の活性炭を担体として使用すると、この活性炭が濾過膜に堆積することで濾過抵抗となってしまう。更に、活性炭が小さすぎると汚泥とともに破棄されてしまい、その後に新たに担体を補充する必要があり経済性が悪い。 Moreover, when performing a filtration process in the processing tank which performs an activated sludge process, if powdered activated carbon is used as a support | carrier, it will become filtration resistance because this activated carbon accumulates on a filtration membrane. Furthermore, if the activated carbon is too small, it is discarded together with the sludge, and it is necessary to replenish the carrier after that, which is not economical.

一方、幅が数mm程度の活性炭から成る大型の担体を使用することも考えるが、このようにすると、上記のように樹脂製濾過膜が担体の衝撃で破壊されてしまう恐れがある。更に、濾過膜同士の間に担体が挟まったり、処理タンクの壁面に担体が接触して破砕され、この破砕された部分の担体の処理が煩雑となる恐れがあった。 On the other hand, although it is considered to use a large carrier made of activated carbon having a width of several millimeters, there is a risk that the resin filtration membrane may be destroyed by the impact of the carrier as described above. Furthermore, the carrier may be sandwiched between the filtration membranes, or the carrier may come into contact with the wall surface of the treatment tank and be crushed, and the treatment of the crushed carrier may be complicated.

本発明は、このような問題点を鑑みてなされたものであり、本発明の目的は、担体を用いることで処理効率が向上された排水処理装置を提供することに有る。 The present invention has been made in view of such problems, and an object of the present invention is to provide a wastewater treatment apparatus in which treatment efficiency is improved by using a carrier.

本発明の排水処理装置は、活性汚泥を含む排水が貯留される処理タンクと、前記排水に浸漬される硬質濾過膜と、前記排水の内部にて前記硬質濾過膜の下方で気体を発生させる気体発生手段と、を備え、水よりも比重が大きい硬質材料から成る硬質担体を前記処理タンクに収納される前記排水に添加し、前記硬質濾過膜で濾過を行っている間に前記排水中を移動する前記硬質担体に、前記活性汚泥が担持され、前記硬質濾過膜の濾過面に、前記活性汚泥を担持した前記硬質担体から成る汚泥層が形成され、前記硬質担体は、前記活性汚泥を担持した状態で前記排水に分散され、且つ、前記汚泥層を形成することを特徴とする。

The wastewater treatment apparatus of the present invention includes a treatment tank in which wastewater containing activated sludge is stored, a hard filtration membrane immersed in the wastewater, and a gas that generates gas below the hard filtration membrane inside the wastewater. A hard carrier made of a hard material having a specific gravity greater than that of water is added to the waste water stored in the treatment tank, and moves through the waste water while being filtered by the hard filtration membrane. The activated sludge is carried on the hard carrier, and a sludge layer comprising the hard carrier carrying the activated sludge is formed on the filtration surface of the hard filtration membrane, and the hard carrier carries the activated sludge. It is dispersed in the waste water in the state, and characterized that you form the sludge layer.

本発明では、活性汚泥に含まれる微生物を担持する担体の材料として、比重が水よりも大きい小型の硬質材料を採用している。よって、担体が排水上面に浮遊すること無く、排水に担体が略均一に分散された状態が実現され、排水の処理効率が向上される。 In the present invention, a small hard material having a specific gravity larger than that of water is used as a material for a carrier supporting microorganisms contained in activated sludge. Therefore, a state in which the carrier is substantially uniformly dispersed in the wastewater is realized without the carrier floating on the upper surface of the wastewater, and the wastewater treatment efficiency is improved.

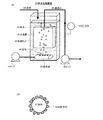

図1を参照して、本形態に係る排水処理装置10の構成を説明する。 With reference to FIG. 1, the structure of the waste water treatment apparatus 10 which concerns on this form is demonstrated.

本発明の排水処理装置10は、排水24が貯留される処理タンク12と、排水24に浸漬された濾過膜16と、処理タンク12の下方に配置されて空気30を発生させる散気部28と、濾過膜16とパイプを経由して連通して吸引圧を与えるポンプ18とを主要に備えている。尚、この図1では、各要素を接続するパイプを太い実線で示している。 The waste water treatment apparatus 10 of the present invention includes a treatment tank 12 in which waste water 24 is stored, a filtration membrane 16 immersed in the waste water 24, and an air diffuser 28 that is disposed below the treatment tank 12 and generates air 30. The filter 18 is mainly provided with a pump 18 that communicates via a pipe and applies a suction pressure. In FIG. 1, the pipes connecting the elements are indicated by thick solid lines.

本形態の排水処理装置10の機能は、処理タンク12に含まれる活性汚泥で、排水24に含まれる有機性物質を減少させ、更に、濾過膜16で濾過された濾過水26を外部に取り出すことに有る。よって、本形態の排水処理装置10で処理された後の濾過水26は、導入される排水24と比較すると、含有される有機性物質が少なく、更に、有機性固形物が殆ど含まれていない状態である。更に本形態では、処理タンク12に貯留された排水に担体を添加しており、これにより活性汚泥32に含まれる微生物が高濃度に維持されて処理効率が高くなっている。 The function of the wastewater treatment apparatus 10 of this embodiment is to reduce the organic substances contained in the wastewater 24 by the activated sludge contained in the treatment tank 12, and further take out the filtered water 26 filtered by the filtration membrane 16 to the outside. There is. Therefore, the filtered water 26 after being treated by the wastewater treatment apparatus 10 of the present embodiment contains less organic substances and contains almost no organic solids compared to the wastewater 24 to be introduced. State. Furthermore, in this embodiment, a carrier is added to the wastewater stored in the treatment tank 12, whereby the microorganisms contained in the activated sludge 32 are maintained at a high concentration and the treatment efficiency is increased.

本形態で処理される排水24は、有機性物質が高濃度に水に含まれたものであり、具体的には、糞尿等を含む一般下水、食品工場等から排出される排水等である。 The wastewater 24 to be treated in this embodiment is one in which an organic substance is contained in water at a high concentration. Specifically, the wastewater 24 is wastewater discharged from general sewage including manure and the like, a food factory, and the like.

処理タンク12は、ステンレス等から成る金属または樹脂製の容器であり、濾過される排水24および濾過膜16等を収納する役割を有する。排水24の汚泥処理および濾過処理は処理タンク12で行われる。 The processing tank 12 is a metal or resin container made of stainless steel or the like, and has a role of storing the drainage 24 to be filtered, the filtration membrane 16 and the like. Sludge treatment and filtration treatment of the drainage 24 are performed in the treatment tank 12.

濾過膜16は、ここでは平膜の濾過膜であり、処理タンク12に収納された排水24に浸漬されている。ここで、濾過膜16は、実質的に濾過を行う濾過面が全面的に排水24に浸漬される状態となっている。濾過膜16の内部空間は、パイプを経由してポンプ18と連通しており、ポンプ18が濾過膜16の内部空間に所定の吸引圧を加える事で、濾過膜16により排水24が濾過される。これにより、濾過された排水24である濾過水が処理タンク12から取り出される。 Here, the filtration membrane 16 is a flat membrane, and is immersed in the waste water 24 stored in the processing tank 12. Here, the filtration membrane 16 is in a state in which the filtration surface for substantial filtration is entirely immersed in the drainage 24. The internal space of the filtration membrane 16 communicates with the pump 18 via a pipe, and the drainage 24 is filtered by the filtration membrane 16 when the pump 18 applies a predetermined suction pressure to the internal space of the filtration membrane 16. . Thereby, the filtered water which is the filtered waste water 24 is taken out from the processing tank 12.

濾過膜16の材料としては、樹脂材料、セラミック、焼結金属、細かい濾過孔が設けられた金属板等が採用される。図1(A)では1つのみの濾過膜16が排水24に浸漬されているが、実際は、所定の間隔で離間された複数の濾過膜16が排水24に浸漬される。 As a material of the filtration membrane 16, a resin material, ceramic, sintered metal, a metal plate provided with fine filtration holes, or the like is employed. In FIG. 1A, only one filtration membrane 16 is immersed in the drainage 24, but actually, a plurality of filtration membranes 16 spaced at a predetermined interval are immersed in the drainage 24.

散気部28は、処理タンク12の内部に於いて濾過膜16の下方に配置されており、空気30を発生させる役割を有する。散気部28の具体的形状は、上部に孔部が設けられた管の如き形状である。散気部28の役割は、空気30を排水24の内部で発生させることで、排水24に酸素を供給し、排水24に添加された担体を流動させることに有る。 The air diffuser 28 is disposed below the filtration membrane 16 inside the processing tank 12 and has a role of generating air 30. The specific shape of the air diffuser 28 is a tube-like shape having a hole at the top. The role of the air diffuser 28 is to generate air 30 inside the drainage 24, thereby supplying oxygen to the drainage 24 and causing the carrier added to the drainage 24 to flow.

ここでは、圧力計20で計測される圧力が一定となるように、ポンプ18から濾過膜16に負圧が加えられ、これにより、排水24が濾過膜16で濾過された濾過水26がパイプを経由して外部に取り出される。濾過膜16の内部空間にポンプ18から付与される吸引圧は例えば10kPa程度である。 Here, a negative pressure is applied from the pump 18 to the filtration membrane 16 so that the pressure measured by the pressure gauge 20 is constant. As a result, the filtered water 26 in which the drainage 24 is filtered by the filtration membrane 16 passes through the pipe. It is taken out via. The suction pressure applied from the pump 18 to the internal space of the filtration membrane 16 is, for example, about 10 kPa.

図1(B)を参照して、本形態では、処理タンク12に貯留された排水24を活性汚泥で生物的に処理する効率を向上させるために、担体23を排水24に添加している。ここで、担体23とは、活性汚泥32に含まれる有用な微生物を担持するための粒子である。この図に示すように担体23の表面には活性汚泥32を構成する微生物が担持されており、これにより多くの活性汚泥32を処理タンク12の内部に留まらせて、処理効率が高くなる。 With reference to FIG. 1 (B), in this embodiment, the carrier 23 is added to the wastewater 24 in order to improve the efficiency of biologically treating the wastewater 24 stored in the treatment tank 12 with activated sludge. Here, the carrier 23 is a particle for supporting useful microorganisms contained in the activated sludge 32. As shown in this figure, the microorganisms constituting the activated sludge 32 are carried on the surface of the carrier 23, so that a large amount of the activated sludge 32 remains inside the treatment tank 12 and the treatment efficiency is increased.

本形態では、担体23として、水よりも比重が大きい(即ち比重が1よりも大きい)材料を採用している。これにより、活性汚泥32を担持した担体23が排水24の液面に浮遊することによる浄化機能の低下が抑制される。即ち、比重が大きい担体23を採用することにより、活性汚泥32を担持した担体23を排水24に分散させた状態にすることが可能となる。 In this embodiment, a material having a specific gravity greater than that of water (that is, a specific gravity greater than 1) is used as the carrier 23. Thereby, the reduction | decrease of the purification function by the support | carrier 23 which carry | supported activated sludge 32 floating on the liquid level of the waste_water | drain 24 is suppressed. That is, by using the carrier 23 having a large specific gravity, the carrier 23 carrying the activated sludge 32 can be dispersed in the drainage 24.

担体23の材料としては、一定以上の硬度を有する無機材料が採用される。担体23の材料として、例えば柔らかい樹脂材料が採用されると、この樹脂材料に発生したクラックから内部に微生物が侵入し、この微生物が発するガスにより膨張した担体が液面に浮上してしまう問題が発生する。本形態の担体23は、硬度が高い硬質材料から成るので、担体23にクラックが発生しづらい。また、担体23にクラックが発生し、このクラックに微生物が進入したとしても、発生したガスで担体23が膨張しないので、この膨張による担体23の浮き上がりは防止されている。具体的な担体23の材料としては、活性炭、発泡ガラス、ゼオライト、シリカ等を採用することが可能である。 As the material of the carrier 23, an inorganic material having a certain hardness or more is employed. If, for example, a soft resin material is used as the material of the carrier 23, microorganisms enter from the cracks generated in the resin material, and the carrier expanded by the gas generated by the microorganisms floats to the liquid surface. Occur. Since the carrier 23 of this embodiment is made of a hard material having high hardness, it is difficult for the carrier 23 to crack. Further, even if a crack is generated in the carrier 23 and a microorganism enters the crack, the carrier 23 does not expand due to the generated gas, so that the carrier 23 is prevented from being lifted by this expansion. As a specific material of the carrier 23, activated carbon, foamed glass, zeolite, silica or the like can be employed.

更に本形態では、硬質材料から成る担体23を採用することで、濾過膜16の閉塞が抑制される効果が得られる。具体的には、本形態で採用される濾過膜16は、極めて微細な濾過孔を有するため、排水24に含まれる微粒子や活性汚泥がこの濾過孔に詰まり、得られるフラックスが減少してしまう恐れがある。これに際して本形態では、排水24の内部における濾過膜16の下方で散気部28から空気30を散気することで、空気30を排水24の内部で上昇させている。これにより、排水24の内部にて、下方から上方への水流が発生し、これに沿って担体23も下方から上方に移動している。この移動に伴い、硬度が高い担体23が濾過膜16の濾過面に接触し、濾過面に付着した粒子が離れて濾過孔の閉塞が抑制される。 Furthermore, in this embodiment, by using the carrier 23 made of a hard material, an effect of suppressing the clogging of the filtration membrane 16 can be obtained. Specifically, since the filtration membrane 16 employed in this embodiment has extremely fine filtration holes, fine particles and activated sludge contained in the drainage 24 may be clogged in the filtration holes and the obtained flux may be reduced. There is. At this time, in this embodiment, the air 30 is diffused from the air diffuser 28 below the filtration membrane 16 inside the drainage 24, thereby raising the air 30 inside the drainage 24. As a result, a water flow from the lower side to the upper side is generated inside the drainage 24, and the carrier 23 also moves from the lower side to the upper side along this flow. Along with this movement, the carrier 23 having a high hardness comes into contact with the filtration surface of the filtration membrane 16, and the particles adhering to the filtration surface are separated to block the filtration holes.

担体23の大きさとしては、比重が水よりも大きい場合であっても排水24の内部を浮遊することが可能な範囲とされる。具体的には、担体23の幅は、0.1μm以上0.5μm以下が好適である。担体23の幅をこの範囲とすることにより、担体23がコロイドの如く振る舞うように成り、担体23を電気化学的に排水24の内部で分散させることができる。一方、担体23の幅がこの範囲よりも小さいと、活性汚泥を構成する微生物に比して担体23が小さすぎ、微生物を担持する機能が発揮されない。また、担体23の幅がこの範囲よりも大きくなると、活性汚泥32が付着した担体23が処理タンク12の底面付近に沈殿してしまい、活性汚泥の処理効率が低下する恐れがある。 The size of the carrier 23 is a range in which the inside of the drainage 24 can float even when the specific gravity is larger than that of water. Specifically, the width of the carrier 23 is preferably 0.1 μm or more and 0.5 μm or less. By setting the width of the carrier 23 within this range, the carrier 23 behaves like a colloid, and the carrier 23 can be electrochemically dispersed inside the drainage 24. On the other hand, if the width of the carrier 23 is smaller than this range, the carrier 23 is too small compared to the microorganisms constituting the activated sludge, and the function of supporting the microorganisms is not exhibited. Moreover, if the width | variety of the support | carrier 23 becomes larger than this range, the support | carrier 23 with which the activated sludge 32 adhered will settle near the bottom face of the processing tank 12, and there exists a possibility that the process efficiency of an activated sludge may fall.

担体23の形状は特に問われないが、球形、六面体または、これらの形状に近似する形状が採用される。担体23の内部に空隙は存在しても良いし、存在しなくても良い。 The shape of the carrier 23 is not particularly limited, but a spherical shape, a hexahedron, or a shape approximating these shapes is adopted. Voids may or may not exist inside the carrier 23.

図2(A)を参照して、平膜状のセラミック濾過膜が濾過膜16として採用された場合、紙面上にて左右方向に対向する主面が濾過面16Aとなる。この濾過面16Aの全体に濾過孔が形成されている。また、濾過膜16の内部には縦方向に細長く直方体形状に伸びる多数の空隙部16B(内部空間)が形成されている。これらの空隙部16Bは、濾過膜16の上端部付近に接続するパイプと連通している。そして、濾過面16Aに形成された濾過孔は空隙部16Bと連通している。よって、濾過時には、濾過面16Aを透過した被処理水である濾過水が、空隙部16Bを経由してパイプに供給される。

Referring to FIG. 2A, when a flat membrane-like ceramic filtration membrane is employed as the filtration membrane 16, the main surface facing in the left-right direction on the paper surface is the filtration surface 16A. Filtration holes are formed in the entire filtration surface 16A. In addition, a large number of

上記したように、濾過膜16はセラミック等の硬質材料から成る。よって、上記した散気処理により撹拌された担体が濾過面16Aに接触しても、担体23の接触により濾過面16Aが破損することは無い。 As described above, the filtration membrane 16 is made of a hard material such as ceramic. Therefore, even if the carrier stirred by the above-described aeration process contacts the filtration surface 16A, the filtration surface 16A is not damaged by the contact of the carrier 23.

図2(B)を参照して、図2(A)にて点線の円で囲んだ部分を拡大して示す断面図である。この図に示すように、濾過面16Aの表面に、活性汚泥を担持した担体23から成る汚泥層22が形成されても良い。この場合、濾過面16Aの閉塞を防止するために、濾過水を濾過膜16に注入して汚泥層22を濾過面16Aから離脱させる逆洗が必要となる。ここで、濾過面16Aに設けられる濾過孔16Cの大きさは、担体23よりも小さい。よって、濾過孔16Cにより濾過孔16Cが閉塞する恐れは小さい。 FIG. 2B is an enlarged cross-sectional view illustrating a portion surrounded by a dotted circle in FIG. 2A with reference to FIG. As shown in this figure, a sludge layer 22 composed of a carrier 23 carrying activated sludge may be formed on the surface of the filtration surface 16A. In this case, in order to prevent clogging of the filtration surface 16A, backwashing is required in which filtered water is injected into the filtration membrane 16 and the sludge layer 22 is separated from the filtration surface 16A. Here, the size of the filtration hole 16 </ b> C provided in the filtration surface 16 </ b> A is smaller than that of the carrier 23. Therefore, the possibility that the filtration hole 16C is blocked by the filtration hole 16C is small.

図3を参照して、排水処理装置10を更に詳述する。ここでは、処理タンク12に貯留された排水24に、複数の濾過膜16D、16E、16Fが、互いの濾過面が対向するように配置されている。複数の濾過膜を備えることで、装置全体としてのフラックスが大きく確保される。

With reference to FIG. 3, the waste water treatment apparatus 10 is further explained in full detail. Here, a plurality of

本形態では、散気部28に設けた散気孔17A等から排水24に空気30を発生させているが、散気孔17Aの場所は、担体23の撹拌に適した箇所に配置される。 In this embodiment, air 30 is generated in the drainage 24 from the air diffuser holes 17 </ b> A provided in the air diffuser 28, but the air diffuser holes 17 </ b> A are arranged at locations suitable for stirring the carrier 23.

具体的には、紙面上にて最も左側に配置された濾過膜16Dと処理タンク12の側壁との間隙に、空気30が侵入するように、散気孔17Aが設けられている。即ち、散気部28の散気孔17Aは、この間隙の下方に配置されている。これにより、濾過膜16Dと処理タンクの側壁との間で、空気30が上昇し、これにより上方向に向く排水24の水流と共に、担体23も上方に移動する。よって、排水24の内部で担体23が撹拌される効果が得られる。

Specifically, a diffuser hole 17 </ b> A is provided so that the air 30 enters the gap between the filtration membrane 16 </ b> D disposed on the leftmost side of the paper and the side wall of the processing tank 12. That is, the air diffuser hole 17A of the air diffuser 28 is disposed below the gap. As a result, the air 30 rises between the

同様に、濾過膜16D、16Eおよび16F同士の間隙の下方に、散気孔17B、17Cが設けられている。更に、右端に配置された濾過膜16Fと処理タンク12の側壁との間隙の下方に散気孔17Dが配置されている。

Similarly, air diffusion holes 17B and 17C are provided below the gaps between the

上記した各図を参照して、上記した排水処理装置10を用いて排水を浄化する方法を説明する。 With reference to each figure mentioned above, the method to purify waste water using the above-mentioned waste water treatment apparatus 10 is demonstrated.

先ず、図1(A)を参照して、処理タンク12の内部に外部から排水24を導入する。本形態で浄化処理される排水は、下水等の有機性の被除去物が水に含まれたものである。下水そのものが処理タンク12に導入されても良いが、沈殿処理等により大型の固形物が除去処理された下水が処理タンク12に導入されても良い。処理タンク12には、下水を濾過処理するための濾過膜16が備えられており、この濾過膜16は全体的に排水24に浸漬された状態となる。 First, referring to FIG. 1A, waste water 24 is introduced into the processing tank 12 from the outside. The wastewater to be purified in this embodiment is one in which organic objects to be removed such as sewage are contained in water. Sewage itself may be introduced into the treatment tank 12, but sewage from which large solids have been removed by precipitation or the like may be introduced into the treatment tank 12. The treatment tank 12 is provided with a filtration membrane 16 for filtering sewage, and the filtration membrane 16 is entirely immersed in the drainage 24.

その後、排水24に担体23を導入して、散気部28から空気30を発生させる。発生される空気30の量は、通常の膜分離活性汚泥法と同程度で良い。これにより、空気30が上昇することにより、処理タンク12の内部で排水24、これに含まれる活性汚泥および担体23が撹拌される。また、空気30が排水24に散気されることにより、排水24に酸素が供給されて活性汚泥32の活動が活発に成る。これにより、担体23の表面に活性汚泥32が担持され、活性汚泥が濃縮されて処理効率が向上する。 Thereafter, the carrier 23 is introduced into the drainage 24 to generate air 30 from the diffuser 28. The amount of air 30 generated may be about the same as that of a normal membrane separation activated sludge method. Thereby, when the air 30 rises, the waste water 24, the activated sludge contained therein, and the carrier 23 are stirred inside the processing tank 12. Further, when the air 30 is diffused into the drainage 24, oxygen is supplied to the drainage 24 and the activity of the activated sludge 32 becomes active. Thereby, the activated sludge 32 is carried on the surface of the carrier 23, the activated sludge is concentrated, and the processing efficiency is improved.

上記したように、本形態の担体23は、比重が1よりも大きい微粒子から成るので、担体23が排水24の液面に浮上することが無く、排水24の流動と共に担体23は良好に撹拌される。 As described above, since the carrier 23 of this embodiment is composed of fine particles having a specific gravity greater than 1, the carrier 23 does not float on the liquid surface of the drainage 24, and the carrier 23 is well stirred as the drainage 24 flows. The

本形態では、上記したように、担体23の材料として活性炭等の硬質材料が採用されているが、濾過膜16としても硬質なセラミックが採用されているので、担体23が接触することにより濾過膜16が破損することが防止されている。 In this embodiment, as described above, a hard material such as activated carbon is used as the material of the carrier 23. However, since a hard ceramic is also used as the filtration membrane 16, the filtration membrane is brought into contact with the carrier 23. 16 is prevented from being damaged.

上記のように担体23に活性汚泥32が十分に担持されたら、ポンプ18で濾過膜16の内部空間に負圧を与えることにより、濾過膜16で濾過された濾過水26を系外に取り出す。ポンプ18で与えられる負圧は圧力計20で所定の範囲となるように制御される。取り出された濾過水は、その後に、沈殿処理、消毒処理等を経て外部に放出される。 When the activated sludge 32 is sufficiently supported on the carrier 23 as described above, the filtered water 26 filtered by the filtration membrane 16 is taken out of the system by applying a negative pressure to the internal space of the filtration membrane 16 by the pump 18. The negative pressure applied by the pump 18 is controlled by the pressure gauge 20 so as to be within a predetermined range. The filtered water taken out is then discharged to the outside through a precipitation process, a disinfection process, and the like.

10 排水処理装置

12 処理タンク

14 ポンプ

16 濾過膜

16A 濾過面

16B 空隙部

16C 濾過孔

16D,16E,16F 濾過膜

17,17A,17B,17C,17D 散気孔

18 ポンプ

20 圧力計

22 汚泥層

23 担体

24 排水

26 濾過水

28 散気部

30 空気

32 活性汚泥

DESCRIPTION OF SYMBOLS 10 Waste water treatment apparatus 12 Processing tank 14 Pump 16 Filtration membrane

Claims (5)

前記排水に浸漬される硬質濾過膜と、

前記排水の内部にて前記硬質濾過膜の下方で気体を発生させる気体発生手段と、を備え、

水よりも比重が大きい硬質材料から成る硬質担体を前記処理タンクに収納される前記排水に添加し、前記硬質濾過膜で濾過を行っている間に前記排水中を移動する前記硬質担体に、前記活性汚泥が担持され、

前記硬質濾過膜の濾過面に、前記活性汚泥を担持した前記硬質担体から成る汚泥層が形成され、

前記硬質担体は、前記活性汚泥を担持した状態で前記排水に分散され、且つ、前記汚泥層を形成することを特徴とする排水処理装置。 A treatment tank in which wastewater containing activated sludge is stored;

A hard filtration membrane immersed in the waste water;

Gas generating means for generating gas under the hard filtration membrane inside the drainage, and

A hard carrier made of a hard material having a specific gravity greater than that of water is added to the waste water stored in the treatment tank, and the hard carrier moving in the waste water while being filtered by the hard filtration membrane, Activated sludge is supported,

A sludge layer made of the hard carrier carrying the activated sludge is formed on the filtration surface of the hard filtration membrane,

The hard carrier is dispersed in the waste water while supporting the activated sludge, and waste water treatment apparatus which is characterized that you form the sludge layer.

The waste water treatment apparatus according to any one of claims 1 to 4, wherein the width of the hard carrier is 0.1 µm or more and 0.5 µm or less.

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013117285A JP6151578B2 (en) | 2013-06-03 | 2013-06-03 | Wastewater treatment equipment |

| PCT/JP2014/002760 WO2014196151A1 (en) | 2013-06-03 | 2014-05-26 | Waste water treatment device |

| TW103118227A TWI526404B (en) | 2013-06-03 | 2014-05-26 | Wastewater treatment apparatus |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013117285A JP6151578B2 (en) | 2013-06-03 | 2013-06-03 | Wastewater treatment equipment |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2014233686A JP2014233686A (en) | 2014-12-15 |

| JP2014233686A5 JP2014233686A5 (en) | 2016-06-16 |

| JP6151578B2 true JP6151578B2 (en) | 2017-06-21 |

Family

ID=52007812

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013117285A Active JP6151578B2 (en) | 2013-06-03 | 2013-06-03 | Wastewater treatment equipment |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP6151578B2 (en) |

| TW (1) | TWI526404B (en) |

| WO (1) | WO2014196151A1 (en) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3209411B1 (en) | 2014-10-22 | 2022-05-18 | Koch Separation Solutions, Inc. | Membrane module system with bundle enclosures and pulsed aeration |

| USD779631S1 (en) | 2015-08-10 | 2017-02-21 | Koch Membrane Systems, Inc. | Gasification device |

| KR101969522B1 (en) * | 2017-10-25 | 2019-04-16 | (주)인바이어플랜텍 | System for processing heavy metals of industrial wastewater |

| JP7004043B1 (en) | 2020-08-21 | 2022-02-10 | 株式会社明電舎 | Ceramic flat membrane |

| JP7004042B1 (en) * | 2020-08-21 | 2022-02-10 | 株式会社明電舎 | Ceramic flat membrane |

Family Cites Families (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0738789B2 (en) * | 1987-03-02 | 1995-05-01 | 三機工業株式会社 | Membrane bioreactor device |

| JPH05317897A (en) * | 1992-04-08 | 1993-12-03 | Hitachi Plant Eng & Constr Co Ltd | Method for digesting sludge |

| JPH0924373A (en) * | 1995-07-12 | 1997-01-28 | Kawasaki Steel Corp | Treatment of water containing organic matter and waste water treating device |

| FR2737202B1 (en) * | 1995-07-25 | 1997-10-17 | Omnium Traitement Valorisa | PLANT FOR BIOLOGICAL TREATMENT OF WATER FOR POTABILIZATION |

| JPH0957292A (en) * | 1995-08-24 | 1997-03-04 | Mitsubishi Rayon Co Ltd | Waste water treating device |

| JPH0957289A (en) * | 1995-08-30 | 1997-03-04 | Mitsubishi Kakoki Kaisha Ltd | Biological treating device of fluidized bed type |

| JPH0966292A (en) * | 1995-09-01 | 1997-03-11 | Kawasaki Steel Corp | Treatment of water containing organic substance |

| JPH09150148A (en) * | 1995-11-30 | 1997-06-10 | Mitsubishi Kakoki Kaisha Ltd | Immersion filter membrane treating device |

| JP3306786B2 (en) * | 1996-05-21 | 2002-07-24 | 株式会社荏原製作所 | Water biological treatment equipment |

| JPH1080624A (en) * | 1996-09-06 | 1998-03-31 | Hitachi Plant Eng & Constr Co Ltd | Membrane filtration method |

| JP3385306B2 (en) * | 1997-02-28 | 2003-03-10 | 株式会社クラレ | Wastewater treatment equipment |

| JP3142792B2 (en) * | 1997-03-14 | 2001-03-07 | 川崎重工業株式会社 | Wastewater treatment method using carbon-based adsorbent |

| JPH10314554A (en) * | 1997-05-16 | 1998-12-02 | Hitachi Metals Ltd | Membrane separation activated sludge process |

| JP4696326B2 (en) * | 1999-01-12 | 2011-06-08 | 栗田工業株式会社 | TOC component removal equipment in ultrapure water production equipment |

| JP2001062488A (en) * | 1999-08-24 | 2001-03-13 | Ebara Corp | Treatment of nitrogen-containing waste water and its device |

| JP2002361237A (en) * | 2001-06-08 | 2002-12-17 | Ebara Corp | Method and device for treating waste water containing cod component |

| JP2005074357A (en) * | 2003-09-02 | 2005-03-24 | Ngk Insulators Ltd | Membrane washing method in membrane separation activated sludge method |

| JP2005230785A (en) * | 2004-02-23 | 2005-09-02 | Sumitomo Heavy Ind Ltd | Biological waste water treatment apparatus and biological waste water treatment method |

| JP4150975B2 (en) * | 2004-04-21 | 2008-09-17 | 株式会社日立プラントテクノロジー | Wastewater treatment equipment |

| JP5390774B2 (en) * | 2006-01-25 | 2014-01-15 | 株式会社クラレ | Wastewater treatment method using immobilized carrier |

| DE102006008453A1 (en) * | 2006-02-17 | 2007-08-23 | Itn Nanovation Ag | Cleaning process for wastewater |

| JP5488156B2 (en) * | 2010-04-19 | 2014-05-14 | 株式会社明電舎 | Membrane unit and membrane separator |

-

2013

- 2013-06-03 JP JP2013117285A patent/JP6151578B2/en active Active

-

2014

- 2014-05-26 WO PCT/JP2014/002760 patent/WO2014196151A1/en active Application Filing

- 2014-05-26 TW TW103118227A patent/TWI526404B/en active

Also Published As

| Publication number | Publication date |

|---|---|

| TWI526404B (en) | 2016-03-21 |

| WO2014196151A1 (en) | 2014-12-11 |

| TW201446662A (en) | 2014-12-16 |

| JP2014233686A (en) | 2014-12-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6151578B2 (en) | Wastewater treatment equipment | |

| CA2796320A1 (en) | Membrane separation apparatus with air bubble plates | |

| JP5128417B2 (en) | Oil-containing wastewater treatment method | |

| JP5853342B2 (en) | Solid-liquid separation module and solid-liquid separation method | |

| KR100827641B1 (en) | Contact oxidation tank for waste water treatment | |

| JP2006082024A (en) | Biological treatment apparatus | |

| JP2009119354A (en) | Biological treatment apparatus and method | |

| WO2014003007A1 (en) | Wastewater treatment method and wastewater treatment device | |

| JP2006212505A (en) | Wastewater treatment apparatus and wastewater treatment system using it | |

| JP2002307088A (en) | Wastewater treatment apparatus | |

| JP2006167551A (en) | Biological treatment apparatus | |

| WO2010101152A1 (en) | Device for membrane separation type activated-sludge treatment and method therefor | |

| JP2008173556A (en) | Sewage treatment apparatus | |

| JP6267567B2 (en) | Vegetable wastewater filtration equipment | |

| JP6110216B2 (en) | Wastewater treatment equipment | |

| CN213680013U (en) | Activated sludge sewage treatment device | |

| JP2011189308A (en) | Active-sludge treatment apparatus and operation method thereof | |

| JP5825807B2 (en) | Waste water treatment apparatus and waste water treatment method | |

| JP2010264449A (en) | Flotation separation apparatus | |

| KR101416451B1 (en) | Apparatus and method for anaerobic wastewater treatment with fludized media membrane bioreactor | |

| JP2003053368A (en) | Device for membrane separation and activated sludge process | |

| JP2007000712A (en) | Solid-liquid separating device | |

| JP2008142640A (en) | Sewage treatment apparatus | |

| JP2014240050A (en) | Biological contact filtration apparatus | |

| JPH10165041A (en) | Filtering vessel and filtering method for circulating and filtering water in water tank |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160421 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20160421 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20161122 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170117 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20170228 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170321 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20170516 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20170525 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6151578 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |