JP6090923B2 - リチウムイオン二次電池用ケースの製造方法 - Google Patents

リチウムイオン二次電池用ケースの製造方法 Download PDFInfo

- Publication number

- JP6090923B2 JP6090923B2 JP2013102663A JP2013102663A JP6090923B2 JP 6090923 B2 JP6090923 B2 JP 6090923B2 JP 2013102663 A JP2013102663 A JP 2013102663A JP 2013102663 A JP2013102663 A JP 2013102663A JP 6090923 B2 JP6090923 B2 JP 6090923B2

- Authority

- JP

- Japan

- Prior art keywords

- cup

- stainless steel

- phase

- lithium ion

- ion secondary

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- HBBGRARXTFLTSG-UHFFFAOYSA-N Lithium ion Chemical compound [Li+] HBBGRARXTFLTSG-UHFFFAOYSA-N 0.000 title claims description 19

- 229910001416 lithium ion Inorganic materials 0.000 title claims description 19

- 238000004519 manufacturing process Methods 0.000 title claims description 7

- 239000011888 foil Substances 0.000 claims description 26

- 238000009792 diffusion process Methods 0.000 claims description 23

- 229910001220 stainless steel Inorganic materials 0.000 claims description 19

- 239000010935 stainless steel Substances 0.000 claims description 16

- 238000003466 welding Methods 0.000 claims description 14

- 229910001566 austenite Inorganic materials 0.000 claims description 13

- 238000000034 method Methods 0.000 claims description 13

- 229910000963 austenitic stainless steel Inorganic materials 0.000 claims description 9

- 229910000859 α-Fe Inorganic materials 0.000 claims description 8

- 230000000630 rising effect Effects 0.000 claims description 4

- 230000009466 transformation Effects 0.000 claims description 4

- 238000010438 heat treatment Methods 0.000 claims description 3

- 238000013508 migration Methods 0.000 claims description 2

- 230000005012 migration Effects 0.000 claims description 2

- 239000000463 material Substances 0.000 description 19

- 229910052782 aluminium Inorganic materials 0.000 description 12

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 11

- 238000005304 joining Methods 0.000 description 9

- 229910000831 Steel Inorganic materials 0.000 description 8

- 239000010959 steel Substances 0.000 description 8

- 229920000642 polymer Polymers 0.000 description 6

- 238000010586 diagram Methods 0.000 description 5

- 239000002648 laminated material Substances 0.000 description 5

- 229910052751 metal Inorganic materials 0.000 description 4

- 239000002245 particle Substances 0.000 description 4

- 239000011347 resin Substances 0.000 description 4

- 229920005989 resin Polymers 0.000 description 4

- 229910001039 duplex stainless steel Inorganic materials 0.000 description 3

- 239000003792 electrolyte Substances 0.000 description 3

- 239000008151 electrolyte solution Substances 0.000 description 3

- -1 polypropylene Polymers 0.000 description 3

- 238000004080 punching Methods 0.000 description 3

- 238000007789 sealing Methods 0.000 description 3

- 229910021642 ultra pure water Inorganic materials 0.000 description 3

- 239000012498 ultrapure water Substances 0.000 description 3

- 239000004743 Polypropylene Substances 0.000 description 2

- 238000002347 injection Methods 0.000 description 2

- 239000007924 injection Substances 0.000 description 2

- 229910001105 martensitic stainless steel Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 229920001155 polypropylene Polymers 0.000 description 2

- 229910045601 alloy Inorganic materials 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- 229910052804 chromium Inorganic materials 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 238000011835 investigation Methods 0.000 description 1

- 238000003475 lamination Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 229910052748 manganese Inorganic materials 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000010295 mobile communication Methods 0.000 description 1

- 229910052750 molybdenum Inorganic materials 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 229910052758 niobium Inorganic materials 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 238000000550 scanning electron microscopy energy dispersive X-ray spectroscopy Methods 0.000 description 1

- 238000004544 sputter deposition Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000009966 trimming Methods 0.000 description 1

- 229910052720 vanadium Inorganic materials 0.000 description 1

- 239000013585 weight reducing agent Substances 0.000 description 1

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Landscapes

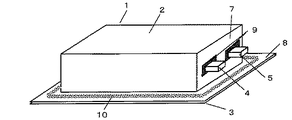

- Sealing Battery Cases Or Jackets (AREA)

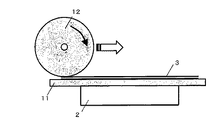

- Pressure Welding/Diffusion-Bonding (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013102663A JP6090923B2 (ja) | 2013-05-15 | 2013-05-15 | リチウムイオン二次電池用ケースの製造方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013102663A JP6090923B2 (ja) | 2013-05-15 | 2013-05-15 | リチウムイオン二次電池用ケースの製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2014225332A JP2014225332A (ja) | 2014-12-04 |

| JP2014225332A5 JP2014225332A5 (cg-RX-API-DMAC7.html) | 2016-06-23 |

| JP6090923B2 true JP6090923B2 (ja) | 2017-03-08 |

Family

ID=52123879

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013102663A Expired - Fee Related JP6090923B2 (ja) | 2013-05-15 | 2013-05-15 | リチウムイオン二次電池用ケースの製造方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP6090923B2 (cg-RX-API-DMAC7.html) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2024070493A1 (ja) | 2022-09-26 | 2024-04-04 | 日鉄ステンレス株式会社 | 電池部品用フェライト系ステンレス鋼材及びその製造方法、並びに電池部品 |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108206247B (zh) * | 2017-10-20 | 2021-05-11 | 西安中兴新软件有限责任公司 | 一种电芯、电子设备和电芯的封装方法 |

| JP7328504B2 (ja) * | 2019-04-17 | 2023-08-17 | 日本製鉄株式会社 | 鋼部品およびその製造方法 |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013041788A (ja) * | 2011-08-19 | 2013-02-28 | Nisshin Steel Co Ltd | リチウムイオン二次電池 |

-

2013

- 2013-05-15 JP JP2013102663A patent/JP6090923B2/ja not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2024070493A1 (ja) | 2022-09-26 | 2024-04-04 | 日鉄ステンレス株式会社 | 電池部品用フェライト系ステンレス鋼材及びその製造方法、並びに電池部品 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2014225332A (ja) | 2014-12-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2013041788A (ja) | リチウムイオン二次電池 | |

| JP6629514B2 (ja) | ラミネート外装材の製造方法 | |

| EP2804247B1 (en) | Secondary battery fabrication method, secondary battery, and welding device | |

| RU2014128829A (ru) | Контактные соединительные выводы для электродов на основе лития | |

| JP2014212012A (ja) | 二次電池の製造方法および二次電池 | |

| JP2011124024A (ja) | 組電池および単電池 | |

| JP6090923B2 (ja) | リチウムイオン二次電池用ケースの製造方法 | |

| CN114614099B (zh) | 用于制造电池单体的方法 | |

| JP5876380B2 (ja) | 積層アルミニウム材の製造方法及びそれを含む密閉型電池の製造方法 | |

| CN107078230B (zh) | 锂离子二次电池用外壳的制造方法 | |

| CN114497838A (zh) | 用于制造电池单池的方法 | |

| JP2014167881A (ja) | 電池及び電池の製造方法 | |

| JP2014059954A (ja) | 角型電池缶及びその製造方法 | |

| JP2015032441A (ja) | タブリード及び非水電解質電池 | |

| WO2007102527A1 (ja) | 電池、及び電池の製造方法 | |

| TW201336141A (zh) | 金屬製之有底或密閉容器及其製造方法 | |

| KR100516768B1 (ko) | 전극탭 병렬결합구조를 갖는 이차전지 및 그 전극탭 결합 방법 | |

| KR20140117151A (ko) | 플럭스 라미네이티드 알루미늄 브레이징 용가재 스트립 | |

| WO2009151007A1 (ja) | 密閉型電池の製造方法 | |

| JP2019106243A (ja) | 電池外装材、電池、およびそれらの製造方法 | |

| JP2014225332A5 (cg-RX-API-DMAC7.html) | ||

| JP2011204590A (ja) | リチウムイオン電池及びヒートシール作製方法 | |

| CN205684893U (zh) | 一种金属搭接件的电阻点焊结构 | |

| JP2016175095A (ja) | 超音波溶接方法 | |

| JP2005123060A (ja) | 密閉型電池の製造法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160408 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20160408 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20160408 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20160408 |

|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7423 Effective date: 20160426 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20160525 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20160610 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20160706 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20160927 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20170124 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20170203 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6090923 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313111 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| LAPS | Cancellation because of no payment of annual fees |