JP5509212B2 - 構造複合材料要素の製造 - Google Patents

構造複合材料要素の製造 Download PDFInfo

- Publication number

- JP5509212B2 JP5509212B2 JP2011533823A JP2011533823A JP5509212B2 JP 5509212 B2 JP5509212 B2 JP 5509212B2 JP 2011533823 A JP2011533823 A JP 2011533823A JP 2011533823 A JP2011533823 A JP 2011533823A JP 5509212 B2 JP5509212 B2 JP 5509212B2

- Authority

- JP

- Japan

- Prior art keywords

- mold

- preform

- resin film

- resin

- temperature

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000002131 composite material Substances 0.000 title claims description 22

- 238000004519 manufacturing process Methods 0.000 title claims description 15

- 239000011347 resin Substances 0.000 claims description 88

- 229920005989 resin Polymers 0.000 claims description 88

- 238000000034 method Methods 0.000 claims description 51

- 239000000835 fiber Substances 0.000 claims description 44

- 238000010438 heat treatment Methods 0.000 claims description 17

- 239000012744 reinforcing agent Substances 0.000 claims description 4

- 239000004593 Epoxy Substances 0.000 claims description 3

- 239000012530 fluid Substances 0.000 claims description 3

- 229920001187 thermosetting polymer Polymers 0.000 claims description 2

- 230000008569 process Effects 0.000 description 32

- 239000000463 material Substances 0.000 description 11

- 239000007788 liquid Substances 0.000 description 10

- 238000000748 compression moulding Methods 0.000 description 7

- 238000009745 resin transfer moulding Methods 0.000 description 7

- 238000000465 moulding Methods 0.000 description 6

- 239000003677 Sheet moulding compound Substances 0.000 description 5

- 239000011230 binding agent Substances 0.000 description 5

- 238000002347 injection Methods 0.000 description 5

- 239000007924 injection Substances 0.000 description 5

- 238000003475 lamination Methods 0.000 description 4

- 238000000926 separation method Methods 0.000 description 4

- 239000002184 metal Substances 0.000 description 3

- 229910052751 metal Inorganic materials 0.000 description 3

- 239000012778 molding material Substances 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- 239000012745 toughening agent Substances 0.000 description 3

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 2

- 229910052799 carbon Inorganic materials 0.000 description 2

- 238000003780 insertion Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 238000002955 isolation Methods 0.000 description 2

- 239000012528 membrane Substances 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 238000010134 structural reaction injection moulding Methods 0.000 description 2

- 229920000049 Carbon (fiber) Polymers 0.000 description 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 239000004917 carbon fiber Substances 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

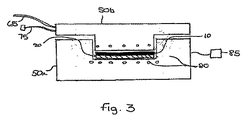

- 238000010586 diagram Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 239000002657 fibrous material Substances 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 239000003365 glass fiber Substances 0.000 description 1

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 230000035699 permeability Effects 0.000 description 1

- 230000002787 reinforcement Effects 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 238000005728 strengthening Methods 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

- 238000001721 transfer moulding Methods 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

- 238000009756 wet lay-up Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/40—Shaping or impregnating by compression not applied

- B29C70/42—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/02—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles

- B29C43/18—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles incorporating preformed parts or layers, e.g. compression moulding around inserts or for coating articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/40—Shaping or impregnating by compression not applied

- B29C70/42—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles

- B29C70/46—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles using matched moulds, e.g. for deforming sheet moulding compounds [SMC] or prepregs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/40—Shaping or impregnating by compression not applied

- B29C70/42—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles

- B29C70/46—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles using matched moulds, e.g. for deforming sheet moulding compounds [SMC] or prepregs

- B29C70/465—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles using matched moulds, e.g. for deforming sheet moulding compounds [SMC] or prepregs and impregnating by melting a solid material, e.g. sheets, powders of fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/40—Shaping or impregnating by compression not applied

- B29C70/42—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles

- B29C70/46—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles using matched moulds, e.g. for deforming sheet moulding compounds [SMC] or prepregs

- B29C70/467—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles using matched moulds, e.g. for deforming sheet moulding compounds [SMC] or prepregs and impregnating the reinforcements during mould closing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/40—Shaping or impregnating by compression not applied

- B29C70/42—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles

- B29C70/46—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles using matched moulds, e.g. for deforming sheet moulding compounds [SMC] or prepregs

- B29C70/48—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles using matched moulds, e.g. for deforming sheet moulding compounds [SMC] or prepregs and impregnating the reinforcements in the closed mould, e.g. resin transfer moulding [RTM], e.g. by vacuum

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/32—Component parts, details or accessories; Auxiliary operations

- B29C43/58—Measuring, controlling or regulating

- B29C2043/5816—Measuring, controlling or regulating temperature

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/02—Moulds or cores; Details thereof or accessories therefor with incorporated heating or cooling means

- B29C33/04—Moulds or cores; Details thereof or accessories therefor with incorporated heating or cooling means using liquids, gas or steam

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C33/00—Moulds or cores; Details thereof or accessories therefor

- B29C33/10—Moulds or cores; Details thereof or accessories therefor with incorporated venting means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/06—Condition, form or state of moulded material or of the material to be shaped containing reinforcements, fillers or inserts

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Composite Materials (AREA)

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

- Moulding By Coating Moulds (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB0820267.3A GB2465159B (en) | 2008-11-05 | 2008-11-05 | Manufacture of a structural composites component |

| GB0820267.3 | 2008-11-05 | ||

| PCT/GB2009/002607 WO2010052457A1 (en) | 2008-11-05 | 2009-11-05 | Manufacture of a structural composites component |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2012506804A JP2012506804A (ja) | 2012-03-22 |

| JP2012506804A5 JP2012506804A5 (enExample) | 2012-05-10 |

| JP5509212B2 true JP5509212B2 (ja) | 2014-06-04 |

Family

ID=40138369

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011533823A Active JP5509212B2 (ja) | 2008-11-05 | 2009-11-05 | 構造複合材料要素の製造 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US9643363B2 (enExample) |

| EP (1) | EP2358517B1 (enExample) |

| JP (1) | JP5509212B2 (enExample) |

| ES (1) | ES2703596T3 (enExample) |

| GB (1) | GB2465159B (enExample) |

| WO (1) | WO2010052457A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20240159214A1 (en) * | 2021-04-09 | 2024-05-16 | Lm Wind Power A/S | A wind turbine blade with a fairing |

Families Citing this family (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2451766T3 (es) * | 2010-11-02 | 2014-03-28 | C-Con Gmbh | Procedimiento y dispositivo para la fabricación de componentes compuestos de fibra |

| DE102011056686B4 (de) * | 2011-12-20 | 2017-11-23 | Markus Brzeski | Verfahren zur Herstellung eines Faserverbundwerkstoffes, ein nach dem Verfahren hergestellter Faserverbundwerkstoff sowie eine Vorrichtung zur Durchführung des Verfahrens |

| US8869361B2 (en) * | 2011-12-21 | 2014-10-28 | GKN Aerospace Services Structures, Corp. | Method and apparatus for applying a compaction pressure to a fabric preform during wrapping |

| ES2463890B1 (es) * | 2012-02-14 | 2015-01-20 | Carbures Sa | Procedimiento de fabricación automática y rápida de estructuras de composite mediante multi-inyección y moldeo por compresión |

| DE102012204136A1 (de) * | 2012-03-16 | 2013-09-19 | Voith Patent Gmbh | Vakuumgestütztes Verpressen |

| DE102012010271B4 (de) * | 2012-05-25 | 2017-10-12 | Premium Aerotec Gmbh | Verfahren zur Herstellung eines Faserverbundbauteils mittels eines Vakuumaufbaues |

| GB2502561B (en) * | 2012-05-30 | 2016-03-23 | Gurit Uk Ltd | Press moulding method |

| DE102013004962A1 (de) * | 2012-09-21 | 2014-03-27 | Audi Ag | Verfahren und Vorformling zur Herstellung eines aus einem faserverstärkten Kunststoffmaterial gebildeten Bauteils |

| DE102013100092B4 (de) * | 2013-01-07 | 2017-01-26 | Thyssenkrupp Steel Europe Ag | Verfahren und Vorrichtung zur Imprägnierungsprüfung |

| JP5761867B2 (ja) * | 2013-01-21 | 2015-08-12 | 株式会社日本製鋼所 | 繊維強化された樹脂基材又は樹脂成形体の製造方法及びこの製造方法に使用する可塑化吐出機 |

| GB2515316B (en) * | 2013-06-19 | 2018-02-07 | Creative Composites Ltd | Methods for composite material processing |

| JP6020826B2 (ja) | 2013-07-12 | 2016-11-02 | パナソニックIpマネジメント株式会社 | 繊維強化複合材の成形方法および繊維強化複合材の成形装置 |

| CN105408080B (zh) * | 2013-07-26 | 2018-09-21 | 麦格纳国际公司 | 模制装置和用于压缩模制纤维增强型预成型件的方法 |

| FR3014008B1 (fr) * | 2013-12-04 | 2016-10-28 | Snecma | Procede d'impregnation d'une preforme fibreuse et dispositif pour la mise en œuvre de ce procede |

| DE102014100882A1 (de) * | 2014-01-27 | 2015-07-30 | Kuka Systems Gmbh | Herstellungstechnik für Bauteile aus faserverstärkten Kunststoffen |

| DE102014109174A1 (de) * | 2014-07-01 | 2016-01-07 | Johnson Controls Interiors Management Gmbh | Verfahren zum Herstellen eines Formkörpers aus einem Fasermaterial sowie eine Vorrichtung zum Durchführen des Verfahrens |

| JP6369720B2 (ja) * | 2014-07-03 | 2018-08-08 | 株式会社ジェイテクト | ラックハウジングの製造方法 |

| DE102014215964A1 (de) * | 2014-08-12 | 2016-02-18 | Bayerische Motoren Werke Aktiengesellschaft | Verfahren zum Herstellen eines mit einem unidirektionalen Fasergelege versehenen SMC-Bauteiles |

| DE102015201559A1 (de) * | 2015-01-29 | 2016-08-04 | Bayerische Motoren Werke Aktiengesellschaft | Nasspressverfahren und Presswerkzeug hierfür |

| US20170157865A1 (en) * | 2015-12-07 | 2017-06-08 | Hattar Tanin LLC | Composite fiber materials |

| US20190224929A1 (en) * | 2016-06-23 | 2019-07-25 | Fpinnovations | Wood pulp fiber- or cellulose filament-reinforced bulk molding compounds, composites, compositions and methods for preparation thereof |

| US20180043642A1 (en) * | 2016-08-11 | 2018-02-15 | GM Global Technology Operations LLC | Mold apparatus and method of using the same |

| KR102127736B1 (ko) * | 2018-10-30 | 2020-07-01 | 재단법인 한국탄소융합기술원 | 항공기 열가소성 보강판넬 제조장치 및 방법 |

| CN114761191A (zh) * | 2019-11-25 | 2022-07-15 | Dic株式会社 | 片状模塑料和成型品的制造方法 |

| CN111086142A (zh) * | 2019-12-26 | 2020-05-01 | 谢祯宇 | 一种模压橡胶复合制品胶料动态填装量工艺方法 |

| CN115056506A (zh) * | 2022-06-16 | 2022-09-16 | 西安交通大学 | 一种树脂膜融渗工艺树脂融渗过程监测方法及系统 |

| SE2350533A1 (en) * | 2023-05-03 | 2024-11-04 | Pulpac AB | Method for dry-forming a cellulose product from cellulose fibres in a product forming unit, a product forming unit, and a cellulose product |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE477350A (enExample) * | 1940-09-07 | |||

| FR2338124A1 (fr) * | 1976-01-16 | 1977-08-12 | Ritter Albert | Procede et dispositif pour le moulage de pieces en matiere plastique expansee |

| JPS62183317A (ja) | 1986-02-07 | 1987-08-11 | Toray Ind Inc | 繊維強化プラスチツクの連続成形方法 |

| CA2009530A1 (en) * | 1989-02-10 | 1990-08-10 | Shohei Masui | Method for producing molded article of fiber-reinforced thermoplastic resin |

| DE4335558A1 (de) | 1993-10-19 | 1995-04-20 | Deutsche Forsch Luft Raumfahrt | Verfahren zum Herstellen von langfaserverstärkten Bauteilen |

| AU2682595A (en) * | 1994-06-17 | 1996-01-15 | Araco Kabushiki Kaisha | Laminated body and method of manufacturing the same |

| JPH09123198A (ja) | 1995-10-30 | 1997-05-13 | Sekisui Chem Co Ltd | 加飾成形品の製造方法 |

| DE10017493B4 (de) * | 2000-04-07 | 2009-02-26 | Daimler Ag | Verfahren zur Herstellung eines Bauteils mit einem innen liegenden Gewebe |

| US6527533B2 (en) | 2000-12-29 | 2003-03-04 | Ford Global Technologies, Inc. | Processing systems for automated manufacture of preforms |

| WO2002072676A2 (en) * | 2001-01-18 | 2002-09-19 | Ernest Nagy De Nagybaczon | Dynamically forced wetting of materials and products produced therefrom |

| EP2067615B1 (en) | 2006-09-28 | 2016-11-16 | Toray Industries, Inc. | Fiber-reinforced plastic and process for production thereof |

| GB2447964B (en) * | 2007-03-29 | 2012-07-18 | Gurit Uk Ltd | Moulding material |

| US7691311B2 (en) * | 2007-04-27 | 2010-04-06 | Vec Industries, L.L.C. | Method for manufacturing a glass fiber reinforced article, and a glass fiber reinforced article |

-

2008

- 2008-11-05 GB GB0820267.3A patent/GB2465159B/en active Active

-

2009

- 2009-11-05 EP EP09752446.6A patent/EP2358517B1/en active Active

- 2009-11-05 US US13/127,960 patent/US9643363B2/en active Active

- 2009-11-05 ES ES09752446T patent/ES2703596T3/es active Active

- 2009-11-05 JP JP2011533823A patent/JP5509212B2/ja active Active

- 2009-11-05 WO PCT/GB2009/002607 patent/WO2010052457A1/en not_active Ceased

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20240159214A1 (en) * | 2021-04-09 | 2024-05-16 | Lm Wind Power A/S | A wind turbine blade with a fairing |

Also Published As

| Publication number | Publication date |

|---|---|

| US9643363B2 (en) | 2017-05-09 |

| ES2703596T3 (es) | 2019-03-11 |

| GB2465159A (en) | 2010-05-12 |

| EP2358517A1 (en) | 2011-08-24 |

| JP2012506804A (ja) | 2012-03-22 |

| EP2358517B1 (en) | 2018-10-03 |

| GB2465159B (en) | 2013-04-17 |

| WO2010052457A1 (en) | 2010-05-14 |

| GB0820267D0 (en) | 2008-12-10 |

| US20120038081A1 (en) | 2012-02-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5509212B2 (ja) | 構造複合材料要素の製造 | |

| KR101151966B1 (ko) | Rtm 성형방법 및 장치 | |

| CN100548644C (zh) | 受控的大气压树脂浸渍法 | |

| RU2445206C2 (ru) | Способ изготовления конструктивного компонента из армированного волокнами композиционного материала с использованием формовочного стержня и формовочный стержень | |

| EP0722826B1 (en) | Resin transfer molding with honeycomb core and core filler | |

| CN1921996B (zh) | Rtm成型方法及装置 | |

| US20130127092A1 (en) | Moulded multilayer plastics component with continuously reinforced fibre plies and process for producing this component | |

| CN103963315B (zh) | 一种复合材料的预浸料/树脂传递模塑共固化工艺方法 | |

| CN101804714A (zh) | 具有表面功能层的复合材料构件及其rtm制备方法 | |

| EP3625039B1 (en) | Multi-stage resin delivery | |

| CN104736312A (zh) | 用于生产较佳为纤维加强的塑料构件的模具、控制装置、方法和设备 | |

| JP2005193587A (ja) | Rtm成形方法 | |

| KR101447136B1 (ko) | 섬유 강화 복합재의 성형방법 | |

| JP4292971B2 (ja) | Frpの製造方法および製造装置 | |

| US20060220273A1 (en) | Process for compression moulding liquid resins with structural reinforcements | |

| JP5362596B2 (ja) | 貼合成形方法、貼合成形用金型および貼合成形装置 | |

| KR102349669B1 (ko) | 섬유 강화 플라스틱의 성형방법 | |

| CN116176003A (zh) | Cfrp立体构件快速成型量产制造工艺 | |

| Bader | Molding processes–An overview | |

| JP2022512189A (ja) | 自動車用トリム部品を成形するための型 | |

| Ma et al. | 4 Laminating Processes | |

| JPH1015978A (ja) | 繊維強化樹脂複合体の製造方法 | |

| JPH1158536A (ja) | 繊維強化樹脂複合体の製造方法 | |

| Smith | The Current Status of Resin Infusion as an Enabling Technology for Toughened Aerospace Structures. | |

| BADER | 3.4 MOLDING PROCESSES |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120125 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20121001 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20121017 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20121001 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20121113 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130213 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20131001 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140127 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140204 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20140207 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20140304 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20140324 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5509212 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |