JP5217080B2 - Resin mold with slide core - Google Patents

Resin mold with slide core Download PDFInfo

- Publication number

- JP5217080B2 JP5217080B2 JP2005224872A JP2005224872A JP5217080B2 JP 5217080 B2 JP5217080 B2 JP 5217080B2 JP 2005224872 A JP2005224872 A JP 2005224872A JP 2005224872 A JP2005224872 A JP 2005224872A JP 5217080 B2 JP5217080 B2 JP 5217080B2

- Authority

- JP

- Japan

- Prior art keywords

- slide core

- resin

- molded product

- mold

- reservoir

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Moulds For Moulding Plastics Or The Like (AREA)

Description

本発明は各種の成形用樹脂材などを使用し、各種成形製品を形成するためのスライドコア付き樹脂成形金型に関するものである。 The present invention relates to a resin molding mold with a slide core for forming various molded products using various molding resin materials.

従来におけるスライドコア付き樹脂成形金型は、キャビティ部が設けられ摺動移動自在なスライドコアを有し、開閉自在な上型と下型で組合せ構成されており、スライドコアの上面や前後あるいは左右の面に、コールドスラッグの溜り部を設け、樹脂成形におけるコールドスラッグが成形製品に支障を与えないような構成としている。 A conventional resin mold with a slide core has a slide core that is provided with a cavity and is slidably movable, and is composed of an upper mold and a lower mold that can be opened and closed. On the surface, a cold slug reservoir is provided so that cold slug in resin molding does not interfere with the molded product.

なお、この出願に関する先行技術文献情報としては、例えば、特許文献1が知られている。

しかしながら、前記従来のスライドコア付き樹脂成形金型においては、スライドコアの上面にコールドスラッグの溜り部を設けた場合、スライドコアを開閉する際にスライドコアの一部がコールドスラッグの溜り部に引っ掛り、ランナー部などが引きちぎられるなどの支障が発生する。 However, in the conventional resin mold with a slide core, when a cold slug reservoir is provided on the upper surface of the slide core, a part of the slide core is pulled to the cold slug reservoir when the slide core is opened and closed. Problems such as hooking and tearing off the runner part occur.

そのため、スライドコアの上面にコールドスラッグの溜り部を設けることができず、樹脂成形機器のノズルおよびスプル内のコールドスラッグが成形製品の付属で成形用樹脂の流路であるゲートに流れ込むことが発生し、そのゲートを塞いで成形用樹脂の流動性を妨げ、成形製品における成形用樹脂の未充填などが発生し、安定した樹脂成形すなわち成形製品ができない。 Therefore, it is not possible to provide a cold slug reservoir on the upper surface of the slide core, and the cold slug in the nozzle and sprue of the resin molding equipment flows into the gate, which is the flow path of the molding resin, attached to the molded product. In addition, the fluidity of the molding resin is hindered by closing the gate, and the molding resin is not filled in the molded product, so that stable resin molding, that is, a molded product cannot be performed.

また、スライドコアの上面にコールドスラッグの溜り部を設けることができないため、コールドスラッグの溜り部にアンダーカット形状を設け、ランナーをスプルブッシュから離型する方法をとることができず、ランナーが樹脂成形金型の上型の移動に対して追従、すなわちランナーが成形製品を損傷して分離するなど、連続生産を行うための効率を下げるという課題を有していた。 Also, since the cold slug reservoir cannot be provided on the upper surface of the slide core, it is not possible to take the method of releasing the runner from the sprue bushing by providing an undercut shape in the cold slug reservoir. There was a problem of lowering the efficiency for continuous production, such as following the movement of the upper mold of the molding die, that is, the runner damaged and separated the molded product.

本発明は前記課題を解決しようとするものであり、インローブロックの一端にて、逃し加工形状からなるスプルブッシュの溜り部における成形用樹脂の流動を阻止し、樹脂成形金型の上型の開閉に伴いインローブロックが上昇し、スライドコアを摺動移動させてスライドコアが開く時、スプルブッシュの溜り部とスライドコアの一部が干渉することなくスライドコアの摺動移動を可能とする構成とするものであり、ランナー部が成形製品から引きちぎられることがなく、連続生産するための効率を良くしたスライドコア付き樹脂成形金型を提供することを目的とするものである。 The present invention is intended to solve the above-mentioned problems, and at one end of the spigot block, the flow of the molding resin in the pool portion of the sprung bush made of the relief shape is prevented, and the upper mold of the resin mold is opened and closed. When the spigot block rises and the slide core is slid and moved to open, the slide core can slide and move without interfering with the sprue bushing reservoir and part of the slide core. It is an object of the present invention to provide a resin mold with a slide core that improves the efficiency for continuous production without the runner portion being torn off from the molded product.

前記目的を達成するために、本発明は以下の構成を有するものである。 In order to achieve the above object, the present invention has the following configuration.

本発明の請求項1に記載の発明は、パーティング面同士を対向させ上下開閉自在な上型および下型と、これら上型および下型の間に配設され、成形製品を形成するためのキャビティ部を有するとともに、いずれか一方の上面に嵌り溝とコールドスラッグの溜り部を設けた対のスライドコアと、前記上型の一面に設けられ、先端が前記嵌り溝に嵌り込み前記スライドコアの摺動移動を可能とするインローブロックと、からなり、前記コールドスラッグの溜り部をアンダーカット形状としたことにより、スライドコアの摺動移動が自在であり、コールドスラッグが成形製品の部分に流入せず、成形製品および成形時に形成される付属物に損傷を与えず、高精度で安定した樹脂成形ができるという作用効果を有する。 According to the first aspect of the present invention, an upper die and a lower die that can be opened and closed with their parting surfaces facing each other, and the upper die and the lower die are disposed between the upper die and the lower die to form a molded product. A pair of slide cores having a cavity portion and having a fitting groove and a cold slug reservoir on either one of the upper surfaces, provided on one surface of the upper mold, and having a tip fitted into the fitting groove, It consists of an inlay block that allows sliding movement, and by making the cold slug reservoir part an undercut shape, the sliding movement of the slide core is free, and cold slug can flow into the molded product part. In addition, the molded product and the accessory formed at the time of molding are not damaged, and there is an effect that a highly accurate and stable resin molding can be performed.

本発明によるスライドコア付樹脂成形金型は、パーティング面同士を対向させ上下開閉自在な上型および下型と、これら上型および下型の間に配設され、成形製品を形成するためのキャビティ部を有するとともに、いずれか一方の上面に嵌り溝とコールドスラッグの溜り部を設けた対のスライドコアと、前記上型の一面に設けられ、先端が前記嵌り溝に嵌り込み前記スライドコアの摺動移動を可能とするインローブロックと、からなり、前記コールドスラッグの溜り部をアンダーカット形状としたことにより、スライドコアにスプールブッシュを設けても、スライドコアが摺動移動した場合にランナーが引きちぎられることなどによる成形製品の損傷がなく、また、コールドスラッグの溜り部が適切な箇所に設置できるため、コールドスラッグが成形製品の部分に流入することがなく、高精度で安定した樹脂成形ができるという効果を有するものである。 A resin molding die with a slide core according to the present invention is disposed between an upper die and a lower die that are openable and closable with the parting surfaces facing each other, and for forming a molded product. A pair of slide cores having a cavity portion and having a fitting groove and a cold slug reservoir on either one of the upper surfaces, provided on one surface of the upper mold, and having a tip fitted into the fitting groove, It is made up of an inlay block that allows sliding movement, and the cold slug reservoir has an undercut shape , so that even if a spool bush is provided on the slide core, the runner can move when the slide core slides. There is no damage to the molded product due to tearing, etc., and the cold slug reservoir can be installed in an appropriate place, so cold slug There is no flow into the portion of the molded product, those having an effect of stable resin molding with high accuracy.

以下、実施の形態を用いて、図面を参照しながら説明する。 Hereinafter, with reference to the embodiment, it will be described with reference to FIG surface.

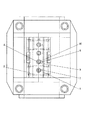

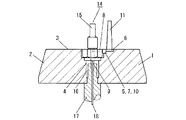

図1は本発明の実施の形態における樹脂成形金型の構造を示す要部断面図、図2は同樹脂成形金型の構造を示す要部平面図、図3は同型閉じ状態の動作工程を説明する要部構成断面図、図4は同型開き状態の動作工程を説明する要部構成断面図、図5は同スライドコア開閉状態の動作工程を説明する要部構成断面図、図6は同成形品突き出し状態の動作工程を説明する要部構成断面図、そして図7は同コールドスラッグの溜り部のアンダーカット形状を示す要部平面および部分断面図である。 FIG. 1 is a cross-sectional view of a main part showing the structure of a resin molding die in an embodiment of the present invention, FIG. 2 is a plan view of the main part showing the structure of the resin molding die, and FIG. FIG. 4 is a cross-sectional view of the main part for explaining the operation process in the same type open state, FIG. 5 is a cross-sectional view of the main part for explaining the operation process in the open / close state of the slide core, and FIG. FIG. 7 is a fragmentary plan view and partial sectional view showing an undercut shape of a reservoir portion of the cold slug.

まず、図1において1は鋼材あるいは超鋼材などからなるスライドコアAであり、成形用樹脂の注入および成形時に発生するコールドスラッグを貯留する溜り部6を片側面に1個あるいは複数個設け、水平に摺動移動自在である。

First, in FIG. 1, 1 is a slide core A made of steel, super steel, or the like. One or a plurality of

2はスライドコアA1とパーティング面3を基準として対向する水平に摺動移動自在で、鋼材あるいは超鋼材などからなるスライドコアBであり、鋼材あるいは超鋼材などからなり上下開閉自在に組み合わされる上型12と下型13との対の成形金型におけるパーティング面3に対して平行に移動自在である。

2 is a slide core B made of a steel material or a super steel material, which is slidable and movable horizontally facing the slide core A1 and the

4は所望形状の成形製品14を得るための空洞部分を形成したキャビティ部であり、スライドコアA1とスライドコアB2の設定配置により所望形状の成形製品14が形成されるものであり、そして、11は成形用樹脂の注入および流動における通路であるスプル、同じく8はランナーである。

6は前記でも説明したが、スライドコアA1の上面でキャビティ部4の近傍に設けられたコールドスラッグを貯留させる溜り部、5は鋼材などからなるインローブロックであり、上型12に取付けられ下先端が溜り部6の縁端部に設けられた嵌り溝10に嵌り込み、キャビティ部4と溜り部6を遮断して分離し、コールドスラッグの溜り部6に対する成形用樹脂の注入あるいは成形用樹脂の流動を阻止するものである。

As described above, 6 is a reservoir portion for storing cold slug provided in the vicinity of the

図2における7は逃し部であり、スライドコアA1の上面で嵌り溝10に連接して設けられており、スライドコアA1の摺動移動、例えばスライドコアB2との開閉時に、溜り部6とスライドコアA1との干渉やコールドスラッグがスライドコアA1の一部分に引っ掛る支障、すなわち成形製品14における成形用樹脂の損傷を防止する。

図1から図3に示すように、成形用樹脂はスプル11、コールドスラッグの溜り部6、ランナー8、そしてゲート9を経由して流動し、キャビティ部4に注入され成形製品14を形成する。

As shown in FIGS. 1 to 3, the molding resin flows through the

図3は所定の樹脂成形直後における樹脂成形金型の状態を示しており、上型12よりインローブロック5の下先端がスライドコアA1の嵌り溝10に挿入され、コールドスラッグの溜り部6における成形用樹脂の不要な流動を阻止している。

FIG. 3 shows a state of the resin molding die immediately after predetermined resin molding. The lower tip of the inlay block 5 is inserted into the

なお、18は下成形型17を移動(下方向)させる際、一端にて成形製品14を維持するための固定および上下移動自在なエジェクタピンである。

図4は上型12が上昇してスライドコアA1およびスライドコアB2から分離した状態を示しており、スプル11における成形樹脂部および成形製品14の製品上部15が、スライドコアA1およびスライドコアB2の上面に露出している。

FIG. 4 shows a state in which the

図5はスライドコアA1とスライドコアB2が、左右水平方向に摺動移動して開いた状態を示しており、この時コールドスラッグの溜り部6はスライドコアA1に干渉あるいは引っ掛ることなく、スライドコアA1とスライドコアB2を開閉することができ、スプル11における成形樹脂部、成形製品14の製品上部15、溜り部6および逃し部7における成形樹脂部、そして成形製品14における製品下部16が露出している。

FIG. 5 shows a state in which the slide core A1 and the slide core B2 are opened by sliding in the horizontal direction. At this time, the

図6はスライドコアが開いた後、下成形型17を固定し、エジェクタピン18を上昇させて成形製品14を樹脂成形金型より離型させている状態を示しており、製品下部16を含む成形製品14および付随するスプル11の成形樹脂部、ランナー8やゲート9における成形樹脂部などが露出しており、一連の樹脂成形加工が終了した状態でエジェクタピン18を降下させるとともに、付随部分の付いたまま成形製品14を次の工程に移動させる。

FIG. 6 shows a state in which after the slide core is opened, the

なお、前記とは逆にエジェクタピン18を固定し、下成形型17を降下させて成形製品14を樹脂成形金型より離型させてもよい。

In contrast to the above, the

図7はコールドスラッグの溜り部6の要部形状を拡大して示したものであり、コールドスラッグの溜り部6の形状は、スプル11が上型12の上昇時に追随して取られることにより、成形製品14に損傷などが発生しないように、下先端部をアンダーカット形状にすることが必要である。

FIG. 7 is an enlarged view of the main part shape of the

すなわち、図7に示すように、ア、イ、ウの3面にアンダーカットになる所定角度、例えば30〜60度の角度を設けた構造とすることにより、スプル11が上型12の移動による追従の発生、すなわち成形製品14本体との強制的なスプル11の分離による成形製品14の損傷などを防止することができる。

That is, as shown in FIG. 7, the

また本形状のアンダーカットは、スライドコアA1およびスライドコアB2の開閉方向、すなわち摺動移動における支障となる部分(面)にはアンダーカットを設けておらず、スライドコアの開閉は無理なく円滑に作動させることができる。 The undercut of this shape is not provided with an undercut in the opening / closing direction of the slide core A1 and the slide core B2, that is, the part (surface) that obstructs the sliding movement, and the opening and closing of the slide core is smooth without difficulty. Can be operated.

本発明にかかるスライドコア付き樹脂成形金型は、スライドコアにスプルブッシュを設けても、スライドコアが摺動移動した場合にランナーが引きちぎられず、またコールドスラッグが成形製品部分に流入することがなく、高精度で安定した成形ができるという効果を有し、各種の成形部材や製品などを樹脂成形する樹脂成形金型などの用途として有用である。 The resin molding die with a slide core according to the present invention is such that even if a sprue bush is provided on the slide core, the runner is not torn off when the slide core slides, and the cold slug does not flow into the molded product part. It has the effect of being able to perform highly accurate and stable molding, and is useful as a resin molding die for resin molding various molded members and products.

1 スライドコアA

2 スライドコアB

3 パーティング面

4 キャビティ部

5 インローブロック

6 溜り部

7 逃し部

8 ランナー

9 ゲート

10 嵌り溝

11 スプル

12 上型

13 下型

14 成形製品

15 製品上部

16 製品下部

17 下成形型

18 エジェクタピン

1 Slide core A

2 Slide core B

DESCRIPTION OF

Claims (1)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005224872A JP5217080B2 (en) | 2005-08-03 | 2005-08-03 | Resin mold with slide core |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005224872A JP5217080B2 (en) | 2005-08-03 | 2005-08-03 | Resin mold with slide core |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2007038512A JP2007038512A (en) | 2007-02-15 |

| JP2007038512A5 JP2007038512A5 (en) | 2008-08-14 |

| JP5217080B2 true JP5217080B2 (en) | 2013-06-19 |

Family

ID=37796934

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005224872A Expired - Fee Related JP5217080B2 (en) | 2005-08-03 | 2005-08-03 | Resin mold with slide core |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP5217080B2 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100849953B1 (en) | 2007-06-29 | 2008-08-01 | 은성기연 주식회사 | Plastic mold slide core with inrow for plastic mold |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS59107223U (en) * | 1983-01-10 | 1984-07-19 | トーワ株式会社 | Mold equipment for resin molding of circular resin molded products |

| JPH02169223A (en) * | 1988-12-22 | 1990-06-29 | Olympus Optical Co Ltd | Injection molding die |

| JPH0295614U (en) * | 1989-01-11 | 1990-07-30 | ||

| JPH0497810A (en) * | 1990-08-17 | 1992-03-30 | Sanritsu Kagaku Kk | Plastic molded product |

| JPH11227008A (en) * | 1998-02-13 | 1999-08-24 | Murata Mfg Co Ltd | Injection compression molding apparatus |

-

2005

- 2005-08-03 JP JP2005224872A patent/JP5217080B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2007038512A (en) | 2007-02-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4830084B2 (en) | Injection mold | |

| CN205522307U (en) | Formula runner structure of hiding of injection moulding mould | |

| JP5217080B2 (en) | Resin mold with slide core | |

| CN109551712A (en) | Four lower dies of upper mold mold-opening structure Composite bottle cap injection mold twice | |

| TWI696507B (en) | Die casting device | |

| KR101037482B1 (en) | Automatic side gate cutting device for injection mold | |

| JP4876684B2 (en) | Injection mold | |

| KR200421065Y1 (en) | Boss undercut processing structure | |

| JP3618700B2 (en) | Injection mold | |

| KR100846851B1 (en) | A ejector pin device for mold assembly | |

| CN208392548U (en) | A kind of blind edge formula ox horn is into cast gate | |

| KR101456999B1 (en) | Controlling method of injection molding which having groove in surface without weldline | |

| JP4095093B2 (en) | Injection mold | |

| JP2007112095A (en) | Mold apparatus for injection molding and injection molding method | |

| KR20080104689A (en) | Mold apparatus | |

| CN205201982U (en) | Injection mould of two die joints | |

| CN109049529A (en) | A kind of rocking bar ejecting mechanism injection mold | |

| JP2008279498A (en) | Mold and injection molding method | |

| CN210026108U (en) | Injection structure and forming machine | |

| CN212795745U (en) | Slider is hidden and is advanced gluey mould | |

| CN217346538U (en) | Precise plastic part stripping mold | |

| CN216732824U (en) | Automatic gate cutting mold | |

| CN219505340U (en) | Mould with balanced runner structure | |

| KR940007314Y1 (en) | Automatic cutting device for gate molding articles of mold | |

| JP2006044063A (en) | Mold device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080630 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20080630 |

|

| RD01 | Notification of change of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7421 Effective date: 20091126 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110119 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110308 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110427 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120207 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120409 |

|

| RD01 | Notification of change of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7421 Effective date: 20121213 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130205 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130218 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20160315 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20160315 Year of fee payment: 3 |

|

| LAPS | Cancellation because of no payment of annual fees |