JP5075133B2 - 可撓性材を加工するための方法および装置 - Google Patents

可撓性材を加工するための方法および装置 Download PDFInfo

- Publication number

- JP5075133B2 JP5075133B2 JP2008557663A JP2008557663A JP5075133B2 JP 5075133 B2 JP5075133 B2 JP 5075133B2 JP 2008557663 A JP2008557663 A JP 2008557663A JP 2008557663 A JP2008557663 A JP 2008557663A JP 5075133 B2 JP5075133 B2 JP 5075133B2

- Authority

- JP

- Japan

- Prior art keywords

- belt

- processing

- flexible material

- shaped

- processing unit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000012545 processing Methods 0.000 title claims description 82

- 239000000463 material Substances 0.000 title claims description 76

- 238000000034 method Methods 0.000 title claims description 72

- 230000008569 process Effects 0.000 claims description 30

- 238000005520 cutting process Methods 0.000 claims description 20

- 238000003780 insertion Methods 0.000 claims description 15

- 230000037431 insertion Effects 0.000 claims description 15

- 238000011084 recovery Methods 0.000 claims description 15

- 238000003754 machining Methods 0.000 claims description 11

- 238000012546 transfer Methods 0.000 claims description 7

- 239000004744 fabric Substances 0.000 claims description 6

- 230000007246 mechanism Effects 0.000 claims description 5

- 238000009499 grossing Methods 0.000 claims description 4

- 230000003139 buffering effect Effects 0.000 claims description 3

- 238000012805 post-processing Methods 0.000 claims description 3

- 238000003672 processing method Methods 0.000 claims 1

- 239000000872 buffer Substances 0.000 description 23

- 238000004519 manufacturing process Methods 0.000 description 23

- 238000012360 testing method Methods 0.000 description 9

- 238000010586 diagram Methods 0.000 description 7

- 238000012432 intermediate storage Methods 0.000 description 6

- 238000003860 storage Methods 0.000 description 6

- 239000011347 resin Substances 0.000 description 5

- 229920005989 resin Polymers 0.000 description 5

- 239000002184 metal Substances 0.000 description 4

- 238000007689 inspection Methods 0.000 description 3

- 238000005259 measurement Methods 0.000 description 3

- 238000012986 modification Methods 0.000 description 3

- 230000004048 modification Effects 0.000 description 3

- 238000003825 pressing Methods 0.000 description 3

- 230000003584 silencer Effects 0.000 description 3

- 238000011144 upstream manufacturing Methods 0.000 description 3

- 238000009958 sewing Methods 0.000 description 2

- 238000005452 bending Methods 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000002708 enhancing effect Effects 0.000 description 1

- 238000013100 final test Methods 0.000 description 1

- 239000010985 leather Substances 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 238000012858 packaging process Methods 0.000 description 1

- 239000004800 polyvinyl chloride Substances 0.000 description 1

- 239000012783 reinforcing fiber Substances 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 239000012209 synthetic fiber Substances 0.000 description 1

- 229920002994 synthetic fiber Polymers 0.000 description 1

- 230000002123 temporal effect Effects 0.000 description 1

- 238000011179 visual inspection Methods 0.000 description 1

- 238000005303 weighing Methods 0.000 description 1

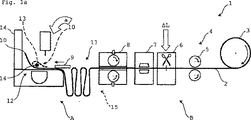

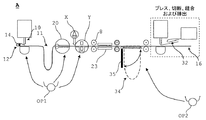

Images

Classifications

-

- D—TEXTILES; PAPER

- D05—SEWING; EMBROIDERING; TUFTING

- D05B—SEWING

- D05B25/00—Sewing units consisting of combinations of several sewing machines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R22/00—Safety belts or body harnesses in vehicles

- B60R22/12—Construction of belts or harnesses

-

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2505/00—Industrial

- D10B2505/12—Vehicles

- D10B2505/122—Safety belts

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Treatment Of Fiber Materials (AREA)

- Sewing Machines And Sewing (AREA)

- Slide Fasteners (AREA)

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE200610010533 DE102006010533B3 (de) | 2006-03-07 | 2006-03-07 | Verfahren zum Verarbeiten von biegeschlaffem Material |

| DE102006010533.8 | 2006-03-07 | ||

| DE102006050611.1 | 2006-10-26 | ||

| DE102006050611 | 2006-10-26 | ||

| PCT/EP2007/001978 WO2007101683A1 (de) | 2006-03-07 | 2007-03-07 | Verfahren und vorrichtung zum verarbeiten von biegeschlaffem material |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2009529103A JP2009529103A (ja) | 2009-08-13 |

| JP2009529103A5 JP2009529103A5 (enExample) | 2010-04-22 |

| JP5075133B2 true JP5075133B2 (ja) | 2012-11-14 |

Family

ID=37944728

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008557663A Expired - Fee Related JP5075133B2 (ja) | 2006-03-07 | 2007-03-07 | 可撓性材を加工するための方法および装置 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US8132522B2 (enExample) |

| EP (1) | EP2004456B1 (enExample) |

| JP (1) | JP5075133B2 (enExample) |

| BR (1) | BRPI0707073A2 (enExample) |

| MX (1) | MX2008011410A (enExample) |

| PL (1) | PL2004456T3 (enExample) |

| WO (1) | WO2007101683A1 (enExample) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107460715A (zh) * | 2017-08-29 | 2017-12-12 | 谢泽波 | 具有可伸缩且固定的多功能内衣裁剪台装置 |

| CN108002089A (zh) * | 2017-11-14 | 2018-05-08 | 嘉善圣士得毛皮服饰有限公司 | 一种用于压布机的输送组件 |

| CN108203875B (zh) * | 2018-02-01 | 2021-09-17 | 大连聿力玩具有限公司 | 一种自动化纺织布料裁剪装置 |

| CN108754886A (zh) * | 2018-07-19 | 2018-11-06 | 苏州锴诚缝制设备有限公司 | 一种连续自动化缝制装置 |

| CN111742102B (zh) * | 2018-10-10 | 2023-06-16 | 艾斯登强生国际股份有限公司 | 销轴插入工具 |

| CN108998954A (zh) * | 2018-10-29 | 2018-12-14 | 嘉兴市赛诺飞服饰有限公司 | 一种服装生产用布匹快速等距的裁剪装置 |

| CN112921631A (zh) * | 2021-01-24 | 2021-06-08 | 李海明 | 一种无纺布加工用废料回收切割设备 |

| CN114016218B (zh) * | 2021-11-05 | 2024-01-19 | 南京中拓科技有限公司 | 汽车安全带安装装备 |

Family Cites Families (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE7221660U (de) | 1975-05-28 | Arbter C | Einrichtung zum Führen und Verarbeiten von Stoffbahnen | |

| US2770204A (en) * | 1955-07-05 | 1956-11-13 | Brownstein Louis | Method and apparatus for forming a closed loop of tape threaded through a buckle |

| US2848147A (en) * | 1956-04-11 | 1958-08-19 | Scovill Manufacturing Co | Buckle threading apparatus |

| US3785907A (en) * | 1971-04-05 | 1974-01-15 | American Safety Equip | Method and apparatus for automatic assembly of a belt and anchor plate |

| DE2157042A1 (de) | 1971-11-17 | 1973-05-24 | Kochs Adler Ag | Verfahren zur herstellung von aufgesetzten taschen an bekleidungsstuecken |

| JPS4873423A (enExample) * | 1971-12-31 | 1973-10-03 | ||

| JPS5184992A (ja) * | 1975-01-21 | 1976-07-24 | Gunze Kk | Teepujokijinoteisunsetsudan orimagehonarabinisonosochi |

| GB1547575A (en) * | 1975-05-14 | 1979-06-20 | Canadian Lady Canadelle | Apoparatus for making shoulder straps |

| US4137856A (en) * | 1977-10-11 | 1979-02-06 | Novatronics, Inc. | Apparatus for forming a permanent end loop in a fabric web |

| US4157687A (en) * | 1977-10-11 | 1979-06-12 | Gateway Industries, Inc. | Method and apparatus for automatically sewing belts |

| US4287841A (en) * | 1979-08-06 | 1981-09-08 | Herman Rovin | Apparatus for cutting and hemming bed sheets and the like |

| US4287842A (en) | 1979-09-17 | 1981-09-08 | Breck Jr Louis W | Automatic belt loop tacker |

| US4527491A (en) * | 1980-11-14 | 1985-07-09 | Joseph Galkin Corporation | Belt loop setting system |

| DE3635727A1 (de) | 1986-10-21 | 1988-04-28 | Baeckmann Reinhard | Verfahren und einrichtung zum automatischen naehen oder konfektionieren und zur integrierten montage von sicherheitsgurten, hebegurten und aehnlichen bandfoermigen werkstuecken |

| DE3832669A1 (de) * | 1988-06-07 | 1989-12-14 | Duerkoppwerke | Verfahren zum falten eines stoffstreifens |

| DE3831199A1 (de) * | 1988-09-14 | 1990-03-22 | Daimler Benz Ag | Verankerung von endpunkten von sicherheitsgurten |

| EP0483728A1 (en) * | 1990-10-29 | 1992-05-06 | Dayco PTI S.p.A. | Process and apparatus to make textile sleeves |

| JPH06142368A (ja) * | 1992-10-30 | 1994-05-24 | Brother Ind Ltd | テープ片縫着用ミシン |

| US5570648A (en) * | 1994-12-13 | 1996-11-05 | Design Technology Corporation | Waist band-forming apparatus and method |

| WO2006076541A2 (en) * | 2005-01-13 | 2006-07-20 | Takata Seat Belts, Inc. | Buckle support assembly and manufacturing method and system |

-

2007

- 2007-03-07 MX MX2008011410A patent/MX2008011410A/es active IP Right Grant

- 2007-03-07 WO PCT/EP2007/001978 patent/WO2007101683A1/de not_active Ceased

- 2007-03-07 JP JP2008557663A patent/JP5075133B2/ja not_active Expired - Fee Related

- 2007-03-07 US US12/282,167 patent/US8132522B2/en not_active Expired - Fee Related

- 2007-03-07 BR BRPI0707073-0A patent/BRPI0707073A2/pt not_active IP Right Cessation

- 2007-03-07 PL PL07711841.2T patent/PL2004456T3/pl unknown

- 2007-03-07 EP EP07711841.2A patent/EP2004456B1/de not_active Not-in-force

Also Published As

| Publication number | Publication date |

|---|---|

| MX2008011410A (es) | 2008-11-28 |

| WO2007101683A1 (de) | 2007-09-13 |

| US8132522B2 (en) | 2012-03-13 |

| JP2009529103A (ja) | 2009-08-13 |

| BRPI0707073A2 (pt) | 2011-04-19 |

| EP2004456B1 (de) | 2016-05-11 |

| EP2004456A1 (de) | 2008-12-24 |

| PL2004456T3 (pl) | 2016-12-30 |

| US20090050663A1 (en) | 2009-02-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5075133B2 (ja) | 可撓性材を加工するための方法および装置 | |

| US20070044896A1 (en) | Auto-splice apparatus and method for a fiber placement machine | |

| US7828032B2 (en) | Apparatus and method for manufacturing sheet | |

| CN110791892B (zh) | 用于形成圈环的方法和设备 | |

| CN101484375A (zh) | 用于实施换卷的方法以及用于实施该方法的接合器 | |

| CA2660787A1 (en) | Tape strapping machine | |

| KR20100057919A (ko) | 권취 장치와, 이 권취 장치에 코일 다발 또는 코일을 고정하기 위한 방법 | |

| JP2009529103A5 (enExample) | ||

| CN114365239B (zh) | 用于自动地缠绕缆线股的组装头以及方法 | |

| CA2694174C (en) | Self-energizing gripper for strapping machine | |

| CN106413459B (zh) | 补强膜接着装置以及补强膜接着方法 | |

| CN104736011B (zh) | 增强膜粘着装置及具有可分离式嵌插件的拉链 | |

| US8057627B2 (en) | Tape application method and tape application device | |

| GB1597347A (en) | Method of tensioning and joining a formed strap loop about a package | |

| US5570648A (en) | Waist band-forming apparatus and method | |

| US20150194077A1 (en) | Method and apparatus for providing a tire with an informative label, and tire provided with such a label | |

| DE102008047967A1 (de) | Vorrichtung und Verfahren zum Befestigen eines Zipper-Verschlusses | |

| CN105491907A (zh) | 连续拉链的制造方法 | |

| US12325943B2 (en) | Embroidery frame, embroidery machine, and method for embroiding endless ribbons | |

| US6599382B2 (en) | Method and apparatus for manufacturing a tape strip folded about a workpiece | |

| US20250206487A1 (en) | System and method for labelling rod bundles or the like | |

| EP3960642B1 (en) | Automatic-strap-feeding system for feeding strap into a strapping machine | |

| CN104411200B (zh) | 补强膜粘结装置及其粘结方法 | |

| JP5317767B2 (ja) | 自動紐掛け機の引締め装置 | |

| ITBG930045A1 (it) | Attrezzatura di allineamento, espulsione e traino per la cucitura di fibbie e passanti su cinture |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100304 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100304 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20111125 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120329 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120629 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120802 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120824 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150831 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |