JP4881497B2 - 化学蒸着法により窒化チタンを基板に蒸着させる方法及び装置 - Google Patents

化学蒸着法により窒化チタンを基板に蒸着させる方法及び装置 Download PDFInfo

- Publication number

- JP4881497B2 JP4881497B2 JP05165098A JP5165098A JP4881497B2 JP 4881497 B2 JP4881497 B2 JP 4881497B2 JP 05165098 A JP05165098 A JP 05165098A JP 5165098 A JP5165098 A JP 5165098A JP 4881497 B2 JP4881497 B2 JP 4881497B2

- Authority

- JP

- Japan

- Prior art keywords

- substrate

- edge

- vapor deposition

- titanium nitride

- gas

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000000758 substrate Substances 0.000 title claims description 202

- NRTOMJZYCJJWKI-UHFFFAOYSA-N Titanium nitride Chemical compound [Ti]#N NRTOMJZYCJJWKI-UHFFFAOYSA-N 0.000 title claims description 83

- 238000000151 deposition Methods 0.000 title claims description 72

- 238000000034 method Methods 0.000 title claims description 49

- 238000005229 chemical vapour deposition Methods 0.000 title claims description 11

- 239000007789 gas Substances 0.000 claims description 82

- 230000008021 deposition Effects 0.000 claims description 61

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 claims description 38

- 238000007740 vapor deposition Methods 0.000 claims description 38

- 239000010936 titanium Substances 0.000 claims description 24

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 claims description 22

- 229910052719 titanium Inorganic materials 0.000 claims description 22

- 230000002401 inhibitory effect Effects 0.000 claims description 21

- 229910052757 nitrogen Inorganic materials 0.000 claims description 19

- 230000001629 suppression Effects 0.000 claims description 12

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 claims description 8

- 230000002093 peripheral effect Effects 0.000 claims description 5

- 229910021529 ammonia Inorganic materials 0.000 claims description 4

- 229910052756 noble gas Inorganic materials 0.000 claims description 2

- 150000002835 noble gases Chemical class 0.000 claims description 2

- 230000004888 barrier function Effects 0.000 description 19

- 239000004065 semiconductor Substances 0.000 description 18

- 229910052751 metal Inorganic materials 0.000 description 13

- 239000002184 metal Substances 0.000 description 13

- 238000002488 metal-organic chemical vapour deposition Methods 0.000 description 8

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 5

- 239000011248 coating agent Substances 0.000 description 3

- 238000000576 coating method Methods 0.000 description 3

- 230000002829 reductive effect Effects 0.000 description 3

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 2

- 238000005336 cracking Methods 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 239000001301 oxygen Substances 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- 239000000047 product Substances 0.000 description 2

- MNWRORMXBIWXCI-UHFFFAOYSA-N tetrakis(dimethylamido)titanium Chemical compound CN(C)[Ti](N(C)C)(N(C)C)N(C)C MNWRORMXBIWXCI-UHFFFAOYSA-N 0.000 description 2

- 229910000838 Al alloy Inorganic materials 0.000 description 1

- 229910000881 Cu alloy Inorganic materials 0.000 description 1

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- 229910052786 argon Inorganic materials 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 239000006227 byproduct Substances 0.000 description 1

- 239000012159 carrier gas Substances 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 230000032798 delamination Effects 0.000 description 1

- 238000007865 diluting Methods 0.000 description 1

- 239000002019 doping agent Substances 0.000 description 1

- 239000001307 helium Substances 0.000 description 1

- 229910052734 helium Inorganic materials 0.000 description 1

- SWQJXJOGLNCZEY-UHFFFAOYSA-N helium atom Chemical compound [He] SWQJXJOGLNCZEY-UHFFFAOYSA-N 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 229910052743 krypton Inorganic materials 0.000 description 1

- DNNSSWSSYDEUBZ-UHFFFAOYSA-N krypton atom Chemical compound [Kr] DNNSSWSSYDEUBZ-UHFFFAOYSA-N 0.000 description 1

- 230000000670 limiting effect Effects 0.000 description 1

- 230000000873 masking effect Effects 0.000 description 1

- 229910052754 neon Inorganic materials 0.000 description 1

- GKAOGPIIYCISHV-UHFFFAOYSA-N neon atom Chemical compound [Ne] GKAOGPIIYCISHV-UHFFFAOYSA-N 0.000 description 1

- 239000011368 organic material Substances 0.000 description 1

- NFHFRUOZVGFOOS-UHFFFAOYSA-N palladium;triphenylphosphane Chemical compound [Pd].C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1.C1=CC=CC=C1P(C=1C=CC=CC=1)C1=CC=CC=C1 NFHFRUOZVGFOOS-UHFFFAOYSA-N 0.000 description 1

- 239000000376 reactant Substances 0.000 description 1

- 239000012495 reaction gas Substances 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 1

- 229910052721 tungsten Inorganic materials 0.000 description 1

- 239000010937 tungsten Substances 0.000 description 1

- 229910052724 xenon Inorganic materials 0.000 description 1

- FHNFHKCVQCLJFQ-UHFFFAOYSA-N xenon atom Chemical compound [Xe] FHNFHKCVQCLJFQ-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

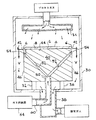

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

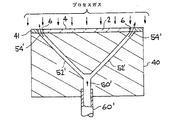

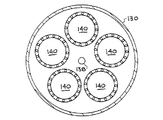

- C23C16/455—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for introducing gases into reaction chamber or for modifying gas flows in reaction chamber

- C23C16/45519—Inert gas curtains

- C23C16/45521—Inert gas curtains the gas, other than thermal contact gas, being introduced the rear of the substrate to flow around its periphery

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/30—Deposition of compounds, mixtures or solid solutions, e.g. borides, carbides, nitrides

- C23C16/34—Nitrides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/455—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for introducing gases into reaction chamber or for modifying gas flows in reaction chamber

Landscapes

- Chemical & Material Sciences (AREA)

- General Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Inorganic Chemistry (AREA)

- Chemical Vapour Deposition (AREA)

- Electrodes Of Semiconductors (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US08/811,818 US5789028A (en) | 1997-03-04 | 1997-03-04 | Method for eliminating peeling at end of semiconductor substrate in metal organic chemical vapor deposition of titanium nitride |

| US811818 | 1997-03-04 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009223007A Division JP2010077534A (ja) | 1997-03-04 | 2009-09-28 | 化学蒸着法により窒化チタンを基板に蒸着させる方法及び装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JPH10303148A JPH10303148A (ja) | 1998-11-13 |

| JPH10303148A5 JPH10303148A5 (enExample) | 2005-09-02 |

| JP4881497B2 true JP4881497B2 (ja) | 2012-02-22 |

Family

ID=25207680

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP05165098A Expired - Fee Related JP4881497B2 (ja) | 1997-03-04 | 1998-03-04 | 化学蒸着法により窒化チタンを基板に蒸着させる方法及び装置 |

| JP2009223007A Pending JP2010077534A (ja) | 1997-03-04 | 2009-09-28 | 化学蒸着法により窒化チタンを基板に蒸着させる方法及び装置 |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009223007A Pending JP2010077534A (ja) | 1997-03-04 | 2009-09-28 | 化学蒸着法により窒化チタンを基板に蒸着させる方法及び装置 |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US5789028A (enExample) |

| JP (2) | JP4881497B2 (enExample) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6087259A (en) * | 1996-06-24 | 2000-07-11 | Hyundai Electronics Industries Co., Ltd. | Method for forming bit lines of semiconductor devices |

| US6071562A (en) * | 1998-05-07 | 2000-06-06 | Lsi Logic Corporation | Process for depositing titanium nitride films |

| SG87084A1 (en) * | 1999-02-09 | 2002-03-19 | Applied Materials Inc | Method for performing metallo-organic chemical vapor deposition of titanium nitride at reduced temperature |

| US6468604B1 (en) | 1999-03-17 | 2002-10-22 | Anelva Corporation | Method for manufacturing a titanium nitride thin film |

| WO2003064718A2 (en) * | 2002-01-29 | 2003-08-07 | Sulzer Metco (Us) Inc. | Method for selectively coating a portion of a substrate with a gas-carried substance |

| KR100534209B1 (ko) * | 2003-07-29 | 2005-12-08 | 삼성전자주식회사 | 반도체소자 제조용 화학기상증착 공정설비 |

| JP4520717B2 (ja) * | 2003-09-24 | 2010-08-11 | キヤノンアネルバ株式会社 | 薄膜形成方法 |

| US20050103265A1 (en) * | 2003-11-19 | 2005-05-19 | Applied Materials, Inc., A Delaware Corporation | Gas distribution showerhead featuring exhaust apertures |

| US10468264B2 (en) | 2016-07-04 | 2019-11-05 | Samsung Electronics Co., Ltd. | Method of fabricating semiconductor device |

| US10851457B2 (en) | 2017-08-31 | 2020-12-01 | Lam Research Corporation | PECVD deposition system for deposition on selective side of the substrate |

| CN114402416A (zh) * | 2019-07-17 | 2022-04-26 | 朗姆研究公司 | 用于衬底处理的氧化分布调节 |

| KR102505474B1 (ko) | 2019-08-16 | 2023-03-03 | 램 리써치 코포레이션 | 웨이퍼 내에서 차동 보우를 보상하기 위한 공간적으로 튜닝 가능한 증착 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5578532A (en) * | 1990-07-16 | 1996-11-26 | Novellus Systems, Inc. | Wafer surface protection in a gas deposition process |

| US5230741A (en) * | 1990-07-16 | 1993-07-27 | Novellus Systems, Inc. | Gas-based backside protection during substrate processing |

| US5238499A (en) * | 1990-07-16 | 1993-08-24 | Novellus Systems, Inc. | Gas-based substrate protection during processing |

| EP0732731A3 (en) * | 1995-03-13 | 1997-10-08 | Applied Materials Inc | Treatment of a titanium nitride layer to improve resistance to higher temperatures |

-

1997

- 1997-03-04 US US08/811,818 patent/US5789028A/en not_active Expired - Lifetime

-

1998

- 1998-03-04 JP JP05165098A patent/JP4881497B2/ja not_active Expired - Fee Related

-

2009

- 2009-09-28 JP JP2009223007A patent/JP2010077534A/ja active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| JPH10303148A (ja) | 1998-11-13 |

| JP2010077534A (ja) | 2010-04-08 |

| US5789028A (en) | 1998-08-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2010077534A (ja) | 化学蒸着法により窒化チタンを基板に蒸着させる方法及び装置 | |

| US6846364B2 (en) | Heater block having catalyst spray means | |

| US6214714B1 (en) | Method of titanium/titanium nitride integration | |

| US6586343B1 (en) | Method and apparatus for directing constituents through a processing chamber | |

| US6700202B2 (en) | Semiconductor device having reduced oxidation interface | |

| US7780789B2 (en) | Vortex chamber lids for atomic layer deposition | |

| KR20190104880A (ko) | 기판 처리용 반도체 처리 장치 및 방법 | |

| JP2760717B2 (ja) | 半導体デバイスの製造方法 | |

| KR100714269B1 (ko) | 반도체 소자 제조에 사용되는 금속층 형성방법 | |

| US20010007244A1 (en) | Film forming apparatus and film forming method | |

| US20050211167A1 (en) | Processing device and processing method | |

| US20080102208A1 (en) | Vortex chamber lids for atomic layer deposition | |

| US20080102203A1 (en) | Vortex chamber lids for atomic layer deposition | |

| JP2021522407A (ja) | エッジエクスクルージョン制御 | |

| KR20010034921A (ko) | 정화 가스 채널과 펌핑 시스템을 갖는 기판 지지 부재 | |

| KR950012635A (ko) | 디클로로실란 가스를 사용하여 반도체 웨이퍼상에 규화 텅스텐층을 형성하기 위한 방법 및 장치 | |

| US6365495B2 (en) | Method for performing metallo-organic chemical vapor deposition of titanium nitride at reduced temperature | |

| US6177149B1 (en) | Method of forming titanium film by CVD | |

| JPH1143771A (ja) | Cvd装置のクリーニング方法 | |

| KR100427905B1 (ko) | 금속의 화학 증착에서 모서리 효과를 제거하기 위한 방법 | |

| US5695831A (en) | CVD method for forming a metallic film on a wafer | |

| JPH0936053A (ja) | 半導体の製造方法 | |

| JP3131855B2 (ja) | 成膜処理方法及びその装置 | |

| US6451388B1 (en) | Method of forming titanium film by chemical vapor deposition | |

| JP2773674B2 (ja) | 半導体装置の製造装置及び半導体装置の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050303 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050303 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20080104 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20081105 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20090205 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20090210 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090507 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20090527 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090928 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20091113 |

|

| A911 | Transfer of reconsideration by examiner before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20091214 |

|

| A912 | Removal of reconsideration by examiner before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20100129 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20110420 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20110425 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110915 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20111205 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20141209 Year of fee payment: 3 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: R3D02 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313113 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |