JP4874329B2 - カバープレートとこのカバープレートに被着された保護層とを備えたタービン翼 - Google Patents

カバープレートとこのカバープレートに被着された保護層とを備えたタービン翼 Download PDFInfo

- Publication number

- JP4874329B2 JP4874329B2 JP2008507029A JP2008507029A JP4874329B2 JP 4874329 B2 JP4874329 B2 JP 4874329B2 JP 2008507029 A JP2008507029 A JP 2008507029A JP 2008507029 A JP2008507029 A JP 2008507029A JP 4874329 B2 JP4874329 B2 JP 4874329B2

- Authority

- JP

- Japan

- Prior art keywords

- turbine

- blade

- cover plate

- protective layer

- shroud

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000011241 protective layer Substances 0.000 title claims description 42

- 239000000463 material Substances 0.000 claims description 47

- 238000007789 sealing Methods 0.000 claims description 44

- 239000010410 layer Substances 0.000 claims description 34

- 238000000034 method Methods 0.000 claims description 15

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 claims description 13

- 229910045601 alloy Inorganic materials 0.000 claims description 13

- 239000000956 alloy Substances 0.000 claims description 13

- 238000003466 welding Methods 0.000 claims description 12

- 229910052751 metal Inorganic materials 0.000 claims description 11

- 239000002184 metal Substances 0.000 claims description 11

- 229910052759 nickel Inorganic materials 0.000 claims description 6

- 238000004519 manufacturing process Methods 0.000 claims description 5

- 238000007750 plasma spraying Methods 0.000 claims description 5

- 239000011651 chromium Substances 0.000 claims description 4

- UFGZSIPAQKLCGR-UHFFFAOYSA-N chromium carbide Chemical compound [Cr]#C[Cr]C#[Cr] UFGZSIPAQKLCGR-UHFFFAOYSA-N 0.000 claims description 4

- 239000010941 cobalt Substances 0.000 claims description 4

- 229910017052 cobalt Inorganic materials 0.000 claims description 4

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 claims description 4

- 229910003470 tongbaite Inorganic materials 0.000 claims description 4

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 claims description 3

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 claims description 3

- 230000015572 biosynthetic process Effects 0.000 claims description 3

- 229910052804 chromium Inorganic materials 0.000 claims description 3

- 229910052582 BN Inorganic materials 0.000 claims description 2

- PZNSFCLAULLKQX-UHFFFAOYSA-N Boron nitride Chemical compound N#B PZNSFCLAULLKQX-UHFFFAOYSA-N 0.000 claims description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 2

- 229910000531 Co alloy Inorganic materials 0.000 claims description 2

- NRTOMJZYCJJWKI-UHFFFAOYSA-N Titanium nitride Chemical compound [Ti]#N NRTOMJZYCJJWKI-UHFFFAOYSA-N 0.000 claims description 2

- 229910052799 carbon Inorganic materials 0.000 claims description 2

- 238000000151 deposition Methods 0.000 claims description 2

- 229910052710 silicon Inorganic materials 0.000 claims description 2

- 239000010703 silicon Substances 0.000 claims description 2

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 claims description 2

- 229910052721 tungsten Inorganic materials 0.000 claims description 2

- 239000010937 tungsten Substances 0.000 claims description 2

- 230000008021 deposition Effects 0.000 claims 1

- 229910052742 iron Inorganic materials 0.000 claims 1

- WPBNNNQJVZRUHP-UHFFFAOYSA-L manganese(2+);methyl n-[[2-(methoxycarbonylcarbamothioylamino)phenyl]carbamothioyl]carbamate;n-[2-(sulfidocarbothioylamino)ethyl]carbamodithioate Chemical compound [Mn+2].[S-]C(=S)NCCNC([S-])=S.COC(=O)NC(=S)NC1=CC=CC=C1NC(=S)NC(=O)OC WPBNNNQJVZRUHP-UHFFFAOYSA-L 0.000 claims 1

- 235000013372 meat Nutrition 0.000 claims 1

- 230000008569 process Effects 0.000 description 8

- 229910000831 Steel Inorganic materials 0.000 description 6

- 239000010959 steel Substances 0.000 description 6

- 229910001347 Stellite Inorganic materials 0.000 description 5

- AHICWQREWHDHHF-UHFFFAOYSA-N chromium;cobalt;iron;manganese;methane;molybdenum;nickel;silicon;tungsten Chemical compound C.[Si].[Cr].[Mn].[Fe].[Co].[Ni].[Mo].[W] AHICWQREWHDHHF-UHFFFAOYSA-N 0.000 description 5

- 238000000576 coating method Methods 0.000 description 5

- 239000000126 substance Substances 0.000 description 5

- 230000002349 favourable effect Effects 0.000 description 4

- 230000009471 action Effects 0.000 description 3

- 239000011324 bead Substances 0.000 description 3

- 230000008901 benefit Effects 0.000 description 3

- 239000011248 coating agent Substances 0.000 description 3

- 238000013461 design Methods 0.000 description 3

- 239000000203 mixture Substances 0.000 description 3

- 239000002245 particle Substances 0.000 description 3

- 230000002093 peripheral effect Effects 0.000 description 3

- 238000005240 physical vapour deposition Methods 0.000 description 3

- 239000000758 substrate Substances 0.000 description 3

- 238000005299 abrasion Methods 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 2

- 238000005260 corrosion Methods 0.000 description 2

- 230000007797 corrosion Effects 0.000 description 2

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 230000001627 detrimental effect Effects 0.000 description 2

- 238000009826 distribution Methods 0.000 description 2

- 239000000428 dust Substances 0.000 description 2

- 239000007789 gas Substances 0.000 description 2

- 239000003779 heat-resistant material Substances 0.000 description 2

- 239000011572 manganese Substances 0.000 description 2

- 239000000843 powder Substances 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- PWHULOQIROXLJO-UHFFFAOYSA-N Manganese Chemical compound [Mn] PWHULOQIROXLJO-UHFFFAOYSA-N 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- WGLPBDUCMAPZCE-UHFFFAOYSA-N Trioxochromium Chemical compound O=[Cr](=O)=O WGLPBDUCMAPZCE-UHFFFAOYSA-N 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 229910000423 chromium oxide Inorganic materials 0.000 description 1

- 230000000052 comparative effect Effects 0.000 description 1

- 239000012141 concentrate Substances 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 229910003460 diamond Inorganic materials 0.000 description 1

- 239000010432 diamond Substances 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 238000010285 flame spraying Methods 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- 229910052500 inorganic mineral Inorganic materials 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 229910052748 manganese Inorganic materials 0.000 description 1

- 229910000734 martensite Inorganic materials 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 150000001247 metal acetylides Chemical class 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 239000011707 mineral Substances 0.000 description 1

- 150000004767 nitrides Chemical class 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 1

- 238000012805 post-processing Methods 0.000 description 1

- 238000002203 pretreatment Methods 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 238000007790 scraping Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000012549 training Methods 0.000 description 1

- 229910052723 transition metal Inorganic materials 0.000 description 1

- 150000003624 transition metals Chemical class 0.000 description 1

- 238000007740 vapor deposition Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

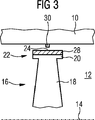

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/22—Blade-to-blade connections, e.g. for damping vibrations

- F01D5/225—Blade-to-blade connections, e.g. for damping vibrations by shrouding

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D11/00—Preventing or minimising internal leakage of working-fluid, e.g. between stages

- F01D11/08—Preventing or minimising internal leakage of working-fluid, e.g. between stages for sealing space between rotor blade tips and stator

- F01D11/12—Preventing or minimising internal leakage of working-fluid, e.g. between stages for sealing space between rotor blade tips and stator using a rubstrip, e.g. erodible. deformable or resiliently-biased part

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D11/00—Preventing or minimising internal leakage of working-fluid, e.g. between stages

- F01D11/08—Preventing or minimising internal leakage of working-fluid, e.g. between stages for sealing space between rotor blade tips and stator

- F01D11/12—Preventing or minimising internal leakage of working-fluid, e.g. between stages for sealing space between rotor blade tips and stator using a rubstrip, e.g. erodible. deformable or resiliently-biased part

- F01D11/122—Preventing or minimising internal leakage of working-fluid, e.g. between stages for sealing space between rotor blade tips and stator using a rubstrip, e.g. erodible. deformable or resiliently-biased part with erodable or abradable material

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/28—Selecting particular materials; Particular measures relating thereto; Measures against erosion or corrosion

- F01D5/288—Protective coatings for blades

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05C—INDEXING SCHEME RELATING TO MATERIALS, MATERIAL PROPERTIES OR MATERIAL CHARACTERISTICS FOR MACHINES, ENGINES OR PUMPS OTHER THAN NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES

- F05C2201/00—Metals

- F05C2201/04—Heavy metals

- F05C2201/0433—Iron group; Ferrous alloys, e.g. steel

- F05C2201/0463—Cobalt

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/20—Manufacture essentially without removing material

- F05D2230/23—Manufacture essentially without removing material by permanently joining parts together

- F05D2230/232—Manufacture essentially without removing material by permanently joining parts together by welding

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/30—Manufacture with deposition of material

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/30—Manufacture with deposition of material

- F05D2230/31—Layer deposition

- F05D2230/312—Layer deposition by plasma spraying

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/30—Manufacture with deposition of material

- F05D2230/31—Layer deposition

- F05D2230/313—Layer deposition by physical vapour deposition

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/90—Coating; Surface treatment

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2300/00—Materials; Properties thereof

- F05D2300/20—Oxide or non-oxide ceramics

- F05D2300/22—Non-oxide ceramics

- F05D2300/226—Carbides

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2300/00—Materials; Properties thereof

- F05D2300/20—Oxide or non-oxide ceramics

- F05D2300/22—Non-oxide ceramics

- F05D2300/228—Nitrides

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2300/00—Materials; Properties thereof

- F05D2300/20—Oxide or non-oxide ceramics

- F05D2300/22—Non-oxide ceramics

- F05D2300/228—Nitrides

- F05D2300/2284—Nitrides of titanium

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49316—Impeller making

- Y10T29/4932—Turbomachine making

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

- Coating By Spraying Or Casting (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP05008811.1 | 2005-04-21 | ||

| EP05008811A EP1715140A1 (de) | 2005-04-21 | 2005-04-21 | Turbinenschaufel mit einer Deckplatte und einer auf der Deckplatte aufgebrachte Schutzschicht |

| PCT/EP2006/050337 WO2006111427A1 (de) | 2005-04-21 | 2006-01-20 | Turbinenschaufel mit einer deckplatte und einer auf der deckplatte aufgebrachte schutzschicht |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2008538399A JP2008538399A (ja) | 2008-10-23 |

| JP2008538399A5 JP2008538399A5 (enExample) | 2009-03-12 |

| JP4874329B2 true JP4874329B2 (ja) | 2012-02-15 |

Family

ID=34935569

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008507029A Expired - Fee Related JP4874329B2 (ja) | 2005-04-21 | 2006-01-20 | カバープレートとこのカバープレートに被着された保護層とを備えたタービン翼 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US8021120B2 (enExample) |

| EP (2) | EP1715140A1 (enExample) |

| JP (1) | JP4874329B2 (enExample) |

| CN (1) | CN101163862B (enExample) |

| WO (1) | WO2006111427A1 (enExample) |

Families Citing this family (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8708658B2 (en) * | 2007-04-12 | 2014-04-29 | United Technologies Corporation | Local application of a protective coating on a shrouded gas turbine engine component |

| KR101115761B1 (ko) * | 2008-12-26 | 2012-06-12 | 주식회사 포스코 | 표면 탈탄이 억제된 강재 및 제조방법 |

| DE102010049398A1 (de) * | 2009-11-02 | 2011-05-05 | Alstom Technology Ltd. | Verschleiss- und oxidationsbeständige Turbinenschaufel |

| CN101922312B (zh) * | 2010-03-24 | 2013-11-06 | 北京航空航天大学 | 一种叶轮机械径向间隙泄漏损失的控制方法 |

| US8579581B2 (en) * | 2010-09-15 | 2013-11-12 | General Electric Company | Abradable bucket shroud |

| US8753093B2 (en) * | 2010-10-19 | 2014-06-17 | General Electric Company | Bonded turbine bucket tip shroud and related method |

| EP2549063A1 (en) * | 2011-07-21 | 2013-01-23 | Siemens Aktiengesellschaft | Heat shield element for a gas turbine |

| US20130034423A1 (en) * | 2011-08-01 | 2013-02-07 | General Electric Company | System and method for passively controlling clearance in a gas turbine engine |

| CN104508251B (zh) * | 2012-04-27 | 2016-08-24 | 通用电气公司 | 用于燃气涡轮发动机的护罩组件和密封件 |

| RU2015117053A (ru) * | 2012-11-06 | 2016-12-27 | Сименс Энерджи, Инк. | Венец лопатки турбины с абразивным покрытием |

| DE102013212252A1 (de) * | 2013-06-26 | 2014-12-31 | Siemens Aktiengesellschaft | Turbine und Verfahren zur Anstreiferkennung |

| US20150093237A1 (en) * | 2013-09-30 | 2015-04-02 | General Electric Company | Ceramic matrix composite component, turbine system and fabrication process |

| GB2521588A (en) * | 2013-10-11 | 2015-07-01 | Reaction Engines Ltd | Turbine blades |

| WO2015068227A1 (ja) * | 2013-11-06 | 2015-05-14 | 川崎重工業株式会社 | タービン翼およびその製造方法 |

| DE102014202457A1 (de) | 2014-02-11 | 2015-08-13 | Siemens Aktiengesellschaft | Verbesserte Verschleißbeständigkeit eines Hochtemperaturbauteils durch Kobaltbeschichtung |

| US10662788B2 (en) * | 2018-02-02 | 2020-05-26 | Raytheon Technologies Corporation | Wear resistant turbine blade tip |

| US11203942B2 (en) | 2018-03-14 | 2021-12-21 | Raytheon Technologies Corporation | Wear resistant airfoil tip |

| US11346232B2 (en) * | 2018-04-23 | 2022-05-31 | Rolls-Royce Corporation | Turbine blade with abradable tip |

| FR3090427B1 (fr) * | 2018-12-21 | 2023-11-10 | Safran | Procede de fabrication d’un noyau |

| WO2022107734A1 (ja) * | 2020-11-20 | 2022-05-27 | 川崎重工業株式会社 | ガスタービンエンジンの回転部構成部材およびその製造方法 |

| WO2023202900A1 (de) * | 2022-04-21 | 2023-10-26 | Siemens Energy Global GmbH & Co. KG | Dichtungsanordnung |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS4913810B1 (enExample) * | 1965-02-24 | 1974-04-03 | ||

| JPH0219603A (ja) * | 1988-07-07 | 1990-01-23 | Union Carbide Corp | 回転式ラビリンスシール部材用耐摩耗性、研削性レーザ彫刻セラミック乃至金属炭化物表面 |

| JP2002256449A (ja) * | 2001-02-28 | 2002-09-11 | Mitsubishi Heavy Ind Ltd | 耐摩耗性コーティング及びその施工方法 |

| JP2003148103A (ja) * | 2001-11-09 | 2003-05-21 | Mitsubishi Heavy Ind Ltd | タービンおよびその製造方法 |

| JP2003532014A (ja) * | 2000-05-04 | 2003-10-28 | シーメンス アクチエンゲゼルシヤフト | 隙間の漏止め装置 |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE676992A (enExample) * | 1965-02-24 | 1966-07-18 | ||

| FI45933C (fi) | 1972-03-22 | 1976-12-03 | Salakarin Oikeudenomistajat | Liukumista estävä laite pyörää ja sentapaista varten. |

| US4291448A (en) * | 1977-12-12 | 1981-09-29 | Turbine Components Corporation | Method of restoring the shrouds of turbine blades |

| US4285108A (en) * | 1979-02-23 | 1981-08-25 | United Technologies Corporation | Apparatus and method for refinishing turbine blade airseals |

| US4822248A (en) * | 1987-04-15 | 1989-04-18 | Metallurgical Industries, Inc. | Rebuilt shrouded turbine blade and method of rebuilding the same |

| US5358379A (en) * | 1993-10-27 | 1994-10-25 | Westinghouse Electric Corporation | Gas turbine vane |

| DE10140742B4 (de) * | 2000-12-16 | 2015-02-12 | Alstom Technology Ltd. | Vorrichtung zur Dichtspaltreduzierung zwischen einer rotierenden und einer stationären Komponente innerhalb einer axial durchströmten Strömungsmaschine |

| JP3902179B2 (ja) * | 2001-05-31 | 2007-04-04 | 三菱重工業株式会社 | 皮膜形成方法及び皮膜形成用材料、並びに研磨性皮膜形成用シート |

| KR101004236B1 (ko) * | 2002-10-09 | 2010-12-24 | 미츠비시덴키 가부시키가이샤 | 회전체 및 그 코팅방법 |

-

2005

- 2005-04-21 EP EP05008811A patent/EP1715140A1/de not_active Withdrawn

-

2006

- 2006-01-20 CN CN200680013189.1A patent/CN101163862B/zh not_active Expired - Fee Related

- 2006-01-20 WO PCT/EP2006/050337 patent/WO2006111427A1/de not_active Ceased

- 2006-01-20 EP EP06703576A patent/EP1871991A1/de not_active Withdrawn

- 2006-01-20 US US11/918,809 patent/US8021120B2/en not_active Expired - Fee Related

- 2006-01-20 JP JP2008507029A patent/JP4874329B2/ja not_active Expired - Fee Related

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS4913810B1 (enExample) * | 1965-02-24 | 1974-04-03 | ||

| JPH0219603A (ja) * | 1988-07-07 | 1990-01-23 | Union Carbide Corp | 回転式ラビリンスシール部材用耐摩耗性、研削性レーザ彫刻セラミック乃至金属炭化物表面 |

| JP2003532014A (ja) * | 2000-05-04 | 2003-10-28 | シーメンス アクチエンゲゼルシヤフト | 隙間の漏止め装置 |

| JP2002256449A (ja) * | 2001-02-28 | 2002-09-11 | Mitsubishi Heavy Ind Ltd | 耐摩耗性コーティング及びその施工方法 |

| JP2003148103A (ja) * | 2001-11-09 | 2003-05-21 | Mitsubishi Heavy Ind Ltd | タービンおよびその製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| US8021120B2 (en) | 2011-09-20 |

| WO2006111427A1 (de) | 2006-10-26 |

| EP1871991A1 (de) | 2008-01-02 |

| EP1715140A1 (de) | 2006-10-25 |

| US20090022583A1 (en) | 2009-01-22 |

| CN101163862A (zh) | 2008-04-16 |

| JP2008538399A (ja) | 2008-10-23 |

| CN101163862B (zh) | 2011-10-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4874329B2 (ja) | カバープレートとこのカバープレートに被着された保護層とを備えたタービン翼 | |

| US6158963A (en) | Coated article and method for inhibiting frictional wear between mating titanium alloy substrates in a gas turbine engine | |

| EP1229252B1 (en) | Abradable coating and method of production | |

| US8871297B2 (en) | Method of applying a nanocrystalline coating to a gas turbine engine component | |

| JP5202837B2 (ja) | 可変静翼アセンブリ | |

| US9429029B2 (en) | Gas turbine blade and method of protecting same | |

| JPH0160680B2 (enExample) | ||

| EP1835046A1 (en) | Wear-resistant coating | |

| JPS63259107A (ja) | 動翼用先端キャップの交換方法 | |

| JP2008538399A5 (enExample) | ||

| US20070147990A1 (en) | Sealing device | |

| US6089828A (en) | Coated article and method for inhibiting frictional wear between mating titanium alloy substrates in a gas turbine engine | |

| US20080263864A1 (en) | Turbomachine blade and turbomachine comprising this blade | |

| EP3372784B1 (en) | Abradable material coating repair and steam turbine stationary component | |

| JP3848155B2 (ja) | ガスタービン燃焼器 | |

| EP2876259B1 (en) | Turbine buckets with high hot hardness shroud-cutting deposits | |

| EP3611350B1 (en) | Turbine abrasive blade tips with improved resistance to oxidation | |

| JP2003185140A (ja) | ガスタービン燃焼器 | |

| KR102063760B1 (ko) | 기능성 코팅부를 구비한 터보 기계 부품 | |

| JP2008275035A (ja) | 蒸気タービン用蒸気弁 | |

| JP2005016523A (ja) | タービン外側ケースと支持式タービンベーンとの間の支持領域の耐摩耗性を改善する方法 | |

| JP2007146836A (ja) | 可変静翼アセンブリ | |

| CN120569546A (zh) | 根部设有抗磨涂层的叶片 | |

| EP3882437A1 (en) | Integrally bladed rotor, gas turbine engine and method for manufacturing an integrally bladed rotor | |

| WO2024196834A1 (en) | Laser treatment of piston seal rings |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090116 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090116 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110111 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20110408 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20110415 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110509 |

|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7423 Effective date: 20110509 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110607 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110901 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20111025 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20111122 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20141202 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |