JP4644872B2 - 折畳み糊付け装置の搬送機 - Google Patents

折畳み糊付け装置の搬送機 Download PDFInfo

- Publication number

- JP4644872B2 JP4644872B2 JP2008131344A JP2008131344A JP4644872B2 JP 4644872 B2 JP4644872 B2 JP 4644872B2 JP 2008131344 A JP2008131344 A JP 2008131344A JP 2008131344 A JP2008131344 A JP 2008131344A JP 4644872 B2 JP4644872 B2 JP 4644872B2

- Authority

- JP

- Japan

- Prior art keywords

- drive shaft

- longitudinal

- conveying

- conveying device

- support structures

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000003292 glue Substances 0.000 title claims description 4

- 239000000463 material Substances 0.000 claims description 14

- 230000001681 protective effect Effects 0.000 claims description 5

- 238000006073 displacement reaction Methods 0.000 abstract 2

- 239000011087 paperboard Substances 0.000 description 11

- 238000004026 adhesive bonding Methods 0.000 description 7

- 238000004519 manufacturing process Methods 0.000 description 4

- 230000000295 complement effect Effects 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 230000008901 benefit Effects 0.000 description 2

- 239000011111 cardboard Substances 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 238000013459 approach Methods 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000000428 dust Substances 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000005022 packaging material Substances 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 238000004513 sizing Methods 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H5/00—Feeding articles separated from piles; Feeding articles to machines

- B65H5/02—Feeding articles separated from piles; Feeding articles to machines by belts or chains, e.g. between belts or chains

- B65H5/021—Feeding articles separated from piles; Feeding articles to machines by belts or chains, e.g. between belts or chains by belts

- B65H5/023—Feeding articles separated from piles; Feeding articles to machines by belts or chains, e.g. between belts or chains by belts between a pair of belts forming a transport nip

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2403/00—Power transmission; Driving means

- B65H2403/50—Driving mechanisms

- B65H2403/52—Translation screw-thread mechanisms

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2407/00—Means not provided for in groups B65H2220/00 – B65H2406/00 specially adapted for particular purposes

- B65H2407/10—Safety means, e.g. for preventing injuries or illegal operations

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2511/00—Dimensions; Position; Numbers; Identification; Occurrences

- B65H2511/10—Size; Dimensions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2511/00—Dimensions; Position; Numbers; Identification; Occurrences

- B65H2511/20—Location in space

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2701/00—Handled material; Storage means

- B65H2701/10—Handled articles or webs

- B65H2701/17—Nature of material

- B65H2701/176—Cardboard

- B65H2701/1764—Cut-out, single-layer, e.g. flat blanks for boxes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2801/00—Application field

- B65H2801/81—Packaging machines

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Making Paper Articles (AREA)

- Structure Of Belt Conveyors (AREA)

- Coating Apparatus (AREA)

- Auxiliary Devices For And Details Of Packaging Control (AREA)

- Closing Of Containers (AREA)

Description

Claims (13)

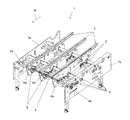

- 折畳み糊付け装置にシート材を搬入するための搬送装置であって、

前記搬送装置は2本の支持構造体(10a、10b)を備えており、支持構造体は長手方向に延びて、横断方向に互いから離隔されており、支持構造体(10a、10b)相互の間には、少なくとも1本の移動用滑走部材(20)が延びており、

前記搬送装置は、少なくとも1本の長手方向部材(60a、60b)を更に備えており、長手方向部材は前記支持構造体(10a、10b)の間に配置されており、少なくとも1本のエンドレスコンベアーベルト(70)が前記長手方向部材(60a、60b)の各々に沿って移動するように支持されており、

前記搬送装置は駆動シャフト(40)を更に備えており、駆動シャフトはエンドレスコンベアーベルト(70)を駆動してシート材を搬送するように作動し、

少なくとも1本の前記長手方向部材(60a、60b)は少なくとも1本の前記移動用滑走部材(20)の上に滑動自在な接続状態で取付けられて、前記支持構造体(10a、10b)相互の間を前記移動用滑走部材(20)に沿って移動させられるとともに、前記駆動シャフト(40)に沿って移動させられ、

前記搬送装置は少なくとも1本の主ネジ(30)を更に備えており、少なくとも1本の主ネジは前記支持構造体(10a、10b)相互の間に延びており、少なくとも1本の前記長手方向部材(60a、60b)は、少なくとも1本の前記主ネジ(30)に螺旋の接続状態で取付けられて、前記支持構造体(10a、10b)相互の間で前記長手方向部材(60a、60b)の各々を移動させ、

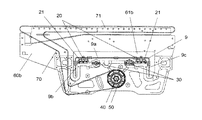

前記搬送装置は保護装置を更に備えており、前記保護装置は、使用者が前記駆動シャフト(40)に接近するのを阻止する形状に設定されているとともに、2本の長手方向の延びる前記支持構造体(10a、10b)を横断方向に接続する形状に設定されていることを特徴とする搬送装置。 - 少なくとも1本の前記移動用滑走部材(20)は前記保護装置に固着されていることを特徴とする、請求項1に記載の搬送装置。

- 前記保護装置は、前記駆動シャフト(40)を覆う外郭部材(9)を有していることを特徴とする、請求項2に記載の搬送装置。

- 前記外郭部材(9)には前記駆動シャフトに向けて延びている凹面が設けられており、凹面の内側には前記シャフトの少なくとも一部が収容されていることを特徴とする、請求項3に記載の搬送装置。

- 前記外郭部材(9)は、その断面部を見た場合に、1枚の桁腹部(9a)および少なくとも1枚の突縁部(9b、9c)を含んでいることを特徴とする、請求項4に記載の搬送装置。

- 前記外郭部材(9)は、その断面部を見た場合に、1枚の桁腹部(9a)および2枚の側面突縁部(9b、9c)を含んでいることを特徴とする、請求項4に記載の搬送装置。

- 前記駆動シャフト(40)は少なくとも一部が、2枚の突縁部(9b、9c)相互の間に設置されていることを特徴とする、請求項6に記載の搬送装置。

- 前記駆動シャフト(40)は前記桁腹部(9b)よりも下方に設置されていることを特徴とする、請求項5に記載の搬送装置。

- 少なくとも1本の前記移動用滑走部材(20)は前記桁腹部(9a)に固着されていることを特徴とする、請求項5に記載の搬送装置。

- 少なくとも1本の前記主ネジ(30)は前記桁腹部(9a)よりも下方に設置されていることを特徴とする、請求項5に記載の搬送装置。

- 前記主ネジ(30)は少なくとも一部が、前記2枚の突縁部(9b、9c)相互の間に設置されていることを特徴とする、請求項6に記載の搬送装置。

- 前記搬送装置は下部コンベアーであることを特徴とする、請求項1に記載の搬送装置。

- 前記搬送装置は上部コンベアーであることを特徴とする、請求項1に記載の搬送装置。

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP07007749 | 2007-04-17 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2008265345A JP2008265345A (ja) | 2008-11-06 |

| JP4644872B2 true JP4644872B2 (ja) | 2011-03-09 |

Family

ID=38542133

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008131344A Active JP4644872B2 (ja) | 2007-04-17 | 2008-04-17 | 折畳み糊付け装置の搬送機 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US7810812B2 (ja) |

| EP (1) | EP1982937B1 (ja) |

| JP (1) | JP4644872B2 (ja) |

| CN (1) | CN101289015B (ja) |

| AT (1) | ATE452845T1 (ja) |

| DE (1) | DE602008000430D1 (ja) |

| ES (1) | ES2337420T3 (ja) |

| TW (1) | TWI357880B (ja) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101669744B1 (ko) * | 2012-04-23 | 2016-10-27 | 봅스트 맥스 에스에이 | 프레임을 구비한 모듈 및 이 모듈이 제공된 폴더/글루어 |

| CN104325686B (zh) * | 2014-10-19 | 2019-04-23 | 广东鸿铭智能股份有限公司 | 送纸定位导向机构 |

| ES2610033B1 (es) * | 2015-09-22 | 2018-01-30 | Biele, S.A. | Dispositivo de apilado automatizado universal |

| CN105666940B (zh) * | 2016-04-11 | 2018-05-04 | 杭州禾康包装材料有限公司 | 一种自动送纸机的送纸卷轴驱动装置 |

| CN115042479B (zh) * | 2022-06-30 | 2023-11-17 | 温州永邦机械有限公司 | 一种具有真空吸附的瓦裱机 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3511361A (en) * | 1967-12-04 | 1970-05-12 | Ernest F Urban | Conveying apparatus with drift correction feature |

| US5087028A (en) * | 1989-03-01 | 1992-02-11 | Stahl Gmbh & Co. Maschinenfabrik | Aligning table |

| DE4123132A1 (de) * | 1990-08-31 | 1992-03-12 | Brehmer Buchbindereimaschinen | Anlegetisch fuer bogenverarbeitende maschinen |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1615590A (en) * | 1924-06-27 | 1927-01-25 | Lisenby Mfg Company | Semiautomatic feed device |

| US2083296A (en) * | 1935-09-27 | 1937-06-08 | Davidson William Ward | Blank conveyer board |

| DE102004022214A1 (de) * | 2004-05-04 | 2005-12-01 | Heidelberger Druckmaschinen Ag | Falt- und Einfädelstation einer Faltschachtelklebemaschine |

| CN2782633Y (zh) * | 2005-03-18 | 2006-05-24 | 宇社机械股份有限公司 | 送纸装置 |

-

2008

- 2008-04-03 ES ES08006790T patent/ES2337420T3/es active Active

- 2008-04-03 DE DE602008000430T patent/DE602008000430D1/de active Active

- 2008-04-03 AT AT08006790T patent/ATE452845T1/de not_active IP Right Cessation

- 2008-04-03 EP EP08006790A patent/EP1982937B1/fr active Active

- 2008-04-08 TW TW097112617A patent/TWI357880B/zh active

- 2008-04-15 CN CN2008100927873A patent/CN101289015B/zh active Active

- 2008-04-17 US US12/104,606 patent/US7810812B2/en active Active

- 2008-04-17 JP JP2008131344A patent/JP4644872B2/ja active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3511361A (en) * | 1967-12-04 | 1970-05-12 | Ernest F Urban | Conveying apparatus with drift correction feature |

| US5087028A (en) * | 1989-03-01 | 1992-02-11 | Stahl Gmbh & Co. Maschinenfabrik | Aligning table |

| DE4123132A1 (de) * | 1990-08-31 | 1992-03-12 | Brehmer Buchbindereimaschinen | Anlegetisch fuer bogenverarbeitende maschinen |

Also Published As

| Publication number | Publication date |

|---|---|

| DE602008000430D1 (de) | 2010-02-04 |

| EP1982937A1 (fr) | 2008-10-22 |

| US7810812B2 (en) | 2010-10-12 |

| JP2008265345A (ja) | 2008-11-06 |

| CN101289015B (zh) | 2010-11-17 |

| ATE452845T1 (de) | 2010-01-15 |

| TWI357880B (en) | 2012-02-11 |

| EP1982937B1 (fr) | 2009-12-23 |

| US20080258381A1 (en) | 2008-10-23 |

| ES2337420T3 (es) | 2010-04-23 |

| TW200842096A (en) | 2008-11-01 |

| CN101289015A (zh) | 2008-10-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4644872B2 (ja) | 折畳み糊付け装置の搬送機 | |

| US9617100B2 (en) | Sheet medium stacking conveying device and method | |

| US8647248B2 (en) | Device for conveying and folding blanks | |

| JP6742242B2 (ja) | 平板物体を搬送するための方法及び装置 | |

| US7416073B1 (en) | Diverting flat belt support system | |

| US20170066214A1 (en) | Box finishing machines | |

| CN102583089A (zh) | 薄片类介质处理装置 | |

| US9771227B2 (en) | Layboy with adjustable lower conveyor and method for operating the layboy | |

| JP2005306034A (ja) | 板状ワークピースを加工する機械において板状ワークピースを整列させるための装置 | |

| EP2460410B1 (en) | Device and method for lapping dough | |

| US9776802B2 (en) | Drive device for belt conveyor device | |

| US6315110B1 (en) | Retractable central conveyor in a folder-gluer | |

| US11472656B2 (en) | Conveyor device for a corrugated web, corrugated board manufacturing line including the conveyor device, and method | |

| TW201544306A (zh) | 折疊站及折疊盒黏貼機 | |

| US699133A (en) | Conveyer and guide for rolling-mills. | |

| US11697263B2 (en) | Folder-gluer | |

| JP4823572B2 (ja) | 紙幣搬送装置 | |

| US11685568B2 (en) | Adjustable packaging machine | |

| US8550970B2 (en) | Apparatus for finishing products coming out from a machine for folding and gluing cardboard or paperboard products with a back | |

| EP3020669B1 (en) | Device for decurling a web of material, such as a paper web | |

| JP5496267B2 (ja) | ベニヤ板材搬送装置 | |

| EP1894869B1 (en) | Sheet material inverter | |

| DE102012021383B4 (de) | Bogenwendeeinheit und Verfahren zum Wenden eines Bogens | |

| GB2269371A (en) | Sheet-feeding roller assemblies. | |

| GB2393177A (en) | Sheet feeder with bias rollers |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20101115 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20101118 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131217 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4644872 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |