JP4392525B2 - Packaging equipment and products - Google Patents

Packaging equipment and products Download PDFInfo

- Publication number

- JP4392525B2 JP4392525B2 JP2000299877A JP2000299877A JP4392525B2 JP 4392525 B2 JP4392525 B2 JP 4392525B2 JP 2000299877 A JP2000299877 A JP 2000299877A JP 2000299877 A JP2000299877 A JP 2000299877A JP 4392525 B2 JP4392525 B2 JP 4392525B2

- Authority

- JP

- Japan

- Prior art keywords

- packaging bag

- packaged

- packaging

- sealing

- article

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Description

【0001】

【産業上の利用分野】

本発明は、ベルトコンベア上を搬送される被包装物をフイルム又はシートからなる包装袋内に所定量収納し、該包装袋の長手方向の端部を封鎖する包装装置及び前記包装袋内に所定量の被包装物が収納された包装品に関する。

【0002】

【従来の技術】

従来のベルトコンベア上を搬送される被包装物をフイルム又はシートからなる包装袋内に所定量収納し、該包装袋の長手方向の端部を封鎖する包装装置によって得られた包装品は、図4(A)に示すように、ロールパンのような被包装物1が収納された包装袋2の長手方向の両端が被包装物1に接近してシールされていたため、該シール部分3,3’のいずれか一方を一旦開封すると、該開封部分を再び封鎖することができなかった。

また、図4(B)に示すように、長手方向の一端のみがシールされ、該シール部分3に寄せて所定量の被包装物1が収納され、且つ他端の開放部分4と被包装物1との間の位置で包装袋2がねじり線やC形クロージャー等のクロージャー5によって絞られている包装品は、クロージャー5によって容易に開封・封鎖ができる反面、包装品を製造した後の輸送過程で異物の混入する惧れがあった。

【0003】

【発明が解決しようとする課題】

本発明は、フイルム又はシートからなる包装袋内に所定量の被包装物が収納された包装品を生産した後の輸送過程で異物の混入する惧れがなく、しかも該包装品を一旦開封した後でも再び封鎖できる包装品を提供すると共に、該包装品を容易に生産できる包装装置を提供することを目的とする。

【0004】

【課題を解決するための手段】

上記課題を解決するために、第一の発明は、フィルム又はシートからセンターシーラーで包装袋を形成し、該包装袋の内部に所定量収納した被包装物をコンベアで搬送して該包装袋の端部をシールする包装装置であって、前記包装袋の一方の端部と前記被包装物との間の位置で前記包装袋がクロージャーによって絞ることのできる充分な長さとなるよう包装袋の長手方向の両端をシールするシール手段と、該シール手段で前記包装袋の一方の端部をシールする前に前記包装袋の上からエアを吹き付けて該包装袋内の空気を排出する第一の脱気手段を備えたことを特徴とすることにより、両端がシールされた状態で前記包装袋をクロージャーで絞ることができる。第二の発明は、第一の発明に加えて前記シール手段と共に上下動して前記包装袋の前端寄り又は後端寄りの被包装物が位置しない部分を上から押圧して該包装袋内の空気を排出する第二の脱気手段を備えたことを特徴とすることにより、両端がシールされた状態で前記包装袋をクロージャーで絞ることが更に容易となる。第三の発明は、前記脱気手段の作動開始順序が第一、第二の順であることを特徴とすることにより、脱気を円滑に行わせることができる。

また、前記フイルム又はシートの材料は、高密度ポリプロピレンが望ましく、前記第一の脱気手段は、エアノズルであることが望ましく、前記第二の脱気手段は、弾力性を有する材料、例えば高発泡のウレタンスポンジが望ましく、脱気の程度は、被包装物が変形せず、前記包装袋の両端がシールされた状態で該包装袋をクロージャーによって絞ることができる程度で充分であり、前記接合強度は、前記シール部分を手で剥離させて開封するときに包装袋の形態を保つ程度が望ましい。

【0005】

【発明の実施の形態】

以下、本発明を実施例に基づいて更に詳細に説明するが、本発明は下記実施形態に何ら限定されるものではなく、その要旨を変更しない範囲において、適宜変更して実施することができる。

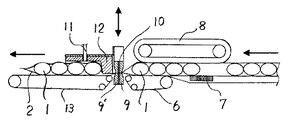

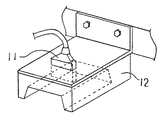

図1は三方シールタイプの包装装置を示しており、ベルトコンベア6上を搬送される被包装物1を、フイルム又はシートからセンターシーラー7で包装袋2を形成しながら内部に所定量収納し、包装袋2の上面を整える押さえブラシ8と、包装袋2の長手方向の両端をシールするシール手段9,9’(エンドシーラー)と、シール手段9,9’と連動して該シール部分で切断するシーラーカッター10と、被包装物1が収納された状態で包装袋2の上からエアを吹き付けて包装袋2内の空気を排出する第一の脱気手段11(脱気用エアノズル)と、シール手段9,9’と共に上下して包装袋2の前端寄り又は後端寄りの被包装物1が位置しない部分を上から押圧して包装袋2内の空気を排出する第二の脱気手段12(脱気用スポンジ)と、被包装物1が収納された包装袋2を次工程に送り出す搬出コンベア13を備えている。図2は、第一の脱気手段11と第二の脱気手段12の配置を示している。

第一の脱気手段11は、第二の脱気手段12に支持されてシール手段9,9’と共に上下するようになっていて、シール手段9によって包装袋2の前端がシールされた後、シール手段9,9’が上下に開いている間に、被包装物1が収納された包装袋2は第一の脱気手段11からのエア圧(60Pa)に曝されて包装袋2内を脱気されながら通過し、次いで、シール手段9,9’が閉じるときに第二の脱気手段12によって、被包装物1が位置しない部分を上から押圧し包装袋2内の空気を排出し、次いで、シール手段9’によって包装袋2の後端がシールされる。このとき、包装袋2の後端と被包装物1との間の被包装物1が位置しない部分は、次工程でクロージャー5によって絞ることのできる充分な長さを有している。

得られる包装品は、図3(A)に示すように、包装袋2は長手方向の両端がシールされており、被包装物1が一端のシール部分3に寄せて収納され、図3(B)に示すように、他端のシール部分3’と被包装物1との間の位置で包装袋2がクロージャー5によって絞られる。シール部分3’が開封し易いようにシール部分3より接合強度を小さくされている。これは、例えば、2000rpmでの運転時では、シール手段9’の加熱温度を116℃、シール手段9の加熱温度を124℃に設定することにより可能となる。

【0006】

【発明の効果】

上述したように、本発明によれば、フイルム又はシートからなる包装袋内に所定量の被包装物が収納された包装品を生産した後の輸送過程で異物の混入する惧れがなく、しかも該包装品を一旦開封した後でも再び封鎖できる包装品を簡便に提供できると共に、該包装品を容易に生産できる包装装置を提供することができる。

【図面の簡単な説明】

【図1】本発明包装装置の一実施形態における基本構成を示す断面図である。

【図2】図1における脱気手段を示す斜視図である。

【図3】本発明包装品の一実施形態を示す斜視図である。

【図4】従来の包装品を示す斜視図である。

【符号の説明】

1は被包装物、2は包装袋、3,3’はシール部分、4は開放部分、5はクロージャー、6はベルトコンベア、7はセンターシーラー、8は押さえブラシ、9,9’はシール手段(エンドシーラー)、10はシーラーカッター、11は第一の脱気手段(脱気用エアノズル)、12は第二の脱気手段(脱気用スポンジ)、13は搬出コンベア[0001]

[Industrial application fields]

The present invention relates to a packaging device for storing a predetermined amount of an article to be packaged conveyed on a belt conveyor in a packaging bag made of a film or a sheet, and sealing the longitudinal end of the packaging bag, and the packaging bag. The present invention relates to a packaged product in which a fixed amount of packaged items is stored.

[0002]

[Prior art]

A packaged article obtained by a packaging apparatus for storing a predetermined amount of a packaged article conveyed on a conventional belt conveyor in a packaging bag made of a film or a sheet and sealing the longitudinal end of the packaging bag is shown in FIG. As shown in FIG. 4 (A), since both ends in the longitudinal direction of the

Further, as shown in FIG. 4B, only one end in the longitudinal direction is sealed, and a predetermined amount of the article to be packaged 1 is stored close to the

[0003]

[Problems to be solved by the invention]

In the present invention, there is no possibility of foreign matters being mixed in the transportation process after producing a packaged product in which a predetermined amount of packaged goods is stored in a packaging bag made of a film or a sheet, and the packaged product is once opened. An object of the present invention is to provide a packaging device that can be sealed again later and to provide a packaging device that can easily produce the packaging product.

[0004]

[Means for Solving the Problems]

In order to solve the above-mentioned problem, the first invention is to form a packaging bag from a film or sheet with a center sealer, convey a packaged article stored in a predetermined amount inside the packaging bag by a conveyor, and A packaging device for sealing an end, wherein the packaging bag is long enough to be squeezed by a closure at a position between one end of the packaging bag and the article to be packaged. Sealing means for sealing both ends in the direction, and a first release for discharging air in the packaging bag by blowing air from above the packaging bag before sealing one end of the packaging bag by the sealing means. By providing the air means, the packaging bag can be squeezed with a closure in a state where both ends are sealed. In addition to the first invention, the second invention moves up and down together with the sealing means and presses the portion of the packaging bag near the front end or the rear end where the article to be packaged is not located to By providing the second deaeration means for discharging the air, it becomes easier to squeeze the packaging bag with the closure in a state where both ends are sealed. The third invention is characterized in that the operation start order of the deaeration means is the first and second order, whereby the deaeration can be performed smoothly .

The material of the film or sheet is preferably high-density polypropylene, the first degassing means is preferably an air nozzle, and the second degassing means is a material having elasticity, for example, high foaming. The urethane sponge is desirable, and the degree of degassing is sufficient that the packaged bag is not deformed and that the packaging bag can be squeezed with a closure in a state where both ends of the packaging bag are sealed, and the bonding strength It is desirable to maintain the form of the packaging bag when the seal part is peeled off by hand and opened.

[0005]

DETAILED DESCRIPTION OF THE INVENTION

EXAMPLES Hereinafter, although this invention is demonstrated further in detail based on an Example, this invention is not limited to the following embodiment at all, In the range which does not change the summary, it can change suitably and can implement.

FIG. 1 shows a three-side seal type packaging device, in which a

The first degassing means 11 is supported by the second degassing means 12 so as to move up and down together with the sealing means 9 and 9 ′. After the front end of the

As shown in FIG. 3 (A), the packaged

[0006]

【The invention's effect】

As described above, according to the present invention, there is no possibility that foreign matter may be mixed in the transportation process after producing a packaged product in which a predetermined amount of an object to be packaged is stored in a packaging bag made of a film or a sheet. It is possible to easily provide a packaged product that can be sealed again even after the packaged product has been opened, and to provide a packaging device that can easily produce the packaged product.

[Brief description of the drawings]

FIG. 1 is a cross-sectional view showing a basic configuration of an embodiment of the packaging apparatus of the present invention.

2 is a perspective view showing a deaeration means in FIG. 1. FIG.

FIG. 3 is a perspective view showing an embodiment of the packaged product of the present invention.

FIG. 4 is a perspective view showing a conventional packaged product.

[Explanation of symbols]

1 is a package, 2 is a packaging bag, 3 and 3 'are seal parts, 4 is an open part, 5 is a closure, 6 is a belt conveyor, 7 is a center sealer, 8 is a pressing brush, and 9 and 9' are sealing means (End sealer) 10 is a sealer cutter, 11 is a first degassing means (degassing air nozzle), 12 is a second degassing means (degassing sponge), and 13 is a carry-out conveyor.

Claims (3)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000299877A JP4392525B2 (en) | 2000-09-29 | 2000-09-29 | Packaging equipment and products |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000299877A JP4392525B2 (en) | 2000-09-29 | 2000-09-29 | Packaging equipment and products |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2002104330A JP2002104330A (en) | 2002-04-10 |

| JP2002104330A5 JP2002104330A5 (en) | 2006-06-15 |

| JP4392525B2 true JP4392525B2 (en) | 2010-01-06 |

Family

ID=18781627

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2000299877A Expired - Lifetime JP4392525B2 (en) | 2000-09-29 | 2000-09-29 | Packaging equipment and products |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4392525B2 (en) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002179008A (en) * | 2000-12-15 | 2002-06-26 | Kyoraku Co Ltd | Package having easy-to-open property and method for manufacturing the same |

| JP4849747B2 (en) * | 2001-08-30 | 2012-01-11 | 株式会社川島製作所 | Degassing device for horizontal bag packaging machine |

| JP5037252B2 (en) * | 2007-07-27 | 2012-09-26 | 雪印メグミルク株式会社 | Packaging equipment |

| JP5763332B2 (en) * | 2010-12-20 | 2015-08-12 | 大森機械工業株式会社 | Packaging machine |

| EP2546154A1 (en) * | 2011-07-12 | 2013-01-16 | Cryovac, Inc. | Packaging apparatus and method of expelling gas |

| CN103086023A (en) * | 2013-02-25 | 2013-05-08 | 江苏金都食品有限公司 | Locating device of food packaging machine |

| CA2945522A1 (en) * | 2014-04-15 | 2015-12-23 | The Skylife Company, Inc. | Remote packing system |

| CN107499608A (en) * | 2017-09-21 | 2017-12-22 | 广州市元昶包装器材有限公司 | Packaging facilities |

| CN108298123A (en) * | 2018-01-24 | 2018-07-20 | 安徽顺和生物科技有限公司 | The exhaust apparatus of packing machine |

| JP7073465B2 (en) * | 2020-09-30 | 2022-05-23 | シマダヤ株式会社 | Sealed drawstring wrapping body for hydrous noodles |

-

2000

- 2000-09-29 JP JP2000299877A patent/JP4392525B2/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| JP2002104330A (en) | 2002-04-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4593718B2 (en) | Zipper strip | |

| CA1225070A (en) | Method of packaging, packaging material therefor and package | |

| US4663915A (en) | Method of packaging and apparatus | |

| US6088998A (en) | High compression transverse zipper system | |

| EP0936993B1 (en) | Process for the production of a hermetic recloseable package of flexible material | |

| JP4392525B2 (en) | Packaging equipment and products | |

| US2546721A (en) | Wrapping machinery and method | |

| JP2004515420A (en) | Filling and using openable bags | |

| WO2008050865A1 (en) | Pleated free-standing packing bag, pleated free-standing package, master roll for pleated free-standing package, and method for producing pleated free-standing package | |

| MXPA00000630A (en) | Transverse direction zipper attaching apparatus and method. | |

| US5806280A (en) | Easy open method, package, and apparatus | |

| US3838549A (en) | Packaging method | |

| WO2014142886A1 (en) | Recloseable flexible packages | |

| US5966907A (en) | Multi-station sealing system and method therefor | |

| US20060179798A1 (en) | Shaped seal bar and knife for sealing and cutting a contoured shape for a flow wrap machine | |

| JP2007030987A (en) | Packaging method by bagging | |

| US4210249A (en) | Reclosable bag closure system | |

| US3844090A (en) | Packaging apparatus | |

| JP2004331136A (en) | Gusset packaging machine | |

| JPH01153410A (en) | Liquid containing type packing method and apparatus for liquid and viscous material | |

| JP3908897B2 (en) | Packaging method with bag | |

| US20220289414A1 (en) | Triple center sealing device in pillow packaging machine | |

| JP3901524B2 (en) | End seal device, packaging machine and package | |

| JP4472268B2 (en) | Bag packing machine | |

| JP2004238065A (en) | Package obtained by folding pillow packaging material |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060419 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20060419 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20060419 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090624 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090630 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090805 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20090901 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20090928 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121023 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20141023 Year of fee payment: 5 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |