JP4209670B2 - クッション性ゴムフロアマット製品及び方法 - Google Patents

クッション性ゴムフロアマット製品及び方法 Download PDFInfo

- Publication number

- JP4209670B2 JP4209670B2 JP2002522741A JP2002522741A JP4209670B2 JP 4209670 B2 JP4209670 B2 JP 4209670B2 JP 2002522741 A JP2002522741 A JP 2002522741A JP 2002522741 A JP2002522741 A JP 2002522741A JP 4209670 B2 JP4209670 B2 JP 4209670B2

- Authority

- JP

- Japan

- Prior art keywords

- rubber

- mat

- floor mat

- layer

- protrusions

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 229920001971 elastomer Polymers 0.000 title claims description 268

- 239000005060 rubber Substances 0.000 title claims description 268

- 238000000034 method Methods 0.000 title claims description 48

- 239000007787 solid Substances 0.000 claims description 60

- 239000000463 material Substances 0.000 claims description 29

- 230000002093 peripheral effect Effects 0.000 claims description 29

- 229920001821 foam rubber Polymers 0.000 claims description 25

- 239000004744 fabric Substances 0.000 claims description 22

- 229910052751 metal Inorganic materials 0.000 claims description 21

- 239000002184 metal Substances 0.000 claims description 21

- 239000002759 woven fabric Substances 0.000 claims description 16

- 239000002131 composite material Substances 0.000 claims description 11

- 239000011148 porous material Substances 0.000 claims description 10

- 239000004088 foaming agent Substances 0.000 claims description 9

- 239000000835 fiber Substances 0.000 claims description 5

- 238000013461 design Methods 0.000 claims description 3

- 239000010410 layer Substances 0.000 description 146

- 239000000047 product Substances 0.000 description 50

- 238000004519 manufacturing process Methods 0.000 description 24

- 238000004140 cleaning Methods 0.000 description 21

- 230000008569 process Effects 0.000 description 21

- 229920000459 Nitrile rubber Polymers 0.000 description 19

- 239000000428 dust Substances 0.000 description 17

- 239000000203 mixture Substances 0.000 description 17

- 239000004604 Blowing Agent Substances 0.000 description 15

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 15

- 229910052710 silicon Inorganic materials 0.000 description 15

- 239000010703 silicon Substances 0.000 description 15

- 239000006260 foam Substances 0.000 description 13

- 239000011162 core material Substances 0.000 description 12

- 150000001875 compounds Chemical class 0.000 description 11

- 229920003048 styrene butadiene rubber Polymers 0.000 description 11

- 238000003490 calendering Methods 0.000 description 9

- 239000002174 Styrene-butadiene Substances 0.000 description 8

- 229920006362 Teflon® Polymers 0.000 description 7

- 230000000694 effects Effects 0.000 description 7

- 238000002156 mixing Methods 0.000 description 7

- 239000000654 additive Substances 0.000 description 6

- 230000015572 biosynthetic process Effects 0.000 description 6

- 238000001035 drying Methods 0.000 description 6

- 239000011152 fibreglass Substances 0.000 description 6

- 238000000465 moulding Methods 0.000 description 6

- 239000004809 Teflon Substances 0.000 description 5

- 239000003795 chemical substances by application Substances 0.000 description 5

- 239000004594 Masterbatch (MB) Substances 0.000 description 4

- CBENFWSGALASAD-UHFFFAOYSA-N Ozone Chemical compound [O-][O+]=O CBENFWSGALASAD-UHFFFAOYSA-N 0.000 description 4

- 230000000996 additive effect Effects 0.000 description 4

- 229920000642 polymer Polymers 0.000 description 4

- 230000009467 reduction Effects 0.000 description 4

- 239000004753 textile Substances 0.000 description 4

- 238000005406 washing Methods 0.000 description 4

- 229910000831 Steel Inorganic materials 0.000 description 3

- 229910052782 aluminium Inorganic materials 0.000 description 3

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 3

- 230000008901 benefit Effects 0.000 description 3

- 239000003086 colorant Substances 0.000 description 3

- 230000006835 compression Effects 0.000 description 3

- 238000007906 compression Methods 0.000 description 3

- 238000002844 melting Methods 0.000 description 3

- 230000008018 melting Effects 0.000 description 3

- 239000004745 nonwoven fabric Substances 0.000 description 3

- -1 polyfluoroethylene Polymers 0.000 description 3

- 238000012545 processing Methods 0.000 description 3

- 230000002787 reinforcement Effects 0.000 description 3

- 239000010959 steel Substances 0.000 description 3

- 238000012360 testing method Methods 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- KAKZBPTYRLMSJV-UHFFFAOYSA-N Butadiene Chemical compound C=CC=C KAKZBPTYRLMSJV-UHFFFAOYSA-N 0.000 description 2

- 239000006057 Non-nutritive feed additive Substances 0.000 description 2

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 2

- 230000000844 anti-bacterial effect Effects 0.000 description 2

- 229920003235 aromatic polyamide Polymers 0.000 description 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 2

- 235000019399 azodicarbonamide Nutrition 0.000 description 2

- 239000011203 carbon fibre reinforced carbon Substances 0.000 description 2

- 230000015556 catabolic process Effects 0.000 description 2

- 239000011248 coating agent Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 230000000052 comparative effect Effects 0.000 description 2

- 238000006731 degradation reaction Methods 0.000 description 2

- 239000007789 gas Substances 0.000 description 2

- 230000036541 health Effects 0.000 description 2

- 239000003779 heat-resistant material Substances 0.000 description 2

- 239000001301 oxygen Substances 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- 229920001296 polysiloxane Polymers 0.000 description 2

- 229920000915 polyvinyl chloride Polymers 0.000 description 2

- 239000004800 polyvinyl chloride Substances 0.000 description 2

- 239000003381 stabilizer Substances 0.000 description 2

- 238000003860 storage Methods 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 239000010936 titanium Substances 0.000 description 2

- 229910052719 titanium Inorganic materials 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- 229920002554 vinyl polymer Polymers 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- NBOCQTNZUPTTEI-UHFFFAOYSA-N 4-[4-(hydrazinesulfonyl)phenoxy]benzenesulfonohydrazide Chemical compound C1=CC(S(=O)(=O)NN)=CC=C1OC1=CC=C(S(=O)(=O)NN)C=C1 NBOCQTNZUPTTEI-UHFFFAOYSA-N 0.000 description 1

- 239000004156 Azodicarbonamide Substances 0.000 description 1

- 244000025254 Cannabis sativa Species 0.000 description 1

- 229910019142 PO4 Inorganic materials 0.000 description 1

- 241000135309 Processus Species 0.000 description 1

- 238000005299 abrasion Methods 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 239000003242 anti bacterial agent Substances 0.000 description 1

- 230000002929 anti-fatigue Effects 0.000 description 1

- 230000000845 anti-microbial effect Effects 0.000 description 1

- 239000004599 antimicrobial Substances 0.000 description 1

- 239000003963 antioxidant agent Substances 0.000 description 1

- XOZUGNYVDXMRKW-AATRIKPKSA-N azodicarbonamide Chemical compound NC(=O)\N=N\C(N)=O XOZUGNYVDXMRKW-AATRIKPKSA-N 0.000 description 1

- 230000004888 barrier function Effects 0.000 description 1

- VJRITMATACIYAF-UHFFFAOYSA-N benzenesulfonohydrazide Chemical compound NNS(=O)(=O)C1=CC=CC=C1 VJRITMATACIYAF-UHFFFAOYSA-N 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 238000012669 compression test Methods 0.000 description 1

- 239000012792 core layer Substances 0.000 description 1

- 238000005336 cracking Methods 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 230000002950 deficient Effects 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- HBGGXOJOCNVPFY-UHFFFAOYSA-N diisononyl phthalate Chemical compound CC(C)CCCCCCOC(=O)C1=CC=CC=C1C(=O)OCCCCCCC(C)C HBGGXOJOCNVPFY-UHFFFAOYSA-N 0.000 description 1

- 230000003670 easy-to-clean Effects 0.000 description 1

- 230000001747 exhibiting effect Effects 0.000 description 1

- 239000012467 final product Substances 0.000 description 1

- 238000009408 flooring Methods 0.000 description 1

- 239000006261 foam material Substances 0.000 description 1

- 238000005187 foaming Methods 0.000 description 1

- 230000005021 gait Effects 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 238000007373 indentation Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 239000011229 interlayer Substances 0.000 description 1

- 230000002045 lasting effect Effects 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 230000014759 maintenance of location Effects 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- MVAOEXBRERPGIT-UHFFFAOYSA-N octamine Chemical compound N.N.N.N.N.N.N.N MVAOEXBRERPGIT-UHFFFAOYSA-N 0.000 description 1

- 150000002894 organic compounds Chemical class 0.000 description 1

- 239000007800 oxidant agent Substances 0.000 description 1

- 230000001590 oxidative effect Effects 0.000 description 1

- 238000000059 patterning Methods 0.000 description 1

- 235000021317 phosphate Nutrition 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004014 plasticizer Substances 0.000 description 1

- 229920002635 polyurethane Polymers 0.000 description 1

- 239000004814 polyurethane Substances 0.000 description 1

- 229910021426 porous silicon Inorganic materials 0.000 description 1

- 238000011417 postcuring Methods 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 239000011241 protective layer Substances 0.000 description 1

- 230000003252 repetitive effect Effects 0.000 description 1

- 238000007788 roughening Methods 0.000 description 1

- 229920002379 silicone rubber Polymers 0.000 description 1

- 239000004945 silicone rubber Substances 0.000 description 1

- 230000032258 transport Effects 0.000 description 1

- 238000009966 trimming Methods 0.000 description 1

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C44/00—Shaping by internal pressure generated in the material, e.g. swelling or foaming ; Producing porous or cellular expanded plastics articles

- B29C44/34—Auxiliary operations

- B29C44/58—Moulds

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L23/00—Cleaning footwear

- A47L23/22—Devices or implements resting on the floor for removing mud, dirt, or dust from footwear

- A47L23/24—Rigid cleaning-gratings; Tread plates or scrapers for cleaning the soles of footwear

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L23/00—Cleaning footwear

- A47L23/22—Devices or implements resting on the floor for removing mud, dirt, or dust from footwear

- A47L23/26—Mats or gratings combined with brushes ; Mats

- A47L23/266—Mats

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C44/00—Shaping by internal pressure generated in the material, e.g. swelling or foaming ; Producing porous or cellular expanded plastics articles

- B29C44/02—Shaping by internal pressure generated in the material, e.g. swelling or foaming ; Producing porous or cellular expanded plastics articles for articles of definite length, i.e. discrete articles

- B29C44/04—Shaping by internal pressure generated in the material, e.g. swelling or foaming ; Producing porous or cellular expanded plastics articles for articles of definite length, i.e. discrete articles consisting of at least two parts of chemically or physically different materials, e.g. having different densities

- B29C44/06—Making multilayered articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C59/00—Surface shaping of articles, e.g. embossing; Apparatus therefor

- B29C59/02—Surface shaping of articles, e.g. embossing; Apparatus therefor by mechanical means, e.g. pressing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B25/00—Layered products comprising a layer of natural or synthetic rubber

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/26—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer

- B32B3/30—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer characterised by a layer formed with recesses or projections, e.g. hollows, grooves, protuberances, ribs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2021/00—Use of unspecified rubbers as moulding material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/732—Floor coverings

- B29L2031/7324—Mats

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Carpets (AREA)

- Laminated Bodies (AREA)

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US65378500A | 2000-09-01 | 2000-09-01 | |

| US09/672,152 US6921502B1 (en) | 2000-09-01 | 2000-09-27 | Cushioned rubber floor mat article and method |

| PCT/US2001/026990 WO2002017759A2 (en) | 2000-09-01 | 2001-08-30 | Cushioned rubber floor mat article and method |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2004518456A JP2004518456A (ja) | 2004-06-24 |

| JP2004518456A5 JP2004518456A5 (enExample) | 2005-04-07 |

| JP4209670B2 true JP4209670B2 (ja) | 2009-01-14 |

Family

ID=27096591

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2002522741A Expired - Fee Related JP4209670B2 (ja) | 2000-09-01 | 2001-08-30 | クッション性ゴムフロアマット製品及び方法 |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP1313388A2 (enExample) |

| JP (1) | JP4209670B2 (enExample) |

| CN (1) | CN1449259A (enExample) |

| AU (2) | AU8692101A (enExample) |

| CA (1) | CA2418750A1 (enExample) |

| WO (1) | WO2002017759A2 (enExample) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10326486B4 (de) * | 2003-06-10 | 2014-11-27 | Lory Orthopädie-Schuhtechnik GmbH | Verfahren zum Herstellen einer Schuheinlage |

| JP5498099B2 (ja) * | 2009-08-28 | 2014-05-21 | 株式会社ダスキン | ゴムマットの製造方法 |

| KR101154296B1 (ko) * | 2010-07-13 | 2012-06-13 | 현대자동차주식회사 | 버스용 바닥 매트 및 그 제조 방법 |

| DK2967275T3 (da) * | 2013-03-14 | 2019-07-08 | Cintas Corp Services Inc | Skridsikker måtte med fugtkanaler |

| US20140272278A1 (en) | 2013-03-14 | 2014-09-18 | Cintas Corporation | Slip resistant mat and method and system for making same |

| CN108952119A (zh) * | 2016-07-23 | 2018-12-07 | 薛峰 | 透水地面用平整机 |

| CN107344438A (zh) * | 2017-08-15 | 2017-11-14 | 莆田市七巧板装饰材料有限公司 | 一种缓冲式软地垫 |

| DE102018116084A1 (de) * | 2018-07-03 | 2020-01-09 | Arntz Beteiligungs Gmbh & Co. Kg | Verfahren zur Herstellung eines Keilrippenriemens mit Rippenbeschichtung |

| WO2020055528A1 (en) * | 2018-09-13 | 2020-03-19 | Nike Innovate C.V. | Multi-layered structures and uses thereof |

| US20220064963A1 (en) * | 2020-08-26 | 2022-03-03 | Wearwell, Llc | Integrated mat assembly and method of use |

| CN114573856B (zh) * | 2022-03-07 | 2023-04-07 | 慈溪赛洁日用品有限公司 | 一种改性pvc发泡垫子及其制备方法 |

| CN115873411B (zh) * | 2022-10-26 | 2023-10-13 | 凤阳加松新型材料科技有限公司 | 一种抗病毒硅胶垫的制备方法 |

| CN116281491B (zh) * | 2023-03-07 | 2023-11-07 | 南通鸿图橡塑有限公司 | 一种基于静音电梯的降噪缓冲型橡胶垫及其安装方法 |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1805038A (en) * | 1927-11-11 | 1931-05-12 | Rubber Craft Products Company | Mat |

| DE1154263B (de) * | 1955-11-21 | 1963-09-12 | Helmut Sandler & Co Schulterpo | Vorrichtung zur Herstellung plattenfoermiger Profilteile aus poroesen und elastischen Werkstoffen |

| US3016317A (en) | 1957-06-21 | 1962-01-09 | Brunner Emil | Resilient mat |

| US4207636A (en) * | 1976-09-27 | 1980-06-17 | Tenneco Chemicals, Inc. | Cushion construction |

| US4262048A (en) * | 1979-10-22 | 1981-04-14 | Mitchell Davis M | Heel protector |

| US4377016A (en) * | 1981-09-17 | 1983-03-22 | Vredestein N.V. | Footmat |

| US4710415A (en) * | 1986-09-11 | 1987-12-01 | Compo Industries, Inc. | Reinforced foam anti-fatigue floor tile module and method of making same |

| US4741065A (en) | 1987-03-09 | 1988-05-03 | Milliken Research Corporation | Interlocking dust control mats |

| ES2044109T3 (es) * | 1988-07-11 | 1994-01-01 | Milliken Res Corp | Felpudo con bordes sin salientes. |

| US5305565A (en) | 1991-05-14 | 1994-04-26 | Duskin Co., Ltd. | Floor mat with prevention of waving |

| DE4136647A1 (de) * | 1991-06-22 | 1992-12-24 | Clouth Gummiwerke Ag | Absorptionsmatte, insbesondere fuer organische kohlenwasserstoffe |

| US5170526A (en) | 1992-02-18 | 1992-12-15 | Milliken Research Corporation | Dust control mat with improved cleat |

| US5227214A (en) | 1992-03-27 | 1993-07-13 | Milliken Research Corporation | Anti-creep mat |

| CA2155384A1 (en) | 1994-08-26 | 1996-02-27 | Robert C. Kerr | Launderable floor mats with ozone resistance |

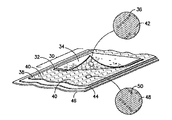

| US6296919B1 (en) * | 1999-08-13 | 2001-10-02 | Milliken & Company | Cushioned carpeted floor mat with at least one cushioning integrated rubber protrusion |

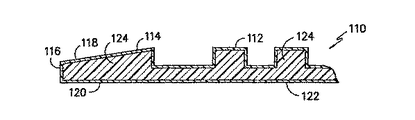

| US6340514B1 (en) * | 1999-08-13 | 2002-01-22 | Milliken & Company | Cushioned rubber floor mat article comprising at least one integrated rubber protrusion and at least two layers of rubber |

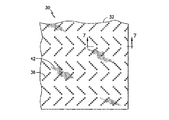

| US6303068B1 (en) * | 1999-09-24 | 2001-10-16 | Milliken & Company | Process of making a cleated floor mat |

| JP5831809B2 (ja) | 2012-03-07 | 2015-12-09 | カシオ計算機株式会社 | 心拍測定装置及びその装着方法 |

-

2001

- 2001-08-30 CA CA002418750A patent/CA2418750A1/en not_active Abandoned

- 2001-08-30 WO PCT/US2001/026990 patent/WO2002017759A2/en not_active Ceased

- 2001-08-30 AU AU8692101A patent/AU8692101A/xx active Pending

- 2001-08-30 EP EP01966402A patent/EP1313388A2/en not_active Withdrawn

- 2001-08-30 CN CN 01814815 patent/CN1449259A/zh active Pending

- 2001-08-30 JP JP2002522741A patent/JP4209670B2/ja not_active Expired - Fee Related

- 2001-08-30 AU AU2001286921A patent/AU2001286921B2/en not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| EP1313388A2 (en) | 2003-05-28 |

| AU8692101A (en) | 2002-03-13 |

| AU2001286921B2 (en) | 2007-01-04 |

| CN1449259A (zh) | 2003-10-15 |

| CA2418750A1 (en) | 2002-03-07 |

| JP2004518456A (ja) | 2004-06-24 |

| WO2002017759A2 (en) | 2002-03-07 |

| WO2002017759A3 (en) | 2002-06-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6921502B1 (en) | Cushioned rubber floor mat article and method | |

| JP2004510497A (ja) | クッション性ゴムフロアマット製品及び方法 | |

| JP3450775B2 (ja) | 少なくとも1つの一体化ゴム突起と少なくとも2つのゴム層を含むクッションゴムフロアマット製品 | |

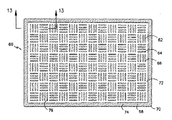

| US6787215B1 (en) | Cleat-forming woven fabric article for the manufacture of anti-creep floor mats | |

| JP2004517650A (ja) | クッション性ゴムフロアマット及び方法 | |

| JP4209670B2 (ja) | クッション性ゴムフロアマット製品及び方法 | |

| US6296919B1 (en) | Cushioned carpeted floor mat with at least one cushioning integrated rubber protrusion | |

| USRE38422E1 (en) | Cushioned carpeted floor mat with at least one cushioning integrated rubber protrusion | |

| AU2001286921A1 (en) | Cushioned rubber floor mat article and method | |

| HK1052953B (en) | Cleat-forming woven fabric article for the manufacture of anti-creep floor mats | |

| AU2001255835B2 (en) | Cleat-forming woven fabric article for the manufacture of anti-creep floor mats | |

| HK1058921A (en) | Flashless rubber floor mat and method | |

| AU2001255835A1 (en) | Cleat-forming woven fabric article for the manufacture of anti-creep floor mats |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050728 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20070410 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20070710 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20070718 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070809 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20080122 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20080422 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20080430 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080722 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20080924 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20081023 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111031 Year of fee payment: 3 |

|

| LAPS | Cancellation because of no payment of annual fees |