JP4046007B2 - Dynamic damper - Google Patents

Dynamic damper Download PDFInfo

- Publication number

- JP4046007B2 JP4046007B2 JP2003146024A JP2003146024A JP4046007B2 JP 4046007 B2 JP4046007 B2 JP 4046007B2 JP 2003146024 A JP2003146024 A JP 2003146024A JP 2003146024 A JP2003146024 A JP 2003146024A JP 4046007 B2 JP4046007 B2 JP 4046007B2

- Authority

- JP

- Japan

- Prior art keywords

- fitting

- elastic body

- rubber elastic

- vibration input

- peripheral surface

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Vibration Prevention Devices (AREA)

Description

【0001】

【発明の属する技術分野】

本発明は、車両等のエンジン又はトランスミッション等に取り付けられるダイナミックダンパに係り、特に内筒金具とその外周側に同軸状に配置された質量金具側との間を振動入力方向に対して直交して径方向に延びて連結するゴム弾性体連結部の剪断変形により振動入力を減衰させるダイナミックダンパに関する。

【0002】

【従来の技術】

従来、この種のダイナミックダンパは、例えば、図10,図11に示すように、内筒金具2と、内筒金具2の外周側に離間して同軸状に配設された外筒金具3と、内外筒金具2,3の対向面間にて振動入力方向(図示上下方向)に対して直交するように径方向に延設されて内外筒金具2,3間を弾性的に連結する厚板状の一対のゴム弾性体連結部4とを備えたゴムブッシュ1と、ゴムブッシュ1の外筒金具3の外周面に中心孔にて圧入によって挿嵌されることにより外筒金具3に固定された筒状の質量金具5とを備えている。このダイナミックダンパは、内筒金具2に加えられる振動入力をゴム弾性体連結部4の剪断変形によって減衰させるものである。同様の構造のダイナミックダンパとしては、例えば特許文献1に開示されている。

【0003】

【特許文献1】

特開2000−337431号公報(第2頁、図1−図4)

【0004】

【発明が解決しようとする課題】

ところで、上記ダイナミックダンパは、振動入力の大きさによって、動バネ特性が変動する性質を備えている。図5に示すように、ゴム弾性体のたわみ(mm)を横軸に、ゴム弾性体に加えられる動荷重(N)を縦軸とすると、ゴム弾性体の振動の1周期ごとに図に示すように閉ループである動荷重−たわみ線図が描かれる。この動荷重−たわみ線図の傾きが動バネ特性を表している。振動入力が小さいすなわち小振幅のときは、ゴム弾性体の動荷重−たわみ線図Aの傾斜が大きくなっており、その動バネ定数が大きいが、振動入力が大きいすなわち大振幅になると、動荷重−たわみ線図Bの傾斜が緩やかになり、その動バネ定数が小さくなる。このような振動入力による動バネ特性の変動が、動バネ特性の振幅依存性と言われている。

【0005】

このように動バネ定数が変動することにより、ダイナミックダンパの共振周波数が変動し、その結果、ダイナミックダンパの振動減衰性能が低下するという問題がある。例えば、振動入力の大きさが1Gのときの共振周波数が100Hzのダイナミックダンパの場合、振動入力の大きさが3Gになると共振周波数が92Hzと大きく低下し、ダイナミックダンパの振動減衰性能が大きく損なわれる結果となる。特に、ダイナミックダンパが、エンジン、トランスミッション等のような加えられる振動入力の大きな部位に適用される場合に、このような共振周波数の変動が問題となる。

【0006】

本発明は上記した問題を解決しようとするもので、車両等から加えられる振動入力の変動に対して、ゴム弾性体連結部の動バネ定数の変動を抑えることにより、共振周波数の変動を小さくして振動減衰性能を適正に発揮できるダイナミックダンパを提供することを目的とする。

【0007】

【課題を解決するための手段】

上記目的を達成するために、上記請求項1に記載の発明の構成上の特徴は、内筒金具と、内筒金具の外周側に離間して同軸状に配置された外筒金具と、内筒金具と外筒金具の対向面間にて振動入力方向に対して直交するように径方向に延設されて内筒金具及び外筒金具間を弾性的に連結し内筒金具に加えられる振動入力を受けて剪断変形する一対のゴム弾性体連結部と、内筒金具及び一対のゴム弾性体連結部を挟んだ振動入力方向の両側にて軸方向に貫通した一対の空間部とを設けたゴムブッシュと、ゴムブッシュの外筒金具の外周面に圧入によって挿嵌されることにより外筒金具に固定された筒状の質量金具とを備えたダイナミックダンパであって、振動入力方向に面した内筒金具の外周面及び外筒金具の内周面の内のいずれか一方に接着されて、空間部内を内筒金具の外周面及び外筒金具の内周面の他方に向けて突出し、突出した先端が他方の面に非接着で当接した一対のゴム弾性体突出部を設け、ゴム弾性体突出部は山形で先端側が断面略三角形に突出したものであり、ゴム弾性体突出部が振動入力に応じて圧縮変形することにより振動入力の変動によるゴム弾性体連結部の動バネ定数の変動を補償するものであり、大振幅時の動バネ特性が小振幅時の動バネ特性に近似したものになることにある。

【0008】

上記のように構成した請求項1の発明においては、ゴム弾性体連結部が内筒金具に加えられる振動入力を受けて剪断変形するのに対して、振動入力方向に面した内筒金具の外周面及び外筒金具の内周面のいずれか一方に固定されて他方に向けて突出したゴム弾性体突出部の先端が、他方の面に非接着で当接しているため、振動入力に応じて圧縮変形するようになっている。そのため、内筒金具に加えられる振動入力が大きくなるにしたがって、振動入力に対して直交方向に延びたゴム弾性体連結部の動バネ定数が小さくなるが、ゴム弾性体突出部の圧縮変形によって、ゴム弾性体連結部の動バネ定数の変動を抑制すなわち補償することができる。

【0009】

具体的には、大振幅の振動入力に対しては、ゴム弾性体突出部が圧縮変形することにより、図5に示すように、ゴム弾性体全体のたわみと振動の動荷重との関係を表す動荷重−たわみ線図Cが、両端側で動荷重が大きくなるように折れ曲り、すなわち従来の線形形状の線図Bから小振幅時の線図A側に曲げられた非線形形状に変形される。そのため、大振幅の振動入力時の動荷重−たわみ線図Cの傾斜が、小振幅時の線図Aの傾斜に近似したものにされ、大振幅時の動バネ特性が小振幅時の特性に近似したものになる。その結果、請求項1の発明においては、振動入力が大きくなっても、ゴム弾性体連結部の動バネ定数の変動が抑えられることにより、ダイナミックダンパの共振周波数の変動が抑えられる。

【0010】

また、ゴム弾性体突出部の先端側が断面略三角形に突出していることにより、振動入力が大きくなるにしたがって、その圧縮変形の程度が徐々に大きくなる。そのため、ゴム弾性体突出部による、ゴム弾性体連結部の動バネ定数の変動を補償する効果が適正に発揮される。

【0011】

また、上記請求項2に記載の発明の構成上の特徴は、内筒金具と、内筒金具の外周側に離間して同軸状に配置された外筒金具と、内筒金具と外筒金具の対向面間にて振動入力方向に対して直交するように径方向に延設されて内筒金具及び外筒金具間を弾性的に連結し内筒金具に加えられる振動入力を受けて剪断変形する一対のゴム弾性体連結部と、内筒金具及び一対のゴム弾性体連結部を挟んだ振動入力方向の両側にて軸方向に貫通した一対の空間部とを設けたゴムブッシュと、ゴムブッシュの外筒金具の外周面に圧入によって挿嵌されることにより外筒金具に固定された筒状の質量金具とを備えたダイナミックダンパであって、振動入力方向に面した内筒金具の外周面及び外筒金具の内周面の内のいずれか一方に接着されて、空間部内を内筒金具の外周面及び外筒金具の内周面の他方に向けて突出し、突出した先端が他方の面に非接着で当接した一対のゴム弾性体突出部を設け、ゴム弾性体突出部は先端側が部分的に突出した小突起部となっており、ゴム弾性体突出部が振動入力に応じて圧縮変形することにより振動入力の変動によるゴム弾性体連結部の動バネ定数の変動を補償するものであり、大振幅時の動バネ特性が小振幅時の動バネ特性に近似したものになることにある。

【0012】

上記のように構成した請求項2の発明においては、上記発明の作用効果に加えて、ゴム弾性体突出部の先端側が部分的に突出した小突起部となっていることにより、振動入力が大きくなるにしたがって、その圧縮変形の程度が徐々に大きくなるため、ゴム弾性体突出部による、ゴム弾性体連結部の動バネ定数の変動を補償する効果が適正に発揮される。

【0013】

【発明の実施の形態】

以下、本発明の実施形態について図面を用いて説明する。図1,図2は、同実施形態である自動車のトランスミッションに固定される取付部材に取り付けられるダイナミックダンパを軸方向断面図及び一部破断側面図により示したものである。図3,図4は、同ダイナミックダンパを構成するゴムブッシュを軸方向断面図及び一部破断側面図により示したものである。

【0014】

ダイナミックダンパは、内筒金具11と、内筒金具11の外方に同軸状に配設された外筒金具13と、内外筒金具11,13の対向面間にて図示上下方向である振動入力方向に対して直交するように水平に径方向に延設されて内外筒金具11,13に接着されて両者間を弾性的に連結する一対のゴム弾性体連結部15と、内筒金具11及びゴム弾性体連結部15を挟んだ振動入力方向両側にて軸方向に貫通した一対の空間部19と、ゴム弾性体連結部15と直交する内筒金具11の外周面に固定されて外筒金具の内周面に向けて空間部19内に突出し、突出した先端が外筒金具13の内周面に非接着で当接した一対のゴム弾性体突出部17とを有するゴムブッシュ10を有しており、外筒金具13の外周面に円筒状の質量金具21が圧入により挿嵌されている。このダイナミックダンパは、内筒金具11に加えられる振動入力に対して、質量金具21の振動に伴うゴム弾性体連結部15及びゴム弾性体突出部17の弾性変形による共振作用によって減衰させるもので、共振周波数として100〜300Hzの周波数域に適用される。なお、ダイナミックダンパの振動入力方向については、図の上下方向に対応するものとする。

【0015】

内筒金具11は、金属製の真直な厚肉パイプであり、その軸孔12の両端側の内周面が全周にわたって切り欠かれて軸方向外方に向けて拡径状態で傾斜した環状の傾斜部12aにされている。傾斜部12aを設けたことにより、棒状部材の内筒金具11へのスムーズな挿嵌が可能になる。外筒金具13は、金属製の真直な薄肉パイプであり、軸方向長さが内筒金具11よりわずかに短く、外径が内筒金具11の外径の略2倍程度になっている。また、外筒金具13は、両端側の外周面が全周にわたって切り欠かれて軸方向外方に向けて縮径状態で傾斜した環状の傾斜部13aにされている。傾斜部13aを設けたことにより、外筒金具13の質量金具21へのスムーズな挿嵌が可能になる。外筒金具13は、内筒金具11の外周側に離間して同軸状にかつ内筒金具11の軸方向両端間にて軸方向に対称に配置されている。

【0016】

ゴム弾性体連結部15は、内外筒金具11,13の対向面間の空間部分を略水平に径方向に延びた厚肉のゴム弾性体であって、その厚さは内筒金具11の外径と略同一になっている。ゴム弾性体連結部15は、外筒金具13との接着部分において、厚肉部分の周方向両端側から周方向に厚肉部分も含めた中心角が略90°になるように広がった薄肉部16になっている。また、ゴム弾性体連結部15は、軸方向両端面が軸方向内方にわずかに湾曲して凹んでいる。一対のゴム弾性体連結部15によって、内外筒金具11,13間の円筒形空間が、内筒金具11及びゴム弾性体連結部15を挟んだ軸方向に貫通した一対の空間部19に仕切られている。

【0017】

ゴム弾性体突出部17は、ゴム弾性体連結部15と直交する内筒金具11の径方向の両外周面から空間部19内に振動入力方向に延びている。ゴム弾性体突出部17は、図3及び図4に示すように、軸方向断面が底角の小さい偏平な等脚台形形状に突出しており、外筒金具近傍位置でさらに底角が小さくなるように折り曲げられて傾斜した偏平な二等辺三角形状になっていると共に、軸直角方向断面が底角の大きな等脚台形形状に突出しており、外筒金具近傍位置で底角がわずかに小さくなるように折り曲げられて傾斜した二等辺三角形になっている。すなわち、ゴム弾性体突出部17は、内筒金具11側の軸方向に長い四角錐台形の基部18aと、基部18aに積み重ねられた外筒金具13側の偏平な四角錐形の先端部18bとにより構成されている。なお、ゴム弾性体突出部17の形状については、これに限らず、単一の四角錐形状であってもよく、さらに先端が突出した類似の形状であってもよい。

【0018】

ゴム弾性体連結部15及びゴム弾性体突出部17は、内筒金具11及び外筒金具13にゴム加硫成形により一体で接着形成されるもので、両金具11,13と共に一体加硫成形品であるゴムブッシュ10を構成している。ゴム加硫成形直後のゴムブッシュ10は、図3及び図4に示すように、ゴム弾性体突出部17の先端部18bの頂部と外筒金具13内周面との間に隙間Gを設けた状態になっている。ゴム加硫成形直後のゴムブッシュ10は、通常は加硫成形後のゴム弾性体の引張歪を除去するために外筒金具13に対して八方絞り等の縮径加工が施される。

【0019】

質量金具21は、厚肉の円筒形の金具であり、その内径が外筒金具13の外径よりわずかに小さく、かつ軸方向長さが外筒金具13の軸方向長さと同等ないしわずかに大きくされている。質量金具21は、中心孔22の軸方向両端側が全周にわたって切り欠かれて軸方向外方に向けて拡径状態で傾斜した環状の傾斜部22aにされており、外筒金具13の質量金具21へのスムーズな挿嵌が可能にされている。

【0020】

質量金具21の中心孔22に、上記縮径加工の施されたゴムブッシュ10が外筒金具13にて圧入によって挿嵌されることにより、外筒金具13がさらに縮径して、質量金具21は外筒金具13の外周面に圧着状態で強固に固定されて、ダイナミックダンパが得られる。このように、外筒金具13が縮径することにより、ゴム弾性体突出部17の先端部18bの頂部と外筒金具13内周面との間の隙間Gが無くされて、両者が非接着で当接した状態となる。また、外筒金具13が質量金具21に圧入されて一体となることにより、外筒金具13も質量金具の一部として機能することになる。なお、縮径加工が施されさらに質量金具21に圧入されて外筒金具13が縮径することにより、ゴム弾性体連結部15が径方向に圧縮されるため、その加硫成形後の収縮による引張歪が除去され、ゴム弾性体が安定状態に維持される。

【0021】

このダイナミックダンパは、ゴム弾性体突出部17を振動入力方向である図示上下方向に向けた状態で、車両のトランスミッションに設けた図示しない取付部材の外周側に、内筒金具11の軸孔12にて圧入によって挿嵌されることにより、取付部材に強固に固定される。

【0022】

上記実施形態においては、ゴム弾性体連結部15と直交して振動入力方向を向いたゴム弾性体突出部17の突出端部である先端部18bの頂部が、外筒金具13の内周面に非接着で当接した状態になっている。そのため、ゴム弾性体連結部15が内筒金具11に加えられる振動入力を受けて剪断変形するのに対して、ゴム弾性体突出部17は、内筒金具11に加えられる振動入力を受けて先端部18b側が徐々に圧縮変形する。そのため、内筒金具11に加えられる振動入力が大きくなるにしたがって、振動入力に対して直交方向に延びたゴム弾性体連結部15の動バネ定数が小さくなるが、ゴム弾性体突出部17の圧縮変形の程度が大きくなる。その結果、図5に示すように、ゴム弾性体全体の動荷重−たわみ線図Cが、両端側で動荷重が大きくなるように折れ曲り、すなわち従来の線形形状の線図Bから小振幅時の線図A側に曲げられた非線形形状に変形される。これにより、大振幅の振動入力時の動荷重−たわみ線図Cの傾斜が、小振幅時の線図Aの傾斜に近似したものにされ、大振幅時の動バネ特性が小振幅時の動バネ特性に近似したものになる。

【0023】

これにより、ゴム弾性体突出部17がゴム弾性体連結部15の動バネ定数の変動を補償し、ゴム弾性体全体としての動バネ定数の変動を抑えることができる。その結果、本実施形態においては、振動入力が大きくなっても、ダイナミックダンパの共振周波数の変動が抑えられ、その振動減衰性能が適正に発揮される。例えば、振動入力の大きさが1Gのときの共振周波数が100Hzのダイナミックダンパの場合、振動入力の大きさが3Gに増大しても、その共振周波数は96Hzとなり、従来例の92Hzに比べてその低下の程度が大幅に抑えられる。そのため、本実施形態のダイナミックダンパは、エンジン、トランスミッション等のような加えられる振動入力の大きな部位に好適に使用される。

【0024】

なお、上記実施形態の変形例として、図6,図7に示すように、ゴム弾性体突出部23を、軸方向に長い外筒金具13内周面近傍まで突出した四角錐台形の基部24に、その先端面の中央から部分的に突出した小突起部25を設けた構成とすることができる。このように、ゴム弾性体突出部23の先端側が小突起部25となっていることにより、振動入力が大きくなるにしたがって、圧縮変形の程度が徐々に大きくなる。そのため、第1実施形態と同様に、ゴム弾性体連結部15の動バネ定数の変動を適正に補償することができる。

【0025】

つぎに、第2実施形態について説明する。

本実施形態においては、上記第1実施形態及び変形例に示したようにゴム弾性体突出部17,23を内筒金具11外周面に設けて、その先端部を外筒金具13の内周面に当接させる代りに、図8,図9に示すように、略四角錐形状の一対のゴム弾性体突出部27を、振動入力方向における外筒金具13の両内周面に接着して空間部19内に突出させ、突出した先端を内筒金具11の両外周面にてゴム弾性体連結部15から延出した薄肉のゴム被覆部15aに非接着で当接させるようにしたものである。このように構成した第2実施形態においても、上記第1実施形態と同様に、振動入力が大きくなっても、ゴム弾性体突出部27によってゴム弾性体連結部15の動バネ定数の変動を適正に補償することができる。その結果、第2実施形態においても、ダイナミックダンパの共振周波数の変動を抑え、ダイナミックダンパの振動減衰性能を適正に発揮させることができる。なお、ゴム弾性体突出部の形状については、上記変形例に示したように、四角錐台部の先端面に小突起部を設けた形状としてもよい。

【0026】

なお、本発明のダイナミックダンパは、車両に限らず、他の同様な用途に使用可能である。その他、上記実施形態に示したダイナミックダンパについては、一例であり、本発明の要旨を逸脱しない範囲において、種々の形態で実施することができる。

【0027】

【発明の効果】

上記請求項1,2の発明によれば、ゴム弾性体連結部と直交する内筒金具の外周面及び外筒金具の内周面のいずれか一方の面に接着固定されたゴム弾性体突出部を設けて、その突出端を他方の面に非接着で当接させたことにより、ゴム弾性体突出部がゴム弾性体連結部の動バネ定数の変動を補償することができ、その結果、ダイナミックダンパの共振周波数の変動が抑えられ、その振動減衰性能が適正に発揮される。

【0028】

また、ゴム弾性体突出部の先端側形状は、断面略三角形に突出させたり、部分的に突出した小突起部とすることにより、ゴム弾性体連結部の動バネ定数の変動を是正する効果が確実に得られる。

【図面の簡単な説明】

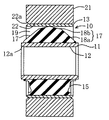

【図1】本発明の第1実施形態であるダイナミックダンパを示す図2のI−I線方向の断面図である。

【図2】同ダイナミックダンパを示す右半分が軸方向中間位置にて破断された一部破断側面図である。

【図3】同ダイナミックダンパのゴムブッシュを示す図4のIII−III線方向の断面図である。

【図4】同ゴムブッシュを示す右半分が軸方向中間位置にて破断された一部破断側面図である。

【図5】ダイナミックダンパの振動入力によるゴム弾性体のたわみと動荷重との関係を概略的に示すグラフである。

【図6】変形例であるダイナミックダンパを示す図6のV−V線方向の断面図である。

【図7】同ダイナミックダンパを示す右半分が軸方向中間位置にて破断された一部破断側面図である。

【図8】第2実施形態であるダイナミックダンパを示す図9のVIII−VIII線方向の断面図である。

【図9】同ダイナミックダンパを示す右半分が軸方向中間位置にて破断された一部破断側面図である。

【図10】従来例であるダイナミックダンパを示す図11のX−X線方向の断面図である。

【図11】同ダイナミックダンパを示す右半分が軸方向中間位置にて破断された一部破断側面図である。

【符号の説明】

10…ゴムブッシュ、11…内筒金具、13…外筒金具、15…ゴム弾性体連結部、17,23,27…ゴム弾性体突出部、18b…先端部、21…質量金具、25…小突起部。[0001]

BACKGROUND OF THE INVENTION

The present invention relates to a dynamic damper attached to an engine or a transmission of a vehicle or the like, and in particular, between an inner cylindrical metal fitting and a mass metal fitting arranged coaxially on the outer peripheral side thereof, orthogonal to the vibration input direction. The present invention relates to a dynamic damper that attenuates vibration input by shear deformation of a rubber elastic body connecting portion that extends in the radial direction and is connected.

[0002]

[Prior art]

Conventionally, this type of dynamic damper includes, for example, as shown in FIGS. 10 and 11, an

[0003]

[Patent Document 1]

JP 2000-337431 A (2nd page, FIGS. 1 to 4)

[0004]

[Problems to be solved by the invention]

By the way, the dynamic damper has a property that the dynamic spring characteristic varies depending on the magnitude of the vibration input. As shown in FIG. 5, when the deflection (mm) of the rubber elastic body is taken on the horizontal axis and the dynamic load (N) applied to the rubber elastic body is taken on the vertical axis, the vibration elastic body is shown in the figure for each period of vibration. Thus, a dynamic load-deflection diagram which is a closed loop is drawn. The inclination of the dynamic load-deflection diagram represents the dynamic spring characteristic. When the vibration input is small, that is, a small amplitude, the slope of the dynamic load-deflection diagram A of the rubber elastic body is large and the dynamic spring constant is large, but when the vibration input is large, that is, a large amplitude, the dynamic load is large. -The inclination of the deflection diagram B becomes gentle and the dynamic spring constant becomes small. Such fluctuation of the dynamic spring characteristics due to vibration input is said to be amplitude dependency of the dynamic spring characteristics.

[0005]

As the dynamic spring constant fluctuates in this way, the resonance frequency of the dynamic damper fluctuates, and as a result, there is a problem that the vibration damping performance of the dynamic damper decreases. For example, in the case of a dynamic damper with a resonance frequency of 100 Hz when the magnitude of the vibration input is 1 G, the resonance frequency is greatly reduced to 92 Hz when the magnitude of the vibration input is 3 G, and the vibration damping performance of the dynamic damper is greatly impaired. Result. In particular, when the dynamic damper is applied to a portion where a large vibration input is applied, such as an engine, a transmission, or the like, such a fluctuation in resonance frequency becomes a problem.

[0006]

The present invention is intended to solve the above-described problem. By suppressing the fluctuation of the dynamic spring constant of the rubber elastic body connecting portion against the fluctuation of the vibration input applied from a vehicle or the like, the fluctuation of the resonance frequency is reduced. It is an object of the present invention to provide a dynamic damper that can properly exhibit vibration damping performance.

[0007]

[Means for Solving the Problems]

In order to achieve the above object, the structural features of the invention described in claim 1 include an inner cylinder fitting, an outer cylinder fitting arranged coaxially and spaced from the outer peripheral side of the inner cylinder fitting, Vibration applied to the inner cylinder fitting by elastically connecting the inner cylinder fitting and the outer cylinder fitting between the opposing surfaces of the cylinder fitting and the outer cylinder fitting so as to be orthogonal to the vibration input direction. Provided with a pair of rubber elastic body connecting portions that receive input and undergo shear deformation, and a pair of space portions that penetrate in the axial direction on both sides of the vibration input direction across the inner cylinder fitting and the pair of rubber elastic body connecting portions A dynamic damper having a rubber bush and a cylindrical mass metal fitting fixed to the outer cylindrical metal fitting by being press-fitted into the outer peripheral surface of the outer cylindrical metal fitting of the rubber bush, facing the vibration input direction Bonded to either the outer peripheral surface of the inner tube bracket or the inner periphery of the outer tube bracket A pair of rubber elastic body protrusions protruding in the space toward the other of the outer peripheral surface of the inner cylindrical fitting and the inner peripheral surface of the outer cylindrical fitting, and the protruding tip non-adhering to the other surface. The rubber elastic body protrusion has a mountain shape and the front end protrudes in a substantially triangular cross section, and the rubber elastic body protrusion is compressed and deformed in response to vibration input, so that the dynamic spring of the rubber elastic body connecting portion due to fluctuations in vibration input This is to compensate for fluctuations in the constant , and the dynamic spring characteristic at the time of large amplitude is approximated to the dynamic spring characteristic at the time of small amplitude .

[0008]

In the invention of claim 1 configured as described above, the rubber elastic body connecting portion undergoes shearing deformation upon receiving vibration input applied to the inner cylinder fitting, whereas the outer periphery of the inner cylinder fitting facing the vibration input direction. The tip of the rubber elastic body protrusion that is fixed to one of the surface and the inner peripheral surface of the outer tube metal fitting and protrudes toward the other is in non-adhesive contact with the other surface, so that it can respond to vibration input. It is designed to be compressed and deformed. Therefore, as the vibration input applied to the inner cylinder fitting increases, the dynamic spring constant of the rubber elastic body connecting portion extending in the direction orthogonal to the vibration input decreases, but due to the compression deformation of the rubber elastic body protruding portion, The fluctuation of the dynamic spring constant of the rubber elastic body connecting portion can be suppressed, that is, compensated.

[0009]

Specifically, for a large amplitude vibration input, the rubber elastic body protrusion is compressed and deformed to represent the relationship between the deflection of the entire rubber elastic body and the dynamic load of vibration, as shown in FIG. The dynamic load-deflection diagram C is bent so that the dynamic load increases at both ends, that is, the conventional linear diagram B is deformed into a non-linear shape bent to the diagram A side at a small amplitude. . For this reason, the inclination of the dynamic load-deflection diagram C at the time of large amplitude vibration input is approximated to the inclination of the diagram A at the time of small amplitude, and the dynamic spring characteristic at the time of large amplitude becomes the characteristic at the time of small amplitude. Approximate. As a result, in the first aspect of the present invention, even if the vibration input is increased, the fluctuation of the dynamic spring constant of the rubber elastic body connecting portion is suppressed, whereby the fluctuation of the resonance frequency of the dynamic damper is suppressed.

[0010]

Further, since the tip end side of the rubber elastic body protruding portion protrudes in a substantially triangular cross section, the degree of the compressive deformation gradually increases as the vibration input increases. Therefore, the effect which compensates the fluctuation | variation of the dynamic spring constant of a rubber elastic body connection part by a rubber elastic body protrusion part is exhibited appropriately.

[0011]

Further, the structural features of the invention described in

[0012]

In the invention of

[0013]

DETAILED DESCRIPTION OF THE INVENTION

Hereinafter, embodiments of the present invention will be described with reference to the drawings. 1 and 2 show a dynamic damper attached to an attachment member fixed to a transmission of an automobile according to the embodiment in an axial sectional view and a partially broken side view. 3 and 4 show a rubber bush constituting the dynamic damper in an axial sectional view and a partially broken side view.

[0014]

The dynamic damper includes an inner

[0015]

The

[0016]

The rubber elastic

[0017]

The rubber elastic

[0018]

The rubber elastic

[0019]

The mass metal fitting 21 is a thick cylindrical metal fitting whose inner diameter is slightly smaller than the outer diameter of the outer cylinder fitting 13 and whose axial length is equal to or slightly larger than the axial length of the

[0020]

When the

[0021]

This dynamic damper is formed in the

[0022]

In the above embodiment, the top of the

[0023]

Thereby, the rubber elastic

[0024]

As a modification of the above-described embodiment, as shown in FIGS. 6 and 7, the rubber elastic

[0025]

Next, a second embodiment will be described.

In the present embodiment, as shown in the first embodiment and the modification, the rubber elastic

[0026]

Note that the dynamic damper of the present invention is not limited to a vehicle and can be used for other similar purposes. In addition, about the dynamic damper shown in the said embodiment, it is an example and can be implemented with a various form in the range which does not deviate from the summary of this invention.

[0027]

【The invention's effect】

According to the first and second aspects of the present invention, the rubber elastic body protruding portion that is bonded and fixed to one of the outer peripheral surface of the inner cylinder fitting and the inner peripheral surface of the outer cylinder fitting orthogonal to the rubber elastic body connecting portion. And the elastic end of the rubber elastic body can compensate for fluctuations in the dynamic spring constant of the connecting portion of the elastic elastic body. The fluctuation of the resonance frequency of the damper is suppressed, and the vibration damping performance is properly exhibited.

[0028]

Moreover, the shape of the tip of the rubber elastic body protruding portion is made to protrude in a substantially triangular cross section or a small protruding portion that partially protrudes, so that the effect of correcting the fluctuation of the dynamic spring constant of the rubber elastic body connecting portion is improved. It is definitely obtained.

[Brief description of the drawings]

1 is a cross-sectional view taken along the line II of FIG. 2, showing a dynamic damper according to a first embodiment of the present invention.

FIG. 2 is a partially broken side view in which a right half showing the dynamic damper is broken at an intermediate position in the axial direction.

3 is a cross-sectional view taken along the line III-III of FIG. 4 showing a rubber bush of the dynamic damper.

FIG. 4 is a partially broken side view in which a right half showing the rubber bush is broken at an intermediate position in the axial direction.

FIG. 5 is a graph schematically showing a relationship between a deflection of a rubber elastic body due to vibration input of a dynamic damper and a dynamic load.

6 is a cross-sectional view taken along the line VV of FIG. 6 showing a dynamic damper according to a modification.

FIG. 7 is a partially broken side view in which the right half of the dynamic damper is broken at an axially intermediate position.

8 is a cross-sectional view taken along line VIII-VIII in FIG. 9 showing a dynamic damper according to a second embodiment.

FIG. 9 is a partially broken side view in which the right half of the dynamic damper is broken at an axially intermediate position.

10 is a cross-sectional view in the XX line direction of FIG. 11 showing a conventional dynamic damper.

FIG. 11 is a partially broken side view in which a right half showing the dynamic damper is broken at an intermediate position in the axial direction.

[Explanation of symbols]

DESCRIPTION OF

Claims (2)

該ゴムブッシュの該外筒金具の外周面に圧入によって挿嵌されることにより該外筒金具に固定された筒状の質量金具とを備えたダイナミックダンパであって、

前記振動入力方向に面した前記内筒金具の外周面及び前記外筒金具の内周面の内のいずれか一方に接着されて、前記空間部内を該内筒金具の外周面及び該外筒金具の内周面の他方に向けて突出し、突出した先端が該他方の面に非接着で当接した一対のゴム弾性体突出部を設け、該ゴム弾性体突出部は山形で先端側が断面略三角形に突出したものであり、該ゴム弾性体突出部が振動入力に応じて圧縮変形することにより振動入力の変動による前記ゴム弾性体連結部の動バネ定数の変動を補償するものであり、大振幅時の動バネ特性が小振幅時の動バネ特性に近似したものになることを特徴とするダイナミックダンパ。An inner cylinder fitting, an outer cylinder fitting arranged coaxially and spaced apart on the outer peripheral side of the inner cylinder fitting, and between the opposing surfaces of the inner cylinder fitting and the outer cylinder fitting so as to be orthogonal to the vibration input direction A pair of rubber elastic body connecting portions that extend in the radial direction and elastically connect between the inner tube fitting and the outer tube fitting and receive a vibration input applied to the inner tube fitting to be subjected to shear deformation, and the inner tube A rubber bush provided with a metal fitting and a pair of space portions penetrating in the axial direction on both sides in the vibration input direction across the pair of rubber elastic body connecting portions;

A dynamic damper comprising a cylindrical mass fitting fixed to the outer cylinder fitting by being press-fitted into the outer peripheral surface of the outer cylinder fitting of the rubber bush;

Adhered to either one of the outer peripheral surface of the inner cylindrical metal fitting and the inner peripheral surface of the outer cylindrical metal fitting facing the vibration input direction, the outer peripheral surface of the inner cylindrical metal fitting and the outer cylindrical metal fitting inside the space portion A pair of rubber elastic body protrusions protruding toward the other of the inner peripheral surface of the inner surface and the protruding tip non-adhering to the other surface are provided, the rubber elastic body protrusions are chevron-shaped and the tip side is substantially triangular in cross section The rubber elastic body protruding portion is compressed and deformed in response to vibration input to compensate for fluctuations in the dynamic spring constant of the rubber elastic body connecting portion due to fluctuations in vibration input , and has a large amplitude. The dynamic damper is characterized in that the dynamic spring characteristic at the time approximates the dynamic spring characteristic at a small amplitude .

該ゴムブッシュの該外筒金具の外周面に圧入によって挿嵌されることにより該外筒金具に固定された筒状の質量金具とを備えたダイナミックダンパであって、

前記振動入力方向に面した前記内筒金具の外周面及び前記外筒金具の内周面の内のいずれか一方に接着されて、前記空間部内を該内筒金具の外周面及び該外筒金具の内周面の他方に向けて突出し、突出した先端が該他方の面に非接着で当接した一対のゴム弾性体突出部を設け、該ゴム弾性体突出部は先端側が部分的に突出した小突起部となっており、該ゴム弾性体突出部が振動入力に応じて圧縮変形することにより振動入力の変動による前記ゴム弾性体連結部の動バネ定数の変動を補償するものであり、大振幅時の動バネ特性が小振幅時の動バネ特性に近似したものになることを特徴とするダイナミックダンパ。An inner cylinder fitting, an outer cylinder fitting arranged coaxially and spaced apart on the outer peripheral side of the inner cylinder fitting, and a direction perpendicular to the vibration input direction between the opposing surfaces of the inner cylinder fitting and the outer cylinder fitting A pair of rubber elastic body connecting portions that extend in the radial direction and elastically connect between the inner tube fitting and the outer tube fitting and receive a vibration input applied to the inner tube fitting to be subjected to shear deformation, and the inner tube A rubber bush provided with a metal fitting and a pair of space portions penetrating in the axial direction on both sides in the vibration input direction across the pair of rubber elastic body connecting portions;

A dynamic damper comprising a cylindrical mass fitting fixed to the outer cylinder fitting by being press-fitted into the outer peripheral surface of the outer cylinder fitting of the rubber bush;

Adhered to either one of the outer peripheral surface of the inner cylindrical metal fitting and the inner peripheral surface of the outer cylindrical metal fitting facing the vibration input direction, the outer peripheral surface of the inner cylindrical metal fitting and the outer cylindrical metal fitting in the space A pair of rubber elastic body protrusions protruding toward the other of the inner peripheral surface of the inner surface and the protruding tip abutting against the other surface in a non-adhesive manner are provided . It has a small protrusion, which the rubber elastic body protruding portion to compensate for variations in the dynamic spring constant of the rubber elastic body connecting part due to variations in the vibration input by compressive deformation in accordance with the vibration input, large A dynamic damper characterized in that a dynamic spring characteristic at an amplitude approximates a dynamic spring characteristic at a small amplitude .

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003146024A JP4046007B2 (en) | 2003-05-23 | 2003-05-23 | Dynamic damper |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003146024A JP4046007B2 (en) | 2003-05-23 | 2003-05-23 | Dynamic damper |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2004347052A JP2004347052A (en) | 2004-12-09 |

| JP4046007B2 true JP4046007B2 (en) | 2008-02-13 |

Family

ID=33533002

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003146024A Expired - Fee Related JP4046007B2 (en) | 2003-05-23 | 2003-05-23 | Dynamic damper |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4046007B2 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4661798B2 (en) * | 2007-02-19 | 2011-03-30 | 東海ゴム工業株式会社 | Dynamic damper and manufacturing method thereof |

| CN110513415A (en) * | 2019-09-24 | 2019-11-29 | 履地科技(天津)有限公司 | A kind of stiffness variable flexural pivot and rigidity-changing method |

-

2003

- 2003-05-23 JP JP2003146024A patent/JP4046007B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2004347052A (en) | 2004-12-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5439203A (en) | Vibration-damping bushing with sliding surface on insert located between inner and outer cylinders | |

| US5257730A (en) | Bound stopper for vehicle suspension having rubber and foam elastic bodies | |

| US20020140146A1 (en) | Cylindrical elastic mount | |

| JP2005180574A (en) | Dynamic damper | |

| US10451133B2 (en) | Tubular vibration-damping device | |

| JPH09280298A (en) | Mount insulator | |

| US20100295224A1 (en) | Tubular vibration-damping mount | |

| JPH09100859A (en) | Suspension bush | |

| JP2001280400A (en) | Upper support for suspension | |

| JP4046007B2 (en) | Dynamic damper | |

| JP2001132795A (en) | Vibration-control device and method of manufacturing the same | |

| JPH10141437A (en) | Cylindrical vibration-proof support body | |

| JP2012127441A (en) | Vibration-proof bush and torque rod comprising the same | |

| JP2002276714A (en) | Vibration isolation device | |

| JP2000249180A (en) | Bushing for leaf spring | |

| JPS634832Y2 (en) | ||

| JP3733306B2 (en) | Cylindrical vibration isolator | |

| JP4205424B2 (en) | Vibration isolator | |

| JP4026609B2 (en) | Cylindrical dynamic damper | |

| JP3428121B2 (en) | Roll mount for engine | |

| JP5396252B2 (en) | Cylindrical vibration isolator | |

| JP3627527B2 (en) | Cylindrical anti-vibration mount | |

| JPH08270698A (en) | Vibration insulation bush | |

| JPS634831Y2 (en) | ||

| JP3740922B2 (en) | Vibration isolator |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20051117 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20070608 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20070619 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070803 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20071030 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20071112 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101130 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111130 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111130 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121130 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131130 Year of fee payment: 6 |

|

| LAPS | Cancellation because of no payment of annual fees |