JP3882577B2 - High-tensile hot-rolled steel sheet excellent in elongation and stretch flangeability, and manufacturing method and processing method thereof - Google Patents

High-tensile hot-rolled steel sheet excellent in elongation and stretch flangeability, and manufacturing method and processing method thereof Download PDFInfo

- Publication number

- JP3882577B2 JP3882577B2 JP2001333375A JP2001333375A JP3882577B2 JP 3882577 B2 JP3882577 B2 JP 3882577B2 JP 2001333375 A JP2001333375 A JP 2001333375A JP 2001333375 A JP2001333375 A JP 2001333375A JP 3882577 B2 JP3882577 B2 JP 3882577B2

- Authority

- JP

- Japan

- Prior art keywords

- hot

- steel sheet

- elongation

- stretch flangeability

- rolled steel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Description

【0001】

【発明の属する技術分野】

本発明は、自動車用足廻り部材の素材に適した伸びおよび伸びフランジ性に優れた高張力熱延鋼板ならびにその製造方法および加工方法に関する。

【0002】

【従来の技術】

環境保護につながる燃費向上の観点から、自動車用熱延鋼板の高強度薄肉化が強く求められている。特に、ホイールや足廻り部材の高強度薄肉化は自動車の燃費向上に極めて有効な手段であるため、これらの部材に対する高強度薄肉化の要望が特に強い。また、ホイールや足廻り部材は複雑な形状であるため、高強度であることに加え伸びおよび伸びフランジ性がともに優れた材料が必要とされている。

【0003】

従来、このような自動車用部材に適用される熱延鋼板が種々提案されている。例えば、特開平4−329848号公報には、フェライトと第2相(パーライト、ベイナイト、マルテンサイト、残留オーステナイトの1種以上)からなる疲労特性と伸びフランジ性の優れた複合組織鋼板が開示されている。しかし、その構成要素に第2相が存在しているため、伸びフランジ性が十分とはいえない。

【0004】

特開平6−172924号公報には、転位密度の高いベイニティック・フェライト組織が生成した伸びフランジ性に優れた鋼板が提案されている。しかし、この鋼板は、転位密度の高いベイニティック・フェライト組織を含むためやはり伸びが十分とはいえない。

【0005】

特開平6−200351号公報には、組織の大部分をポリゴナルフェライトとし、TiCを中心として析出強化および固溶強化により高強度化を図った伸びフランジ性に優れる鋼板が提案されている。しかし、この鋼板に用いられている一般的によく知られた析出物で高張力化するには多量のTi添加を必要とし、寸法の大きい析出物が生成しやすく、特性が不安定になりやすいという欠点がある。

【0006】

特開平7−11382号公報には、微細なTiCおよび/またはNbCが析出したアシキュラー・フェライト組織を有する伸びフランジ性に優れる鋼板が提案されている。しかし、この鋼板も転位密度の高いアシキュラー・フェライト組織であるため伸びフランジ性には優れるものの十分な伸びが得られていない。

【0007】

【発明が解決しようとする課題】

本発明はかかる事情に鑑みてなされたものであって、自動車用足廻り部材のようなプレス時の断面形状が複雑な部材に好適な、伸びおよび伸びフランジ性に優れた高張力熱延鋼板ならびにその製造方法および加工方法を提供することを目的とする。

【0008】

【課題を解決するための手段】

本発明者らは、上記課題を解決すべく鋭意研究を行った結果、以下の知見を得た。

(1)Mo添加により、炭・窒化物が微細に析出する。

(2)延性に富むフェライト組織に、Mo添加により炭・窒化物を微細に析出させると、高張力でありながら優れた伸びおよび伸びフランジ性が得られる。

(3)Ti,Nbを過度に添加すると、析出物が過多となり伸びおよび伸びフランジ性がともに低下する。

(4)良好な伸びを得るためには固溶C量が少ないほど好ましい。

(5)(C/12)/{(Ti/48)+(Mo/96)}が0.5〜1.5を満足するようにC,Ti,Moを添加すると、TiとMoとを含む析出物が微細化する。

(6)Ti、Moと結合しないC量が0.005%以下で材質安定性は向上する。

【0009】

本発明はこれらの知見に基づいてなされたものであり、以下の(1)〜(11)を提供する。

【0012】

(1)質量%で、C≦0.06%、Si≦0.3%、Mn:1〜2%、P≦0.06%、S≦0.005%、Al≦0.06%、N≦0.006%、Mo:0.07〜0.45%、Ti:0.03〜0.10%、Nb≦0.08%を含み、残部がFeおよび不可避的不純物からなり、固溶Cが0.0020%以下であり、TiとMoとを含む炭化物が析出したフェライト組織からなることを特徴とする伸びおよび伸びフランジ性に優れた高張力熱延鋼板。

【0013】

(2)上記(1)において、C、Ti、Moを以下の(1)式を満足するように含有することを特徴とする伸びおよび伸びフランジ性に優れた高張力熱延鋼板。

0.5≦(C/12)/{(Ti/48)+(Mo/96)}≦1.5 …(1)

ただし、上記(1)式中、C、Ti、Moは各成分の質量%を表す。

【0014】

(3)上記(1)において、C、Ti、N、Moを以下の(2)式を満足するように含有することを特徴とする伸びおよび伸びフランジ性に優れた高張力熱延鋼板。

C−[{Ti−(48/14)N}×(12/48)+(12/96)×Mo]≦0.005 …(2)

ただし、上記(2)式中、C、Ti、N、Moは各成分の質量%を表す。

【0016】

(4)上記(1)〜(3)において、質量%で、さらに、Cr≦0.1%を含むことを特徴とする伸びおよび伸びフランジ性に優れた高張力熱延鋼板。

(5)上記(1)〜(4)において、表面に溶融亜鉛系めっき皮膜を有することを特徴とする伸びおよび伸びフランジ性に優れた高張力熱延鋼板。

【0017】

(6)質量%で、C≦0.06%、Si≦0.3%、Mn:1〜2%、P≦0.06%、S≦0.005%、Al≦0.06%、N≦0.006%、Mo:0.07〜0.45%、Ti:0.03〜0.10%、Nb≦0.08%を含み、残部がFeおよび不可避的不純物からなる鋼を溶製し、連続鋳造により鋼スラブとなし、直ちに、または、一旦冷却してから1150℃以上に加熱した後、熱間圧延し、仕上熱間圧延出側温度を850℃以上とし、550℃〜700℃で巻取ることを特徴とする伸びおよび伸びフランジ性に優れた高張力熱延鋼板の製造方法。

【0018】

(7)上記(6)において、前記鋼は、質量%で、さらにCr≦0.1%を含むことを特徴とする伸びおよび伸びフランジ性に優れた高張力熱延鋼板の製造方法。

(8)上記(1)から(5)のいずれかの鋼板からなる部材を準備する第1の工程と、前記部材にプレス成形を施して所望の形状のプレス成形品に加工する第2の工程とを有する高張力熱延鋼板の加工方法。

【0019】

(9)上記(8)において、プレス成形品は、自動車用部品、特に自動車用足廻り部材である高張力熱延鋼板の加工方法。

【0020】

(10)上記(1)から(5)のいずれかに記載の鋼板により製造された自動車用部品。

【0021】

なお、本発明において、炭・窒化物とは、炭化物、窒化物および炭窒化物のいずれか、またはこれらが2種類以上複合したものをいう。

【0022】

【発明の実施の形態】

以下、本発明について成分組成、金属組織および製造条件に分けて具体的に説明する。

【0023】

[成分組成]

本発明における鋼板は、質量%で、C≦0.06%、Si≦0.3%、Mn:1〜2%、P≦0.06%、S≦0.005%、Al≦0.06%、N≦0.006%、Mo:0.07〜0.45%、Ti:0.03〜0.10%、Nb≦0.08%を含む。また、固溶Cが0.0020%以下である。以下、各成分をこのように規定した理由を説明する。

【0024】

C≦0.06%

Cは炭化物を形成し、鋼を強化するのに有効である。しかし、0.06%を超えて添加するとパーライトが形成され、伸びおよび伸びフランジ性を損なうため0.06%以下とする。

【0025】

Si≦0.3%

Siは固溶強化元素として有効である。しかし、0.3%を超えて添加するとフェライトからのC排出が促進されて粒界に粗大な鉄炭化物が析出しやすくなり、伸びフランジ性が低下するため、0.3%以下とする。

【0026】

Mn:1〜2%

Mnは鋼を強化するため1%以上添加する。しかし、2%を超えて添加すると偏析し、かつ硬質相が形成され、伸びおよび伸びフランジ性がともに低下する。したがってMn量を1〜2%の範囲とする。

【0027】

P≦0.06%

Pは固溶強化に有効である。しかし、0.06%を超えて添加すると偏析して伸びおよび伸びフランジ性がともに低下するため0.06%以下とする。

【0028】

S≦0.005%

Sは少ないほど好ましい。0.005%を超えると伸びフランジ性を低下させるため0.005%以下とする。

【0029】

Al≦0.06%

Alは脱酸剤として添加される。しかし、0.06%を超えると伸びおよび伸びフランジ性がともに低下するため0.06%以下とする。

【0030】

N≦0.006%

Nは少ないほど好ましい。0.006%を超えると粗大な窒化物が増え、伸びおよび伸びフランジ性がともに低下するため0.006%以下とする。

【0031】

Mo:0.07〜0.45%

Moは本発明において重要な元素である。0.07%以上添加することでパーライト変態を抑制し、TiまたはTiとNbとを含む炭・窒化物を微細化させ、かつMo自体も炭化物を形成して析出するため、高強度を得つつ伸びフランジ性が向上する。しかし、0.45%を超えて添加すると硬質相が形成され、伸びフランジ性が低下する。したがってMo量を0.07〜0.45%以下とする。

【0032】

Ti:0.03〜0.10%

Tiは本発明において重要な元素である。0.03%以上添加することで炭・窒化物析出による効果が得られ、高強度でありながら伸びおよび伸びフランジ性が向上する。しかし、0.10%を超えてTiを多量に添加するとMoを複合添加しても粗大なTiCが生成しやすくなり、伸びフランジ性が低下する。したがって、Ti量は0.03〜0.10%とする。

【0033】

Nb≦0.08%

Nbは炭・窒化物の析出により高強度でありながら伸びおよび伸びフランジ性を向上させる。しかし、0.08%を超えて添加すると析出物が過多となり、伸びおよび伸びフランジ性が低下するため0.08%以下とする。

【0034】

本発明においては、このように鋼組成、特にC,Ti,Mo量を適正化することにより、後述するように、鋼中Cのほとんどを微細な炭・窒化物として析出させているため、固溶Cは非常に少ない。良好な伸びを得るためには固溶C量が少ないほど好ましく、固溶C量が0.0020%を超えると伸びが低下する傾向にあるため0.0020%以下とする。より好ましくは0.0010%以下である。

【0035】

鋼中のCと(Ti+Mo)との原子数比が0.5〜1.5となるように、C、Ti、Moの含有量を制御すると、TiとMoとを含む炭化物が微細に析出しやすくなる。その結果、高張力でありながら、優れた伸びおよび伸びフランジ性が容易に得られる。したがって、(C/12)/{(Ti/48)+(Mo/96)}の値が以下の(1)式を満たすことが望ましい。

0.5≦(C/12)/{(Ti/48)+(Mo/96)}≦1.5 …(1)

ただし、上記(1)式中、C、Ti、Moは各成分の質量%を表す。

上記(C/12)/{(Ti/48)+(Mo/96)}の値は、0.8〜1.3を満たすことがより望ましい。

【0036】

TiとMoとを含む炭化物を形成しないC量が0.005%を超える場合、材質のばらつきが大きくなる傾向がある。また、Tiは、Nと結合した後の残余がCと結合する。したがって、以下の(2)式を満たすことが好ましい。

C−[{Ti−(48/14)N}×(12/48)+(12/96)×Mo]≦0.005 …(2)

ただし、上記(2)式中、C、Ti、N、Moは各成分の質量%を表す。

このことを実験結果で説明する。

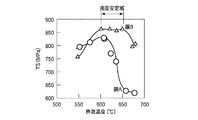

C=0.050%、Si=0.21%、Mn=1.61%、Ti=0.083%、N=0.0036%、Mo=0.20%を含む鋼A(上記(2)式のC−[{Ti−(48/14)N}×(12/48)+(12/96)×Mo]の値(以下、B値という)が0.0073)と、C=0.040%、Si=0.03%、Mn=1.34%、Ti=0.095%、N=0.0040%、Mo=0.24%を含む鋼B(B値が0以下)を用いて熱延鋼板を作成した。仕上温度は910℃と、巻取温度を550〜700℃まで変化させ、巻取温度と強度との関係を調査した。強度(TS)は、JIS5号試験片で測定した。これにより、コイル内で巻取温度が変化したときに強度が変化するかどうかがわかる。すなわち、巻取温度の依存性が強い場合、小さい巻取温度の変動で強度が著しく変化することとなる。

【0037】

調査結果を図1に示す。図1に示すように、Ti、Moと結合しないC(A値)が0.005%を超える鋼Aでは、TSの巻き取り温度依存性が著しいことがわかる。

【0038】

次に、C=0.040〜0.055%、Si=0.2%、Mn=1.6%、Ti=0.080〜0.090%、Mo=0.10〜0.20%、N=0.0020%の鋼を用いて、巻取温度を650℃で一定として熱間圧延を行い、上記B値とTSとの関係を求めた。その結果を図2に示す。図2に示すように、B値が0.005%以上になるとTSが低下する傾向が大きくなることがわかる。

【0039】

なお、Crはパーライト変態を抑制し、伸びフランジ性を高める作用を有するので0.1%以下の範囲で添加してもよい。0.1%以下とするのは、0.1%を超えて添加すると硬質相が形成され、伸びフランジ性が低下するためである。

【0040】

また、残部はFeおよび不可避的な不純物である。

【0041】

[金属組織]

本発明では、優れた伸びおよび伸びフランジ性を確保するため、TiもしくはTiとNbの炭・窒化物およびMoの炭化物がそれぞれ単独でおよび/または複合化して析出したフェライト組織としている。すなわち、延性に富むフェライト組織に適正量の炭・窒化物を析出させることで優れた伸びおよび伸びフランジ性の両立が可能となる。

【0042】

なお、TiもしくはTiとNbの炭・窒化物およびMoの炭化物がそれぞれ単独でおよび/または複合化して析出する形態としては、Tiの炭化物およびMoの炭化物がそれぞれ単独でおよび/または複合化して析出するものが好ましい。特に、これらが複合化したTiとMoとを含む炭化物が析出することが望ましい。TiとMoとを含む炭化物は微細かつ均一に分散析出することから、高張力と優れた伸びおよび伸びフランジ性との両立が容易となる。

【0043】

また、上述したように、本発明鋼板は鋼組成、特にC,Ti,Mo量を適正化し、鋼中Cのほとんどを微細な炭・窒化物として析出させているため、固溶Cは非常に少ないが、良好な伸びを得るためには固溶C量がより少ないほど好ましく、固溶C量が0.0020%を超えると伸びが低下する傾向にあるため0.0020%以下、好ましくは0.0010%以下とする。

【0044】

本発明の高張力熱延鋼板には、表面に溶融亜鉛系めっき皮膜を形成し、溶融亜鉛系めっき鋼板としたものも含む。本発明の高張力熱延鋼板は良好な伸びおよび伸びフランジ性を有することから、溶融亜鉛系めっき皮膜を形成しても良好な伸びおよび伸びフランジ性を維持することができる。ここで、溶融亜鉛系めっきとは、亜鉛および亜鉛を主体とした溶融めっきであり、亜鉛の他にAl、Cr等の合金元素を含んだものを含む。このような溶融亜鉛系めっきを施した本発明の高張力熱延鋼板は、めっきままでもめっき後合金化処理を行ってもかまわない。

【0045】

[製造条件]

本発明の熱延鋼板は、上記成分組成を有する鋼を溶製し、連続鋳造により鋼スラブとなし、直ちに、または、一旦冷却してから1150℃以上に加熱した後、熱間圧延し、仕上熱間圧延出側温度を850℃以上とし、550℃〜700℃で巻取ることによって製造される。

【0046】

・鋼スラブを直ちに、または一旦冷却してから1150℃以上に加熱後、熱間圧延

熱間圧延後に、TiもしくはTiとNbの炭・窒化物およびMoの炭化物をそれぞれ単独でおよび/または複合化して析出させるために、特に、Tiの炭化物とMoの炭化物が複合化したTiとMoとを含む炭化物を析出させるために、熱間圧延前のスラブ段階ではTi,NbおよびMoを固溶させる必要があるため、鋼スラブを直ちに熱間圧延するか、または一旦冷却してから1150℃以上に加熱後熱間圧延する。つまり、スラブ製造後はTi,NbおよびMoは固溶しているため直ちに熱間圧延する場合は固溶状態が保たれているが、一旦冷却した場合には粗大な析出物が形成されるので1150℃以上に加熱してTi,NbおよびMoを再度固溶させる必要がある。

【0047】

・仕上熱間圧延出側温度:850℃以上

伸びおよび伸びフランジ性を確保するため、仕上熱間圧延出側温度を850℃以上とする。850℃未満とした場合、表層が粗大粒となり伸びおよび伸びフランジ性が損なわれる。

【0048】

・巻取温度:550℃〜700℃

フェライト組織を得るため、巻取温度を550℃〜700℃とする。550℃未満では転位密度の高い組織となるため伸びが低下し、700℃を超えるとTi,NbおよびMoによる析出強化の効果が小さくなる。さらに望ましくは600〜660℃である。巻取温度を600〜660℃とすると、強度と伸びおよび伸びフランジ性とのバランスがさらに良好となる。

【0049】

熱延鋼板製造後に溶融亜鉛系めっき処理を施す場合には、常法にしたがって行えばよいが、めっき前焼鈍温度については、450℃未満ではめっきがつかず、750℃超えでは強度低下が生じやすい。そのため、焼鈍温度は450℃以上、750℃以下が好ましい。

【0050】

なお、本発明の熱延鋼板は、スケールのついた状態でも酸洗材でもその特性に差異はない。調質圧延についても通常行われる条件であれば問題はない。また、上記溶融亜鉛めっきは、酸洗後であってもスケールのついたままであってもよい。電気めっきを施したものでもかまわず、化成処理を施したものであっても特に問題はない。鋳造後直ちにまたは補熱を目的とした加熱を施した後にそのまま熱間圧延を行う直送圧延を行ったものであっても本発明の効果に影響はない。また、粗圧延後に仕上圧延前もしくは仕上圧延中に圧延材を加熱または保熱しても、粗圧延後に圧延材を接合して行う連続圧延を行っても、また、圧延材の加熱と連続圧延とを同時に行っても本発明の効果は損なわれない。

【0051】

本発明の熱延鋼板は、伸びおよび伸びフランジ性に優れているのでこれをプレス成形した場合、その特質が活かされ、自動車用部材、特にサスペンションアーム等の足廻り部材のようなプレス時の断面形状が複雑な部材を良好な品質で製造することができ、特に、プレス成形品の軽量化に資することができる。以下に具体的に、本発明に係る熱延鋼板の加工方法、換言すればプレス成形品の製造方法について説明する。

【0052】

図3は、本発明に係る熱延鋼板の加工方法の作業フローの一例を示すフローチャートである。この作業フローは、通常、本発明に係る鋼板を製造することまたはその製造された鋼板を例えばコイルにして目的場所に搬送することを前工程としており、まず、本発明に係る熱延鋼板を準備することから始まる(S0、S1)。この鋼板に対してプレス加工を施す前に、鋼板に対して前処理的な加工を施すこともあれば(S2)、裁断機により所定の寸法や形状に加工することもある(S3)。前者のS2の工程では、例えば鋼板の幅方向の所定箇所に切り込みや穿孔を行い、引き続くプレス加工を終えた段階またはそのプレス加工の過程で、所定の寸法および形状のプレス成形品または被プレス加工部材として切り離すことができるようにしておく。後者のS3の工程では、最終的なプレス成形品の寸法、形状等を予め考慮して、所定の寸法および形状の鋼板部材に加工(したがって裁断)するようにしておく。その後、S2およびS3の工程を経由した部材には、プレス加工が施され、最終的に目的とする寸法・形状の所望のプレス成形品が製造される(S4)。このプレス加工は、通常は多段階で行われ、3段階以上7段階以下であることが多い。

【0053】

S4の工程は、S2およびS3の工程を経由した部材に対してさらに所定の寸法や形状に裁断する工程を含む場合もある。この場合の「裁断」という作業は、例えば、少なくともプレス加工の過程で、S2およびS3の工程を経由した部材の端部のような最終的なプレス成形品には不要部分を切り離す作業であっても構わないし、また、S2の工程で設けられた鋼板の幅方向の切り込みや穿孔に沿って被プレス加工部材を切り離す作業であっても構わない。

【0054】

なお、図3中、N1ないしN3は、鋼板、部材、プレス成形品を、機械的にあるいは作業員による搬送作業である場合がある。

【0055】

こうして製造されるプレス成形品は、必要に応じて次工程に送られる。次工程としては、例えば、プレス成形品に更に機械加工を施し、寸法や形状を調整する工程、プレス成形品を所定場所に搬送し、格納する工程、プレス成形品に表面処理を施す工程、プレス成形品を用いて自動車のような目的物を組み立てる組立工程がある。

【0056】

図4は、図3に示した作業を実際に行う装置と鋼板、部材、プレス成形品の流れとの関係を示すブロック図である。この図においては、本発明に係る熱延鋼板はコイル状で準備されており、プレス加工機によりプレス成形品が製造される。プレス加工機は多段プレスを行う機種のものであるが、本件発明はこれに限定されない。

【0057】

プレス加工機の前段に、裁断機その他の前処理機械を設置する場合(図4の(a))もあれば、設置しない場合(図4の(b))もある。裁断機が設置される場合には、コイルから供給される長尺の本発明に係る鋼板から、必要な寸法又は形状の部材を裁断し、この部材がプレス加工機においてプレス加工され、所定のプレス成形品となる。鋼板の幅方向に切り欠きや穿孔を施す前処理機械が設置される場合には、プレス加工機においてその切り欠きや穿孔に沿って裁断が行われても構わない。前処理機械を設置しない場合には、プレス加工機において鋼板がプレス加工される過程で、裁断が行われ、最終的に所定の寸法、形状を有するプレス成形品が製造される。なお、図4における「裁断」の意味は、図3における裁断と同じである。

【0058】

こうして製造されるプレス成形品は、その原材料として伸び及び伸びフランジ性に優れている本発明に係る鋼板を使用しているので、プレス時の断面形状が複雑であっても、良好な品質で製造することができ、軽量なものとなる。このような特長は、プレス成形品が自動車用部材、特にサスペンションアーム等の足廻り部材である場合に特に有用である。

【0059】

【実施例】

[実施例1]

表1に示す化学成分を有する鋼を、表2に示す製造条件を用いて板厚3.2mmの熱延鋼板とした。表1において、A値は上記(1)式の(C/12)/{(Ti/48)+(Mo/96)}の値、B値は上記(2)式のC−[{Ti−(48/14)N}×(12/48)+(12/96)×Mo]の値を示す。また、表2においてSRTはスラブ加熱温度であり、FTは仕上熱間圧延出側温度、およびCTは巻取温度である。

【0060】

得られた熱延鋼板を酸洗後、JIS5号引張試験片および穴広げ試験片を採取し、引張試験および穴広げ試験を実施するとともに、光学顕微鏡および走査型電子顕微鏡(SEM)で金属組織を確認した。穴広げ試験は130mm角の鋼板の中央に10mmφのポンチによりクリアランス12.5%で打ち抜いた穴を有する試験片を準備し、60°円錐ポンチにより打ち抜き穴のバリ側の反対方向から押し上げる方法で行った。また、鋼板から作製した薄膜を透過型電子顕微鏡(TEM)によって観察し析出物を確認した。また、析出物の成分をTEMに装備されたエネルギー分散型X線分光装置(EDX)により分析した。

【0061】

金属組織および試験結果を表2に併記する。試験結果の評価については、引張強さ(TS)が780MPa以上、伸び(El)が20%以上かつ穴広げ率(λ)が70%以上を良好とした。

【0062】

表2に示すように、No.1〜3および5〜15の鋼板は、成分組成が本発明の範囲で、金属組織も本発明の範囲内である適正な量のTiとMoとを含む炭化物が析出したフェライト組織であった。このため伸びおよび伸びフランジ性がともに優れた結果が得られている。なお、図5に、No.2の鋼板の透過型電子顕微鏡写真を示す。この写真から、微細なTiとMoとを含む炭化物がフェライト単相組織中に均一に分散していることがわかる。

【0063】

これに対して、No.4の鋼板は、CTが低いため転位密度の高いベイナイト組織となりElが低く、No.16〜18,20の熱延鋼板は、第2相であるパーライトまたはマルテンサイトが形成され、伸びおよび伸びフランジ性がともに低く、No.19の鋼板はMoの添加量が少ないためTi,Nbの炭・窒化物が微細とならず、かつ、Mo炭化物の析出もほとんどないためλが低く、No.21の鋼板はTi添加量が少なくTiの炭・窒化物が少ないためTS、λが低く、No.22〜26の鋼板はTiまたはNbまたはこれらの両方の添加量が多すぎるため、析出物量が過多となり、El、λともに低くなっている。

【0064】

【表1】

【0065】

【表2】

【0066】

[実施例2]

表1の鋼種A,F,MおよびVのスラブを準備し、そのスラブを1250℃に加熱後、仕上熱間圧延出側温度890℃で熱間圧延した後、巻取温度630℃として板厚3.0mmの鋼板を作製した。得られた鋼板からJIS5号引張試験片を採取し、引張試験を行った。また、固溶C量を内部摩擦測定により決定した。固溶C量と、引張試験により測定されたElとの関係を図6に示す。

【0067】

図6から、固溶C量を0.0020%以下とすることで伸びが良好となることが確認される。

【0068】

[実施例3]

表3に示す鋼を溶解し、仕上げ温度920℃、巻き取り温度610℃で熱間圧延を行い、板圧1.8mmの熱延鋼板を製造した。得られた熱延鋼板を酸洗後、合金化溶融亜鉛めっきを行った。亜鉛めっき板よりJIS5号引張試験片および穴広げ試験片を採取し、引張試験および穴広げ試験を実施するとともに、光学顕微鏡および走査型電子顕微鏡(SEM)で金属組織を確認し、析出物の成分を透過型顕微鏡(TEM)に装備されたエネルギー分散型X線分光装置(EDX)により分析した。その際のTS、El、λの値を表3に併記する。なお、表3中のA値、B値は表1と同様である。

【0069】

表3に示すように、本発明例であるNo.27は、合金化溶融亜鉛めっきを行っても優れた伸びおよび伸びフランジ性を示したが、比較例であるNo.28はMoを含有していないため、析出物がMoを含まないものとなり、伸びフランジ性が著しく低い値となった。

【0070】

【表3】

【0071】

[実施例4]

表4に示す成分組成の鋼を仕上げ温度910℃、巻取温度600℃と650℃で熱間圧延を行った。得られた板厚3.2mmの鋼板の組織を確認し、析出物の分析を行った後、鋼板よりJIS5号引張試験片を作成して引張試験を行った。600℃巻取材と650℃巻取材とでTSの差をとり、巻き取り温度依存性を調査した。結果を表4に併記する。なお、表4に示すNo.29〜32は、いずれもフェライト組織に本発明の炭化物が析出した組織を有していた。

【0072】

表4に示すように、B値が0.005%以下で上記(2)式を満たすNo.29〜31はTSの差は小さく、巻取温度依存性が小さいが、上記(2)式を満たさないNo.32は巻取温度依存性が大きいことが確認された。

【0073】

【表4】

【0074】

【発明の効果】

以上説明したように、本発明によれば、成分組成を適切に調整することにより、微細な炭・窒化物が析出したフェライト組織を形成するので、伸びおよび伸びフランジ性に優れた高張力熱延鋼板を提供することができる。したがって、本発明は、自動車用足廻り部材の軽量化に大いに寄与するものである。

【図面の簡単な説明】

【図1】巻取温度とTSとの関係を示すグラフ。

【図2】C−[{Ti−(48/14)N}×(12/48)+(12/96)×Mo]の値とTSとの関係を示すグラフ。

【図3】本発明に係る熱延鋼板の加工方法の作業フローの一例を示すフローチャート。

【図4】図3に示した作業を実際に行う装置と鋼板、部材、プレス成形品の流れとの関係を示すブロック図。

【図5】本発明に係る高張力熱延鋼板の金属組織を示す透過型電子顕微鏡写真。

【図6】固溶C量と、引張試験により測定されたElとの関係を示すグラフ。[0001]

BACKGROUND OF THE INVENTION

The present invention relates to a high-tensile hot-rolled steel sheet excellent in elongation and stretch flangeability suitable for a material for an automobile suspension member, and a manufacturing method and a processing method thereof.

[0002]

[Prior art]

From the viewpoint of improving fuel efficiency leading to environmental protection, there is a strong demand for high-strength and thin-walled hot-rolled steel sheets for automobiles. In particular, the high strength and thinning of wheels and suspension members is an extremely effective means for improving the fuel efficiency of automobiles. Therefore, there is a strong demand for reduction of the strength and thickness of these members. Further, since the wheel and the suspension member have a complicated shape, a material that is excellent in both elongation and stretch flangeability in addition to high strength is required.

[0003]

Conventionally, various hot-rolled steel sheets applied to such automobile members have been proposed. For example, Japanese Unexamined Patent Publication No. 4-329848 discloses a steel sheet having a composite structure having excellent fatigue characteristics and stretch flangeability composed of ferrite and a second phase (one or more of pearlite, bainite, martensite, and retained austenite). Yes. However, since the second phase exists in the constituent elements, the stretch flangeability is not sufficient.

[0004]

Japanese Patent Laid-Open No. 6-172924 proposes a steel sheet having excellent stretch flangeability formed by a bainitic ferrite structure having a high dislocation density. However, since this steel sheet contains a bainitic ferrite structure having a high dislocation density, it cannot be said that the elongation is sufficient.

[0005]

Japanese Patent Laid-Open No. 6-200351 proposes a steel sheet having excellent stretch flangeability, in which most of the structure is polygonal ferrite and the strength is increased by precipitation strengthening and solid solution strengthening centering on TiC. However, in order to increase the tension with generally well-known precipitates used in this steel plate, it is necessary to add a large amount of Ti, and precipitates having large dimensions are likely to be formed, and the characteristics are likely to be unstable. There is a drawback.

[0006]

Japanese Patent Laid-Open No. 7-11382 proposes a steel sheet having an acicular ferrite structure in which fine TiC and / or NbC is precipitated and having excellent stretch flangeability. However, since this steel sheet also has an acicular ferrite structure with a high dislocation density, it is excellent in stretch flangeability but is not sufficiently stretched.

[0007]

[Problems to be solved by the invention]

The present invention has been made in view of such circumstances, and is suitable for a member having a complicated cross-sectional shape at the time of pressing, such as an automobile suspension member, and a high-tensile hot-rolled steel sheet excellent in elongation and stretch flangeability, and It aims at providing the manufacturing method and the processing method.

[0008]

[Means for Solving the Problems]

As a result of intensive studies to solve the above problems, the present inventors have obtained the following knowledge.

(1) By adding Mo, charcoal / nitride precipitates finely.

(2) When carbon and nitride are finely precipitated by adding Mo to a ductile structure rich in ductility, excellent elongation and stretch flangeability can be obtained while being high tension.

(3) When Ti and Nb are added excessively, precipitates become excessive, and both elongation and stretch flangeability deteriorate.

(4) In order to obtain good elongation, the smaller the amount of dissolved C, the better.

(5) When C, Ti, and Mo are added so that (C / 12) / {(Ti / 48) + (Mo / 96)} satisfies 0.5 to 1.5, a precipitate containing Ti and Mo Becomes finer.

(6) The amount of C not bonded to Ti or Mo is0.005Material stability improves at less than%.

[0009]

The present invention has been made based on these findings and provides the following (1) to (11).

[0012]

(1) By mass%, C ≦ 0.06%, Si ≦ 0.3%, Mn: 1 to 2%, P ≦ 0.06%, S ≦ 0.005%, Al ≦ 0.06%, N ≦ 0.006%, Mo: 0.07 to 0.45%, Ti: 0.03 to 0.10%, Nb ≦ 0.08% included,The balance consists of Fe and inevitable impurities,A high-strength hot-rolled steel sheet excellent in elongation and stretch flangeability, characterized by comprising a ferrite structure in which solid solution C is 0.0020% or less and carbide containing Ti and Mo is precipitated.

[0013]

(2A high-tensile hot-rolled steel sheet excellent in elongation and stretch flangeability, characterized in that, in (1) above, C, Ti, and Mo are contained so as to satisfy the following expression (1).

0.5 ≦ (C / 12) / {(Ti / 48) + (Mo / 96)} ≦ 1.5 (1)

However, in said Formula (1), C, Ti, and Mo represent the mass% of each component.

[0014]

(3A high-tensile hot-rolled steel sheet excellent in elongation and stretch flangeability, characterized in that in the above (1), C, Ti, N, and Mo are contained so as to satisfy the following expression (2).

C − [{Ti− (48/14) N} × (12/48) + (12/96) × Mo] ≦ 0.005 (2)

However, in said Formula (2), C, Ti, N, and Mo represent the mass% of each component.

[0016]

(4) A high-tensile hot-rolled steel sheet excellent in elongation and stretch flangeability, characterized in that, in (1) to (3) above, the composition further contains Cr ≦ 0.1% by mass.

(5) Above (1)-(4), A high-tensile hot-rolled steel sheet excellent in elongation and stretch flangeability, characterized by having a hot-dip galvanized film on the surface.

[0017]

(6)% By mass, C ≦ 0.06%, Si ≦ 0.3%, Mn: 1-2%, P ≦ 0.06%, S ≦ 0.005%, Al ≦ 0.06%, N ≦ 0 0.006%, Mo: 0.07 to 0.45%, Ti: 0.03 to 0.10%, Nb ≦ 0.08% includedThe remainder consists of Fe and inevitable impuritiesSteel is melted and formed into a steel slab by continuous casting. Immediately or after cooling, the steel is heated to 1150 ° C. or higher and then hot-rolled to a finish hot rolling outlet temperature of 850 ° C. or higher. A method for producing a high-strength hot-rolled steel sheet excellent in elongation and stretch flangeability, characterized by winding at a temperature of from 700C to 700C.

[0018]

(7) The method for producing a high-tensile hot-rolled steel sheet excellent in elongation and stretch flangeability, characterized in that, in the above (6), the steel contains mass% and further contains Cr ≦ 0.1%.

(8) From (1) to (5) Processing of a high-tensile hot-rolled steel sheet having a first step of preparing a member made of any one of the steel plates and a second step of pressing the member into a press-formed product having a desired shape Method.

[0019]

(9)the above(8), The press-formed product is a method for processing a high-tensile hot-rolled steel sheet, which is an automobile part, particularly an automobile suspension member.

[0020]

(10) From (1) to (5) An automotive part manufactured from the steel sheet according to any of the above.

[0021]

In the present invention, carbon / nitride refers to any of carbide, nitride and carbonitride, or a combination of two or more of these.

[0022]

DETAILED DESCRIPTION OF THE INVENTION

Hereinafter, the present invention will be specifically described by dividing it into component composition, metal structure and production conditions.

[0023]

[Ingredient composition]

The steel plate in the present invention ismass%, C ≦ 0.06%, Si ≦ 0.3%, Mn: 1 to 2%, P ≦ 0.06%, S ≦ 0.005%, Al ≦ 0.06%, N ≦ 0.006 %, Mo: 0.07 to 0.45%, Ti: 0.03 to 0.10%, Nb ≦ 0.08%Including. Further, the solid solution C is 0.0020% or less.. Hereinafter, the reason why each component is defined in this way will be described.

[0024]

C ≦ 0.06%

C forms carbides and is effective in strengthening steel. However, if added over 0.06%, pearlite is formed, and the elongation and stretch flangeability are impaired.

[0025]

Si ≦ 0.3%

Si is effective as a solid solution strengthening element. However, if added over 0.3%, C discharge from the ferrite is promoted, and coarse iron carbide tends to precipitate at the grain boundaries, and the stretch flangeability deteriorates.

[0026]

Mn: 1-2%

Mn is added at 1% or more to strengthen the steel. However, if added over 2%, segregation occurs, a hard phase is formed, and both elongation and stretch flangeability deteriorate. Therefore, the amount of Mn is made into the range of 1-2%.

[0027]

P ≦ 0.06%

P is effective for solid solution strengthening. However, if added over 0.06%, segregation occurs and elongation and stretch flangeability both decrease, so the content is made 0.06% or less.

[0028]

S ≦ 0.005%

The smaller the S, the better. If it exceeds 0.005%, the stretch flangeability is deteriorated, so the content is made 0.005% or less.

[0029]

Al ≦ 0.06%

Al is added as a deoxidizer. However, if it exceeds 0.06%, both elongation and stretch flangeability deteriorate, so the content is made 0.06% or less.

[0030]

N ≦ 0.006%

The smaller N, the better. If it exceeds 0.006%, coarse nitrides increase, and both elongation and stretch flangeability deteriorate, so the content is made 0.006% or less.

[0031]

Mo: 0.07 to 0.45%

Mo is an important element in the present invention. Addition of 0.07% or more suppresses pearlite transformation, refines the carbon / nitride containing Ti or Ti and Nb, and also forms a carbide and precipitates Mo itself, thereby obtaining high strength. Stretch flangeability is improved. However, if added over 0.45%, a hard phase is formed, and stretch flangeability deteriorates. Therefore, the Mo amount is set to 0.07 to 0.45% or less.

[0032]

Ti: 0.03-0.10%

Ti is an important element in the present invention. By adding 0.03% or more, the effect of carbon / nitride precipitation is obtained, and the elongation and stretch flangeability are improved while being high strength. However, if Ti is added in a large amount exceeding 0.10%, coarse TiC is likely to be generated even if Mo is added together, and stretch flangeability is deteriorated. Therefore, the Ti content is 0.03 to 0.10%.

[0033]

Nb ≦ 0.08%

Nb improves elongation and stretch flangeability while being high strength by precipitation of charcoal and nitride. However, if added over 0.08%, the amount of precipitates becomes excessive, and elongation and stretch flangeability deteriorate, so the content is made 0.08% or less.

[0034]

In the present invention, by optimizing the steel composition, in particular, the amount of C, Ti, and Mo, as described later, most of the C in the steel is precipitated as fine carbon / nitride. There is very little melt C. In order to obtain good elongation, the smaller the amount of dissolved C, the better. The amount of dissolved C exceeds 0.0020%, and the elongation tends to decrease. More preferably, it is 0.0010% or less.

[0035]

When the content of C, Ti, and Mo is controlled so that the atomic ratio between C and (Ti + Mo) in the steel is 0.5 to 1.5, carbides containing Ti and Mo precipitate finely. It becomes easy. As a result, excellent elongation and stretch flangeability can be easily obtained while having high tension. Therefore, it is desirable that the value of (C / 12) / {(Ti / 48) + (Mo / 96)} satisfies the following expression (1).

0.5 ≦ (C / 12) / {(Ti / 48) + (Mo / 96)} ≦ 1.5 (1)

However, in said Formula (1), C, Ti, and Mo represent the mass% of each component.

The value of (C / 12) / {(Ti / 48) + (Mo / 96)} more preferably satisfies 0.8 to 1.3.

[0036]

When the amount of C that does not form a carbide containing Ti and Mo exceeds 0.005%, the material variation tends to increase. Further, Ti is bonded to C by the remainder after bonding with N. Therefore, it is preferable to satisfy the following expression (2).

C − [{Ti− (48/14) N} × (12/48) + (12/96) × Mo] ≦ 0.005 (2)

However, in said Formula (2), C, Ti, N, and Mo represent the mass% of each component.

This will be explained by experimental results.

Steel A containing C = 0.050%, Si = 0.21%, Mn = 1.61%, Ti = 0.083%, N = 0.636%, Mo = 0.20% (above (2) C − [{Ti− (48/14) N} × (12/48) + (12/96) × Mo] in the formula (hereinafter referred to as B value) is 0.0073), and C = 0. Steel B containing 040%, Si = 0.03%, Mn = 1.34%, Ti = 0.095%, N = 0.040%, Mo = 0.24% (B value is 0 or less) is used. A hot-rolled steel sheet was prepared. The finishing temperature was 910 ° C. and the winding temperature was changed from 550 to 700 ° C., and the relationship between the winding temperature and the strength was investigated. Strength (TS) was measured with a JIS No. 5 test piece. Thereby, it can be seen whether or not the strength changes when the winding temperature changes in the coil. That is, when the dependency on the coiling temperature is strong, the strength changes remarkably with a small variation in the coiling temperature.

[0037]

The survey results are shown in FIG. As shown in FIG. 1, it can be seen that in steel A in which C (A value) not bonded to Ti and Mo exceeds 0.005%, the winding temperature dependence of TS is remarkable.

[0038]

Next, C = 0.040-0.055%, Si = 0.2%, Mn = 1.6%, Ti = 0.080-0.090%, Mo = 0.10-0.20%, Using N = 0.020% steel, hot rolling was performed at a constant coiling temperature of 650 ° C., and the relationship between the B value and TS was determined. The result is shown in FIG. As shown in FIG. 2, it can be seen that when the B value is 0.005% or more, TS tends to decrease.

[0039]

In addition, since Cr has the effect | action which suppresses a pearlite transformation and improves stretch flangeability, you may add in 0.1% or less of range. The reason why the content is 0.1% or less is that when the content exceeds 0.1%, a hard phase is formed and stretch flangeability is deteriorated.

[0040]

Also,The balance is Fe and inevitable impurities.

[0041]

[Metal structure]

In the present invention, in order to ensure excellent elongation and stretch flangeability, a ferrite structure is formed in which Ti or Ti and Nb carbon / nitride and Mo carbide are precipitated individually and / or in combination. That is, it is possible to achieve both excellent elongation and stretch flangeability by precipitating an appropriate amount of carbon / nitride in a ferrite structure rich in ductility.

[0042]

As a form in which Ti or Ti and Nb carbon / nitride and Mo carbide precipitate each independently and / or in combination, Ti carbide and Mo carbide precipitate each independently and / or combine and precipitate. Those that do are preferred. In particular, it is desirable that a carbide containing Ti and Mo in which these are combined is precipitated. Since carbides containing Ti and Mo are finely and uniformly dispersed and precipitated, it is easy to achieve both high tension and excellent elongation and stretch flangeability.

[0043]

Also,As mentioned above,Since the steel sheet of the present invention optimizes the steel composition, especially the amount of C, Ti, and Mo, and precipitates most of the C in the steel as fine carbon / nitride, there is very little solute C.But,In order to obtain good elongation, the amount of dissolved C isThanThe smaller the amount, the better. The amount of solute C exceeds 0.0020%, and the elongation tends to decrease.,Preferably 0.0010% or lessTo.

[0044]

The high-tensile hot-rolled steel sheet of the present invention includes a hot-dip galvanized steel sheet that has a hot-dip galvanized film formed on the surface. Since the high-tensile hot-rolled steel sheet of the present invention has good elongation and stretch flangeability, good stretch and stretch flangeability can be maintained even when a hot dip galvanized film is formed. Here, the hot dip galvanizing is hot dip plating mainly composed of zinc and zinc, and includes those containing alloy elements such as Al and Cr in addition to zinc. The high-tensile hot-rolled steel sheet of the present invention subjected to such hot-dip galvanizing may be subjected to an alloying treatment after plating or as it is plated.

[0045]

[Production conditions]

The hot-rolled steel sheet of the present invention is a steel slab produced by melting a steel having the above-mentioned composition, and immediately or immediately after cooling to 1150 ° C. or higher, and then hot rolling and finishing. It is manufactured by setting the hot rolling outlet temperature to 850 ° C. or higher and winding at 550 ° C. to 700 ° C.

[0046]

・ Steel slab is immediately or once cooled and then heated to 1150 ℃ or higher, then hot rolled

In order to deposit Ti or Ti and Nb charcoal / nitrides and Mo carbides individually and / or in combination after hot rolling,In particular, in order to precipitate a carbide containing Ti and Mo in which Ti carbide and Mo carbide are combined,Since it is necessary to dissolve Ti, Nb and Mo in the slab stage before hot rolling, the steel slab is immediately hot rolled, or once cooled, heated to 1150 ° C. or higher and then hot rolled. In other words, since Ti, Nb and Mo are in solid solution after slab production, the solid solution state is maintained when hot rolling is performed immediately, but coarse precipitates are formed once cooled. It is necessary to re-dissolve Ti, Nb and Mo by heating to 1150 ° C. or higher.

[0047]

-Finishing hot rolling delivery temperature: 850 ° C or higher

In order to ensure elongation and stretch flangeability, the finish hot rolling outlet temperature is set to 850 ° C. or higher. When it is less than 850 ° C., the surface layer becomes coarse particles, and elongation and stretch flangeability are impaired.

[0048]

-Winding temperature: 550 ° C to 700 ° C

In order to obtain a ferrite structure, the coiling temperature is set to 550 ° C to 700 ° C. If the temperature is lower than 550 ° C., the structure has a high dislocation density, so that the elongation is lowered. More preferably, it is 600-660 degreeC. When the coiling temperature is 600 to 660 ° C., the balance between strength, elongation and stretch flangeability is further improved.

[0049]

When hot-dip steel sheet is subjected to hot dip galvanizing treatment, it may be carried out in accordance with a conventional method. However, as for the pre-plating annealing temperature, plating is not possible at less than 450 ° C., and strength reduction is likely to occur at temperatures exceeding 750 ° C. . Therefore, the annealing temperature is preferably 450 ° C. or higher and 750 ° C. or lower.

[0050]

In addition, the hot-rolled steel sheet of the present invention has no difference in characteristics between the scaled state and the pickling material. There is no problem with temper rolling as long as it is a condition normally performed. In addition, the hot dip galvanizing may remain scaled even after pickling. Electroplating may be performed, and even chemical conversion treatment is not particularly problematic. The effect of the present invention is not affected even if the direct feed rolling is performed in which hot rolling is performed as it is immediately after casting or after heating for supplementary heat. In addition, even if the rolled material is heated or heated after rough rolling and before or during finish rolling, continuous rolling performed by joining the rolled material after rough rolling, or heating and continuous rolling of the rolled material Even if it performs simultaneously, the effect of this invention is not impaired.

[0051]

Since the hot-rolled steel sheet of the present invention is excellent in stretch and stretch flangeability, when it is press-molded, its characteristics are utilized, and a cross section at the time of pressing such as an automobile member, particularly a suspension member such as a suspension arm. A member having a complicated shape can be manufactured with good quality, and in particular, can contribute to weight reduction of a press-formed product. Hereinafter, a method for processing a hot-rolled steel sheet according to the present invention, in other words, a method for manufacturing a press-formed product will be described.

[0052]

FIG. 3 is a flowchart showing an example of a work flow of the method for processing a hot-rolled steel sheet according to the present invention. This work flow usually has a pre-process of manufacturing a steel plate according to the present invention or transporting the manufactured steel plate to a destination place as a coil, for example. First, a hot-rolled steel plate according to the present invention is prepared. (S0, S1). Before pressing the steel sheet, the steel sheet may be pre-processed (S2), or may be processed into a predetermined size or shape by a cutting machine (S3). In the former step S2, for example, cutting or drilling is performed at a predetermined position in the width direction of the steel sheet, and a press-formed product having a predetermined size and shape or pressed processing is performed at the stage where the subsequent press processing is completed or in the process of the press processing. It can be separated as a member. In the latter step of S3, the final press-molded product is processed (and thus cut) into a steel plate member having a predetermined size and shape in consideration of the size and shape of the final press-formed product in advance. Thereafter, the member that has undergone the steps S2 and S3 is subjected to press working, and finally a desired press-formed product having a desired size and shape is manufactured (S4). This press working is usually performed in multiple stages, and often has 3 stages or more and 7 stages or less.

[0053]

The step S4 may include a step of further cutting the member that has passed through the steps S2 and S3 into a predetermined size and shape. The operation of “cutting” in this case is, for example, an operation of cutting an unnecessary portion in a final press-formed product such as an end portion of a member that has passed through steps S2 and S3 at least in the process of pressing. Alternatively, it may be an operation of cutting the member to be pressed along the cutting or perforation in the width direction of the steel plate provided in the step S2.

[0054]

In FIG. 3, N1 to N3 may be a work of conveying a steel plate, a member, or a press-formed product mechanically or by an operator.

[0055]

The press-formed product manufactured in this way is sent to the next step as necessary. As the next process, for example, a process for further machining the press-molded product to adjust dimensions and shape, a process for transporting and storing the press-molded product to a predetermined place, a process for performing a surface treatment on the press-molded product, a press There is an assembly process for assembling an object such as an automobile using a molded product.

[0056]

FIG. 4 is a block diagram showing the relationship between the apparatus that actually performs the operation shown in FIG. 3 and the flow of the steel plate, member, and press-formed product. In this figure, the hot-rolled steel sheet according to the present invention is prepared in a coil shape, and a press-formed product is manufactured by a press machine. The press machine is of a type that performs multi-stage pressing, but the present invention is not limited to this.

[0057]

In some cases, a cutting machine or other pre-processing machine is installed in the front stage of the press machine (FIG. 4A), and in some cases, it is not installed (FIG. 4B). When a cutting machine is installed, a member having a required size or shape is cut from a long steel sheet according to the present invention supplied from a coil, and this member is pressed by a press machine, and a predetermined press It becomes a molded product. In the case where a pre-processing machine that performs notches and perforations in the width direction of the steel sheet is installed, the press machine may cut along the notches and perforations. When the pretreatment machine is not installed, cutting is performed in the process of pressing the steel plate in the press machine, and finally a press-formed product having a predetermined size and shape is manufactured. The meaning of “cutting” in FIG. 4 is the same as the cutting in FIG.

[0058]

The press-formed product manufactured in this way uses the steel sheet according to the present invention which is excellent in elongation and stretch flangeability as its raw material, so it is manufactured with good quality even if the cross-sectional shape at the time of pressing is complicated Can be lightweight. Such a feature is particularly useful when the press-formed product is a member for an automobile, particularly a suspension member such as a suspension arm.

[0059]

【Example】

[Example 1]

Steel having the chemical components shown in Table 1 was used as a hot-rolled steel plate having a thickness of 3.2 mm using the manufacturing conditions shown in Table 2. In Table 1, the A value is the value of (C / 12) / {(Ti / 48) + (Mo / 96)} in the above formula (1), and the B value is C-[{Ti− in the above formula (2). (48/14) N} × (12/48) + (12/96) × Mo]. In Table 2, SRT is the slab heating temperature, FT is the finish hot rolling outlet temperature, and CT is the coiling temperature.

[0060]

After pickling the obtained hot-rolled steel sheet, a JIS No. 5 tensile test piece and a hole-expansion test piece were collected and subjected to a tensile test and a hole-expansion test, and the metal structure was measured with an optical microscope and a scanning electron microscope (SEM). confirmed. The hole expansion test is performed by preparing a test piece with a hole punched at a clearance of 12.5% with a 10mmφ punch at the center of a 130mm square steel plate and pushing it up in the opposite direction on the burr side of the punched hole with a 60 ° conical punch. It was. Moreover, the thin film produced from the steel plate was observed with the transmission electron microscope (TEM), and the deposit was confirmed. Moreover, the component of the deposit was analyzed by an energy dispersive X-ray spectrometer (EDX) equipped in the TEM.

[0061]

The metal structure and test results are also shown in Table 2. Regarding the evaluation of the test results, the tensile strength (TS) was 780 MPa or more, the elongation (El) was 20% or more, and the hole expansion ratio (λ) was 70% or more.

[0062]

As shown in Table 2, no. The steel sheets 1 to 3 and 5 to 15 were ferrite structures in which carbides containing appropriate amounts of Ti and Mo having a component composition within the scope of the present invention and a metal structure within the scope of the present invention were precipitated. For this reason, the result which was excellent in both elongation and stretch flangeability has been obtained. In FIG. The transmission electron micrograph of the steel plate of No. 2 is shown. From this photograph, it can be seen that carbides containing fine Ti and Mo are uniformly dispersed in the ferrite single phase structure.

[0063]

In contrast, no. No. 4 steel sheet has a low dislocation density and has a high dislocation density, resulting in a bainite structure with a low El. The hot rolled steel sheets of 16 to 18 and 20 are formed with pearlite or martensite as the second phase, and have low elongation and stretch flangeability. Steel No. 19 has a small addition amount of Mo, so that Ti and Nb charcoal / nitrides are not fine, and there is almost no precipitation of Mo carbides, so λ is low. Steel No. 21 has a low TS and λ due to a small amount of Ti addition and a small amount of Ti charcoal / nitride. The steel sheets 22 to 26 have too much added amount of Ti or Nb or both, so that the amount of precipitates is excessive and both El and λ are low.

[0064]

[Table 1]

[0065]

[Table 2]

[0066]

[Example 2]

After preparing slabs of steel types A, F, M and V in Table 1, heating the slabs to 1250 ° C, hot rolling at the finish hot rolling exit temperature of 890 ° C, and then setting the coiling temperature to 630 ° C A 3.0 mm steel plate was produced. A JIS No. 5 tensile test piece was collected from the obtained steel plate and subjected to a tensile test. Further, the amount of solute C was determined by internal friction measurement. FIG. 6 shows the relationship between the amount of solute C and El measured by a tensile test.

[0067]

From FIG. 6, it is confirmed that the elongation becomes good when the solid solution C amount is 0.0020% or less.

[0068]

[Example 3]

The steel shown in Table 3 was melted and hot rolled at a finishing temperature of 920 ° C. and a winding temperature of 610 ° C. to produce a hot-rolled steel plate having a plate pressure of 1.8 mm. The obtained hot-rolled steel sheet was pickled and then galvannealed. JIS No. 5 tensile test piece and hole expansion test piece were collected from the galvanized plate, and the tensile test and hole expansion test were conducted. The metal structure was confirmed with an optical microscope and a scanning electron microscope (SEM). Was analyzed by an energy dispersive X-ray spectrometer (EDX) equipped with a transmission microscope (TEM). The values of TS, El, and λ at that time are also shown in Table 3. The A value and B value in Table 3 are the same as in Table 1.

[0069]

As shown in Table 3, No. 1 as an example of the present invention. No. 27 showed excellent elongation and stretch flangeability even when alloyed hot dip galvanizing was performed. Since 28 did not contain Mo, the precipitates did not contain Mo, and the stretch flangeability was extremely low.

[0070]

[Table 3]

[0071]

[Example 4]

Steels having the component compositions shown in Table 4 were hot-rolled at a finishing temperature of 910 ° C. and winding temperatures of 600 ° C. and 650 ° C. After confirming the structure of the obtained steel plate having a thickness of 3.2 mm and analyzing the precipitate, a JIS No. 5 tensile test piece was prepared from the steel plate and subjected to a tensile test. The difference in TS was measured between the 600 ° C winding material and the 650 ° C winding material, and the winding temperature dependency was investigated. The results are also shown in Table 4. In addition, No. shown in Table 4 Each of 29 to 32 had a structure in which the carbide of the present invention was precipitated in a ferrite structure.

[0072]

As shown in Table 4, when the B value is 0.005% or less, No. 2 satisfying the above formula (2) is satisfied. Nos. 29 to 31 have a small TS difference and a small dependency on the winding temperature, but No. 29 does not satisfy the above equation (2). It was confirmed that No. 32 has a large coil temperature dependency.

[0073]

[Table 4]

[0074]

【The invention's effect】

As described above, according to the present invention, by appropriately adjusting the component composition, a ferrite structure in which fine carbon / nitride is precipitated is formed. A steel plate can be provided. Therefore, the present invention greatly contributes to the weight reduction of the automobile suspension member.

[Brief description of the drawings]

FIG. 1 is a graph showing the relationship between winding temperature and TS.

FIG. 2 is a graph showing a relationship between a value of C − [{Ti− (48/14) N} × (12/48) + (12/96) × Mo] and TS.

FIG. 3 is a flowchart showing an example of a work flow of a method for processing a hot-rolled steel sheet according to the present invention.

4 is a block diagram showing the relationship between an apparatus that actually performs the work shown in FIG. 3 and the flow of a steel plate, member, and press-formed product. FIG.

FIG. 5 is a transmission electron micrograph showing the metal structure of a high-tensile hot-rolled steel sheet according to the present invention.

FIG. 6 is a graph showing the relationship between the amount of solute C and El measured by a tensile test.

Claims (10)

0.5≦(C/12)/{(Ti/48)+(Mo/96)}≦1.5 …(1)

ただし、上記(1)式中、C、Ti、Moは各成分の質量%を表す。C, Ti, and Mo are contained so that the following (1) Formula may be satisfied, The high-tensile-strength hot-rolled steel plate excellent in the elongation and stretch flangeability of Claim 1 characterized by the above-mentioned.

0.5 ≦ (C / 12) / {(Ti / 48) + (Mo / 96)} ≦ 1.5 (1)

However, in said Formula (1), C, Ti, and Mo represent the mass% of each component.

C−[{Ti−(48/14)N}×(12/48)+(12/96)×Mo]≦0.005 …(2)

ただし、上記(2)式中、C、Ti、N、Moは各成分の質量%を表す。C, Ti, N, and Mo are contained so that the following formula (2) may be satisfied, The high-tensile hot-rolled steel sheet excellent in elongation and stretch flangeability according to claim 1.

C − [{Ti− (48/14) N} × (12/48) + (12/96) × Mo] ≦ 0.005 (2)

However, in said Formula (2), C, Ti, N, and Mo represent the mass% of each component.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001333375A JP3882577B2 (en) | 2000-10-31 | 2001-10-30 | High-tensile hot-rolled steel sheet excellent in elongation and stretch flangeability, and manufacturing method and processing method thereof |

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000-331681 | 2000-10-31 | ||

| JP2000331681 | 2000-10-31 | ||

| JP2001044355 | 2001-02-20 | ||

| JP2001-44355 | 2001-02-20 | ||

| JP2001333375A JP3882577B2 (en) | 2000-10-31 | 2001-10-30 | High-tensile hot-rolled steel sheet excellent in elongation and stretch flangeability, and manufacturing method and processing method thereof |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2002322540A JP2002322540A (en) | 2002-11-08 |

| JP2002322540A5 JP2002322540A5 (en) | 2005-06-23 |

| JP3882577B2 true JP3882577B2 (en) | 2007-02-21 |

Family

ID=27345069

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2001333375A Expired - Fee Related JP3882577B2 (en) | 2000-10-31 | 2001-10-30 | High-tensile hot-rolled steel sheet excellent in elongation and stretch flangeability, and manufacturing method and processing method thereof |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3882577B2 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TWI635187B (en) * | 2017-03-31 | 2018-09-11 | 新日鐵住金股份有限公司 | Hot rolled steel sheet and steel forged parts and manufacturing method thereof |

Families Citing this family (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101019791B1 (en) † | 2002-12-24 | 2011-03-04 | 신닛뽄세이테쯔 카부시키카이샤 | High strength steel sheet exhibiting good burring workability and excellent resistance to softening in heat-affected zone |

| JP4622783B2 (en) * | 2005-09-29 | 2011-02-02 | Jfeスチール株式会社 | High-strength thin steel sheet with excellent rigidity and manufacturing method thereof |

| JP4819489B2 (en) * | 2005-11-25 | 2011-11-24 | Jfeスチール株式会社 | High strength steel plate with excellent uniform elongation characteristics and method for producing the same |

| CN101646794B (en) | 2007-03-27 | 2010-12-08 | 新日本制铁株式会社 | High-strength hot rolled steel sheet being free from peeling and excelling in surface and burring properties and process for manufacturing the same |

| JP5338525B2 (en) * | 2009-07-02 | 2013-11-13 | 新日鐵住金株式会社 | High yield ratio hot-rolled steel sheet excellent in burring and method for producing the same |

| TWI460289B (en) | 2011-03-31 | 2014-11-11 | Nippon Steel & Sumitomo Metal Corp | High strength hot rolled steel sheet with variable toughness type and excellent manufacturing process |

| WO2012141290A1 (en) | 2011-04-13 | 2012-10-18 | 新日本製鐵株式会社 | Hot-rolled steel sheet and manufacturing method thereof |

| US9453269B2 (en) | 2011-04-13 | 2016-09-27 | Nippon Steel & Sumitomo Metal Corporation | Hot-rolled steel sheet for gas nitrocarburizing and manufacturing method thereof |

| KR101658744B1 (en) | 2012-09-26 | 2016-09-21 | 신닛테츠스미킨 카부시키카이샤 | Compositestructure steel sheet and process for producing same |

| WO2016132549A1 (en) | 2015-02-20 | 2016-08-25 | 新日鐵住金株式会社 | Hot-rolled steel sheet |

| KR101957078B1 (en) | 2015-02-20 | 2019-03-11 | 신닛테츠스미킨 카부시키카이샤 | Hot-rolled steel sheet |

| MX2017010532A (en) | 2015-02-25 | 2017-12-14 | Nippon Steel & Sumitomo Metal Corp | Hot-rolled steel sheet or plate. |

| WO2016135898A1 (en) | 2015-02-25 | 2016-09-01 | 新日鐵住金株式会社 | Hot-rolled steel sheet or plate |

| WO2017022025A1 (en) | 2015-07-31 | 2017-02-09 | 新日鐵住金株式会社 | High-strength hot-rolled steel sheet |

| BR112018001133A2 (en) | 2015-07-31 | 2018-09-11 | Nippon Steel & Sumitomo Metal Corporation | steel plate with composite structure of the type of tension-induced transformation and method for manufacturing it |

| WO2018026015A1 (en) | 2016-08-05 | 2018-02-08 | 新日鐵住金株式会社 | Steel sheet and plated steel sheet |

| MX2019000576A (en) | 2016-08-05 | 2019-09-02 | Nippon Steel Corp | Steel sheet and plated steel sheet. |

| EP3495530A4 (en) | 2016-08-05 | 2020-01-08 | Nippon Steel Corporation | Steel sheet and plated steel sheet |

| WO2018179389A1 (en) | 2017-03-31 | 2018-10-04 | 新日鐵住金株式会社 | Hot-rolled steel sheet, forged steel part and production methods therefor |

| WO2018179391A1 (en) | 2017-03-31 | 2018-10-04 | 新日鐵住金株式会社 | Hot-rolled steel sheet, forged steel part and production methods therefor |

-

2001

- 2001-10-30 JP JP2001333375A patent/JP3882577B2/en not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TWI635187B (en) * | 2017-03-31 | 2018-09-11 | 新日鐵住金股份有限公司 | Hot rolled steel sheet and steel forged parts and manufacturing method thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2002322540A (en) | 2002-11-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3882577B2 (en) | High-tensile hot-rolled steel sheet excellent in elongation and stretch flangeability, and manufacturing method and processing method thereof | |

| JP3888128B2 (en) | High formability, high-tensile hot-rolled steel sheet with excellent material uniformity, manufacturing method and processing method thereof | |

| KR100673424B1 (en) | High strength steel sheet and method for maufacturing same | |

| KR100968013B1 (en) | High strength steel sheet and method for manufacturing the same | |

| JP5076394B2 (en) | High-tensile steel plate and manufacturing method thereof | |

| JP3637885B2 (en) | Ultra-high-strength steel sheet excellent in workability, manufacturing method and processing method thereof | |

| KR102356746B1 (en) | Hot-pressed member and manufacturing method thereof, cold-rolled steel sheet for hot pressing, and manufacturing method thereof | |

| KR101986033B1 (en) | High strength steel sheet and manufacturing method therefor | |

| JP2003089848A5 (en) | ||

| WO2017203347A1 (en) | Cold rolled and annealed steel sheet, method of production thereof and use of such steel to produce vehicle parts | |

| US20190292622A1 (en) | Cold rolled and annealed steel sheet, method of production thereof and use of such steel to produce vehicle parts | |

| KR20200066350A (en) | Hot press steel plate member and its manufacturing method | |

| JP4006974B2 (en) | High formability, high-tensile hot-rolled steel sheet with excellent material uniformity, manufacturing method and processing method thereof | |

| JP3821043B2 (en) | Hot-dip galvanized high-strength hot-rolled steel sheet with excellent weldability, manufacturing method and processing method thereof | |

| JP3591502B2 (en) | High-tensile steel sheet excellent in workability, and its manufacturing method and processing method | |

| JP3760888B2 (en) | High-tensile cold-rolled steel sheet with excellent workability, manufacturing method and processing method thereof | |

| JP2002322543A5 (en) | ||

| JP3775337B2 (en) | High formability, high-tensile hot-rolled steel sheet with excellent material uniformity, manufacturing method and processing method thereof | |

| JP3775341B2 (en) | High-tensile hot-rolled steel sheet with excellent workability, manufacturing method and processing method thereof | |

| JP3775340B2 (en) | High-tensile hot-rolled steel sheet with excellent workability and processing method | |

| JP3637888B2 (en) | High tensile hot-rolled steel sheet with excellent peel strength and processing method thereof | |

| JP2008174813A (en) | High-strength steel sheet and its production method | |

| JP3821042B2 (en) | High-formability high-tensile steel sheet with excellent strength stability and method for producing and processing the same | |

| JP3775339B2 (en) | High-tensile hot-rolled steel sheet with excellent workability, manufacturing method and processing method thereof | |

| JP3775334B2 (en) | High-strength steel sheet with excellent workability, manufacturing method and processing method thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20040924 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20041124 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20050208 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050408 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20060704 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060901 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20061024 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20061106 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101124 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111124 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111124 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121124 Year of fee payment: 6 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131124 Year of fee payment: 7 |

|

| LAPS | Cancellation because of no payment of annual fees |