JP2023166319A - ガス供給装置 - Google Patents

ガス供給装置 Download PDFInfo

- Publication number

- JP2023166319A JP2023166319A JP2022126554A JP2022126554A JP2023166319A JP 2023166319 A JP2023166319 A JP 2023166319A JP 2022126554 A JP2022126554 A JP 2022126554A JP 2022126554 A JP2022126554 A JP 2022126554A JP 2023166319 A JP2023166319 A JP 2023166319A

- Authority

- JP

- Japan

- Prior art keywords

- gas

- evaporator

- carrier gas

- mixed gas

- tube

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J7/00—Apparatus for generating gases

- B01J7/02—Apparatus for generating gases by wet methods

-

- C—CHEMISTRY; METALLURGY

- C30—CRYSTAL GROWTH

- C30B—SINGLE-CRYSTAL GROWTH; UNIDIRECTIONAL SOLIDIFICATION OF EUTECTIC MATERIAL OR UNIDIRECTIONAL DEMIXING OF EUTECTOID MATERIAL; REFINING BY ZONE-MELTING OF MATERIAL; PRODUCTION OF A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; SINGLE CRYSTALS OR HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; AFTER-TREATMENT OF SINGLE CRYSTALS OR A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; APPARATUS THEREFOR

- C30B25/00—Single-crystal growth by chemical reaction of reactive gases, e.g. chemical vapour-deposition growth

- C30B25/02—Epitaxial-layer growth

- C30B25/14—Feed and outlet means for the gases; Modifying the flow of the reactive gases

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D1/00—Evaporating

- B01D1/04—Evaporators with horizontal tubes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D1/00—Evaporating

- B01D1/14—Evaporating with heated gases or vapours or liquids in contact with the liquid

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D3/00—Distillation or related exchange processes in which liquids are contacted with gaseous media, e.g. stripping

- B01D3/34—Distillation or related exchange processes in which liquids are contacted with gaseous media, e.g. stripping with one or more auxiliary substances

- B01D3/343—Distillation or related exchange processes in which liquids are contacted with gaseous media, e.g. stripping with one or more auxiliary substances the substance being a gas

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/448—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for generating reactive gas streams, e.g. by evaporation or sublimation of precursor materials

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/448—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for generating reactive gas streams, e.g. by evaporation or sublimation of precursor materials

- C23C16/4481—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for generating reactive gas streams, e.g. by evaporation or sublimation of precursor materials by evaporation using carrier gas in contact with the source material

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/448—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for generating reactive gas streams, e.g. by evaporation or sublimation of precursor materials

- C23C16/452—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for generating reactive gas streams, e.g. by evaporation or sublimation of precursor materials by activating reactive gas streams before their introduction into the reaction chamber, e.g. by ionisation or addition of reactive species

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/455—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for introducing gases into reaction chamber or for modifying gas flows in reaction chamber

- C23C16/45561—Gas plumbing upstream of the reaction chamber

-

- C—CHEMISTRY; METALLURGY

- C30—CRYSTAL GROWTH

- C30B—SINGLE-CRYSTAL GROWTH; UNIDIRECTIONAL SOLIDIFICATION OF EUTECTIC MATERIAL OR UNIDIRECTIONAL DEMIXING OF EUTECTOID MATERIAL; REFINING BY ZONE-MELTING OF MATERIAL; PRODUCTION OF A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; SINGLE CRYSTALS OR HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; AFTER-TREATMENT OF SINGLE CRYSTALS OR A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; APPARATUS THEREFOR

- C30B29/00—Single crystals or homogeneous polycrystalline material with defined structure characterised by the material or by their shape

- C30B29/02—Elements

- C30B29/06—Silicon

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28C—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA COME INTO DIRECT CONTACT WITHOUT CHEMICAL INTERACTION

- F28C3/00—Other direct-contact heat-exchange apparatus

- F28C3/06—Other direct-contact heat-exchange apparatus the heat-exchange media being a liquid and a gas or vapour

- F28C3/08—Other direct-contact heat-exchange apparatus the heat-exchange media being a liquid and a gas or vapour with change of state, e.g. absorption, evaporation, condensation

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D7/00—Heat-exchange apparatus having stationary tubular conduit assemblies for both heat-exchange media, the media being in contact with different sides of a conduit wall

- F28D7/16—Heat-exchange apparatus having stationary tubular conduit assemblies for both heat-exchange media, the media being in contact with different sides of a conduit wall the conduits being arranged in parallel spaced relation

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Organic Chemistry (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- General Chemical & Material Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Crystallography & Structural Chemistry (AREA)

- Thermal Sciences (AREA)

- Physics & Mathematics (AREA)

- Chemical Vapour Deposition (AREA)

- Heat-Exchange Devices With Radiators And Conduit Assemblies (AREA)

- Feeding, Discharge, Calcimining, Fusing, And Gas-Generation Devices (AREA)

- Crystals, And After-Treatments Of Crystals (AREA)

- Silicon Compounds (AREA)

Abstract

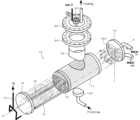

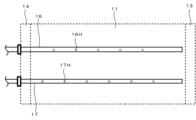

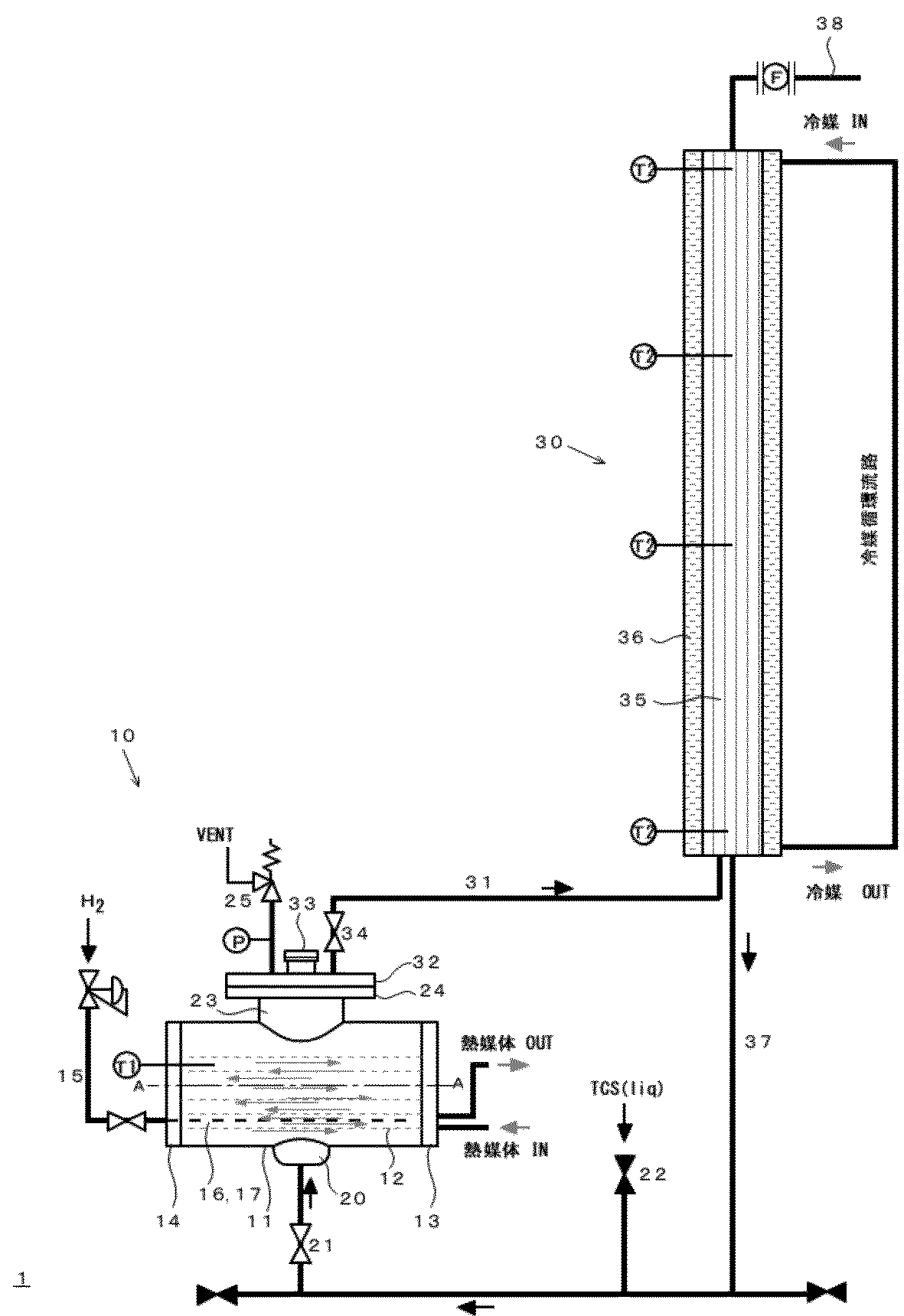

【解決手段】混合ガス供給装置1が、液体成分とキャリアガスとを加熱し、液体成分が気化した成分ガスとキャリアガスとの混合ガスを生成する蒸発器10、及び蒸発器10で生成された混合ガスを冷却し、過飽和分を凝縮分離させた成分ガスとキャリアガスとの混合ガスを供給する冷却器30を備える。蒸発器10は、シェルアンドチューブ型加熱機構を備え、蒸発器10の胴11内には、キャリアガスのバブリング用の孔16H、17Hが複数箇所に開いたキャリアガス用チューブ16、17が水平方向に伸び、蒸発器10の胴11の下部には液体成分供給口20が設けられ、蒸発器10の胴11の上部には、液体成分が気化した成分ガスとキャリアガスとの混合ガスを送出する送出口23が設けられ、冷却器30の下部が蒸発器10の送出口23と配管31で連続する。

【選択図】図1

Description

蒸発器で生成された混合ガスを冷却し、過飽和分を凝縮分離させた成分ガスとキャリアガスとの混合ガスを供給する冷却器

を備えた混合ガス供給装置であって、

蒸発器は、軸を水平方向に向けた筒型の胴を有し、胴内に軸方向に伸びた熱媒体用チューブを有するシェルアンドチューブ型加熱機構を備え、

蒸発器の胴内には、キャリアガスのバブリング用の孔が複数箇所に開いたキャリアガス用チューブが水平方向に伸びており、

蒸発器の胴の下部には液体成分供給口が設けられ、

蒸発器の胴の上部には、液体成分が気化した成分ガスとキャリアガスとの混合ガスを送出する送出口が設けられ、

冷却器の下部が蒸発器の送出口と配管で連続すると共に、液体成分供給口と配管で連続し、冷却器で形成された凝縮液が、液体成分供給口から蒸発器の胴内に戻る混合ガス供給装置を提供する。

したがって、蒸発器を小型化し、混合ガス供給装置全体をコンパクトに構成することができる。

また、前述の配管31には仕切弁34が設けられている。仕切弁34により、混合ガス供給装置1は法規で規定される「圧力容器」に該当しなくなり、取り扱いが簡便になる。

10 蒸発器

11 胴

12 熱媒体用チューブ

13 管板

13A 管板溝

14 管板

14A 管板溝

15 配管

16 キャリアガス用チューブ

16H キャリアガスのバブリング用孔

17 キャリアガス用チューブ

17H キャリアガスのバブリング用孔

20 液体成分供給口

21 蒸発器下端バルブ

22 液体成分補給弁

23 送出口

24 フランジ

25 圧力放出弁

30 冷却器

31 配管

32 フランジ

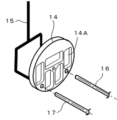

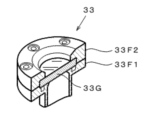

33 蒸発器の胴内の観察用窓

34 仕切弁

35 チューブ

36 冷媒の流路

37 配管

38 濃度調整ガス供給口

A 軸

F 流量計

P 圧力計

T1、T2 温度計

Claims (8)

- 液体成分とキャリアガスとを加熱し、液体成分が気化した成分ガスとキャリアガスとの混合ガスを生成する蒸発器、及び

蒸発器で生成された混合ガスを冷却し、過飽和分を凝縮分離させた成分ガスとキャリアガスとの混合ガスを供給する冷却器

を備えた混合ガス供給装置であって、

蒸発器は、軸を水平方向に向けた筒型の胴を有し、胴内に軸方向に伸びた熱媒体用チューブを有するシェルアンドチューブ型加熱機構を備え、

蒸発器の胴内には、キャリアガスのバブリング用の孔が複数箇所に開いたキャリアガス用チューブが水平方向に伸びており、

蒸発器の胴の下部には液体成分供給口が設けられ、

蒸発器の胴の上部には、液体成分が気化した成分ガスとキャリアガスとの混合ガスを送出する送出口が設けられ、

冷却器の下部が蒸発器の送出口と配管で連続すると共に、液体成分供給口と配管で連続し、冷却器で形成された凝縮液が、液体成分供給口から蒸発器の胴内に戻る混合ガス供給装置。 - キャリアガス用チューブが、蒸発器の胴の軸方向の一方の管板から対向する管板に向かって伸びている請求項1記載の混合ガス供給装置。

- キャリアガス用チューブは、キャリアガスのバブリング用孔として下向きに開口した孔を有する請求項1又は2記載の混合ガス供給装置。

- 複数本のキャリアガス用チューブが、胴内の下部で並列しており、隣り合うキャリアガス用チューブのバブリング用孔が蒸発器の胴の軸方向に互い違いに形成されている請求項3記載の混合ガス供給装置。

- 蒸発器の送出口の開口径が、胴の内径の50%以上である請求項1~4のいずれかに記載の混合ガス供給装置。

- 熱媒体用チューブを流れる熱媒体が胴内に導入されてから排出されるまでに胴の両端の管板の間を複数回往復する請求項1~4のいずれかに記載の混合ガス供給装置。

- 蒸発器の送出口と冷却器下部から伸びた配管との接続部分に、蒸発器の胴内の観察用窓が設けられている請求項1~4のいずれかに記載の混合ガス供給装置。

- 液体成分が液体トリクロロシランであり、キャリアガスが水素ガスである請求項1~4のいずれかに記載の混合ガス供給装置。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2022126554A JP7765012B2 (ja) | 2022-05-09 | 2022-08-08 | ガス供給装置 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2022077155A JP7127792B1 (ja) | 2022-05-09 | 2022-05-09 | ガス供給装置 |

| JP2022126554A JP7765012B2 (ja) | 2022-05-09 | 2022-08-08 | ガス供給装置 |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2022077155A Division JP7127792B1 (ja) | 2022-05-09 | 2022-05-09 | ガス供給装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2023166319A true JP2023166319A (ja) | 2023-11-21 |

| JP2023166319A5 JP2023166319A5 (ja) | 2024-11-26 |

| JP7765012B2 JP7765012B2 (ja) | 2025-11-06 |

Family

ID=83103179

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2022077155A Active JP7127792B1 (ja) | 2022-05-09 | 2022-05-09 | ガス供給装置 |

| JP2022126554A Active JP7765012B2 (ja) | 2022-05-09 | 2022-08-08 | ガス供給装置 |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2022077155A Active JP7127792B1 (ja) | 2022-05-09 | 2022-05-09 | ガス供給装置 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20240316517A1 (ja) |

| EP (1) | EP4538430A1 (ja) |

| JP (2) | JP7127792B1 (ja) |

| KR (1) | KR102795853B1 (ja) |

| CN (1) | CN117897520A (ja) |

| WO (1) | WO2023219179A1 (ja) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7127792B1 (ja) * | 2022-05-09 | 2022-08-30 | 東横化学株式会社 | ガス供給装置 |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0515766A (ja) * | 1991-07-09 | 1993-01-26 | Toshiba Ceramics Co Ltd | 液体原料供給装置 |

| JPH08187427A (ja) * | 1995-01-06 | 1996-07-23 | Tokyo Electron Ltd | 処理液供給装置 |

| JP2000319095A (ja) * | 1999-04-30 | 2000-11-21 | Komatsu Electronic Metals Co Ltd | トリクロロシランガス気化供給装置及び方法 |

| JP2008124356A (ja) * | 2006-11-15 | 2008-05-29 | Sekisui Chem Co Ltd | 表面処理方法及び装置 |

| JP2009038047A (ja) * | 2006-04-26 | 2009-02-19 | Entegris Inc | 液体気化装置 |

| JP2012000537A (ja) * | 2010-06-14 | 2012-01-05 | Shibata Kagaku Kk | ガス発生装置 |

| WO2015012257A1 (ja) * | 2013-07-26 | 2015-01-29 | 株式会社 テクノ・バンダリー | 連続蒸留式トリクロロシラン気化供給装置および連続蒸留式トリクロロシランガス気化方法 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4542643B2 (ja) | 1999-08-30 | 2010-09-15 | Sumco Techxiv株式会社 | ガス供給装置およびガス供給方法 |

| JP5473421B2 (ja) | 2009-06-15 | 2014-04-16 | ヘンミ計算尺株式会社 | 液体原料のバブリング気化供給方法及び装置 |

| JP2013115208A (ja) | 2011-11-28 | 2013-06-10 | Tokyo Electron Ltd | 気化原料供給装置、これを備える基板処理装置、及び気化原料供給方法 |

| JP7127792B1 (ja) | 2022-05-09 | 2022-08-30 | 東横化学株式会社 | ガス供給装置 |

-

2022

- 2022-05-09 JP JP2022077155A patent/JP7127792B1/ja active Active

- 2022-08-08 JP JP2022126554A patent/JP7765012B2/ja active Active

-

2023

- 2023-06-27 EP EP23803651.1A patent/EP4538430A1/en active Pending

- 2023-06-27 US US18/575,556 patent/US20240316517A1/en active Pending

- 2023-06-27 WO PCT/JP2023/023767 patent/WO2023219179A1/ja not_active Ceased

- 2023-06-27 CN CN202380013099.6A patent/CN117897520A/zh active Pending

- 2023-06-27 KR KR1020247002118A patent/KR102795853B1/ko active Active

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0515766A (ja) * | 1991-07-09 | 1993-01-26 | Toshiba Ceramics Co Ltd | 液体原料供給装置 |

| JPH08187427A (ja) * | 1995-01-06 | 1996-07-23 | Tokyo Electron Ltd | 処理液供給装置 |

| JP2000319095A (ja) * | 1999-04-30 | 2000-11-21 | Komatsu Electronic Metals Co Ltd | トリクロロシランガス気化供給装置及び方法 |

| JP2009038047A (ja) * | 2006-04-26 | 2009-02-19 | Entegris Inc | 液体気化装置 |

| JP2008124356A (ja) * | 2006-11-15 | 2008-05-29 | Sekisui Chem Co Ltd | 表面処理方法及び装置 |

| JP2012000537A (ja) * | 2010-06-14 | 2012-01-05 | Shibata Kagaku Kk | ガス発生装置 |

| WO2015012257A1 (ja) * | 2013-07-26 | 2015-01-29 | 株式会社 テクノ・バンダリー | 連続蒸留式トリクロロシラン気化供給装置および連続蒸留式トリクロロシランガス気化方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20250002090A (ko) | 2025-01-07 |

| JP7765012B2 (ja) | 2025-11-06 |

| JP2023166240A (ja) | 2023-11-21 |

| JP7127792B1 (ja) | 2022-08-30 |

| WO2023219179A1 (ja) | 2023-11-16 |

| US20240316517A1 (en) | 2024-09-26 |

| KR102795853B1 (ko) | 2025-04-14 |

| CN117897520A (zh) | 2024-04-16 |

| EP4538430A1 (en) | 2025-04-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10480071B2 (en) | Continuous distillation trichlorosilane vaporization supply apparatus | |

| JP3946398B2 (ja) | 中間媒体式気化器及び当該気化器を用いた天然ガスの供給方法 | |

| US7160357B2 (en) | Oxygen transport membrane reactor and method | |

| KR101058976B1 (ko) | 액체재료 기화장치 | |

| Abu-Zeid et al. | Improving the performance of the air gap membrane distillation process by using a supplementary vacuum pump | |

| JP2023166319A (ja) | ガス供給装置 | |

| US20130037974A1 (en) | Liquid material vaporizer | |

| US10782073B2 (en) | Waste heat boiler system, mixing chamber, and method for cooling a process gas | |

| CN102016107B (zh) | 均热装置和有机膜成膜装置 | |

| US20110180383A1 (en) | Membrane distillation system and method | |

| ES2226030T3 (es) | Procedimiento y dispositivo para mejorar la transmision del calor. | |

| KR20100093530A (ko) | 연료전지 유닛용으로 개질될 연소 가스를 가습 및 가열하기 위한 장치 | |

| TWI870912B (zh) | 氣體供給裝置 | |

| JP4867722B2 (ja) | 液体濃縮器 | |

| US20100025219A1 (en) | System and method for membrane distillation with low reynolds numbers | |

| JP2023166319A5 (ja) | ||

| CN100538235C (zh) | 用于分离空气的方法和设备 | |

| JP2002219452A (ja) | 造水装置 | |

| US20140050852A1 (en) | Vaporizer, center rod used therein, and method for vaporizing material carried by carrier gas | |

| JP2001064093A (ja) | ガス供給装置およびガス供給方法 | |

| KR20230042639A (ko) | 액체 재료 기화 장치 | |

| CA2391029A1 (en) | Apparatus, systems and methods for facilitating the accurate calculation of a steam-carbon ratio in a hydrocarbon reformer | |

| GB2614358A (en) | Improvements in or relating to gas apparatus | |

| EP4196439A1 (en) | Deep cooler |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| RD01 | Notification of change of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7426 Effective date: 20220914 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20241118 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20241118 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20250829 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20250916 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20251015 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 7765012 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |