JP2018009821A - Strength estimation system for concrete demolding - Google Patents

Strength estimation system for concrete demolding Download PDFInfo

- Publication number

- JP2018009821A JP2018009821A JP2016137231A JP2016137231A JP2018009821A JP 2018009821 A JP2018009821 A JP 2018009821A JP 2016137231 A JP2016137231 A JP 2016137231A JP 2016137231 A JP2016137231 A JP 2016137231A JP 2018009821 A JP2018009821 A JP 2018009821A

- Authority

- JP

- Japan

- Prior art keywords

- concrete

- strength

- ultrasonic

- measurement

- test

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Landscapes

- Investigating Or Analyzing Materials By The Use Of Ultrasonic Waves (AREA)

Abstract

【課題】本発明は、配合の僅かな変動や練り上がり温度による準備工程数を増加させることなく精度を確保できる脱型時強度推定システムを提供することを目的とする。【解決手段】打設に用いるコンクリートと略同配合のコンクリートを用いて試験練り体を形成し、試験練り体につき、超音波測定と圧縮強度試験とを各々同時刻に行い、超音波測定で測定した記録波形の振幅及び同時刻での強度試験で得られた圧縮強度との関係から推定式を導き出し、覆工コンクリート打設に際して、覆工コンクリートの超音波測定を行うべく超音波発信子及び受信子を設置して、覆工コンクリートの超音波試験による振幅取得を可能とし、覆工コンクリートの打設及び締固めが完了した時点で、超音波測定を開始し、測定により得られた波形から振幅を読み取り、推定式に代入することで、測定時点における覆工コンクリートの推定強度を得ることを特徴とする。【選択図】 図1An object of the present invention is to provide a demolding strength estimation system capable of ensuring accuracy without increasing the number of preparation steps due to slight variations in formulation and kneading temperature. SOLUTION: A test kneaded body is formed using concrete having substantially the same composition as the concrete used for placing, and an ultrasonic measurement and a compressive strength test are performed on the test kneaded body at the same time and measured by ultrasonic measurement. From the relationship between the amplitude of the recorded waveform and the compressive strength obtained from the strength test at the same time, an estimation equation is derived, and when placing the lining concrete, an ultrasonic transmitter and receiver are used to perform ultrasonic measurement of the lining concrete. When the lining concrete is placed and compacted, the ultrasonic measurement is started and the amplitude is obtained from the waveform obtained by the measurement. Is obtained, and the estimated strength of the lining concrete at the time of measurement is obtained by substituting into the estimation formula. [Selection] Figure 1

Description

本発明は、たとえば、コンクリート脱型時強度推定システムに係り、詳しくは、山岳トンネルの覆工コンクリートの強度発現を監視して、脱型時に必要な強度を推定するシステムに関するものである。

The present invention relates to, for example, a concrete demolding strength estimation system, and more particularly, to a system for monitoring strength development of mountain tunnel lining concrete and estimating a necessary strength during demolding.

例えば、山岳トンネルなどの覆工コンクリートの型枠脱型時期は、圧縮強度で2.0〜3.0N/mm2程度を目安としている。 For example, the mold release time of lining concrete such as a mountain tunnel is about 2.0 to 3.0 N / mm 2 in terms of compressive strength.

従来では、現場養生した管理供試体による圧縮強度試験から、所望の圧縮強度に達したことを確認して脱型作業を行うことが要求されるが、一般的には打設終了からの経過材齢、すなわち「圧縮強度が十分に発現したであろう期間」に基づいて脱型作業が行われることが多い。

しかしながら、この経過材齢に基づく場合、現場環境や打設条件に変化が生じた際には対処できないという課題がある。

Conventionally, it is required to perform demolding work after confirming that the desired compressive strength has been reached from a compressive strength test using a management specimen cured in the field. Demolding work is often performed based on age, that is, “a period during which compressive strength will be sufficiently developed”.

However, when based on this progress age, there is a problem that it cannot be dealt with when a change occurs in the site environment or placement conditions.

そこで、近年のトンネル工事においては、覆工コンクリートの温度を測定し、この測定温度から積算温度を算出し、積算温度が任意の数値に達することで所望の圧縮強度に到達したと推定して脱型可能と判定する手段が(例えば、特許文献1参照)が採られている。 Therefore, in recent tunnel construction, the temperature of the lining concrete is measured, the accumulated temperature is calculated from this measured temperature, and it is estimated that the desired compressive strength has been reached when the accumulated temperature reaches an arbitrary value. A means for determining that the mold is possible (see, for example, Patent Document 1) is adopted.

特許文献1の技術は、打設時の温度や空気量もパラメータとして加えることで、より精度よく圧縮強度を推定することであるため、配合毎に、練り上がり温度を複数水準とする試験練りを各々行い、この複数水準の各試験練りについて積算温度測定と圧縮強度試験を行い、練り上がり温度・空気量・積算温度・圧縮強度の関係式を複数用意する。その上で、受入検査時の練り上がり温度と空気量に基づき関係式を選択して強度推定に用いる。したがって、目標強度が同じであっても、配合の僅かな変動、例えば混和剤の種類や使用量に変動があれば、その都度、上記の試験練りを実施する必要がある。更に、練り上がり温度を複数水準とするための材料調整なども加わるなど、精度を確保するために多くの準備を要するとの課題があった。

The technique of Patent Document 1 is to estimate the compressive strength more accurately by adding the temperature and air amount at the time of placement as parameters, so test kneading with multiple levels of kneading temperature for each blending is performed. Each is carried out, and an integrated temperature measurement and a compressive strength test are performed for each test kneading at the plurality of levels, and a plurality of relational expressions of kneading temperature, air amount, integrated temperature, and compressive strength are prepared. After that, a relational expression is selected based on the kneading temperature and the air volume at the time of receiving inspection and used for strength estimation. Therefore, even if the target strength is the same, if there is a slight change in the blending, for example, a change in the type or amount of the admixture, it is necessary to carry out the above-mentioned test kneading each time. Furthermore, there has been a problem that many preparations are required to ensure accuracy, such as material adjustment for making the kneading temperature into a plurality of levels.

かくして、本発明は前記従来の課題に対処すべく創案されたものであって、配合の僅かな変動や練り上がり温度による準備工程数を増加させることなく精度を確保できる脱型時強度推定システムを提供することを目的とするものである。

Thus, the present invention was devised to address the above-described conventional problems, and a demolding strength estimation system that can ensure accuracy without increasing the number of preparation steps due to slight fluctuations in formulation and kneading temperature. It is intended to provide.

本発明は、

打設に用いるコンクリートと略同配合のコンクリートを用いて試験練り体を形成し、前記試験練り体につき、超音波測定と圧縮強度試験とを各々同時刻に行い、前記超音波測定で測定した記録波形の振幅及び同時刻での強度試験で得られた圧縮強度との関係から推定式を導き出し、

覆工コンクリート打設に際して、覆工コンクリートの超音波測定を行うべく超音波発信子及び受信子を設置して、覆工コンクリートの超音波試験による振幅取得を可能とし、覆工コンクリートの打設及び締固めが完了した時点で、超音波測定を開始し、前記測定により得られた波形から前記振幅を読み取り、前記推定式に代入することで、前記測定時点における覆工コンクリートの推定強度を得る、

ことを特徴とし、

または、

打設に用いるコンクリートと略同配合のコンクリートを用いて試験練り体を形成し、前記試験練り体につき、超音波測定と圧縮強度試験とを各々同時刻に行い、前記超音波測定で測定した記録波形の振幅及び同時刻での強度試験で得られた圧縮強度との関係から推定式を導き出し、

覆工コンクリート打設に際して、覆工コンクリートの超音波測定を行うべく超音波発信子及び受信子を設置して、覆工コンクリートの超音波試験による振幅取得を可能とし、覆工コンクリートの打設及び締固めが完了した時点で、超音波測定を開始し、前記測定により得られた波形から前記振幅を読み取り、前記推定式に代入することで、前記測定時点における覆工コンクリートの推定強度を得る共に、前記得られた推定強度より目標強度への到達時刻を予測する

ことを特徴とし、

または、

前記推定式は、

σ=αln(A)+β、

σ:圧縮強度(N/mm2)、A:振幅(例として、V)、α及びβ:定数

であることを特徴とし、

または、

前記超音波測定を行う超音波発信子及び受信子は、覆工コンクリートの型枠にあらかじめ取り付けられ、型枠の繰り返し使用の際、前記超音波発信子及び受信子の取り付け作業を行うことなく使用できる、

ことを特徴とするものである。

The present invention

A test kneaded body is formed using concrete having substantially the same composition as the concrete used for placing, and the test kneaded body is subjected to an ultrasonic measurement and a compressive strength test at the same time, and recorded by the ultrasonic measurement. An estimation formula is derived from the relationship between the amplitude of the waveform and the compression strength obtained in the strength test at the same time,

When placing lining concrete, an ultrasonic transmitter and receiver are installed to perform ultrasonic measurement of lining concrete, enabling amplitude acquisition by ultrasonic testing of lining concrete, When compaction is completed, ultrasonic measurement is started, the amplitude is read from the waveform obtained by the measurement, and is substituted into the estimation formula, thereby obtaining the estimated strength of the lining concrete at the measurement time.

It is characterized by

Or

A test kneaded body is formed using concrete having substantially the same composition as the concrete used for placing, and the test kneaded body is subjected to an ultrasonic measurement and a compressive strength test at the same time, and recorded by the ultrasonic measurement. An estimation formula is derived from the relationship between the amplitude of the waveform and the compression strength obtained in the strength test at the same time,

When placing lining concrete, an ultrasonic transmitter and receiver are installed to perform ultrasonic measurement of lining concrete, enabling amplitude acquisition by ultrasonic testing of lining concrete, When the compaction is completed, ultrasonic measurement is started, the amplitude is read from the waveform obtained by the measurement, and is substituted into the estimation formula, thereby obtaining the estimated strength of the lining concrete at the measurement time. The arrival time to the target intensity is predicted from the obtained estimated intensity,

Or

The estimation formula is

σ = αln (A) + β,

σ: compressive strength (N / mm 2 ), A: amplitude (for example, V), α and β: constants,

Or

The ultrasonic transmitter and receiver for performing the ultrasonic measurement are attached in advance to a formwork of lining concrete, and are used without performing the work of attaching the ultrasonic transmitter and receiver when the mold is repeatedly used. it can,

It is characterized by this.

本発明によれば、配合の僅かな変動や練り上がり温度による準備工程数を増加させることなく精度を確保できる脱型時強度推定システムを提供ができるとの優れた効果を奏する。

According to the present invention, there is an excellent effect that it is possible to provide a demolding strength estimation system capable of ensuring accuracy without increasing the number of preparation steps due to slight fluctuations in blending or kneading temperature.

以下、本発明につき、図に基づいて説明する。 Hereinafter, the present invention will be described with reference to the drawings.

まず、打設に用いるコンクリートと略同配合にしたコンクリートを用いて、試験練り体1を形成する。

そして、形成した前記試験練り体1につき、超音波測定と圧縮強度試験とを各々同時刻に行う。図1において、符号2は、前記試験練り体1に配置された超音波発信子であり、符号3は超音波受信子である。

First, the test kneaded body 1 is formed using concrete having substantially the same composition as the concrete used for placing.

Then, for the formed test paste 1, the ultrasonic measurement and the compressive strength test are performed at the same time. In FIG. 1, the code |

前記超音波発信子2により超音波を発信し、発信した超音波を超音波受信子3により受信する。そして、これら超音波発信子2と超音波受信子3を超音波試験機7に接続し、試験練り体1内を伝播する超音波の波形変動を測定する。

前記測定は、試験練り体1内で受信した超音波の波形変化すなわち振幅につき時間をおいて複数回測定するものとなる。

An ultrasonic wave is transmitted by the

The measurement is performed several times with respect to the waveform change, that is, the amplitude of the ultrasonic wave received in the test paste 1.

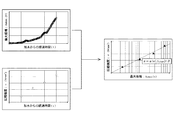

ここで、当該振幅は、図2のグラフから理解されるように、コンクリートへの加水からの経過時間、すなわち試験練り体1から水分が減衰し、固化するに従って、伝播する超音波の振幅、例えば最大振幅が大きくなっていくことが理解できる。 Here, as understood from the graph of FIG. 2, the amplitude is the elapsed time from the addition to the concrete, that is, the amplitude of the ultrasonic wave that propagates as the moisture attenuates and solidifies from the test paste 1, for example, It can be understood that the maximum amplitude increases.

また、前記試験練り体1につき、圧縮強度試験をも行う。この試験は、通常行われるコンクリートの圧縮試験と同様に、例えば前記試験練り体1につき、略円柱形に形成し、それに対し、上方から圧縮力を加えて圧縮強度を計測するがごときである。そして、当該圧縮強度試験は、前記時間をおいて行われる前記超音波試験と同時刻に行うものとする。 Further, a compressive strength test is also performed on the test paste 1. This test is similar to a concrete compression test that is usually performed, for example, the test paste 1 is formed in a substantially cylindrical shape, and a compressive force is applied from above to measure the compressive strength. And the said compressive strength test shall be performed at the same time as the said ultrasonic test performed at the said time.

しかして、時間をおいて測定した超音波測定での前記振幅、例えば最大振幅(Amax)と、同時刻に計測した圧縮強度(σ)の数値から、推定式[σ=αln(Amax)+β]を導き出すことができ(図2参照)、もって圧縮強度(σ)と超音波測定での最大振幅(Amax)との関係グラフ、例えば直線状の一次関数グラフを導き出すことができるのである。 Thus, from the numerical value of the amplitude, for example, the maximum amplitude (Amax), and the compressive strength (σ) measured at the same time in the ultrasonic measurement measured over time, the estimation formula [σ = αln (Amax) + β] (See FIG. 2), and therefore, a relationship graph between the compressive strength (σ) and the maximum amplitude (Amax) in ultrasonic measurement, for example, a linear function graph can be derived.

次に、現場において、実際の覆工コンクリート5の打設作業に入る。図3に示すように、符号4は、覆工コンクリート5の型枠を示す。当該型枠4には、任意の位置に取り付け孔6が穿設され、この取り付け孔6には超音波発信子2および超音波受信子3があらかじめ取り付けられる。

Next, the actual lining concrete 5 is placed on site. As shown in FIG. 3,

そして、これら超音波発信子2および超音波受信子3は図4に示す超音波試験機7に接続され、超音波測定での覆工コンクリート内を伝播する超音波の振幅、例えば最大振幅(Amax)が測定され、求められる。

この測定作業は、任意の時間間隔、例えば15分ごとに複数回、少なくとも3回以上行われることが好ましい。

The

This measurement operation is preferably performed at an arbitrary time interval, for example, a plurality of times every 15 minutes, at least three times.

そして、前記複数回の測定結果から、測定時刻における各々の前記最大振幅を前記推定式に代入し、もって測定時刻での圧縮強度を得ることができるのである。 Then, from the measurement results of the plurality of times, the maximum amplitude at each measurement time is substituted into the estimation formula, and thereby the compression strength at the measurement time can be obtained.

さらに、図2および図3から理解されるように圧縮強度と最大振幅との関係を示すσ=αln(Amax)+βの式を表したグラフにおける直線状をなす一次関数グラフの傾斜(例えば定数αの値)から推定して、型枠4を脱型できるとされる圧縮強度、例えば2.0〜3.0N/mm2程度の圧縮強度に到達する時刻を予測することができるものとなる。

Further, as understood from FIGS. 2 and 3, the slope of the linear function graph forming a straight line in the graph representing the relationship between the compression strength and the maximum amplitude σ = αln (Amax) + β (for example, the constant α From this, it is possible to predict the compression strength at which the

なお、前記複数回の測定結果から、測定時刻における各々の前記最大振幅を前記推定式に代入し、もって測定時刻での圧縮強度を得ること、並びに圧縮強度と最大振幅との関係を示すσ=αln(Amax)+βの式を表したグラフにおける直線の傾斜(例えば定数αの値)から、型枠4を脱型できるとされる圧縮強度、例えば2.0〜3.0N/mm2程度の圧縮強度に到達する予測時刻を推定する演算は、図4に示すように、超音波試験装置7に接続されたパソコンなどの演算装置8で行え、さらにその演算結果は、演算装置8に接続されたディスプレイ9上に、リアルタイムに表示されるものとなっている。

From the measurement results of the plurality of times, each maximum amplitude at the measurement time is substituted into the estimation formula, thereby obtaining the compression strength at the measurement time, and σ = From the slope of the straight line (for example, the value of the constant α) in the graph representing the expression of αln (Amax) + β, the compressive strength at which the

よって、目標の圧縮強度への予測時刻が推定、確認できることにより、速やかにその結果を施工現場へ報知し、型枠4の脱型時刻指示を出すことができるものとなる。

Therefore, when the predicted time to the target compression strength can be estimated and confirmed, the result can be promptly notified to the construction site, and the time for removing the

なお、型枠4にはあらかじめ超音波発信子2や超音波受信子3が装着されているため、脱型時には電源をオフにした後、前記超音波発信子2や超音波受信子3を取り外すことなく前記型枠4とともに移動でき、次のコンクリート打設箇所で型枠4を取り付けた後、覆工コンクリートを打設し、再度前記の測定をスムーズに行うことができる。

Since the

このように、本件発明であれば、コンクリート配合の僅かな変動や練り上がり温度を考慮して目標の圧縮強度を計測するとの準備工程数を増加させることなく、きわめて精度の高い目標圧縮強度が得られる時刻を計測できる脱型時強度推定システムを提供することができる。 As described above, according to the present invention, a highly accurate target compressive strength can be obtained without increasing the number of preparation steps for measuring the target compressive strength in consideration of slight fluctuations in concrete composition and kneading temperature. It is possible to provide a demolding strength estimation system capable of measuring a given time.

特に、最大振幅と圧縮強度の推定式を用いて、打設した覆工コンクリートの最大振幅を算出することで脱型時強度を推定する構成により、配合の僅かな変動や練り上がり温度による複数の関係式を予め用意することなく、目標となる強度に対し一意的な推定式を予め用意するに留めることができ、その点においても極めて有効である。

In particular, using the estimation formula for maximum amplitude and compressive strength, the maximum amplitude of the laid concrete is calculated, and the strength at the time of demolding is estimated. Without preparing a relational expression in advance, a unique estimation expression for the target strength can be prepared in advance, which is also extremely effective.

1 試験練り体

2 超音波発信子

3 超音波受信子

4 覆工コンクリートの型枠

5 覆工コンクリート

6 取り付け孔

7 超音波試験機

8 演算装置

9 ディスプレイ

1 Test Kneaded

Claims (4)

覆工コンクリート打設に際して、覆工コンクリートの超音波測定を行うべく超音波発信子及び受信子を設置して、覆工コンクリートの超音波試験による振幅取得を可能とし、覆工コンクリートの打設及び締固めが完了した時点で、超音波測定を開始し、前記測定により得られた波形から前記振幅を読み取り、前記推定式に代入することで、前記測定時点における覆工コンクリートの推定強度を得る、

ことを特徴とするコンクリート脱型時強度推定システム。

A test kneaded body is formed using concrete having substantially the same composition as the concrete used for placing, and the test kneaded body is subjected to an ultrasonic measurement and a compressive strength test at the same time, and recorded by the ultrasonic measurement. An estimation formula is derived from the relationship between the amplitude of the waveform and the compression strength obtained in the strength test at the same time,

When placing lining concrete, an ultrasonic transmitter and receiver are installed to perform ultrasonic measurement of lining concrete, enabling amplitude acquisition by ultrasonic testing of lining concrete, When compaction is completed, ultrasonic measurement is started, the amplitude is read from the waveform obtained by the measurement, and is substituted into the estimation formula, thereby obtaining the estimated strength of the lining concrete at the measurement time.

Strength estimation system for concrete demolding.

覆工コンクリート打設に際して、覆工コンクリートの超音波測定を行うべく超音波発信子及び受信子を設置して、覆工コンクリートの超音波試験による振幅取得を可能とし、覆工コンクリートの打設及び締固めが完了した時点で、超音波測定を開始し、前記測定により得られた波形から前記振幅を読み取り、前記推定式に代入することで、前記測定時点における覆工コンクリートの推定強度を得る共に、前記得られた推定強度より目標強度への到達時刻を予測する

ことを特徴とするコンクリート脱型時強度推定システム。

A test kneaded body is formed using concrete having substantially the same composition as the concrete used for placing, and the test kneaded body is subjected to an ultrasonic measurement and a compressive strength test at the same time, and recorded by the ultrasonic measurement. An estimation formula is derived from the relationship between the amplitude of the waveform and the compression strength obtained in the strength test at the same time,

When placing lining concrete, an ultrasonic transmitter and receiver are installed to perform ultrasonic measurement of lining concrete, enabling amplitude acquisition by ultrasonic testing of lining concrete, When the compaction is completed, ultrasonic measurement is started, the amplitude is read from the waveform obtained by the measurement, and is substituted into the estimation formula, thereby obtaining the estimated strength of the lining concrete at the measurement time. The strength estimation system at the time of demolding of concrete, wherein the arrival time to the target strength is predicted from the obtained estimated strength.

σ=αln(A)+β、

σ:圧縮強度(N/mm2)、A:振幅(例として、V)、α及びβ:定数

であることを特徴とする請求項1または請求項2記載のコンクリート脱型時強度推定システム。

The estimation formula is

σ = αln (A) + β,

3. The concrete demolding strength estimation system according to claim 1, wherein σ is compressive strength (N / mm 2 ), A is amplitude (for example, V), α and β are constants.

ことを特徴とする請求項1、請求項2または請求項3記載のコンクリート脱型時強度推定システム。

The ultrasonic transmitter and receiver for performing the ultrasonic measurement are attached in advance to a formwork of lining concrete, and are used without performing the work of attaching the ultrasonic transmitter and receiver when the mold is repeatedly used. it can,

4. The concrete demolding strength estimation system according to claim 1, 2, or 3 characterized by the above-mentioned.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016137231A JP6497707B2 (en) | 2016-07-12 | 2016-07-12 | Strength estimation system for concrete demolding |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016137231A JP6497707B2 (en) | 2016-07-12 | 2016-07-12 | Strength estimation system for concrete demolding |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2018009821A true JP2018009821A (en) | 2018-01-18 |

| JP6497707B2 JP6497707B2 (en) | 2019-04-10 |

Family

ID=60993755

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016137231A Active JP6497707B2 (en) | 2016-07-12 | 2016-07-12 | Strength estimation system for concrete demolding |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP6497707B2 (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2018143470A1 (en) | 2017-02-06 | 2018-08-09 | 三菱マテリアル株式会社 | Ceramic/aluminum conjugate, insulated circuit board, led module, ceramic member, method for producing ceramic/aluminum conjugate, and method for producing insulated circuit board |

| JP2022055488A (en) * | 2020-09-29 | 2022-04-08 | 太平洋セメント株式会社 | System for estimating strength development amount of cement water kneaded body, method for estimating strength development amount of cement water kneaded body, and sensor for estimating strength development amount of cement water kneaded body |

| CN114354414A (en) * | 2021-12-30 | 2022-04-15 | 中国水利水电第七工程局有限公司 | Construction site concrete hardening monitoring method |

| CN117162225A (en) * | 2023-11-03 | 2023-12-05 | 江苏神禹港务工程有限公司 | Demoulding and forming method and system for concrete prefabricated part |

Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5437331A (en) * | 1977-08-29 | 1979-03-19 | Nippon Telegraph & Telephone | Automatic covering type shielding excavator |

| JPS5719652A (en) * | 1980-07-09 | 1982-02-01 | Nec Corp | Inspection device of construction state of structure |

| JPS62225949A (en) * | 1986-03-27 | 1987-10-03 | Nippon Kokan Kk <Nkk> | Method of judging setting and hardening of concrete |

| JPH04276546A (en) * | 1991-03-04 | 1992-10-01 | Hitachi Constr Mach Co Ltd | Strength testing method for cement structure using ultrasonic wave |

| JPH04309860A (en) * | 1991-04-09 | 1992-11-02 | Tokimec Inc | Measurement of hardened state of asphalt-paved road and device thereof |

| JPH1010098A (en) * | 1996-06-20 | 1998-01-16 | Idemitsu Kosan Co Ltd | Method for measuring physical properties of asphalt |

| US20020112540A1 (en) * | 2000-12-20 | 2002-08-22 | Schlumberger Technology Corporation | Acoustic method for estimating mechanical properties of a material and apparatus therefor |

| JP2002340864A (en) * | 2001-05-11 | 2002-11-27 | Tokyo Yogyo Co Ltd | Method for measuring the state of hardening of the pouring material layer |

| JP2003194615A (en) * | 2001-12-27 | 2003-07-09 | Akebono Brake Ind Co Ltd | Method and device for detecting filler |

| JP2004150945A (en) * | 2002-10-30 | 2004-05-27 | Central Giken:Kk | Apparatus and method for non-destructive measurement of concrete mechanical properties by surface waves |

| JP2004170099A (en) * | 2002-11-18 | 2004-06-17 | Kurosaki Harima Corp | Method and apparatus for inspecting physical properties of heterogeneous material |

| JP2007333498A (en) * | 2006-06-14 | 2007-12-27 | Shikoku Electric Power Co Inc | Quality evaluation method of concrete and quality evaluation device thereof |

| JP2008050765A (en) * | 2006-08-22 | 2008-03-06 | Okumura Corp | Tunnel lining method |

| JP2010223614A (en) * | 2009-03-19 | 2010-10-07 | Kurosaki Harima Corp | Solidification judgment method for dredged soil |

-

2016

- 2016-07-12 JP JP2016137231A patent/JP6497707B2/en active Active

Patent Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5437331A (en) * | 1977-08-29 | 1979-03-19 | Nippon Telegraph & Telephone | Automatic covering type shielding excavator |

| JPS5719652A (en) * | 1980-07-09 | 1982-02-01 | Nec Corp | Inspection device of construction state of structure |

| JPS62225949A (en) * | 1986-03-27 | 1987-10-03 | Nippon Kokan Kk <Nkk> | Method of judging setting and hardening of concrete |

| JPH04276546A (en) * | 1991-03-04 | 1992-10-01 | Hitachi Constr Mach Co Ltd | Strength testing method for cement structure using ultrasonic wave |

| JPH04309860A (en) * | 1991-04-09 | 1992-11-02 | Tokimec Inc | Measurement of hardened state of asphalt-paved road and device thereof |

| JPH1010098A (en) * | 1996-06-20 | 1998-01-16 | Idemitsu Kosan Co Ltd | Method for measuring physical properties of asphalt |

| US20020112540A1 (en) * | 2000-12-20 | 2002-08-22 | Schlumberger Technology Corporation | Acoustic method for estimating mechanical properties of a material and apparatus therefor |

| JP2002340864A (en) * | 2001-05-11 | 2002-11-27 | Tokyo Yogyo Co Ltd | Method for measuring the state of hardening of the pouring material layer |

| JP2003194615A (en) * | 2001-12-27 | 2003-07-09 | Akebono Brake Ind Co Ltd | Method and device for detecting filler |

| JP2004150945A (en) * | 2002-10-30 | 2004-05-27 | Central Giken:Kk | Apparatus and method for non-destructive measurement of concrete mechanical properties by surface waves |

| JP2004170099A (en) * | 2002-11-18 | 2004-06-17 | Kurosaki Harima Corp | Method and apparatus for inspecting physical properties of heterogeneous material |

| JP2007333498A (en) * | 2006-06-14 | 2007-12-27 | Shikoku Electric Power Co Inc | Quality evaluation method of concrete and quality evaluation device thereof |

| JP2008050765A (en) * | 2006-08-22 | 2008-03-06 | Okumura Corp | Tunnel lining method |

| JP2010223614A (en) * | 2009-03-19 | 2010-10-07 | Kurosaki Harima Corp | Solidification judgment method for dredged soil |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2018143470A1 (en) | 2017-02-06 | 2018-08-09 | 三菱マテリアル株式会社 | Ceramic/aluminum conjugate, insulated circuit board, led module, ceramic member, method for producing ceramic/aluminum conjugate, and method for producing insulated circuit board |

| JP2022055488A (en) * | 2020-09-29 | 2022-04-08 | 太平洋セメント株式会社 | System for estimating strength development amount of cement water kneaded body, method for estimating strength development amount of cement water kneaded body, and sensor for estimating strength development amount of cement water kneaded body |

| JP7561558B2 (en) | 2020-09-29 | 2024-10-04 | 太平洋セメント株式会社 | System for estimating strength development amount of cement-water mixture, method for estimating strength development amount of cement-water mixture, and sensor for estimating strength development amount of cement-water mixture |

| CN114354414A (en) * | 2021-12-30 | 2022-04-15 | 中国水利水电第七工程局有限公司 | Construction site concrete hardening monitoring method |

| CN117162225A (en) * | 2023-11-03 | 2023-12-05 | 江苏神禹港务工程有限公司 | Demoulding and forming method and system for concrete prefabricated part |

| CN117162225B (en) * | 2023-11-03 | 2024-02-23 | 江苏神禹港务工程有限公司 | Demoulding and forming method and system for concrete prefabricated part |

Also Published As

| Publication number | Publication date |

|---|---|

| JP6497707B2 (en) | 2019-04-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6497707B2 (en) | Strength estimation system for concrete demolding | |

| US11604154B2 (en) | Method and system for prediction of concrete maturity | |

| CN109682954A (en) | Multi-modal Assessment of Concrete Intensity method and system | |

| Granja et al. | Comparison between different experimental techniques for stiffness monitoring of cement pastes | |

| JP2009002721A (en) | Method for determining time of demolding concrete | |

| JP2012229982A (en) | Method and apparatus for health monitoring of concrete structure | |

| Providakis et al. | T-WiEYE: An early-age concrete strength development monitoring and miniaturized wireless impedance sensing system | |

| JP6548953B2 (en) | Concrete workability judgment method | |

| CN105510393B (en) | A kind of the multi-parameter detection system and its monitoring method of cemented fill consolidation characteristics | |

| CN104165795A (en) | Method for determining residual flexural capacity of historic building beams | |

| JP7738287B2 (en) | Method for estimating the state of hardened cement paste | |

| JP6198060B2 (en) | Method and apparatus for estimating mortar compressive strength | |

| JP7613891B2 (en) | Method and device for predicting timing of concrete construction, and method for constructing concrete | |

| JP5769074B2 (en) | Quality control test method for crack-suppressing concrete. | |

| JP7257797B2 (en) | Concrete setting time determination device, determination method and concrete construction method | |

| JP2016095210A (en) | Method of estimating concrete strength | |

| JP6198059B2 (en) | Method and apparatus for estimating mortar compressive strength | |

| Fjellström | Measurement and modelling of young concrete properties | |

| JP7145001B2 (en) | Ground strength estimation method | |

| CN108225617A (en) | Sensor calibration apparatus and scaling method | |

| JP2020110999A (en) | Predicting method and predicting device for predicting concrete roughening work possible time and method of constructing concrete | |

| CN100516825C (en) | Method for calculating the shear strength of non-uniform structural planes | |

| JP2016156264A (en) | Concrete re-vibration control method | |

| CN113639804B (en) | Method and system for detecting quality of cable conduit | |

| JP2006329809A (en) | Estimation method of improved ground characteristics |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20180216 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20190107 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20181227 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190301 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20190306 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20190306 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6497707 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |