JP2016064357A - Substrate cleaning device and substrate cleaning method - Google Patents

Substrate cleaning device and substrate cleaning method Download PDFInfo

- Publication number

- JP2016064357A JP2016064357A JP2014194743A JP2014194743A JP2016064357A JP 2016064357 A JP2016064357 A JP 2016064357A JP 2014194743 A JP2014194743 A JP 2014194743A JP 2014194743 A JP2014194743 A JP 2014194743A JP 2016064357 A JP2016064357 A JP 2016064357A

- Authority

- JP

- Japan

- Prior art keywords

- substrate

- cleaning

- brush

- cleaning liquid

- speed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000004140 cleaning Methods 0.000 title claims abstract description 137

- 239000000758 substrate Substances 0.000 title claims abstract description 98

- 238000000034 method Methods 0.000 title claims abstract description 33

- 239000007788 liquid Substances 0.000 claims abstract description 60

- 238000012545 processing Methods 0.000 claims abstract description 20

- 238000012546 transfer Methods 0.000 claims description 3

- 230000003749 cleanliness Effects 0.000 description 2

- 238000001514 detection method Methods 0.000 description 2

- 238000002474 experimental method Methods 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 239000004065 semiconductor Substances 0.000 description 2

- 239000011521 glass Substances 0.000 description 1

- 239000004973 liquid crystal related substance Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000003892 spreading Methods 0.000 description 1

Images

Abstract

Description

本発明は、基板洗浄装置および基板洗浄方法に関する。 The present invention relates to a substrate cleaning apparatus and a substrate cleaning method.

たとえば、液晶表示装置や半導体装置の製造工程においては、ガラス板や半導体ウェーハなどの基板を高い清浄度で洗浄することが要求される工程がある。基板を洗浄する方式としては、洗浄液中に基板を浸漬するディップ方式や、基板を一枚ずつ洗浄する枚葉方式があり、最近では高い清浄度で洗浄することができる枚葉方式が採用されることが多くなってきている。 For example, in a manufacturing process of a liquid crystal display device or a semiconductor device, there is a process that requires cleaning a substrate such as a glass plate or a semiconductor wafer with high cleanliness. As a method for cleaning the substrate, there are a dip method in which the substrate is immersed in a cleaning liquid and a single wafer method in which the substrates are cleaned one by one. Recently, a single wafer method that can be cleaned with high cleanliness is adopted. A lot is happening.

枚葉方式の1つとして、回転駆動される洗浄ブラシを用いて洗浄する洗浄装置が知られている(たとえば、特許文献1)。この洗浄装置は、基板を搬送ローラによって所定方向に搬送するとともに、この基板の搬送経路の上下に洗浄ブラシを対向配置し、この洗浄ブラシを回転させながらブラシを構成する毛材を基板の表面に所定の圧力で接触させ、かつその接触箇所に洗浄液を供給することで、基板を洗浄するようにしている。 As one of the single wafer systems, a cleaning apparatus that performs cleaning using a rotationally driven cleaning brush is known (for example, Patent Document 1). In this cleaning apparatus, the substrate is transported in a predetermined direction by a transport roller, and cleaning brushes are arranged oppositely above and below the transport path of the substrate, and the bristle material constituting the brush is rotated on the surface of the substrate while rotating the cleaning brush. The substrate is cleaned by contacting with a predetermined pressure and supplying a cleaning liquid to the contact location.

従来の基板洗浄装置においては、装置の電源を入れてから切るまで、一定の速度で洗浄用のブラシが回転駆動される。また、装置の電源を入れると、ブラシに向けて洗浄液の供給も開始される。このため、電源を入れた直後に搬入された基板を処理する場合において、洗浄液が行きわたっていないブラシで洗浄を行うことになる。ここで、ブラシに処理液が行きわたっている状態というのは、ブラシのすべての毛束全体に、満遍なく洗浄液が供給されていることを意味する。 In a conventional substrate cleaning apparatus, a cleaning brush is rotationally driven at a constant speed from turning on the apparatus to turning it off. Further, when the apparatus is turned on, supply of the cleaning liquid toward the brush is also started. For this reason, when processing a substrate carried in immediately after the power is turned on, cleaning is performed with a brush that does not have a cleaning solution. Here, the state in which the treatment liquid is distributed to the brush means that the cleaning liquid is uniformly supplied to all the hair bundles of the brush.

ところが、電源を入れた直後のブラシは乾いており、洗浄液が供給され始めると、洗浄液が供給された箇所から濡れ始める。そして、毛束の材質自体の親水性の程度も起因して、ブラシが基板の表面に接触しないうちは、洗浄液がブラシ全体に均一に行きわたりにくい。洗浄液がブラシ全体に均一にいきわたっておらずに偏っていると、ブラシが偏心して回転することになってしまい、これによって、ブラシの回転当初には振動が発生する。このような振動が生じているブラシを用いて基板の表面の洗浄を行なうと、基板の表面に対してブラシが均等に接触しないため、洗浄処理にムラが発生してしまう。 However, the brush immediately after the power is turned on is dry, and when the cleaning liquid starts to be supplied, it begins to get wet from the place where the cleaning liquid is supplied. Further, due to the degree of hydrophilicity of the material of the hair bundle itself, the cleaning liquid does not easily reach the entire brush unless the brush contacts the surface of the substrate. If the cleaning liquid does not spread evenly over the entire brush and is biased, the brush will be eccentric and rotate, which causes vibrations at the beginning of the rotation of the brush. When the surface of the substrate is cleaned using a brush in which such vibration is generated, the brush does not uniformly contact the surface of the substrate, resulting in unevenness in the cleaning process.

このような課題は、上述した電源の入り切り時だけでなく、例えば、基板の搬送経路の途中に基板検出用のセンサを配置し、基板が洗浄位置に到達したことをこのセンサによって検出したことを条件に、ブラシの回転と、ブラシに向けての洗浄液供給が、開始あるいは再開されるような場合にも生じ得る。また、ブラシは連続回転しているがブラシが基板に接している時以外には洗浄液の供給が停止している場合、さらには、洗浄液の供給は続いているがブラシの回転が停止している場合にも生じ得る。 Such a problem is not only when the power supply is turned on and off, but also, for example, a substrate detection sensor is arranged in the middle of the substrate transport path, and this sensor detects that the substrate has reached the cleaning position. As a condition, the rotation of the brush and the supply of the cleaning liquid toward the brush may be started or restarted. In addition, when the brush is continuously rotating but the supply of the cleaning liquid is stopped except when the brush is in contact with the substrate, the supply of the cleaning liquid is continued but the rotation of the brush is stopped. It can also happen.

この発明は、処理液の供給とブラシの回転の少なくともいずれかが行われていなかった状態からでも、洗浄処理を良好に行うことが可能な基板洗浄装置および基板洗浄方法を提供することにある。 It is an object of the present invention to provide a substrate cleaning apparatus and a substrate cleaning method capable of performing a cleaning process satisfactorily even when at least one of supply of a processing liquid and rotation of a brush has not been performed.

本発明に係る基板洗浄装置は、

処理槽において基板を搬送しながら洗浄する基板洗浄装置であって、

前記基板を搬送する複数の搬送ローラを備え、回転可能な複数の搬送軸と、

前記基板の表面に回転しながら接触することにより洗浄処理を行うブラシと、

前記ブラシに洗浄液を供給することができる洗浄液供給部と、

前記基板が前記ブラシによる洗浄位置に到達する前に、洗浄液供給部から洗浄液を供給させながら、前記ブラシの回転速度を、所定時間、前記ブラシによって前記基板の洗浄するときの洗浄時回転速度よりも低速な低速回転となるように制御する制御部と、

を備えたことを特徴とする。

The substrate cleaning apparatus according to the present invention includes:

A substrate cleaning apparatus for cleaning while transporting a substrate in a processing tank,

A plurality of transport rollers for transporting the substrate, and a plurality of transport shafts rotatable;

A brush that performs cleaning by contacting the surface of the substrate while rotating;

A cleaning liquid supply unit capable of supplying a cleaning liquid to the brush;

Before the substrate reaches the cleaning position by the brush, while supplying the cleaning liquid from the cleaning liquid supply unit, the rotation speed of the brush is higher than the rotation speed at the time of cleaning the substrate by the brush for a predetermined time. A control unit for controlling the rotation at a low speed and a low speed,

It is provided with.

また、本発明に係る基板洗浄方法は、

処理槽において搬送軸に備えられた搬送ローラによって基板を搬送しながら、洗浄液を供給しつつ、回転するブラシを前記基板表面に接触することによって洗浄処理する基板洗浄方法であって、

前記基板が前記ブラシによる洗浄位置に到達する前に、前記洗浄液を供給させながら前記ブラシの回転速度を、所定時間、低速回転となるようにする低速回転工程と、

前記低速回転工程の後、前記基板を前記処理槽に搬入させる基板搬送工程と、

前記基板搬送工程の後、前記低速回転工程における前記ブラシの回転速度よりも速い洗浄時回転速度となるようにするブラシ回転速度変更工程と、

を有することを特徴とする。

The substrate cleaning method according to the present invention includes:

A substrate cleaning method for performing a cleaning process by bringing a rotating brush into contact with the substrate surface while supplying a cleaning liquid while transporting a substrate by a transport roller provided on a transport shaft in a processing tank,

A low-speed rotation step of rotating the brush at a low speed for a predetermined time while supplying the cleaning liquid before the substrate reaches the cleaning position by the brush;

After the low-speed rotation step, a substrate transfer step for bringing the substrate into the processing tank,

After the substrate transport step, a brush rotation speed changing step that makes the rotation speed at the time of cleaning faster than the rotation speed of the brush in the low speed rotation step,

It is characterized by having.

この発明によれば、処理液の供給とブラシの回転の少なくともいずれかが行われていなかった状態からでも、基板の洗浄処理を良好に行うことが可能となる。 According to the present invention, it is possible to satisfactorily clean the substrate even in a state where at least one of the supply of the processing liquid and the rotation of the brush has not been performed.

以下、この発明の実施形態について図を用いて説明する。 Embodiments of the present invention will be described below with reference to the drawings.

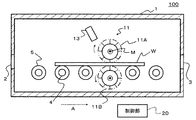

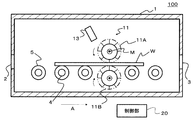

図1に示すように、実施の一形態に係る基板洗浄装置100は、基板Wを洗浄処理する処理槽1と、処理槽1に基板Wを搬入するための搬入口2と、処理を終えた基板Wを搬出する搬出口3とを有している。処理槽1内には、基板の搬送方向(図1に示す矢印Aの方向)とは直交する方向に延びる搬送軸4が、基板の搬送方向に沿って複数本、所定間隔で回転可能に配置されており、各搬送軸4には複数の搬送ローラ5が所定間隔で設けられている。各搬送軸4は、図示しない駆動装置によって回転駆動されるようになっている。さらに、処理槽1内には、上下2本で対をなすブラシ11(上部ブラシ11A、下部ブラシ11B)が、軸線を基板Wの搬送方向(図1に示す矢印Aの方向)に対して交差させて配置されている。一対のブラシ11は、その軸方向一端側に連結された駆動モータMによって同期して回転駆動される。

As shown in FIG. 1, the

上部ブラシ11A付近には、洗浄液Lを供給する洗浄ノズル13(洗浄液供給ノズル)が設けられ、ブラシ11および基板Wに洗浄液Lが供給され得るようになっている。

A cleaning nozzle 13 (cleaning liquid supply nozzle) for supplying the cleaning liquid L is provided in the vicinity of the

搬送軸4の駆動装置やブラシ11の駆動モータMは、制御部20によって、後述するように制御される。洗浄ノズル13からの洗浄液Lの供給タイミングおよび供給量も、制御部20にて制御される。詳細は、後述する。

The drive device for the transport shaft 4 and the drive motor M for the

次に、基板洗浄装置100による洗浄工程について図1および図2を用いて説明する。

Next, a cleaning process by the

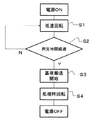

まず、基板洗浄装置100の電源が入れられると、上部ブラシ11Aは基板Wの搬送方向とは逆方向に、下部ブラシ11Bは基板Wの搬送方向と同方向に回転されるようになっている。なお、この回転方向は逆方向であってもいい。またこのときの回転速度は、基板洗浄時の回転速度よりも低速とされる(低速回転工程:S1)。ここで、低速回転工程におけるブラシの回転速度とは、回転するブラシ全体に洗浄液Lを短時間で満遍なく行きわたり得る回転速度をいう。この回転速度は、ブラシ11が基板の表面に接し、基板を洗浄するときの回転速度(洗浄処理に最も適した洗浄時回転速度)より低速とされる。例をあげれば、洗浄時回転速度の1/10程度とされる。なお、ブラシ11の径や洗浄液Lの供給量によって最適な回転速度が異なるため、行う処理に応じて予め実験によって求めた好ましい速度が設定される。

First, when the

さらに基板洗浄装置100の電源が入れられると、洗浄ノズル13からの洗浄液Lの供給も始まる。洗浄液Lの供給開始は、ブラシ11の低速回転開始と同時でも良いし、ブラシ11の低速回転開始の直後でも良いし、ブラシ11の低速回転開始の直前でも良い。基板Wの搬送開始前に、ブラシ11の低速回転と洗浄液Lの供給とが所定時間行われる。ここで「所定時間」とは、ブラシ11を前述した低速で回転させたときの、洗浄液Lがブラシ全体に満遍なく行きわたる時間を予め求めておき、この時間を採用する。この洗浄液Lを満遍なくブラシ11全体に行きわたらせるための最適な所定時間は、ブラシ11の径や洗浄液Lの供給量によって異なるため、行う処理に応じて予め実験によって求めた時間が設定される。

Further, when the

そこで、低速回転開始時から所定時間(例えば、1分)が経過したか否かが判断され、所定時間経過していない場合は(S2でN)、低速回転工程が継続される。所定時間が経過したと判断されると(S2でY)、搬送軸4が回転し始め、搬入口2から基板Wが搬入され、基板W搬送が開始される(基板搬送工程:S3)。そして、基板Wがブラシ11に到達する前にブラシ11の回転速度が洗浄時回転速度に設定される(ブラシ回転速度変更工程:S4)。基板Wの処理が完了すると、電源が切られ、ブラシ11の回転、搬送軸4の回転、洗浄ノズル13からの洗浄液Lの供給が止まる。

Therefore, it is determined whether or not a predetermined time (for example, 1 minute) has elapsed since the start of low-speed rotation. If the predetermined time has not elapsed (N in S2), the low-speed rotation process is continued. When it is determined that the predetermined time has elapsed (Y in S2), the transport shaft 4 starts to rotate, the substrate W is loaded from the carry-in entrance 2, and the substrate W transport is started (substrate transport process: S3). Then, before the substrate W reaches the

このように所定時間低速回転工程を行うことによって、ブラシ11の毛束と毛束の間を含めたブラシ全体に満遍なく洗浄液Lが行きわたり、ブラシの回転による振動も抑えられる。従って、その後、搬送されてくる基板W表面にブラシは均等に接触し、ムラのない良好な洗浄処理が行われる。

By performing the low-speed rotation process for a predetermined time in this way, the cleaning liquid L is distributed evenly over the entire brush including between the hair bundles of the

以上述べたように、上記実施の形態に係る基板洗浄装置100においては、基板洗浄装置100の電源が切られるなどして、しばらく洗浄液Lの供給やブラシ11の回転が行われていなかった状態からでも、基板の洗浄処理を良好に行うことが可能となる。

As described above, in the

なお、本発明の適用においては、電源の入り切り時だけでなく、前述したように、基板検出用のセンサによって検出したことを条件に、ブラシの回転と、ブラシに向けての洗浄液供給が、開始あるいは再開されるような場合、ブラシは連続回転しているがブラシが基板に接している時以外には洗浄液の供給が停止している場合、さらには、洗浄液の供給は続いているがブラシの回転が停止している場合にも適用できる。要は、洗浄される基板が、ブラシによる洗浄位置に到達する前に、低速回転工程が実施され、そして終了させられるように構成されていればよい。 In addition, in the application of the present invention, the rotation of the brush and the supply of the cleaning liquid toward the brush are started not only when the power is turned on and off, but on the condition that it is detected by the substrate detection sensor as described above. Alternatively, in the case of restarting, when the brush is continuously rotating but the supply of the cleaning liquid is stopped except when the brush is in contact with the substrate, the supply of the cleaning liquid continues, but the brush It can also be applied when rotation is stopped. In short, it is only necessary that the low-speed rotation process is performed and terminated before the substrate to be cleaned reaches the cleaning position by the brush.

また、上記実施形態においては、ブラシは上部ブラシと下ブラシの一対である例を説明したがこれに限らず、いずれか一方であっても良い。 In the above-described embodiment, an example in which the brush is a pair of the upper brush and the lower brush has been described.

さらに、上記実施形態においては、洗浄ノズル13は、上部ブラシ11A側に位置している例を説明したが、これに限らず、上部ブラシ11A側、下部ブラシ11B側の両方に備えるようにしても良い。両方に備えられている場合、より短い時間でブラシの毛束と毛束の間に満遍なく洗浄液Lが行きわたりやすくなる。

Furthermore, in the above embodiment, the example in which the cleaning

また、洗浄ノズル13等の洗浄液供給部から供給される洗浄液の量は、ブラシの低速回転工程、ブラシ回転速度変更工程のいずれにおいても同量でもよいし、いずれかを他方よりも多くするようにしてもよい。特に、基板がブラシによる洗浄位置に到達したブラシ回転速度変更工程よりも、洗浄位置に到達する前の方のブラシ低速回転工程の方が少なくする方が好ましい。ブラシ低速回転工程においては、既述のとおり、ブラシの振動を抑えることが目的となるため、一度に多くの洗浄液を供給するよりも、少量の洗浄液を満遍なく供給することが望ましい。

Further, the amount of the cleaning liquid supplied from the cleaning liquid supply unit such as the cleaning

以上、本発明のいくつかの実施形態を説明したが、これらの実施形態は、例として提示したものであり、発明の範囲を限定することは意図していない。これら新規な実施形態は、その他の様々な形態で実施されることが可能であり、発明の要旨を逸脱しない範囲で、種腫の省略、置き換え、変更を行うことができる。これら実施形態やその変形は、発明の範囲や要旨に含まれるとともに、特許請求の範囲に記載された発明とその均等の範囲に含まれる。 As mentioned above, although some embodiment of this invention was described, these embodiment is shown as an example and is not intending limiting the range of invention. These novel embodiments can be implemented in various other forms, and ovarium can be omitted, replaced, or changed without departing from the gist of the invention. These embodiments and modifications thereof are included in the scope and gist of the invention, and are included in the invention described in the claims and the equivalents thereof.

1 処理槽

2 搬入口

3 搬出口

4 搬送軸

5 搬送ローラ

11 ブラシ

11A 上部ブラシ

11B 下部ブラシ

13 洗浄ノズル(洗浄液供給部)

100 基板洗浄装置

A 基板搬送方向

L 洗浄液

W 基板

DESCRIPTION OF SYMBOLS 1 Processing tank 2 Carry-in

100 Substrate cleaning device A Substrate transport direction L Cleaning liquid W Substrate

Claims (4)

前記基板を搬送する複数の搬送ローラを備え、回転可能な複数の搬送軸と、

前記基板の表面に回転しながら接触することにより洗浄処理を行うブラシと、

前記ブラシに洗浄液を供給することができる洗浄液供給部と、

前記基板が前記ブラシによる洗浄位置に到達する前に、洗浄液供給部から洗浄液を供給させながら、前記ブラシの回転速度を、所定時間、前記ブラシによって前記基板の洗浄するときの洗浄時回転速度よりも低速な低速回転となるように制御する制御部と、

を備えたことを特徴とする基板洗浄装置。 A substrate cleaning apparatus for cleaning while transporting a substrate in a processing tank,

A plurality of transport rollers for transporting the substrate, and a plurality of transport shafts rotatable;

A brush that performs cleaning by contacting the surface of the substrate while rotating;

A cleaning liquid supply unit capable of supplying a cleaning liquid to the brush;

Before the substrate reaches the cleaning position by the brush, while supplying the cleaning liquid from the cleaning liquid supply unit, the rotation speed of the brush is higher than the rotation speed at the time of cleaning the substrate by the brush for a predetermined time. A control unit for controlling the rotation at a low speed and a low speed,

A substrate cleaning apparatus comprising:

前記基板が前記ブラシによる洗浄位置に到達する前に、前記洗浄液を供給させながら前記ブラシの回転速度を、所定時間、低速回転となるようにする低速回転工程と、

前記低速回転工程の後、前記基板を前記処理槽に搬入させる基板搬送工程と、

前記基板搬送工程の後、前記低速回転工程における前記ブラシの回転速度よりも速い洗浄時回転速度となるようにするブラシ回転速度変更工程と、

を有することを特徴とする基板洗浄方法。 A substrate cleaning method for performing a cleaning process by bringing a rotating brush into contact with the substrate surface while supplying a cleaning liquid while transporting a substrate by a transport roller provided on a transport shaft in a processing tank,

A low-speed rotation step of rotating the brush at a low speed for a predetermined time while supplying the cleaning liquid before the substrate reaches the cleaning position by the brush;

After the low-speed rotation step, a substrate transfer step for bringing the substrate into the processing tank,

After the substrate transport step, a brush rotation speed changing step that makes the rotation speed at the time of cleaning faster than the rotation speed of the brush in the low speed rotation step,

A substrate cleaning method characterized by comprising:

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014194743A JP2016064357A (en) | 2014-09-25 | 2014-09-25 | Substrate cleaning device and substrate cleaning method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014194743A JP2016064357A (en) | 2014-09-25 | 2014-09-25 | Substrate cleaning device and substrate cleaning method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2016064357A true JP2016064357A (en) | 2016-04-28 |

| JP2016064357A5 JP2016064357A5 (en) | 2018-06-07 |

Family

ID=55804721

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014194743A Pending JP2016064357A (en) | 2014-09-25 | 2014-09-25 | Substrate cleaning device and substrate cleaning method |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2016064357A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107537800A (en) * | 2017-09-04 | 2018-01-05 | 东莞市沃顿印刷有限公司 | A kind of new raw material dust removal machine |

| CN112718865A (en) * | 2021-01-08 | 2021-04-30 | 中铝东南材料院(福建)科技有限公司 | Production method for reducing aluminum adhesion on surface of aluminum alloy hot rolling roller and aluminum powder |

| WO2023195537A1 (en) * | 2022-04-08 | 2023-10-12 | 株式会社荏原製作所 | Substrate cleaning device, substrate processing device, substrate cleaning method, and program |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH076987A (en) * | 1993-06-15 | 1995-01-10 | Toshiba Corp | Cleaning apparatus |

| JP2002096037A (en) * | 2000-09-22 | 2002-04-02 | Tokyo Electron Ltd | Tool and device for cleaning substrate |

| JP2002307023A (en) * | 2001-04-13 | 2002-10-22 | Display Technologies Inc | Brush washing apparatus provided with self washing function and method of manufacturing flat display apparatus or semiconductor element using the same |

| JP2003112951A (en) * | 2001-10-05 | 2003-04-18 | Dainippon Printing Co Ltd | Apparatus for cleaning glass sheet |

-

2014

- 2014-09-25 JP JP2014194743A patent/JP2016064357A/en active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH076987A (en) * | 1993-06-15 | 1995-01-10 | Toshiba Corp | Cleaning apparatus |

| JP2002096037A (en) * | 2000-09-22 | 2002-04-02 | Tokyo Electron Ltd | Tool and device for cleaning substrate |

| JP2002307023A (en) * | 2001-04-13 | 2002-10-22 | Display Technologies Inc | Brush washing apparatus provided with self washing function and method of manufacturing flat display apparatus or semiconductor element using the same |

| JP2003112951A (en) * | 2001-10-05 | 2003-04-18 | Dainippon Printing Co Ltd | Apparatus for cleaning glass sheet |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107537800A (en) * | 2017-09-04 | 2018-01-05 | 东莞市沃顿印刷有限公司 | A kind of new raw material dust removal machine |

| CN112718865A (en) * | 2021-01-08 | 2021-04-30 | 中铝东南材料院(福建)科技有限公司 | Production method for reducing aluminum adhesion on surface of aluminum alloy hot rolling roller and aluminum powder |

| WO2023195537A1 (en) * | 2022-04-08 | 2023-10-12 | 株式会社荏原製作所 | Substrate cleaning device, substrate processing device, substrate cleaning method, and program |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5535687B2 (en) | Substrate cleaning method and substrate cleaning apparatus | |

| JP2011504653A5 (en) | ||

| JP2016064357A (en) | Substrate cleaning device and substrate cleaning method | |

| JP2010212295A (en) | Substrate cleaning device and substrate cleaning method | |

| KR102220059B1 (en) | Workpiece conveyance method and workpiece conveyance device | |

| JP2010114123A (en) | Substrate processing apparatus and method | |

| JP2017098278A (en) | Etching apparatus | |

| JP2016064357A5 (en) | ||

| JP3628919B2 (en) | Substrate processing apparatus and substrate processing method | |

| JP6060140B2 (en) | Dry fingerprint cleaning device | |

| JP2002239485A (en) | Apparatus and method for cleaning substrate | |

| KR20050077275A (en) | Substrate treating apparatus and method | |

| JP6552363B2 (en) | Substrate drying apparatus and substrate processing apparatus | |

| JP4908316B2 (en) | Cleaning apparatus, flat panel display manufacturing apparatus and flat panel display | |

| US20100307539A1 (en) | Substrate liquid processing apparatus, substrate liquid processing method, and storage medium having substrate liquid processing program stored therein | |

| JP2007317802A (en) | Apparatus and method of dry-processing substrate | |

| KR102278073B1 (en) | Apparatus for treating substrate | |

| JP2015191963A (en) | Substrate cleaning device and substrate cleaning method | |

| JP6218621B2 (en) | Semiconductor wafer direction aligning apparatus and semiconductor wafer direction aligning method | |

| JP5784459B2 (en) | Processing equipment | |

| JP2007175653A (en) | Washing device, and manufacturing method of display device using the same | |

| JP2001284310A (en) | Apparatus and method for treating substrate | |

| KR102202465B1 (en) | Unit for conveying substrate and apparatus for treating substrate with the unit and substrate conveying method | |

| JP6420181B2 (en) | Cleaning device | |

| JP2017135305A (en) | Etching device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20170921 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20180419 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20180613 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20180627 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20180827 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20190108 |