JP2013521196A - 柔軟な金属合金の壁部を備えた流体サンプリング容器 - Google Patents

柔軟な金属合金の壁部を備えた流体サンプリング容器 Download PDFInfo

- Publication number

- JP2013521196A JP2013521196A JP2012555191A JP2012555191A JP2013521196A JP 2013521196 A JP2013521196 A JP 2013521196A JP 2012555191 A JP2012555191 A JP 2012555191A JP 2012555191 A JP2012555191 A JP 2012555191A JP 2013521196 A JP2013521196 A JP 2013521196A

- Authority

- JP

- Japan

- Prior art keywords

- sampling

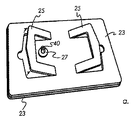

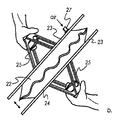

- valve

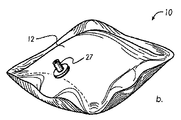

- bag

- metal alloy

- sampling bag

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 229910001092 metal group alloy Inorganic materials 0.000 title claims abstract description 93

- 238000005070 sampling Methods 0.000 title claims description 291

- 239000012530 fluid Substances 0.000 title abstract description 34

- 229910001220 stainless steel Inorganic materials 0.000 claims abstract description 14

- 239000010935 stainless steel Substances 0.000 claims abstract description 14

- 229910001000 nickel titanium Inorganic materials 0.000 claims abstract description 6

- 229910001256 stainless steel alloy Inorganic materials 0.000 claims abstract description 6

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims abstract description 4

- 229910052799 carbon Inorganic materials 0.000 claims abstract description 4

- HLXZNVUGXRDIFK-UHFFFAOYSA-N nickel titanium Chemical compound [Ti].[Ti].[Ti].[Ti].[Ti].[Ti].[Ti].[Ti].[Ti].[Ti].[Ti].[Ni].[Ni].[Ni].[Ni].[Ni].[Ni].[Ni].[Ni].[Ni].[Ni].[Ni].[Ni].[Ni].[Ni] HLXZNVUGXRDIFK-UHFFFAOYSA-N 0.000 claims abstract description 4

- 238000000034 method Methods 0.000 claims description 82

- 239000000463 material Substances 0.000 claims description 52

- 239000004033 plastic Substances 0.000 claims description 33

- 229920003023 plastic Polymers 0.000 claims description 33

- 238000007789 sealing Methods 0.000 claims description 19

- KRKNYBCHXYNGOX-UHFFFAOYSA-N citric acid Chemical compound OC(=O)CC(O)(C(O)=O)CC(O)=O KRKNYBCHXYNGOX-UHFFFAOYSA-N 0.000 claims description 15

- 239000000203 mixture Substances 0.000 claims description 13

- NBVXSUQYWXRMNV-UHFFFAOYSA-N fluoromethane Chemical compound FC NBVXSUQYWXRMNV-UHFFFAOYSA-N 0.000 claims description 10

- 238000003466 welding Methods 0.000 claims description 10

- 239000002253 acid Substances 0.000 claims description 8

- 239000000853 adhesive Substances 0.000 claims description 7

- 230000001070 adhesive effect Effects 0.000 claims description 7

- 238000005520 cutting process Methods 0.000 claims description 7

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 claims description 6

- GRYLNZFGIOXLOG-UHFFFAOYSA-N Nitric acid Chemical compound O[N+]([O-])=O GRYLNZFGIOXLOG-UHFFFAOYSA-N 0.000 claims description 5

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 claims description 5

- 238000001035 drying Methods 0.000 claims description 5

- 229910017604 nitric acid Inorganic materials 0.000 claims description 5

- 229910052710 silicon Inorganic materials 0.000 claims description 5

- 239000010703 silicon Substances 0.000 claims description 5

- VEXZGXHMUGYJMC-UHFFFAOYSA-N Hydrochloric acid Chemical compound Cl VEXZGXHMUGYJMC-UHFFFAOYSA-N 0.000 claims description 4

- 238000005260 corrosion Methods 0.000 claims description 4

- 230000007797 corrosion Effects 0.000 claims description 4

- 239000000123 paper Substances 0.000 claims description 4

- 239000011087 paperboard Substances 0.000 claims description 4

- 239000000126 substance Substances 0.000 claims description 4

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 claims description 3

- 238000011049 filling Methods 0.000 claims description 3

- 238000010438 heat treatment Methods 0.000 claims description 3

- 229910052759 nickel Inorganic materials 0.000 claims description 3

- 238000005498 polishing Methods 0.000 claims description 3

- 229920001343 polytetrafluoroethylene Polymers 0.000 claims description 3

- 239000004810 polytetrafluoroethylene Substances 0.000 claims description 3

- 229910052719 titanium Inorganic materials 0.000 claims description 3

- 239000010936 titanium Substances 0.000 claims description 3

- FJKROLUGYXJWQN-UHFFFAOYSA-N 4-hydroxybenzoic acid Chemical compound OC(=O)C1=CC=C(O)C=C1 FJKROLUGYXJWQN-UHFFFAOYSA-N 0.000 claims description 2

- 229920004943 Delrin® Polymers 0.000 claims description 2

- DHKHKXVYLBGOIT-UHFFFAOYSA-N acetaldehyde Diethyl Acetal Natural products CCOC(C)OCC DHKHKXVYLBGOIT-UHFFFAOYSA-N 0.000 claims description 2

- 125000002777 acetyl group Chemical class [H]C([H])([H])C(*)=O 0.000 claims description 2

- 239000003522 acrylic cement Substances 0.000 claims description 2

- 239000003093 cationic surfactant Substances 0.000 claims description 2

- 239000003153 chemical reaction reagent Substances 0.000 claims description 2

- 238000005553 drilling Methods 0.000 claims description 2

- YAGKRVSRTSUGEY-UHFFFAOYSA-N ferricyanide Chemical compound [Fe+3].N#[C-].N#[C-].N#[C-].N#[C-].N#[C-].N#[C-] YAGKRVSRTSUGEY-UHFFFAOYSA-N 0.000 claims description 2

- 238000003698 laser cutting Methods 0.000 claims description 2

- 229920009441 perflouroethylene propylene Polymers 0.000 claims description 2

- 239000002985 plastic film Substances 0.000 claims description 2

- 238000009428 plumbing Methods 0.000 claims description 2

- 239000003566 sealing material Substances 0.000 claims description 2

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 claims description 2

- 229920002554 vinyl polymer Polymers 0.000 claims description 2

- 238000010030 laminating Methods 0.000 claims 1

- 239000007789 gas Substances 0.000 description 15

- 230000035699 permeability Effects 0.000 description 14

- 230000008569 process Effects 0.000 description 10

- 229910052751 metal Inorganic materials 0.000 description 9

- 239000002184 metal Substances 0.000 description 9

- 238000001179 sorption measurement Methods 0.000 description 8

- 230000037303 wrinkles Effects 0.000 description 7

- 230000007774 longterm Effects 0.000 description 6

- 230000008901 benefit Effects 0.000 description 5

- 238000004519 manufacturing process Methods 0.000 description 5

- 238000002161 passivation Methods 0.000 description 5

- -1 polyethylene Polymers 0.000 description 5

- 230000002829 reductive effect Effects 0.000 description 5

- 239000000956 alloy Substances 0.000 description 4

- 238000013461 design Methods 0.000 description 4

- 238000003475 lamination Methods 0.000 description 4

- 239000007788 liquid Substances 0.000 description 4

- 238000011084 recovery Methods 0.000 description 4

- 229910045601 alloy Inorganic materials 0.000 description 3

- 230000008859 change Effects 0.000 description 3

- 150000001875 compounds Chemical class 0.000 description 3

- 238000011109 contamination Methods 0.000 description 3

- 239000002648 laminated material Substances 0.000 description 3

- 238000010926 purge Methods 0.000 description 3

- 239000012855 volatile organic compound Substances 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- 239000004698 Polyethylene Substances 0.000 description 2

- 238000010521 absorption reaction Methods 0.000 description 2

- 239000003929 acidic solution Substances 0.000 description 2

- 238000013459 approach Methods 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000009835 boiling Methods 0.000 description 2

- 238000006388 chemical passivation reaction Methods 0.000 description 2

- 238000004891 communication Methods 0.000 description 2

- 239000002131 composite material Substances 0.000 description 2

- 239000002650 laminated plastic Substances 0.000 description 2

- 238000012423 maintenance Methods 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 230000036961 partial effect Effects 0.000 description 2

- 229920000573 polyethylene Polymers 0.000 description 2

- 229920000642 polymer Polymers 0.000 description 2

- 229920002620 polyvinyl fluoride Polymers 0.000 description 2

- 238000005096 rolling process Methods 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- 238000012360 testing method Methods 0.000 description 2

- 241001391944 Commicarpus scandens Species 0.000 description 1

- 229910001200 Ferrotitanium Inorganic materials 0.000 description 1

- 229920006370 Kynar Polymers 0.000 description 1

- 239000002033 PVDF binder Substances 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 1

- 239000004809 Teflon Substances 0.000 description 1

- 229920006362 Teflon® Polymers 0.000 description 1

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 1

- 238000004026 adhesive bonding Methods 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 230000008602 contraction Effects 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 238000012864 cross contamination Methods 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000003795 desorption Methods 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 239000011888 foil Substances 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 238000010348 incorporation Methods 0.000 description 1

- 230000000670 limiting effect Effects 0.000 description 1

- 239000011344 liquid material Substances 0.000 description 1

- 230000005923 long-lasting effect Effects 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 239000000178 monomer Substances 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 229910052756 noble gas Inorganic materials 0.000 description 1

- 238000010943 off-gassing Methods 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 238000005192 partition Methods 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 239000004417 polycarbonate Substances 0.000 description 1

- 229920000515 polycarbonate Polymers 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920000098 polyolefin Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 229920002981 polyvinylidene fluoride Polymers 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 238000005086 pumping Methods 0.000 description 1

- 238000012797 qualification Methods 0.000 description 1

- 238000012552 review Methods 0.000 description 1

- 229920006395 saturated elastomer Polymers 0.000 description 1

- 239000013464 silicone adhesive Substances 0.000 description 1

- 239000007779 soft material Substances 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 229910052717 sulfur Inorganic materials 0.000 description 1

- 239000011593 sulfur Substances 0.000 description 1

- 230000002123 temporal effect Effects 0.000 description 1

- 238000005406 washing Methods 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N1/00—Sampling; Preparing specimens for investigation

- G01N1/02—Devices for withdrawing samples

Landscapes

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Sampling And Sample Adjustment (AREA)

- Bag Frames (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US30850210P | 2010-02-26 | 2010-02-26 | |

| US61/308,502 | 2010-02-26 | ||

| PCT/US2011/026293 WO2011106680A1 (en) | 2010-02-26 | 2011-02-25 | Container for fluid sampling with flexible metal alloy walls |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2013521196A true JP2013521196A (ja) | 2013-06-10 |

| JP2013521196A5 JP2013521196A5 (enExample) | 2014-04-17 |

Family

ID=44507237

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012555191A Pending JP2013521196A (ja) | 2010-02-26 | 2011-02-25 | 柔軟な金属合金の壁部を備えた流体サンプリング容器 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US20110219891A1 (enExample) |

| EP (1) | EP2539239A1 (enExample) |

| JP (1) | JP2013521196A (enExample) |

| CN (1) | CN102883967A (enExample) |

| BR (1) | BR112012021008A2 (enExample) |

| CA (1) | CA2790035A1 (enExample) |

| MX (1) | MX2012009703A (enExample) |

| WO (1) | WO2011106680A1 (enExample) |

Families Citing this family (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9188509B2 (en) | 2011-12-28 | 2015-11-17 | Nextteq Llc | Sampling device |

| EP2798329A4 (en) * | 2011-12-28 | 2015-12-16 | Nextteq Llc | SAMPLING DEVICE |

| DE102012210040A1 (de) * | 2012-06-14 | 2013-12-19 | Inficon Gmbh | Prüfvorrichtung mit einem Prüfgasbehälter |

| CN103336106B (zh) * | 2013-06-24 | 2015-04-22 | 浙江大学 | 内置柔性反应腔的高温高压试验平台 |

| US20150282634A1 (en) * | 2014-04-04 | 2015-10-08 | American Recreation Products, LLC. | Inflatable device having integrated bellows |

| WO2016197022A1 (en) * | 2015-06-05 | 2016-12-08 | Vecere William T | Low permeability sample bag |

| CN105067391A (zh) * | 2015-07-16 | 2015-11-18 | 苏州华达仪器设备有限公司 | 一种方便携带的空气快速取样袋 |

| CN106323700A (zh) * | 2016-08-03 | 2017-01-11 | 上海化工研究院 | 一种弹簧内撑自吸式常压/负压气体采样装置及其应用 |

| EP3617690B1 (en) * | 2018-08-31 | 2022-10-26 | Endress + Hauser Conducta GmbH+Co. KG | Sampling system and sampling method for processing a liquid sample |

| US10634558B1 (en) | 2018-11-13 | 2020-04-28 | Anna Ailene Scott | Air quality monitoring system and enhanced spectrophotometric chemical sensor |

| CN109289955B (zh) * | 2018-11-28 | 2023-08-22 | 北京市中医研究所 | 一种风琴竖式可调间距多浓度加样槽 |

| US10697947B1 (en) | 2019-01-23 | 2020-06-30 | Project Canary, Inc. | Apparatus and methods for reducing fugitive gas emissions at oil facilities |

| US11150167B1 (en) | 2020-04-03 | 2021-10-19 | Project Canary, Pbc | Air sampling actuator and associated method |

| CA3191655A1 (en) | 2020-09-10 | 2022-03-17 | Anna Ailene Scott | Air quality monitoring system and method |

| US11774426B1 (en) | 2022-03-25 | 2023-10-03 | Project Canary, Pbc | Emissions detection system and methods |

| US11887203B1 (en) | 2023-02-01 | 2024-01-30 | Project Canary, Pbc | Air quality monitors minimization system and methods |

| US11727519B1 (en) | 2023-02-01 | 2023-08-15 | Project Canary, Pbc | Air quality monitors minimization system and methods |

| US11861753B1 (en) | 2023-02-01 | 2024-01-02 | Project Canary, Pbc | Air quality monitors minimization system and methods |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5218390A (en) * | 1975-08-01 | 1977-02-10 | Osaka Kagaku Bunseki Center:Kk | Method of smpling gas for analysis |

| JP3005096U (ja) * | 1994-06-09 | 1994-12-06 | 株式会社司測研 | 流体試料用サンプルバッグ |

| JPH11165745A (ja) * | 1997-12-04 | 1999-06-22 | Tsukasa Sokken:Kk | 流体試料用薄板製バッグ |

Family Cites Families (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3346883A (en) * | 1965-10-21 | 1967-10-17 | Louise Sandler | Receptacles |

| FR2512481A1 (fr) * | 1981-09-04 | 1983-03-11 | Stein Industrie | Dispositif de supportage tangentiel d'un reservoir horizontal d'epaisseur faible par rapport a son diametre |

| US4415085A (en) * | 1981-12-21 | 1983-11-15 | Eli Lilly And Company | Dry pharmaceutical system |

| CA1196800A (en) * | 1983-04-08 | 1985-11-19 | Her Majesty The Queen, In Right Of Canada, As Represented By The Minister Of National Defence | Atmospheric air sample collection device |

| US5442289A (en) * | 1989-07-31 | 1995-08-15 | Biomagnetic Technologies, Inc. | Biomagnetometer having flexible sensor |

| CH679886A5 (enExample) * | 1989-09-04 | 1992-04-30 | Topic Ag | |

| US5218874A (en) * | 1990-08-29 | 1993-06-15 | Vecere William T | Fitting and tube apparatus for gas emission sample container |

| US5074155A (en) * | 1990-08-29 | 1991-12-24 | Vecere William T | Fitting and tube apparatus for gas emission sample container |

| US5239877A (en) * | 1992-06-26 | 1993-08-31 | Engineered Devices, Inc. | Gas emission sample container with internal mixing fitting |

| US5522272A (en) * | 1993-11-04 | 1996-06-04 | Bellaire Industries, Inc. | Gas emission sample container with heating means |

| US5437199A (en) * | 1994-02-16 | 1995-08-01 | Kaplan; Larry | Sampling kit for compressed air/gas sources |

| US5456126A (en) * | 1994-03-21 | 1995-10-10 | Bellaire Industries, Inc. | Fluid valve and gas sample container using same |

| US5479739A (en) * | 1994-08-31 | 1996-01-02 | Livingston; J. Mark | Spring actuated marine animal capturing device |

| US5913232A (en) * | 1996-05-20 | 1999-06-15 | Sendx Medical, Inc. | reference solution container for blood gas/electrolyte measuring system |

| FR2791645B1 (fr) * | 1999-04-02 | 2001-06-15 | Valois Sa | Echantillon de produit fluide destine a la presse |

| US6497156B2 (en) * | 1999-12-28 | 2002-12-24 | Horiba Instruments, Inc. | Method for collecting exhaust gases |

| AT4039U3 (de) * | 2000-10-03 | 2001-07-25 | Avl List Gmbh | Abgas-probenbeutel |

| CA2364520C (en) * | 2000-12-08 | 2010-04-20 | Toyo Seikan Kaisha, Ltd. | Packaging material and multi-layer container |

| CA2484215C (en) * | 2002-04-23 | 2015-02-24 | Kirk Max Ririe | Sample withdrawal and dispensing device |

| US8337475B2 (en) * | 2004-10-12 | 2012-12-25 | C. R. Bard, Inc. | Corporeal drainage system |

| DE102006048754A1 (de) * | 2006-10-12 | 2008-04-17 | Fev Motorentechnik Gmbh | Abgassammelbeutel |

| US8191437B2 (en) * | 2007-05-15 | 2012-06-05 | O.I. Corporation | Gas sample collection and analysis |

| CA2623928A1 (en) * | 2007-11-13 | 2009-05-13 | Emballage Rouville Inc. | Bag with reinforced handles and process of making the bag |

| US7886580B2 (en) * | 2007-12-06 | 2011-02-15 | Apv North America, Inc. | Heat exchanger leak testing method and apparatus |

-

2011

- 2011-02-25 US US13/035,163 patent/US20110219891A1/en not_active Abandoned

- 2011-02-25 CA CA2790035A patent/CA2790035A1/en not_active Abandoned

- 2011-02-25 WO PCT/US2011/026293 patent/WO2011106680A1/en not_active Ceased

- 2011-02-25 EP EP11748167A patent/EP2539239A1/en not_active Withdrawn

- 2011-02-25 CN CN2011800108966A patent/CN102883967A/zh active Pending

- 2011-02-25 JP JP2012555191A patent/JP2013521196A/ja active Pending

- 2011-02-25 BR BR112012021008A patent/BR112012021008A2/pt not_active IP Right Cessation

- 2011-02-25 MX MX2012009703A patent/MX2012009703A/es not_active Application Discontinuation

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5218390A (en) * | 1975-08-01 | 1977-02-10 | Osaka Kagaku Bunseki Center:Kk | Method of smpling gas for analysis |

| JP3005096U (ja) * | 1994-06-09 | 1994-12-06 | 株式会社司測研 | 流体試料用サンプルバッグ |

| JPH11165745A (ja) * | 1997-12-04 | 1999-06-22 | Tsukasa Sokken:Kk | 流体試料用薄板製バッグ |

Also Published As

| Publication number | Publication date |

|---|---|

| CA2790035A1 (en) | 2011-09-01 |

| US20110219891A1 (en) | 2011-09-15 |

| EP2539239A1 (en) | 2013-01-02 |

| BR112012021008A2 (pt) | 2017-07-11 |

| CN102883967A (zh) | 2013-01-16 |

| WO2011106680A1 (en) | 2011-09-01 |

| MX2012009703A (es) | 2013-04-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2013521196A (ja) | 柔軟な金属合金の壁部を備えた流体サンプリング容器 | |

| US9846108B2 (en) | Containers for fluids with composite agile walls | |

| EP2536641B1 (en) | Device for fluid sampling | |

| EP2271906A1 (en) | Apparatus and method for the integrity testing of flexible containers | |

| US5074155A (en) | Fitting and tube apparatus for gas emission sample container | |

| JP2017523397A (ja) | サンプリング装置のためのフロータイマー | |

| US5218874A (en) | Fitting and tube apparatus for gas emission sample container | |

| US9322746B2 (en) | Sampling bag with multilayer walls | |

| HK1181014A (en) | Container for fluid sampling with flexible metal alloy walls | |

| CN212410360U (zh) | 低温容器的吸氢剂评价装置 | |

| KR20230093633A (ko) | 가스 샘플링 백 | |

| HK1181013B (en) | Containers for fluids with composite agile walls | |

| JP2018520370A (ja) | 低透過率サンプルバッグ | |

| HK1181012B (en) | Device for fluid sampling |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140225 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20140225 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20141212 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20141222 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20150525 |