JP2010146812A - Electrical connection device, light source device, and electrical connection method - Google Patents

Electrical connection device, light source device, and electrical connection method Download PDFInfo

- Publication number

- JP2010146812A JP2010146812A JP2008321317A JP2008321317A JP2010146812A JP 2010146812 A JP2010146812 A JP 2010146812A JP 2008321317 A JP2008321317 A JP 2008321317A JP 2008321317 A JP2008321317 A JP 2008321317A JP 2010146812 A JP2010146812 A JP 2010146812A

- Authority

- JP

- Japan

- Prior art keywords

- wiring board

- light emitting

- light source

- emitting module

- electrical

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Abstract

Description

本発明は、発光部等の電気部品を配線基板に電気的に接続する電気接続装置に関し、特に前記電気部品と前記配線基板を被取付体に取り付けることにより電気的接続を行う電気接続装置、光源装置及び電気的接続方法に関する。 The present invention relates to an electrical connection device that electrically connects an electrical component such as a light emitting unit to a wiring board, and in particular, an electrical connection device that performs electrical connection by attaching the electrical component and the wiring board to an attached body, and a light source The present invention relates to an apparatus and an electrical connection method.

従来の電気接続装置及び該電気接続装置を用いた光源装置には、例えば、正電極外部接続ランド及び負電極外部接続ランドと電源をそれぞれ電気的に接続するための外部接続配線が設けられた発光モジュールを用いたものがある(特許文献1参照)。 For example, a light source device using a conventional electrical connection device and a light source device using the electrical connection device is provided with an external connection wiring for electrically connecting a positive electrode external connection land and a negative electrode external connection land to a power source, respectively. There is one using a module (see Patent Document 1).

なお、上記特許文献1において、前記発光モジュール9は、図12に示す通り、発光部90及び正電極外部接続ランド91a及び負電極外部接続ランド91bが一方の面上に設けられ、それぞれの外部接続ランド91a、91bに対して、図示しない電源と電気的に接続するためのハーネスケーブルなどの外部接続配線92が設けられてなるものである。

上記のような従来の発光モジュールを用いた光源装置などに用いられる電気接続装置においては、正電極外部接続ランド91a及び負電極外部接続ランド91bと外部接続配線92とを半田付けにて固定して接続することが一般的であった。

In the electrical connection device used in the light source device using the conventional light emitting module as described above, the positive electrode

しかし、正電極外部接続ランド91a及び負電極外部接続ランド91bと外部接続配線92とを半田付けにて固定して接続する場合、各外部接続ランド91a、91bについて個別に半田付けを行う必要がある。

However, when the positive electrode external connection land 91a and the negative electrode

ここで、前記半田付けの作業をする場合の手順を説明する。まず、発光モジュール9を図示しない支持部に対して取り付ける。前記発光モジュール9の取り付けは、例えば、前記発光モジュール9の光源基板93に設けられたネジ挿通孔93aを挿通する図示しない雄ネジと支持部に設けた図示しない雌ネジとの螺合機構にて行われる。

Here, a procedure for performing the soldering operation will be described. First, the

次に、図示しない配線基板を被取付体に別途取り付けた後、前記配線基板の配線基板側接続端子と前記発光モジュール9の各外部接続ランド91a、91bとを外部接続配線92を介して接続することで電気的接続が為される。

Next, after separately attaching a wiring board (not shown) to the body to be attached, the wiring board side connection terminals of the wiring board and the external connection lands 91 a and 91 b of the

上述の接続方法では、前記発光モジュール9を支持部に取り付ける作業工程と、前記配線基板を支持部に取り付ける作業工程と、前記配線基板側接続端子と前記発光モジュール9の各外部接続ランド91a、91bとの電気的に接続する作業工程の全ての作業工程を別々に行う必要があり、組み立てる際の作業工程数が多く、組み立てが煩雑であるという課題があった。

In the connection method described above, the work process of attaching the

本発明は、このような従来の構成が有していた課題を解決しようとするものであり、組み立てが簡便な電気接続装置、光源装置及び電気的接続方法を提供することを目的とするものである。 The present invention is intended to solve the problems of such a conventional configuration, and aims to provide an electrical connection device, a light source device, and an electrical connection method that are easy to assemble. is there.

本発明の電気接続装置は、発光モジュール等の電気部品と、配線基板と、前記電気部品及び前記配線基板を取り付ける被取付体とからなる電気接続装置であって、前記配線基板を前記被取付体に取り付けることにより、前記電気部品と前記配線基板の電気的接続を行う接続機構を有することを特徴とする。 The electrical connection device of the present invention is an electrical connection device including an electrical component such as a light emitting module, a wiring board, and a mounting body to which the electrical component and the wiring board are attached, and the wiring board is attached to the mounting body. It is characterized by having a connection mechanism for making an electrical connection between the electrical component and the wiring board by attaching to the wiring board.

本発明にあっては、配線基板を被取付体に取り付けることにより、前記電気部品と前記配線基板の電気的接続を行う接続機構を有するため、前記配線基板を前記被取付体に取り付けると同時に前記電気部品と前記配線基板との電気的接続が行われることとなり、組み立てる際の作業工程数が少なく、組み立てが簡便な電気接続装置を実現することができる。 In the present invention, since the wiring board is attached to the attached body, the electrical component and the wiring board have a connection mechanism for electrical connection. Therefore, the wiring board is attached to the attached body at the same time as the attachment. The electrical connection between the electrical component and the wiring board is performed, so that an electrical connection device with a small number of work steps during assembly and simple assembly can be realized.

また、本発明の電気接続装置の前記接続機構は、前記接続機構は、前記配線基板を前記被取付体に取り付ける取付機構と、前記電気部品の電気部品側接続端子と前記配線基板の配線基板側接続端子とを電気的に接続する電気的接続機構とからなることを特徴とする。 Further, the connection mechanism of the electrical connection device of the present invention is characterized in that the connection mechanism includes an attachment mechanism for attaching the wiring board to the mounted body, an electrical component side connection terminal of the electrical component, and a wiring board side of the wiring board. And an electrical connection mechanism for electrically connecting the connection terminals.

本発明にあっては、前記取付機構と電気的接続機構とからなる前記接続機構が、前記配線基板を前記被取付体に取り付けると同時に前記電気部品と前記配線基板との電気的接続を行うため、組立作業工程数の少ない電気接続装置を実現することができる。 In the present invention, the connection mechanism including the attachment mechanism and the electrical connection mechanism attaches the wiring board to the attached body and simultaneously performs electrical connection between the electrical component and the wiring board. Thus, an electrical connection device with a small number of assembly work steps can be realized.

さらに、本発明の電気接続装置の前記電気部品は、前記配線基板と前記被取付体との間に配設され、前記取付機構は、前記電気部品を挟圧すべく前記配線基板と前記被取付体とを取り付ける挟圧機構を有することを特徴とする。 Furthermore, the electrical component of the electrical connection device according to the present invention is disposed between the wiring board and the mounted body, and the mounting mechanism is configured so that the wiring board and the mounted body are pressed between the electrical components. And a pinching mechanism for attaching the two.

本発明にあっては、前記電気部品を前記配線基板と前記被取付体との間に配設し、前記取付機構によって前記電気部品を挟圧することで、確実な電気的接続が実現できる。 In the present invention, the electrical component is disposed between the wiring board and the mounted body, and the electrical component is clamped by the mounting mechanism, whereby reliable electrical connection can be realized.

そして、本発明の電気接続装置の前記挟圧機構は、1つの前記電気部品に対して複数の螺合機構を備えることを特徴とする。 And the said pinching mechanism of the electrical-connection apparatus of this invention is provided with the some screwing mechanism with respect to the said one electrical component.

本発明にあっては、挟圧機構として、1つの前記電気部品に対して複数の螺合機構を備えることで、確実な電気的接続が実現できる。 In the present invention, a reliable electrical connection can be realized by providing a plurality of screwing mechanisms for one electrical component as the clamping mechanism.

また、本発明の電気接続装置の前記螺合機構は、前記電気部品側接続端子及び前記配線基板側接続端子付近にて螺合することを特徴とする。 Further, the screwing mechanism of the electric connecting device according to the present invention is characterized in that it is screwed in the vicinity of the electric component side connecting terminal and the wiring board side connecting terminal.

本発明にあっては、前記電気部品側接続端子及び前記配線基板側接続端子付近にて螺合することによって、螺合機構によって挟圧される前記配線基板と前記支持部の間に働く挟圧のための力が確実に前記電気部品側接続端子及び前記配線基板側接続端子に伝わり、確実な電気的接続が実現できる。 In the present invention, the clamping pressure acting between the wiring board and the support portion that is clamped by the screwing mechanism by screwing in the vicinity of the electrical component side connection terminal and the wiring board side connection terminal. For this reason, the force for transmission is surely transmitted to the electrical component side connection terminal and the wiring board side connection terminal, and a reliable electrical connection can be realized.

さらに、本発明の電気接続装置の前記電気部品側接続端子及び前記配線基板側接続端子の少なくともどちらか一方は、バネ構造の接続端子であることを特徴とする。 Furthermore, at least one of the electrical component side connection terminal and the wiring board side connection terminal of the electrical connection device of the present invention is a connection terminal having a spring structure.

本発明にあっては、前記電気部品側接続端子及び前記配線基板側接続端子の少なくともどちらか一方は、バネ構造の接続端子を備えることで、力が加わって変形したバネの復元力を利用した、確実な電気的接続が実現できる。 In the present invention, at least one of the electrical component side connection terminal and the wiring board side connection terminal is provided with a connection terminal having a spring structure, thereby utilizing the restoring force of the spring deformed by applying a force. A reliable electrical connection can be realized.

そして、本発明の電気接続装置の前記被取付体は、前記電気部品を取り付けるためのガイド部を有することを特徴とする。 And the said to-be-attached body of the electrical-connection apparatus of this invention has a guide part for attaching the said electrical component, It is characterized by the above-mentioned.

本発明にあっては、前記電気部品を取り付けるためのガイド部を有することで、前記電気部品の位置決めが容易になる電気接続装置が実現できる。 In the present invention, an electrical connection device that facilitates positioning of the electrical component can be realized by having a guide portion for attaching the electrical component.

そして、本発明の光源装置は、前記電気接続装置を備えた光源装置であって、前記電気部品は、一方の面に発光部を備えた発光モジュールであることを特徴とする。 And the light source device of this invention is a light source device provided with the said electrical-connection apparatus, Comprising: The said electrical component is a light emitting module provided with the light emission part on one surface, It is characterized by the above-mentioned.

本発明にあっては、前記電気接続装置を備えることにより、組み立てる際の作業工程数が少なく、組み立てが簡便な光源装置を実現することができる。 In the present invention, by providing the electrical connection device, it is possible to realize a light source device that requires a small number of work steps during assembly and is easy to assemble.

また、本発明の光源装置の前記接続機構は、前記発光部を備えた一方の面側から前記配線基板を取り付けることを特徴とする。 Further, the connection mechanism of the light source device of the present invention is characterized in that the wiring board is attached from one surface side provided with the light emitting part.

本発明にあっては、発光部を備えた一方の面側から前記配線基板を取り付けることで、前記配線基板を前記被取付体に取り付ける際、同時に前記発光モジュールと前記配線基板との電気的接続が図れるため、組み立てる際の作業工程数が少なく、組み立てが簡便な光源装置を実現することができる。 In the present invention, when the wiring board is attached to the mounted body by attaching the wiring board from one surface side provided with the light-emitting portion, electrical connection between the light-emitting module and the wiring board is performed at the same time. Therefore, it is possible to realize a light source device with a small number of work steps during assembly and easy assembly.

さらに、本発明の光源装置の前記配線基板は、前記発光部の光を出射するための光出射窓を有することを特徴とする。 Furthermore, the wiring board of the light source device of the present invention has a light exit window for emitting the light of the light emitting unit.

本発明にあっては、前記発光部の光を出射するための光出射窓を有するため、効率良く光を出射する光源装置を実現することが可能となる。 In the present invention, since the light emitting window for emitting the light from the light emitting unit is provided, it is possible to realize a light source device that emits light efficiently.

そして、本発明の光源装置の前記被取付体は、前記光源装置内の熱を外部へ放出する放熱部を兼ねることを特徴とする。 And the said to-be-attached body of the light source device of this invention serves as the thermal radiation part which discharge | releases the heat | fever in the said light source device outside, It is characterized by the above-mentioned.

本発明にあっては、前記被取付体が放熱部を兼ねることで、放熱性能を確保した光源装置を実現することが可能となる。 In the present invention, since the attached body also serves as a heat radiating portion, it is possible to realize a light source device that ensures heat radiating performance.

また、本発明の光源装置の前記配線基板は複数の回路部品を備え、前記複数の回路部品の中で発熱量の最も大きな回路部品は前記放熱部に熱接触すべく配設されることを特徴とする。 The wiring board of the light source device of the present invention includes a plurality of circuit components, and the circuit component having the largest heat generation amount among the plurality of circuit components is disposed so as to be in thermal contact with the heat radiating portion. And

本発明にあっては、複数の回路部品の中で発熱量の最も大きな回路部品を前記放熱部に熱接触すべく配設することで、放熱性能のより向上した光源装置を実現することが可能となる。 In the present invention, it is possible to realize a light source device with improved heat dissipation performance by arranging a circuit component having the largest heat generation amount among a plurality of circuit components so as to be in thermal contact with the heat dissipation portion. It becomes.

さらに、本発明の電気的接続方法は、配線基板を被取付体に取り付ける取付手段と、該取付手段によって前記配線基板を前記被取付体に取り付けることにより、発光モジュール等の電気部品の電気部品側接続端子と前記配線基板の配線基板側接続端子とを電気的に接続する電気的接続手段とを備えることを特徴とする。 Furthermore, the electrical connection method of the present invention includes an attaching means for attaching a wiring board to an attached body, and attaching the wiring board to the attached body by the attaching means, whereby an electric component side of an electrical component such as a light emitting module is provided. An electrical connection means for electrically connecting the connection terminal and the connection terminal on the wiring board side of the wiring board is provided.

本発明にあっては、配線基板を被取付体に取り付けることにより、前記電気部品と前記配線基板の電気的接続を行う接続機構を有するため、前記配線基板を前記被取付体に取り付けると同時に前記電気部品と前記配線基板との電気的接続が行われることとなり、組み立てる際の作業工程数が少なく、組み立てが簡便な電気的接続を行うことが可能となる。 In the present invention, since the wiring board is attached to the attached body, the electrical component and the wiring board have a connection mechanism for electrical connection. Therefore, the wiring board is attached to the attached body at the same time as the attachment. Electrical connection between the electrical component and the wiring board is performed, and the number of work steps during assembly is small, and electrical connection that is easy to assemble can be performed.

本発明の電気接続装置、光源装置及び電気的接続方法によれば、電気部品及び配線基板を被取付体に取り付けることにより電気的接続を行う接続機構を有する構成であるため、組立作業工程数の少ない電気的接続が可能となる。 According to the electrical connection device, the light source device, and the electrical connection method of the present invention, the electrical connection device and the electrical connection method have a connection mechanism that performs electrical connection by attaching the electrical component and the wiring board to the mounted body. Less electrical connection is possible.

(実施の形態1)

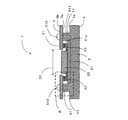

以下、本発明の実施の形態1を、図1〜図3を参照して説明する。図1は、本発明の電気接続装置を用いた光源装置の実施の形態1の構成の概略を示す概略上面図である。図2は、図1におけるA−A線による概略断面図である。図3は、図2における破線領域Bの部分拡大図である。

(Embodiment 1)

本発明の実施の形態1に係る光源装置1は、発光部22及び電気部品側接続端子である発光モジュール側接続端子を光源基板21の一方の面上に備えた発光モジュール2と、該発光モジュール2に電源を供給するための配線を備えた配線基板3と、前記発光モジュール2を支持し前記配線基板3を取り付ける被取付体である支持部4とを備えている。

The

上記構成において、前記発光モジュール2は、光を発する発光部22と、外部からの電源を前記発光部22へと供給するために電気的接続を行う電極パッドからなる発光モジュール側接続端子23と、前記発光部22及び前記発光モジュール側接続端子23を配設するための光源基板21とからなる。

In the above-described configuration, the

なお、前記発光部22は、前記光源基板21の光源配設面21a上に複数のLED(Light Emitting Diode)ベアチップ(図示せず)を配設した後、該複数のLEDベアチップの上から蛍光体を混合した樹脂性材料にて封止したものである。

The

また、光源基板21は放熱性又は熱伝導性の高いアルミナセラミックからなり、略四角形板形状を有し、4つの長辺211と4つの頂点を面取りした短辺212とから構成されている。

The

そして、前記配線基板3は、前記発光モジュール2の光源配設面21aに対向する光源対向面である配線基板3の下面3aに電極パッドからなる配線基板側接続端子31を備えたプリント基板で、前記配線基板3の下面3aの前記発光モジュール2の発光部22に対向する領域に、前記発光部22と同程度の形状及び大きさを有する孔状の開口である光出射窓32をさらに備えてなるものである。前記光出射窓32を設けることで、光が遮られることなく出射されるため、発光部22からの光を効率的に照明に用いることができる。

The

特に、前記光出射窓32の形状を前記発光モジュール2の発光部22の発光領域と略同一形状及び大きさとなるように設けることで、発光モジュール2の発する光を遮蔽によって減衰させることがなくなり、より効率的に照明に用いることができる。

In particular, by providing the

なお、前記配線基板3は、後述する螺合機構を構成する雄ネジを挿通させるためのネジ挿通孔33をさらに設けている。

The

さらに、配線基板3の上面3bの全面には、図1の斜線で示す領域には、熱伝導性の高い銅からなる放熱用パターン34が設けられ、配線基板3や該配線基板3に接する発光モジュール2からの熱を効率的に外部へと逃がす効果がある。

Further, a

そして、前記支持部4は、光源支持面4aに設けられた2つの支柱41を備える。前記2つの支柱41は四角柱形状を成しており、発光モジュール2の光源基板21の2つの発光モジュール側接続端子23に近い2つの短辺と接するように配設されている。発光モジュール2を配設する際に、前記支柱41をガイド部として配設位置の目安にすることが可能となり、発光モジュール2を配設する作業の効率化を図ることができる。

And the said

また、前記支持部4は、銅やアルミ、アルミナセラミック等の放熱性又は熱伝導性の高い素材からなり、前記光源装置の放熱部も兼ねるべく設けられてなるものである。

The

なお、上述の構成において、前記光源装置1は、前記配線基板3を前記支持部4に取り付けることにより前記配線基板側接続端子31と前記発光モジュール側接続端子23とを接触させて電気的接続を行う接続機構5を有する。該接続機構5は、図3に示す通り、前記発光モジュール2及び前記配線基板3を前記支持部4に取り付けて固定する取付機構である螺合機構51と、前記発光モジュール2の発光モジュール側接続端子23と前記配線基板3の配線基板側接続端子31とを電気的に接続する電気的接続機構52とからなる。

In the above-described configuration, the

なお、前記取付機構である螺合機構51は、前記発光モジュール2を前記配線基板3及び前記支持部4にて挟圧して固定する挟圧機構としても機能する。

The screwing

上述の構成において、前記螺合機構51は、雄ネジと雌ネジの螺合によって前記配線基板3を前記支持部4に取り付けて固定するものであり、該固定された前記配線基板3と前記支持部4との間に配設される前記発光モジュール2を挟圧するものである。

In the above-described configuration, the screwing

また、前記電気的接続機構52は、配線基板3の配線基板側接続端子31と発光モジュール2の発光モジュール側接続端子23とからなる。そして、電気的接続機構52は、前記取付機構である挟圧機構としての螺合機構51によって、前記配線基板3と前記支持部4が取り付けられ、また、前記発光モジュール2が前記配線基板3と前記支持部4によって挟圧され、前記発光モジュール2の発光モジュール側接続端子23と前記配線基板3の配線基板側接続端子31の間に前記挟圧する力が働くため、前記発光モジュール2の発光モジュール側接続端子23と前記配線基板3の配線基板側接続端子31とが確実に接触し、電気的接続が確実になされる。

The

なお、前記螺合機構51についてさらに詳細に説明すると、前記螺合機構51は、雄ネジである固定用ネジ512と前記支柱41の支柱上面41aに設けられた雌ネジであるネジ孔511からなり、固定用ネジ512を前記配線基板3のネジ挿通孔33に挿通させて前記支持部のネジ孔511に螺合させることで前記配線基板3を前記支持部4に取り付けて固定する。ここで、前記固定用ネジ512のヘッド部512aの半径はネジ挿通孔33の半径より大きく設計されており、螺合した際に前記ヘッド部512aが前記配線基板3に密着することで、前記配線基板3は前記支持部4に強固に取り付けられて固定される。

The screwing

さらに、前記螺合機構51によって前記配線基板3と前記支持部4とが固定される際、前記配線基板3と前記支持部4との間に配設される前記発光モジュール2の発光モジュール側接続端子23と前記配線基板3の配線基板側接続端子31との接触及び電気的接続を確実なものとするため、支柱41の寸法h1は、図3に示す通り、光源基板21の寸法(厚み)h2と発光モジュール側接続端子23の寸法h3と配線基板側接続端子31の寸法h4の総和よりも小さいことが望ましい、即ち、

h1<h2+h3+h4 ・・・・・・・・・・(1)

(1)式を満たすことが望ましい。(1)式を満たす寸法に設定することによって、螺合機構51によって前記配線基板3と前記支持部4が固定された際、前記配線基板3と前記支持部4との間に配設される発光モジュール2が挟圧され、該発光モジュール2の発光モジュール側接続端子23と前記配線基板3の配線基板側接続端子31との間に挟圧のための力が働いて、前記発光モジュール側接続端子23と前記配線基板側接続端子31は、確実に、機械的かつ電気的に接続されることとなる。

Further, when the

h1 <h2 + h3 + h4 (1)

It is desirable to satisfy the equation (1). By setting the dimensions to satisfy the formula (1), when the

上述のように、前記発光モジュール2は、前記支持部4へ取り付けるための機構を前記発光モジュール2自体の構成としては備えておらず、前記配線基板3が前記支持部4に取り付けられる際に、前記発光モジュール2が前記配線基板3と前記支持部4との間に予め配設されていることで、前記配線基板3が前記支持部4に取り付けられると同時に、前記配線基板3と前記支持部4に挟圧されるという形での取り付けがなされる構成である。本明細書中では、このような構成要素自体には取り付けるための機構を有さず、他の構成要素の取り付けの関係で取り付けられることを「間接的に取り付けられる」と表現する。

As described above, the

また、本実施の形態1において、光源装置1は、1つの前記発光モジュール2に対して複数箇所に電気的接続機構を設けているため、各電気的接続機構において、発光モジュール側接続端子23の寸法h3や配線基板側接続端子31の寸法h4などにばらつきが生じる場合がある。しかし、各電気的接続機構を設けた箇所の付近に螺合機構が設けられているため、各電気的接続機構を設けた箇所において、h1〜h4の寸法に合わせて前記螺合機構51を用いて挟圧する力を調節することで、前記発光モジュール2の発光モジュール側接続端子23と前記配線基板3の配線基板側接続端子31との強固な接触を実現し、確実な電気的接続が可能となる。

In the first embodiment, the

例えば、前記発光モジュール2の発光モジュール側接続端子23と前記配線基板3の配線基板側接続端子31との接触が弱く、電気的接続が確実ではない箇所があれば、その最も近くにある螺合機構51の螺合を強固にすることで、該螺合機構51付近での前記発光モジュール2を挟圧する力が大きくなり、部分的に挟圧する力が強くなることで配線基板3が撓んで、前記発光モジュール2の発光モジュール側接続端子23と前記配線基板3の配線基板側接続端子31との接触をより強固にすることが可能となる。

For example, if there is a place where the contact between the light emitting module

上述の通り、発光モジュール2と配線基板3を被取付体である支持部4に取り付けることにより、前記発光モジュール2と前記配線基板3とが接触して電気的接続が為されるため、前記発光モジュール2と前記配線基板3を取り付けた後に別途電気的接続を行う作業工程が不要となり、全体の組立作業工程数が少なくなる。

As described above, since the

なお、本発明の光源装置は、照明装置を構成する光源として用いても良いし、表示装置を構成する光源として用いても良いし、その他様々な装置を構成する光源として用いて良い。 The light source device of the present invention may be used as a light source that constitutes an illumination device, may be used as a light source that constitutes a display device, or may be used as a light source that constitutes various other devices.

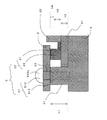

また、本発明の実施の形態1において、光源装置1の支持部4に設けられたガイド部としての支柱41の形状は、四角柱形状を成しており、発光モジュール2の光源基板21の2つの発光モジュール側接続端子23に近い2つの短辺と接するように配設されているものとしたが、これに限られることはなく、支柱41の形状及び大きさは、図4に示す支柱壁410のように、光源基板21の外形に沿った形状及び大きさとしても良い。前記支柱壁410が発光モジュール2の光源基板21の四方の側面に熱接触することで、放熱部でもある支持部4との接触面積が増加し放熱性能の向上が図れる。なお、本明細書において前記熱接触というのは、熱伝導が十分に行われる程度の接触を指し、必ずしも接触する面の全体が接している必要はない。

Moreover, in

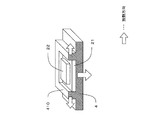

さらに、本発明の実施の形態1において、光源装置1の配線基板3の配線基板側接続端子31は、電極パッド同士の接触であるとしたが、これに限られることはなく、図5(a),(b)に示す配線側バネ接続端子310のように、湾曲した板バネを用いたバネ構造を有していても良い。挟圧構造にて挟圧されることにより配線側バネ接続端子310が撓み、挟圧される以前の形状へ復元しようとする復元力がかかることにより、確実に接触が為され、電極パッド同士の接触に比べて信頼性の高い確実な電気的接続が可能となる。

Furthermore, in

また、図5(a),(b)に示す配線側バネ接続端子310を用いると、特に複数点で発光モジュール2と配線基板3が接触する場合に効果的である。つまり、接続端子の大きさや発光モジュール2の光源基板21及び配線基板3の厚みのバラツキが生じる可能性があるのだが、各配線側バネ接続端子310が可撓性を有しているため、それぞれの端子間距離に応じて撓むことで、端子間距離のバラツキが生じていても、配線基板側接続端子310と発光モジュール側接続端子23の間で電気的接続が実現される。

5A and 5B is effective particularly when the

なお、バネ構造は板バネ以外にも、コイルバネ(スプリング)を利用した押バネや引っ張りバネを利用しても良い。また、バネ構造は配線基板3の配線基板側接続端子310側ではなく、発光モジュール2の発光モジュール側接続端子23側に設けても良いし、配線基板側接続端子310及び発光モジュール側接続端子23の両方にバネ構造の接続端子を設けても良い。

The spring structure may use a push spring or a tension spring using a coil spring (spring) in addition to the plate spring. The spring structure may be provided not on the wiring board

そして、本発明の実施の形態1において、光源装置1は、雄ネジである固定用ネジ512及び被取付体である支持部4に備えたネジ孔511との螺合機構51にて、前記配線基板3が前記支持部4に取り付けられる際に、前記配線基板3と前記支持部4との間に配設されている前記発光モジュール2が間接的に取り付けられる構成としたが、これに限られることはなく、例えば、前記発光モジュール2にネジ孔を設け、該ネジ孔と前記配線基板3のネジ挿通孔33を挿通する固定用ネジ512との螺合機構によって、前記発光モジュール2と前記配線基板3とを取り付けても良い。本明細書において、このように、構成要素自体に取り付けるための機構の一部を有しており、他の構成要素に取り付けられることを「直接的に取り付けられる」と表現する。

In

また、本発明の実施の形態1において、配線基板3の放熱用パターン34は、銅のパターンを用いて説明したが、これに限られることはなく、他の熱伝導性の高い金属を用いても良いし、凹凸形状などの形状パターンで表面積を大きくして放熱用パターンとしても良いし、金属パターンと形状パターンの両方を用いても良い。

In

さらに、本発明の実施の形態1において、光出射窓32は孔状の開口として説明したが、これに限られるものではなく、透明な樹脂板を用いて発光モジュール2からの光を透過して出射しても良いし、半透明な樹脂板を用いても良い。樹脂板を用いることで、埃塵などのゴミが発光モジュール2付近に溜まることを防ぐことができる。

Furthermore, in

そして、本発明の実施の形態1において、発光モジュール2は、光源基板21の光源配設面21a上に複数のLEDベアチップを配設した後に蛍光体を混合した樹脂性材料にて封止したものとして説明したが、これに限られるものではなく、有機ELなどの他の光源を用いても良い。

In the first embodiment of the present invention, the

さらにまた、本発明の実施の形態1において、挟圧機構としての螺合機構51は、雄ネジと雌ネジの螺合によって前記配線基板3と前記支持部4を固定する螺合機構51を複数備えるものとして説明したが、これに限られるものではなく、支持部4が配線基板3を嵌合する嵌合機構を備え、該嵌合機構によって前記配線基板3と前記支持部4が固定されることで、間に挟まれる前記発光モジュール2と前記配線基板3との電気的接続が為されるとしても良い。

Furthermore, in the first embodiment of the present invention, the screwing

(実施の形態2)

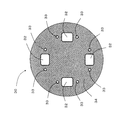

次に、本発明の光源装置の実施の形態2について、図6〜図8を用いて説明する。なお、上記実施の形態1と同一部分には同一符号を付し、その説明は省略する。図6は本発明の光源装置の実施の形態2の構成の概略を示す概略上面図である。図7は図6の配線基板30の概略上面図である。図8は図6の配線基板30の概略下面図である。

(Embodiment 2)

Next, a second embodiment of the light source device of the present invention will be described with reference to FIGS. The same parts as those in the first embodiment are denoted by the same reference numerals, and the description thereof is omitted. FIG. 6 is a schematic top view showing an outline of the configuration of the light source device according to

本発明の光源装置1Aは、実施の形態1と同様に、発光部22及び発光モジュール側接続端子23を光源基板の一方の面上に備えた発光モジュール2と、前記発光モジュール2を支持し前記配線基板3を取り付ける被取付体である支持部4とを設けて構成するものである。

As in

なお、本発明の実施の形態2の光源装置1Aにおいては、発光モジュール2を4個配設し、該4個の発光モジュール2の発光部22に対応する位置に光出射窓32を有する配線基板30を備えた構成となっている。

In the

ここで、配線基板30について詳細に説明する。配線基板30は円形板上のプリント基板からなり、上面から見ると、図7に示すように、4個の光出射窓32が同一半径の円周上に等間隔で配設され、各光出射窓32付近には、螺合機構51を構成する雄ネジである固定用ネジ512を通すためのネジ挿通孔33が2箇所、配線基板30に対して合計8箇所に設けられている。同一半径の円周上に等間隔で配設することで、各発光モジュール2間の距離が一定に保たれ、発光モジュール2から発生する熱が等間隔で支持部4に伝わるため、熱の偏りが生じたり、急激な温度勾配になる可能性を低減したりすることが可能となり、効率の良い放熱効果が得られる。

Here, the

また、配線基板30の上面には、熱伝導性の高い銅からなる放熱用パターン34が設けられ、配線基板30や該配線基板30に接する発光モジュール2からの熱を効率的に外部へと逃がす効果がある。

In addition, a

さらに、配線基板30の下面には、図8に示すように、配線用パターン35が設けられている。配線用パターン35は、配線基板3の下面中央にあるコネクタ36から2個の発光モジュール2を直列接続すべく、銅線にてパターニングされている。前記発光モジュール2を2個ずつ直列接続することで、光源装置1Aの2系統制御が可能となり、系統別に点灯を制御したり、どちらか一方の系統において断線等の故障が生じた場合でも照明を継続するよう制御したりすることが可能となる。

Furthermore, a

そして、前記放熱用パターン34は前記配線基板30の下面にも存在し、前記コネクトから4個の発光モジュールへと電気的接続を行っている配線用パターン35を避けるべく設けられている。

The

なお、本実施の形態2において、前記発光モジュール2を2個ずつ直列接続することで、光源装置1Aの2系統制御を行うものとして説明したが、これに限られることはなく、1個の発光モジュールからなる系統と3個の発光モジュールからなる系統の夫々を制御する2系統制御でも良いし、2系統制御だけでなく、3系統もしくは4系統で発光モジュールの点灯・消灯・調光を制御する仕様としても良く、多様な制御を行うことが可能である。

In the second embodiment, it has been described that the two

また、前記発光モジュール2及び前記配線基板30の光出射窓32は、同一半径の円周上に等間隔で4個ずつ配設したが、これに限られることはなく、複数半径の円周上の各円周上に複数個ずつ等間隔で配設しても良いし、多角形環上に複数個ずつ等間隔で配置しても良い。

Further, four light emitting

(実施の形態3)

次に、本発明の光源装置の実施の形態3について、図9及び図10を用いて説明する。なお、上記実施の形態1及び実施の形態2と同一部分には同一符号を付し、その説明は省略する。図9は、本発明の光源装置の実施の形態3の構成の概略を示す概略斜視図である。図10は、図9におけるC−C線による概略断面図である。

(Embodiment 3)

Next, a third embodiment of the light source device of the present invention will be described with reference to FIGS. In addition, the same code | symbol is attached | subjected to the same part as the said

本発明の光源装置1Bは、本発明の実施の形態1と同様に、発光部22及び発光モジュール側接続端子23を光源基板の一方の面上に備えた発光モジュール2と、該発光モジュール2に電源を供給するための配線を備えた配線基板3と、前記発光モジュール2を支持し前記配線基板3を取り付ける被取付体である支持部4とを設けて構成するものである。

As in the first embodiment of the present invention, the

また、光源装置1Bは、光学部材として反射板61と透過板62を、外装体として器具ケース71をさらに備える。また、前記支持部4も外装体の一部を兼ねる。

The

なお、前記器具ケース71は、器具ケース固定用ネジ71aにて前記支持部4に固定される。

The

次に電力の供給方法について説明する。外部から供給される商用交流電源を電源ユニット80にて定電流に変換し、変換された定電流が外装体底部である支持部4底面に設けた端子台8に供給され、該端子台8から支持部4を貫通する孔を通るワイヤーハーネス81が配線基板3に設けられたコネクタ36と接続され、配線基板3の配線用パターンを通り、配線基板側接続端子31から発光モジュール2の発光モジュール側接続端子23を通って供給される。

Next, a method for supplying power will be described. The commercial AC power supplied from the outside is converted into a constant current by the

なお、前記端子台8は、該端子台8を固定する端子台固定用ネジ8aによって固定されている。

The

また、本発明の実施の形態3では、前記発光モジュール2は1つしか配設されなかったが、コレに限られるものではなく、例えば、本発明の実施の形態2で説明したように、複数個の発光モジュール2を配設し、該各発光モジュール2からの光を透過すべく、該各発光モジュール2の発光部22に対応した領域に光出射窓32とを有する配線基板30を用いても良い。

In the third embodiment of the present invention, only one

(実施の形態4)

次に、本発明の光源装置の実施の形態4について、本発明の実施の形態1と同様に、図11を用いて説明する。なお、上記実施の形態1〜実施の形態3と同一部分には同一符号を付し、その説明は省略する。図11は、本発明の光源装置の実施の形態4の構成の概略を示す概略断面図である。

(Embodiment 4)

Next, the fourth embodiment of the light source device of the present invention will be described using FIG. 11 as in the first embodiment of the present invention. In addition, the same code | symbol is attached | subjected to the same part as the said Embodiment 1-

本発明の光源装置1Cは、実施の形態3と同様に、発光部22及び発光モジュール側接続端子23を光源基板21の一方の面上に備えた発光モジュール2と、該発光モジュール2に電源を供給するための配線を備えた配線基板300と、前記発光モジュール2を支持し前記配線基板300を取り付ける被取付体である支持部4と、光学部材として反射板61と透過板62を、外装体として器具ケース71をさらに備える。なお、前記支持部4及び前記透過板62も外装体の一部を兼ねる。

In the

また、前記配線基板300は、該配線基板300上に設けられた発光モジュール2を駆動すべく、外部からの供給された電源を定電流に変換して供給する定電流電源回路を内蔵した回路部37を有するものである。

Further, the

上記の構成において、前記回路部37は、抵抗37aやコンデンサ37b、コイル37c、FET37dなどの回路部品からなる。

In the above configuration, the

なお、前記FET37dのように発熱量の大きな回路部品は、外装体である器具ケース71付近に配設することが望ましい。発熱量の大きな回路部品を外装体付近に配設することで、回路部品から発せられる熱が外装体である器具ケース71に早期に伝わり、光源装置内部に熱が溜まることを防止することができる。このように、外装体である器具ケース71は、外装体の一部を兼ねる前記支持部4とともに、前記発光モジュール2及び発熱する回路部品の熱を外部へ放出するための放熱部として機能している。

It should be noted that a circuit component having a large calorific value, such as the

また、前記発光モジュール2は前記FET37dと同じく発熱量の大きな回路部品であるため、発熱量の大きな複数の回路部品の間隔や、該発熱量の大きな回路部品と発光モジュール2との間隔は、駆動中の配線基板300又は光源装置1C全体の温度勾配が緩やかになるよう、互いに離れて配置することが望ましい。駆動中の配線基板300又は光源装置1C全体の温度勾配が緩やかになることで、回路部品や発光モジュール2からの熱が局所的に溜まり高温に達し、回路部品や発光モジュール2などを損傷することを防ぐことができる。

Further, since the

さらに、前記器具ケース71が熱伝導性の高い金属やセラミック等の素材からなり、放熱性を有している場合は、発熱量の大きな回路部品は前記器具ケース71に熱接触すべく前記配線基板300に備えられると良い。前記器具ケース71が放熱性を有し、発熱量の大きな回路部品と熱的に接触していることで、前記回路部品の熱が速やかに前記器具ケース71へと伝わり、該器具ケース71に伝わった熱は外部へと放出されるため、効率的な放熱が可能となる。

Further, when the

上述した通り、発光モジュール2を駆動するための定電流を供給する定電流電源回路を備えた回路部品37を光源装置1C内部に設けることで、商用交流電源を定電流に変換するための電源ユニットを別途設ける必要がなくなり、装置全体としての導入コストを低減でき、また、光源装置施工時の作業負担も低減できる。

As described above, a power supply unit for converting a commercial AC power source into a constant current by providing a

さらに、実施の形態2で説明した、発光モジュール2を複数個設けた場合の配線基板30を有しても良い。

Furthermore, you may have the

1,1A,1B,1C 光源装置

2,9 発光モジュール

3,30,300 配線基板

4 支持部

4a 光源支持面

5 接続機構

8 端子台

21,93 光源基板

21a 光源配設面

22,90 発光部

23 発光モジュール側接続端子

31,310 配線基板側接続端子

32 光出射窓

33 ネジ挿通孔

34 放熱用パターン

35 配線用パターン

36 コネクタ

37 回路部

41 支柱

51 螺合機構

52 電気的接続機構

61 反射板

62 透過板

71 器具ケース

410 支柱壁

511 ネジ孔

512 固定用ネジ

1, 1A, 1B, 1C

Claims (13)

前記配線基板を前記被取付体に取り付けることにより、前記電気部品と前記配線基板の電気的接続を行う接続機構を有することを特徴とする電気接続装置。 An electrical connection device comprising an electrical component such as a light emitting module, a wiring board, and an attachment body to which the electrical component and the wiring board are attached,

An electrical connection apparatus comprising: a connection mechanism for electrically connecting the electrical component and the wiring board by attaching the wiring board to the attached body.

前記取付機構は、前記電気部品を挟圧すべく前記配線基板と前記被取付体とを取り付ける挟圧機構を有することを特徴とする請求項2に記載の電気接続装置。 The electrical component is disposed between the wiring board and the attached body,

The electrical connection device according to claim 2, wherein the attachment mechanism includes a clamping mechanism that attaches the wiring board and the attached body so as to clamp the electrical component.

前記電気部品は、一方の面に発光部を備えた発光モジュールであることを特徴とする光源装置。 A light source device comprising the electrical connection device according to any one of claims 1 to 7,

The light source device, wherein the electrical component is a light emitting module having a light emitting portion on one surface.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008321317A JP2010146812A (en) | 2008-12-17 | 2008-12-17 | Electrical connection device, light source device, and electrical connection method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008321317A JP2010146812A (en) | 2008-12-17 | 2008-12-17 | Electrical connection device, light source device, and electrical connection method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2010146812A true JP2010146812A (en) | 2010-07-01 |

Family

ID=42567011

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008321317A Pending JP2010146812A (en) | 2008-12-17 | 2008-12-17 | Electrical connection device, light source device, and electrical connection method |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2010146812A (en) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012038822A (en) * | 2010-08-04 | 2012-02-23 | Toshiba Lighting & Technology Corp | Light-emitting device and luminaire |

| JP2012049530A (en) * | 2010-08-27 | 2012-03-08 | Tyco Electronics Corp | Light module |

| JP2012094566A (en) * | 2010-10-23 | 2012-05-17 | Citizen Electronics Co Ltd | Led module |

| JP2014120544A (en) * | 2012-12-14 | 2014-06-30 | Mitsubishi Electric Corp | Light emitting device |

| JP2015207783A (en) * | 2015-06-22 | 2015-11-19 | シャープ株式会社 | Light-emitting device and luminaire having the same |

-

2008

- 2008-12-17 JP JP2008321317A patent/JP2010146812A/en active Pending

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012038822A (en) * | 2010-08-04 | 2012-02-23 | Toshiba Lighting & Technology Corp | Light-emitting device and luminaire |

| JP2012049530A (en) * | 2010-08-27 | 2012-03-08 | Tyco Electronics Corp | Light module |

| KR101817357B1 (en) * | 2010-08-27 | 2018-01-11 | 티이 커넥티비티 코포레이션 | Light module |

| JP2012094566A (en) * | 2010-10-23 | 2012-05-17 | Citizen Electronics Co Ltd | Led module |

| JP2014120544A (en) * | 2012-12-14 | 2014-06-30 | Mitsubishi Electric Corp | Light emitting device |

| JP2015207783A (en) * | 2015-06-22 | 2015-11-19 | シャープ株式会社 | Light-emitting device and luminaire having the same |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR101285889B1 (en) | LED Lighting Device | |

| TWI413470B (en) | Wiring board contributable to reduction in thickness of light emitting apparatus and having high versatility | |

| US7880389B2 (en) | LED lighting lamp | |

| JP4552897B2 (en) | LED lighting unit and lighting apparatus using the same | |

| WO2011090073A1 (en) | Illumination apparatus | |

| US8950896B2 (en) | Illumination apparatus | |

| JP2009231473A (en) | Lighting module and electronic apparatus using the same | |

| JP2012244018A (en) | Light-emitting module and illumination apparatus | |

| JP4564465B2 (en) | Light source body and lighting device | |

| JP2010146812A (en) | Electrical connection device, light source device, and electrical connection method | |

| KR20100129850A (en) | Illumination assembly for substitution fluorescent lamp and illumination apparatus including the same | |

| JP5511290B2 (en) | Light emitting device | |

| JP4812828B2 (en) | LED lighting device | |

| JP5351817B2 (en) | lighting equipment | |

| JP2009170642A (en) | Electric device | |

| JP2007066906A (en) | Light emitting diode bulb | |

| JP2015133248A (en) | Led lighting lamp and light-emitting type signboard apparatus | |

| JP2010161046A (en) | Led lighting device | |

| JP2011159825A (en) | Module device for led lighting, and method of manufacturing the same | |

| JP5896125B2 (en) | Light emitting device and lighting device | |

| KR101191566B1 (en) | LED Illumination Equipment | |

| JP5328468B2 (en) | Solid state light emitting device, solid state light emitting element unit and lighting fixture | |

| JP2016039183A (en) | Method of manufacturing lighting fixture and lighting fixture | |

| KR101607543B1 (en) | Light emitting device | |

| KR200471342Y1 (en) | Led module and electronic apparatus having it |