JP2005297036A - 金属製屈曲溝状部材の製造方法 - Google Patents

金属製屈曲溝状部材の製造方法 Download PDFInfo

- Publication number

- JP2005297036A JP2005297036A JP2004119414A JP2004119414A JP2005297036A JP 2005297036 A JP2005297036 A JP 2005297036A JP 2004119414 A JP2004119414 A JP 2004119414A JP 2004119414 A JP2004119414 A JP 2004119414A JP 2005297036 A JP2005297036 A JP 2005297036A

- Authority

- JP

- Japan

- Prior art keywords

- bent

- bending

- plate portion

- joining

- groove

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Landscapes

- Bending Of Plates, Rods, And Pipes (AREA)

Abstract

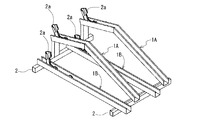

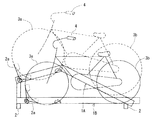

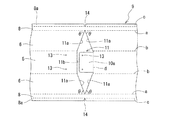

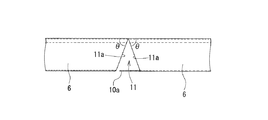

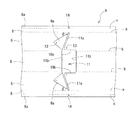

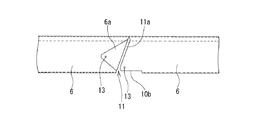

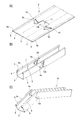

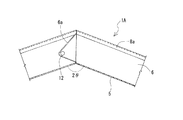

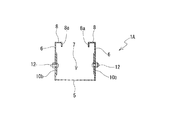

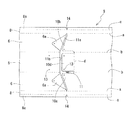

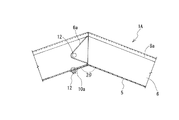

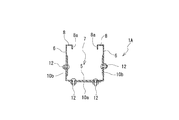

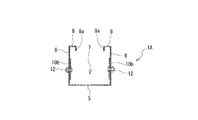

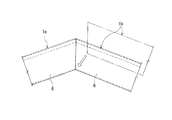

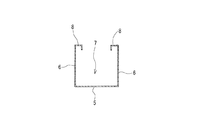

【解決手段】 一定幅の底板部5と、底板部の両側縁から同方向へ折れ曲がった左右一対の側板部6と、両側板部の先端から溝7の内側又は外側へ底板部と平行に折れ曲がった折曲板部8とを備え、且つ、溝の開口と反対側へ屈曲した形状の金属製屈曲溝状部材1Aを製造するにあたり、帯状平板9に所定の折り曲げ線a,a、b,b、を形成し、一方の側板部6と折曲板部8との折り曲げ線aから他方の側板部6と折曲板部8との折り曲げ線aに至る板部に、一部を切り残して接合用舌片10a,10bとした屈曲用切欠き部11を打抜き形成し、帯状平板を夫々の折り曲げ線から折り曲げると共に、接合用舌片10a,10bを屈曲用切欠き部11の反対側に位置する板部と重ね合わせ、この重ね合わせ部分を接合して、金属製屈曲溝状部材を製造する。

【選択図】 図5

Description

5 底板部

6 側板部

7 溝

8 折曲板部

9 帯状平板

10a,10b 接合用舌片

11 屈曲用切欠き部

a,b,c 折り曲げ線

Claims (4)

- 一定幅の底板部と、底板部の両側縁から同方向へ折れ曲がった左右一対の側板部と、両側板部の先端から溝の内側又は外側へ底板部と平行に折れ曲がった折曲板部とを備え、且つ、溝の開口と反対側へ屈曲した形状の金属製屈曲溝状部材を製造するにあたり、帯状平板に所定の折り曲げ線を形成し、一方の側板部と折曲板部との折り曲げ線から他方の側板部と折曲板部との折り曲げ線に至る板部に、一部を切り残して接合用舌片とした屈曲用切欠き部を打抜き形成し、帯状平板を夫々の折り曲げ線から折り曲げると共に、接合用舌片を屈曲用切欠き部の反対側に位置する板部と重ね合わせ、この重ね合わせ部分を接合して、金属製屈曲溝状部材を製造することを特徴とする金属製屈曲溝状部材の製造方法。

- 接合用舌片が底板部に連設されていることを特徴とする請求項1に記載の金属製屈曲溝状部材の製造方法。

- 接合用舌片が側板部に連設されていることを特徴とする請求項1に記載の金属製屈曲溝状部材の製造方法。

- 接合用舌片が底板部と側板部の各々に連設されていることを特徴とする請求項1に記載の金属製屈曲溝状部材の製造方法。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004119414A JP3983230B2 (ja) | 2004-04-14 | 2004-04-14 | 金属製屈曲溝状部材の製造方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004119414A JP3983230B2 (ja) | 2004-04-14 | 2004-04-14 | 金属製屈曲溝状部材の製造方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2005297036A true JP2005297036A (ja) | 2005-10-27 |

| JP3983230B2 JP3983230B2 (ja) | 2007-09-26 |

Family

ID=35329213

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004119414A Expired - Lifetime JP3983230B2 (ja) | 2004-04-14 | 2004-04-14 | 金属製屈曲溝状部材の製造方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3983230B2 (ja) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101036292B1 (ko) * | 2008-07-22 | 2011-05-25 | 오경호 | 접이식 프레임 제조방법 |

| KR101308647B1 (ko) | 2012-08-07 | 2013-09-23 | 주식회사 월드퍼니처 | 가구용 프레임 다리구조 |

| JP2014054669A (ja) * | 2012-09-12 | 2014-03-27 | Rah Seong Industrial Co Ltd | ラウンド状のコーナーを形成する方法(methodformingaroundedcorner) |

-

2004

- 2004-04-14 JP JP2004119414A patent/JP3983230B2/ja not_active Expired - Lifetime

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101036292B1 (ko) * | 2008-07-22 | 2011-05-25 | 오경호 | 접이식 프레임 제조방법 |

| KR101308647B1 (ko) | 2012-08-07 | 2013-09-23 | 주식회사 월드퍼니처 | 가구용 프레임 다리구조 |

| JP2014054669A (ja) * | 2012-09-12 | 2014-03-27 | Rah Seong Industrial Co Ltd | ラウンド状のコーナーを形成する方法(methodformingaroundedcorner) |

Also Published As

| Publication number | Publication date |

|---|---|

| JP3983230B2 (ja) | 2007-09-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10619404B2 (en) | Welded steel door | |

| US6351882B1 (en) | Method of constructing a door | |

| JP6203470B2 (ja) | ドアサッシュ | |

| AU2007330603B2 (en) | Process for producing a die | |

| WO2021262070A1 (en) | Mesh container and method for producing a mesh container | |

| JPS5838244B2 (ja) | ハニカム状の金属製芯構造体を製造するのに用いられる金属製芯部材 | |

| JP2010012891A (ja) | 車両用ドアサッシュ | |

| JP3983230B2 (ja) | 金属製屈曲溝状部材の製造方法 | |

| JP3857267B2 (ja) | 自動車の自動変速機用オイルクーラ構造 | |

| CA2496803A1 (en) | Method of forming a joist assembly and a chord used in such joist assembly | |

| CA2526808A1 (en) | A girder for a vehicle chassis | |

| JP4545228B1 (ja) | 復層軽量h形鋼 | |

| JP2003118734A (ja) | 金属製パレット及び金属製パレットの組立方法 | |

| JP2013123958A (ja) | パネルの接合構造 | |

| JP3929816B2 (ja) | ヘアライン加工方法 | |

| JPH09187875A (ja) | 剛性シートの折構造体 | |

| CN221049785U (zh) | 一种一体式侧围门环 | |

| JP5027518B2 (ja) | 車体パネルの結合部の構造 | |

| JP2703857B2 (ja) | 集合ブランク部材 | |

| JP2013111581A (ja) | 接合体及び接合体からなる車両、接合体の製造方法 | |

| JP2010221235A (ja) | 作業機械のアタッチメント及びその溶接方法 | |

| JPH0780580A (ja) | 箱状製品及び同製品の製造方法 | |

| JP4368300B2 (ja) | 自動車の後部車体構造 | |

| JP2008184024A (ja) | 車体パネルの結合部の構造 | |

| JPH049389Y2 (ja) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20070406 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20070605 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20070703 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20100713 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 3983230 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20100713 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110713 Year of fee payment: 4 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120713 Year of fee payment: 5 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130713 Year of fee payment: 6 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| EXPY | Cancellation because of completion of term |