EP4198243B1 - Rahmenprofilanordnung - Google Patents

Rahmenprofilanordnung Download PDFInfo

- Publication number

- EP4198243B1 EP4198243B1 EP22212733.4A EP22212733A EP4198243B1 EP 4198243 B1 EP4198243 B1 EP 4198243B1 EP 22212733 A EP22212733 A EP 22212733A EP 4198243 B1 EP4198243 B1 EP 4198243B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- profile

- frame

- carrier

- fastened

- arrangement according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/54—Fixing of glass panes or like plates

- E06B3/58—Fixing of glass panes or like plates by means of borders, cleats, or the like

- E06B3/585—Fixing of glass panes or like plates by means of borders, cleats, or the like adjustable, e.g. for accommodating panes of various thickness, or with provisions for altering the clamping force on the pane

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/30—Coverings, e.g. protecting against weather, for decorative purposes

- E06B3/301—Coverings, e.g. protecting against weather, for decorative purposes consisting of prefabricated profiled members or glass

- E06B3/306—Covering plastic frames with metal or plastic profiled members

Definitions

- the invention relates to a frame profile arrangement for window or door frames, with a frame profile and a glazing bead that can be clamped to it.

- the invention also relates to a glazing bead for a frame profile arrangement and a frame that is composed of several frame profile arrangements.

- Such arrangements are generally known in the art, e.g. from DE-OS 2 012 353 .

- the glazing bead is used to attach a glass element between the frame profiles and the glazing bead after a frame has been made from several such frame profile arrangements.

- This type of structure is used regardless of the material of the frame profile arrangement, i.e. both for plastic windows and doors and for those made of aluminum.

- a classic aluminum frame system also includes an aluminum glazing bead that forms the transition between the sash frame profile or, in the case of fixed glazing, between the frame profile and the glazing.

- glazing beads are arranged on the side facing the room.

- the glass element can be easily inserted from the room, and the glass element is also easily accessible in the event of repairs.

- glazing beads are installed/inserted/mounted towards the inside of the building as standard.

- the glazing bead can be snapped into the frame profile and fixes the glass element in the frame or its frame profiles.

- the respective glazing bead is part of the cross or longitudinal beam.

- the glazing bead forms a surrounding frame and presses the glass pane to a stop in the frame profile and thus locks the glass in the correct place within the glass rebate. There is a seal between the glass strip and the glass pane, the so-called glazing seal.

- Window frames and door frames are widely made from hollow plastic profiles with glazing beads, also made from plastic, which are mitred at the end. Since the plastic glazing beads have a certain elasticity and are flexible, they can be fitted precisely by bending them. The two short sides are first snapped into place, the two long glazing beads are slightly bent before being inserted and positioned in the corners of the sash frame and hammered into the groove of the sash or frame profile with a soft-face hammer. In order to achieve the best possible seal in the corner areas of the glazing bead profiles that meet one another, the glazing bead profiles can be given an oversize.

- a seal to the glass does not need to be added in a further step if it can be extruded during the extrusion process of glazing bead profile production. Otherwise, it is mounted on the glazing bead after production.

- glazing beads are particularly important. They ensure a smooth and routine assembly process.

- a primary goal is to apply the proven advantages of a tried and tested frame processing method with plastic frame profiles, also for frames, e.g. for windows or doors, with an aluminum look.

- Aluminium profiles are rigid and not bendable, which is why the conventional glazing bead assembly with bending at mitre cuts is not applicable here. Due to the material properties of aluminium, a glazing bead can be in the corner area, only make a straight cut into the sash or frame profile. The glazing beads are joined together to form a frame parallel to the glass element on the sash or frame profile and meet butt-jointed in the corners.

- the glazing seal can only be inserted after the glazing beads have been installed, between the glazing beads and the glass element. This step must always be carried out by hand and cannot be automated. The current processing of glazing beads by aluminum system providers is therefore laborious. Easier and faster processing is required.

- a subsequently installed wedge seal has a very large gap for technical reasons, which represents the visible width of the seal of approx. 12 mm, which is also undesirable and has a negative impact on the external appearance.

- the object of the invention is therefore to combine the advantages of elastic PVC with the corrosion-resistant and optical properties of aluminum and to provide a frame profile arrangement with a glazing bead that enables rapid glazing by bending and preferably allows the use of extruded, extruded or rolled-in seals, since the seal in the glazing bead can be introduced automatically and the gap size, in particular of e.g. approx. 3-5 mm, is significantly smaller.

- glazing beads made of plastic can be equipped with seals during production and the subsequent insertion of a wedge seal between the glass element and the glazing bead is not necessary.

- a glazing bead which comprises a plastic carrier profile that can be clamped to the frame profile and an aluminium cover, is made of DE202019107047U and out FR2904354A known.

- the invention can therefore exploit the advantages of mounting a classic plastic glazing bead with the plastic support profile and then exploit the advantages provided by aluminum as a material with the aluminum cover.

- the carrier profile fulfils the function of a conventional glazing bead.

- This is characterised by a fully-fledged plastic profile, preferably one that, when viewed in cross-section, has a closed plastic cover on all outer sides that encloses hollow spaces on the inside.

- the carrier profile is preferably connected to the frame profile via a clip connection or at least can be connected. To do this, the clip foot is positioned on the receiving groove of the frame profile and clipped in securely.

- the carrier profile has at least one sealing lip. This can preferably be extruded onto the carrier profile, extruded in or inserted, in particular rolled in.

- the carrier profile preferably has a receiving groove to accommodate this so-called glazing seal. This can already have been extruded in during the extrusion process or it can be rolled in with the help of a machine or inserted manually afterwards.

- a preferred variant provides that at least one sealing lip is extruded during the extrusion process. It should be emphasized that the possibility of extruding or extruding sealing materials such as EPDM is only possible on plastic material.

- the aluminum cover has at least one locking lug or positioning lug, with which the aluminum cover is held in a locking or at least positioning manner in a receiving groove of the carrier profile.

- the locking lug or positioning lug can further preferably be shaped complementarily to the receiving groove.

- the aluminum cover has two locking lugs or positioning lugs, each of which is assigned a receiving groove on the support profile.

- the receiving groove serves as a fastening means and/or positioning for the aluminum cover, which forms the outer cover of the visible surface of the carrier profile.

- the aluminum cover forms a clamp connection with the plastic support profile when clicked onto it and gives the frame profile with glazing bead a uniform external appearance with an aluminum look.

- the aluminum cover preferably has two locking lugs, which are formed by projections that can be locked into the carrier profile and are preferably shaped to complement the receiving grooves in the carrier profile for a locking connection.

- the locking lug can be designed in the shape of a hook, for example, but can optionally also be designed as knobs or beads that lock into corresponding recesses, undercuts or cutouts in the carrier profile after assembly.

- a snap-in connection is a type of connection that is extremely suitable for the material and easy to assemble and disassemble.

- the aluminum cover is placed parallel to the support profile like a cap and pressed into place. When the aluminum cover is clicked onto the support profile, a locking connection is created between the two profiles.

- an aluminum cover is conceivable that is provided with a locking lug or at least with a positioning lug and is additionally glued to the support profile.

- the locking lug or positioning lug is used during assembly to position the aluminum cover, which is then pivoted onto the support profile and glued.

- the aluminum cover can therefore be connected to the support profile only by locking, only by adhesive (in particular positioned with a positioning lug) or by a combination of locking and adhesive.

- the aluminum cover When viewed in cross-section, the aluminum cover preferably has two arms, each with a free end, preferably which are prestressed towards one another, in particular thereby giving the locking connection a tight fit.

- the angle between the arms with the free end can be 90 degrees. It can also be provided that the angle is less than 90 degrees, in particular 87 to 89.9 degrees, in order to achieve prestress.

- the arms with the free ends can be connected directly to one another.

- the aluminum cover has two arms with free ends that are connected by a connecting arm, wherein each arm with a free end encloses an angle of greater than 90 degrees with the connecting arm, in particular an angle of 125 to 145 degrees.

- the aluminum cover can be snapped/clicked onto the plastic support profile without tools and can preferably be dismantled just as easily.

- the PVC support profiles which fulfill the function of the glazing beads, are first joined to the frame profile and assembled in the usual way.

- the aluminum covers are then placed, in particular snapped, onto the support profiles to ensure a uniform external appearance.

- the glazing bead frame When assembled, the glazing bead frame according to the invention comprises a concealed frame of PVC support profiles and a visually visible frame consisting of aluminum covers.

- the aluminum covers can be cut straight or mitred in the corners.

- the support profiles are preferably mitred like conventional glazing beads.

- the aluminum cover can be attached to the carrier profile by additional, point-by-point or surface bonding, e.g. using adhesives or double-sided adhesive tape.

- suitable adhesives ensures that the aluminum cover can be removed without leaving any residue if the aluminum cover or the carrier profile is replaced.

- the aluminum cover can be designed in different geometries. It can be provided that the aluminum cover is arranged in the assembled state, in particular in the visible area, in contact with the carrier profile and/or partially spaced from it. In particular, at least one cavity can be enclosed between the carrier profile and the aluminum cover, in particular if the carrier profile has a bevel on the outer visible side that is covered by the aluminum cover. It is preferably provided that the aluminum cover completely covers the visible area of the carrier profile from the glazing seal of the carrier profile to the frame profile, in particular adjoins the glazing seal without gaps.

- the wall thickness of the webs forming the outer wall of the carrier profile is smaller than the wall thickness of the webs of the carrier profile pointing towards the glass rebate of the frame profile and/or than the wall thickness of the webs of the carrier profile not in contact with the aluminum cover.

- the width of the glazing beads must be adjusted.

- the preferred method for this is to use a universally applicable support profile.

- the invention provides that the carrier profile is formed by a base profile and an attachment profile attached/attachable to it.

- the carrier profile is thus formed in two parts.

- the base profile and attachment profile can preferably also be detached from each other again after attachment.

- the attachment profile has the glazing seal in the form of at least one sealing lip.

- connection between the base profile and the attachment profile is preferably formed in a leg of the carrier profile, which, or its lower surface, lies parallel to the glazing rebate surface of the frame profile when installed.

- the invention preferably provides for the length of this leg of the support profile to be variable.

- At least one of the profiles of the base profile and the attachment profile can be shortened.

- the shortening is preferably implemented in such a way that even after shortening, the respective profile has a fastening area for the other profile.

- the base profile is particularly preferably designed to be shortenable, in particular on the side facing the glazing seal.

- the shortenable profile in particular the base profile, can be designed to be open in the direction of the other profile, in particular the attachment profile.

- a recess is formed at these open ends, to or in which the other profile, in particular the attachment profile, can be or is attached.

- the open recess on the shortenable profile is preferably surrounded by recess walls and at least one recess wall has a fastening structure pointing into the interior of the recess, to which the other profile can be fastened, in particular with a corresponding fastening element.

- At least one recess wall preferably two opposite recess walls, have several, preferably equidistant, locking grooves.

- Each locking groove preferably runs parallel to the opening plane of the open recess. Different locking grooves on the same recess wall have different distances from the opening plane.

- the profile that can be fastened to the shortenable profile e.g. the base profile, e.g. the attachment profile, preferably has a fastening area that can be inserted into the open recess, e.g. with a collar as a corresponding fastening element that engages in at least one locking groove of a recess wall.

- the carrier profile can be shortened to suit the glass thickness by cutting, sawing or milling one of the two profiles of the base profile or attachment profile from which the carrier profile is formed, in particular by reducing the depth of the open recess.

- the open profile side of the cut profile, in particular the base profile, is closed with the other profile, in particular the attachment profile, preferably made of TPE.

- thermoplastic elastomers combine the efficient processing properties of thermoplastics with the softness and flexibility of elastomers and fulfill the function of a plug that closes the open profile.

- the attachment profile has the collar located in the open recess, which is inserted into the inner profile formed by the locking grooves of the base profile, so that a firm locking connection is created between the attachment profile and the base profile.

- the attachment profile and the preferably open base profile together form a support profile that is covered with the aluminum cover.

- the aluminium cover When installed, the aluminium cover preferably connects seamlessly to the glazing seal and to the frame profile, in particular to an aluminium cover that is also located on the frame profile.

- the glazing bead according to the invention offers a significant advantage for the isothermal curve due to its "substructure" of the plastic support profile. Since plastic has a lower thermal conductivity than aluminum, thermal insulation is supported and the isothermal curve is optimized in the critical transition area between the glazing bead and the glazing.

- Figure 1 is a cross-section through a sash and a frame profile 10, 20 with the glazing bead 25 with extruded sealing lips 40.

- a frame group consisting of a sash frame and a frame profile 10, 20 is shown in the closed position.

- This is a system in which the sash frame and frame profile 10, 20 essentially has a core made of plastic and is covered with aluminum shells 20 ⁇ , 20" on the visible surfaces on the weather and room sides.

- the two-part glazing bead 25 is composed of the carrier profile 30 and an aluminum cover 30'.

- the carrier profile 30 is made of a hollow plastic profile.

- the carrier profile 30 takes over the function of the glass strip known to date in the state of the art and clamps the glass element (not shown) between the sash overlap 23 and the support profile 30.

- the support profile 30 is elastically clipped with its clip foot 31 in the receiving groove 32 of the sash frame profile 20.

- the contact pressure positions the glass element centrally between the sash overlap 23 and the support profile 30 and clamps it in the area of the glass rebate.

- the Figure 1 shows a seal extruded onto the carrier profile 30 during the extrusion process.

- Two sealing lips 40 of the seal are arranged between the glass element and the sash frame profile 20 and when the carrier profile 30 is fitted, the sealing lips 40 are pressed together to form a gap of, for example, approx. 3-5 mm to the glass element. Only one sealing lip 40 can also be provided. The appearance of a narrow sealing gap is desired.

- the PVC carrier profile 30 is covered with an aluminum cover 30'.

- Figure 2 shows a detailed view of Figure 1 in cross-section through the two-part glass strip 25 with extruded sealing lips 40.

- the aluminum cover 30' can be snapped/clicked onto the plastic support profile 30 without tools and can be removed just as easily. It serves to enhance the appearance and has no static holding function for the glass element.

- the aluminum cover 30' has two arms with free ends 35, 36, which are pre-tensioned towards each other and give the locking connection a tight fit.

- the arms of the aluminum cover with the free ends 35, 36 are connected directly to each other and can form an angle of 90 degrees between them or, to create a pre-tension, an angle that is slightly smaller than 90 degrees, e.g. 87 to 89.9 degrees.

- the aluminium cover 30 ⁇ which preferably corresponds in length to the length of the support profile 30, is fixed with the locking lugs shown in the cross section 33, which form continuous projections in their longitudinal extension, are clicked into the preferably complementarily shaped receiving grooves 32, which in turn form grooves extending in the longitudinal direction.

- the receiving grooves 32 can preferably be provided with undercuts so that the respective locking lug 33 can engage behind them.

- adhesive can be used as an additional connecting means, which is applied between the support profile 30 and the aluminum cover 30' in a point-by-point or planar manner, in particular on the surface of one or each of the two arms with the free ends 35, 36.

- the two-part glazing bead 25 is preferably characterized in that the wall thickness of the webs of the carrier profile 30 facing the outer visible side in the contact area with the aluminum cover 30' is smaller than the wall thickness of the webs of the carrier profile 30 facing the inside or the glass rebate surface in the area not contacted by the aluminum cover.

- the webs or outer walls 37 of the carrier profile 30 oriented towards the visible area can have a material-saving, smaller wall thickness than the inner webs/inner walls.

- the aluminum cover 30' completely covers the visible area from the glazing seal 40 to the frame profile 10/20 (sash or frame profile) or its aluminum cover.

- the geometry of the aluminum cover 30' can preferably correspond to the geometry of the visible surface of the carrier profile 30.

- Figure 3 represents a cross-section through a sash frame and a frame profile 20, 10 with the glazing bead 25 with rolled or hand-drawn seal 40.

- the type of seal 40 is the only difference in this embodiment to the frame assembly in Figure 1 .

- the carrier profile 30 has a seal receiving groove 41 to accommodate a so-called glazing seal 40.

- a so-called glazing seal 40 An example of a rolled-in seal 40 is shown. This may have already been rolled in with the aid of a machine during the extrusion process.

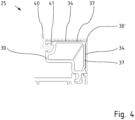

- Figure 4 shows the detailed view of Figure 3 in cross section through the glazing bead 25 with rolled or hand-drawn seal 40.

- the carrier profile 30 here forms the part of the glazing bead 25 with holding and clamping function and the aluminum cover 30' surrounds the outer surfaces 37 of the carrier profile 30 in the visible area.

- the outer wall thickness of the walls/webs 37 of the carrier profile 30 is also smaller than the webs in the non-contact area or those facing the glass rebate surface.

- the aluminum cover 30' adjoins the seal 40 and the sash frame profile 20 / or, in the case of fixed glazing, the frame profile 10 without any gaps.

- Figure 5 shows a detailed view in cross section through the glazing bead 25 in a further embodiment of the carrier profile 30 with rolled-in or hand-drawn seal 40'.

- This embodiment can also be provided with an extruded seal 40.

- This variant differs in a different embodiment of the carrier profile 30.

- the outer wall 37 is provided with a bevel on the room side.

- the same aluminum cover 30 as for the Figures 1 to 4 described, can be used despite varying shapes of the carrier profile 30.

- the aluminum cover 30' can contact the carrier profile 30 in the visible area in sections and can be arranged at a distance in sections, in particular in the overlap area of the bevel, and thereby enclose at least one cavity 42 between itself and the support profile 30.

- Figure 6 shows a detailed view in cross section through the glass strip 25 in a further embodiment of the aluminum cover 30' with rolled or hand-drawn seal 40, which is also possible with extruded seal 40.

- the support profile 30 is arranged in the visible area in complete contact with the aluminum cover 30'.

- the aluminum cover 30' has two arms with free ends that are indirectly connected via a connecting arm, wherein the angles between an arm with a free end and the connecting arm are greater than 90 degrees and the arms with the free ends are at least substantially at 90 degrees to one another or at an angle of less than 90 degrees, in particular 87 to 89.9 degrees.

- the outer shape of the carrier element 30 and the inner shape of the aluminum cover 30' are preferably congruent.

- Figure 7a shows a detailed view in cross section through the glazing bead 25 according to the invention in a further embodiment in which the carrier profile 30 is formed from a base profile 30a and an attachment profile 50.

- the attachment profile 50 has a seal 40 extruded onto it or, as shown here, inserted into the sealing groove 41.

- the base profile 30a is an open profile which, in terms of the cross section, can be shortened on the side facing the seal 40.

- the open profile side is closed with the attachment profile 50, preferably made of TPE.

- Thermoplastic elastomers (TPE) combine the efficient processing properties of thermoplastics with the softness and flexibility of elastomers and here fulfill the function of a plug that closes the open base profile 30a.

- the base profile has an open recess 30b on the side facing the seal 40, e.g. in the profile arm 38, which in the assembled state lies parallel to the glass rebate surface of the frame profile 10/20, wherein at least two opposing walls surrounding the recess 30b have a profile.

- the profile is formed here by locking grooves 30c. Each locking groove 30c runs parallel to the opening plane of the recess 30b of the base profile 30a.

- the locking grooves 30c are preferably arranged equidistant from one another on the same inner wall of the recess 30b.

- the collar 50a of the attachment profile 50 located inside the recess engages in the inner profiling, in particular the locking groove 30c on the inner wall of the recess 30b of the support profile 30a, so that a firm locking connection is created between the attachment profile 50 and the base profile 30a.

- the attachment profile 50 and the open base profile 30a form in conjunction with each other the carrier profile 30 of a glazing bead 25, which is analogous to the carrier profile 30 of the previously described embodiments of the Figures 1 to 6 corresponds.

- the glazing bead 25 can be adapted to glass elements of different thicknesses.

- the aluminum cover 30' When installed, the aluminum cover 30' connects seamlessly to the seal 40 and to the sash frame profile 20/ or, in the case of fixed glazing, to the frame profile 10 or its aluminum cover.

- Figure 7b and 7c show detailed views in cross section through the glazing bead 25 according to the invention in further embodiments of an open, shortened base profile 30a with an attachment profile 50 in a medium length at Figure 7b or, as in Figure 7c shown in a maximum shortened length of the base profile 30a.

- the attachment profile 50 is always the same.

- the base profile 30a is also always the same, just with different degrees of shortening. This means that different installation situations can be served with the same components.

- the base profile 30a can be shortened to suit the glass width by cutting, sawing or milling it.

- the shortenable connection type between the base profile and the attachment profile shown here can also be implemented in the opposite way, ie the attachment profile can be shortened in length and attached to the base profile 30a.

- the attachment profile can have an open recess for attachment purposes, the depth of which can be changed by shortening the attachment profile.

Landscapes

- Engineering & Computer Science (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Securing Of Glass Panes Or The Like (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102021132878.0A DE102021132878A1 (de) | 2021-12-14 | 2021-12-14 | Rahmenprofilanordnung |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP4198243A1 EP4198243A1 (de) | 2023-06-21 |

| EP4198243C0 EP4198243C0 (de) | 2025-02-12 |

| EP4198243B1 true EP4198243B1 (de) | 2025-02-12 |

Family

ID=84488469

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP22212733.4A Active EP4198243B1 (de) | 2021-12-14 | 2022-12-12 | Rahmenprofilanordnung |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP4198243B1 (pl) |

| DE (1) | DE102021132878A1 (pl) |

| PL (1) | PL4198243T3 (pl) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102024100547A1 (de) * | 2024-01-10 | 2025-07-10 | SCHÜCO International KG | Verfahren zur Herstellung eines Verbundprofils und Verbundprofil |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2012353A1 (de) | 1970-03-16 | 1971-10-07 | VAW Leichtmetall Werke GmbH, 5300 Bonn | Aluminium-Falzprofil zur Schutzverkleidung von Fensterholzrahmen |

| DE2704808A1 (de) * | 1977-02-05 | 1978-08-10 | Agura Ets | Fenster |

| EP0244494B1 (de) | 1986-05-05 | 1990-02-21 | PLUS PLAN Kunststoff- u. Verfahrenstechnik GmbH | Bausatz zur Erstellung von Fenster- oder Türrahmen |

| DE20002142U1 (de) | 2000-02-08 | 2001-06-07 | Montanstahl Sa, Stabio | Fenster-/Türsystem |

| FR2904354B1 (fr) | 2006-07-25 | 2008-12-05 | Denis Metrat | Ouvrant a capot |

| DE102019106876A1 (de) * | 2019-03-18 | 2020-09-24 | Veka Ag | Rahmenprofil eines Blend- und/oder Flügelrahmens, sowie Verfahren zu dessen Herstellung und zur Eckverbindung |

| DE202019107047U1 (de) | 2019-12-17 | 2021-03-18 | Rehau Ag + Co | Fenster- oder Türflügel sowie diesen umfassendes Fenster oder diesen umfassende Tür |

| GB2591304B (en) | 2020-01-27 | 2024-05-08 | Garner Aluminium Extrusions Ltd | A glazing bead |

-

2021

- 2021-12-14 DE DE102021132878.0A patent/DE102021132878A1/de active Pending

-

2022

- 2022-12-12 PL PL22212733.4T patent/PL4198243T3/pl unknown

- 2022-12-12 EP EP22212733.4A patent/EP4198243B1/de active Active

Also Published As

| Publication number | Publication date |

|---|---|

| PL4198243T3 (pl) | 2025-05-19 |

| EP4198243C0 (de) | 2025-02-12 |

| EP4198243A1 (de) | 2023-06-21 |

| DE102021132878A1 (de) | 2023-06-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2285612B1 (de) | Profilelement zum verbinden einer fahrzeugscheibe mit einem wasserkasten | |

| EP3712368B1 (de) | Rahmenprofil eines blend- und/oder flügelrahmens, sowie verfahren zu dessen herstellung | |

| EP0616107B1 (de) | Stossverbindung von Hohlprofilabschnitten | |

| DE4309088A1 (de) | Ortsfest einbaubare Scheibe für Kraftfahrzeuge | |

| DE202014009250U1 (de) | Dichtungsvorrichtung für einen verschiebbaren Flügel als Schiebeflügel oder verschiebbaren Hebe-Schiebeflügel eines Fensters oder einer Tür | |

| DE19745750C5 (de) | Kämpfer-Verbinder für Fenster- und Türrahmen | |

| EP2666948A1 (de) | Rahmenanordnung für ein Sektionaltorpaneel | |

| EP4198243B1 (de) | Rahmenprofilanordnung | |

| EP0814228A2 (de) | Verstärkungsprofil für Kunststoff-Hohlprofile zur Herstellung von Fenster, Türen oder dgl. | |

| EP0215456A1 (de) | Extrudierter Kunststoffhohlprofilstab für Rahmen von Fenstern und Türen | |

| EP2476854A2 (de) | Außenverkleidung für ein Fenster, eine Tür oder dergleichen | |

| EP2985394A1 (de) | Pfosten-riegel-konstruktion | |

| DE3241652C2 (de) | Sonnendach für Fahrzeuge | |

| AT501199A1 (de) | Zweiteiliges laibungsanschlussprofil für an putz angrenzende bauteile | |

| EP3680438B1 (de) | Anordnung aus einem rahmenprofil und einem dichtprofil für einen fenster- oder türrahmen | |

| EP2428633B1 (de) | Blendrahmenprofil für Tür-, Fenster- oder Fassadenkonstruktion | |

| DE29818846U1 (de) | Fenster- oder Türflügel | |

| DE4412414A1 (de) | Glasfalzdichtung, insbesondere für Fenster oder Türen | |

| DE20100618U1 (de) | Rahmenprofil | |

| EP2184433B1 (de) | Rahmenkörper für Fenster oder Türen | |

| EP2131005B1 (de) | Dichtung, insbesondere für Türen, Fenster oder Fassaden | |

| EP1811112B1 (de) | Scheibenverklebung | |

| DE19713392C1 (de) | Anordnung zur kraft- und/oder formschlüssigen Halterung von Profilleisten an einem Fenster- oder einem Türrahmen bzw. -flügel | |

| EP4357574B1 (de) | Flügelprofil und flügelrahmen | |

| EP4174242B1 (de) | Dichtungsanordnung zur abdichtung des übergangs zwischen fassadenelementen einer elementfassade |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC ME MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20231218 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC ME MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20240913 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC ME MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502022002865 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| U01 | Request for unitary effect filed |

Effective date: 20250227 |

|

| U07 | Unitary effect registered |

Designated state(s): AT BE BG DE DK EE FI FR IT LT LU LV MT NL PT RO SE SI Effective date: 20250310 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250512 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250612 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250512 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250513 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250212 |