EP3556980A1 - Scharnier zur kontrolle von geneigten türen oder türblättern - Google Patents

Scharnier zur kontrolle von geneigten türen oder türblättern Download PDFInfo

- Publication number

- EP3556980A1 EP3556980A1 EP19169402.5A EP19169402A EP3556980A1 EP 3556980 A1 EP3556980 A1 EP 3556980A1 EP 19169402 A EP19169402 A EP 19169402A EP 3556980 A1 EP3556980 A1 EP 3556980A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- section

- hinge

- axis

- closing

- rotation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05F—DEVICES FOR MOVING WINGS INTO OPEN OR CLOSED POSITION; CHECKS FOR WINGS; WING FITTINGS NOT OTHERWISE PROVIDED FOR, CONCERNED WITH THE FUNCTIONING OF THE WING

- E05F1/00—Closers or openers for wings, not otherwise provided for in this subclass

- E05F1/08—Closers or openers for wings, not otherwise provided for in this subclass spring-actuated, e.g. for horizontally sliding wings

- E05F1/10—Closers or openers for wings, not otherwise provided for in this subclass spring-actuated, e.g. for horizontally sliding wings for swinging wings, e.g. counterbalance

- E05F1/12—Mechanisms in the shape of hinges or pivots, operated by springs

- E05F1/1246—Mechanisms in the shape of hinges or pivots, operated by springs with a coil spring perpendicular to the pivot axis

- E05F1/1253—Mechanisms in the shape of hinges or pivots, operated by springs with a coil spring perpendicular to the pivot axis with a compression spring

- E05F1/1261—Mechanisms in the shape of hinges or pivots, operated by springs with a coil spring perpendicular to the pivot axis with a compression spring for counterbalancing

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05F—DEVICES FOR MOVING WINGS INTO OPEN OR CLOSED POSITION; CHECKS FOR WINGS; WING FITTINGS NOT OTHERWISE PROVIDED FOR, CONCERNED WITH THE FUNCTIONING OF THE WING

- E05F1/00—Closers or openers for wings, not otherwise provided for in this subclass

- E05F1/02—Closers or openers for wings, not otherwise provided for in this subclass gravity-actuated, e.g. by use of counterweights

- E05F1/04—Closers or openers for wings, not otherwise provided for in this subclass gravity-actuated, e.g. by use of counterweights for wings which lift during movement, operated by their own weight

- E05F1/06—Mechanisms in the shape of hinges or pivots, operated by the weight of the wing

- E05F1/068—Mechanisms in the shape of hinges or pivots, operated by the weight of the wing with inclined pivot-axes

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05F—DEVICES FOR MOVING WINGS INTO OPEN OR CLOSED POSITION; CHECKS FOR WINGS; WING FITTINGS NOT OTHERWISE PROVIDED FOR, CONCERNED WITH THE FUNCTIONING OF THE WING

- E05F3/00—Closers or openers with braking devices, e.g. checks; Construction of pneumatic or liquid braking devices

- E05F3/20—Closers or openers with braking devices, e.g. checks; Construction of pneumatic or liquid braking devices in hinges

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2201/00—Constructional elements; Accessories therefor

- E05Y2201/60—Suspension or transmission members; Accessories therefor

- E05Y2201/622—Suspension or transmission members elements

- E05Y2201/638—Cams; Ramps

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2900/00—Application of doors, windows, wings or fittings thereof

- E05Y2900/30—Application of doors, windows, wings or fittings thereof for domestic appliances

- E05Y2900/31—Application of doors, windows, wings or fittings thereof for domestic appliances for refrigerators

Definitions

- the present invention generally regards the technical field of hinges, and it particularly regards a control hinge, in particular for doors, door-leaves and the like of the inclined type.

- the glass door-leaves of refrigerators for the large-scale distribution, such as supermarkets or hypermarkets are relatively heavy, about 20 - 25 kg.

- the door-leaf is particularly heavy to open.

- An object of the present invention is to overcome the aforementioned drawbacks, by providing a control hinge in particular for inclined doors that is highly efficient and relatively economic.

- Another object of the invention is to provide a hinge that allows to control the inclined door-leaf for the entire angular rotation from the opening position to the closing position.

- Another object of the invention is to provide a hinge that allows to have a substantially constant closing speed of the inclined door-leaf for the entire angular rotation from the opening position to the closing position.

- Another object of the invention is to provide a hinge that allows an easy opening of the inclined door-leaf.

- the hinge according to the invention can advantageously be used with closing elements A mounted inclined on a support structure S .

- the hinge 1 may be applied to cold stores with inclined doors, or it can be integrated in the tubular frame thereof.

- the hinge 1 may be applied to glass door-leaves, such as those of a display window or display case.

- the hinge 1 is suitable for rotatably coupling a stationary support structure, for example a tubular frame S , and a closing element, for example a door-leaf A , rotatably movable between an opening position, illustrated for example in FIG. 1A , and a closing position, illustrated for example in FIG. 4A , around a rotation axis X .

- a stationary support structure for example a tubular frame S

- a closing element for example a door-leaf A

- the hinge 1 may be a control or hydraulic brake hinge for hydraulically damping the opening or closing displacement of the door-leaf A .

- the hinge 1 may hydraulically brake the closing displacement of the door-leaf A .

- hinge 1 acting as a closing control or hydraulic brake hinge, it may also act as an opening control or hydraulic brake hinge without departing from the scope of protection of the attached claims.

- the hinge 1 may include a hinge body 10 , may be substantially sheet-like defining a plane, and a pin 20 defining the rotation axis X .

- closing element A and the stationary support structure S may also rotate around an axis parallel to the axis X without departing from the scope of protection of the attached claims.

- the hinge body 10 may be anchored to the frame S and the pin 20 to the door-leaf A .

- the pin 20 may be movable, while the hinge body 10 may be fixed.

- the pin 20 may be fixed and the hinge body 10 may be movable without departing from the scope of protection of the attached claims.

- the hinge body 10 and the pin 20 may be mutually coupled to rotate around the axis X between the door-leaf open A , illustrated for example in FIG. 1A , and the door-leaf closed position A , illustrated for example in FIG. 4A .

- the hinge 1 may open in both directions of rotation of the pin 20 .

- the hinge may also open in a single direction of rotation without departing from the scope of protection of the attached claims.

- the pin 20 may include a cam element 21 integrally joined thereto interacting with a slider 11 slidable along an axis Y defined by the working chamber 11 ' inside the hinge body 10 .

- Such axis Y may be substantially perpendicular to the axis X . It is clear that the axes X and Y may also be parallel without departing from the scope of protection of the attached claims.

- the slider 11 may slide in the hinge body 10 between a retracted end-stop position proximal to the bottom cap 17 , illustrated for example in FIG. 1C , and an extended end-stop position distal therefrom, illustrated for example in FIG. 4C .

- Such retracted and extended end-stop positions may suitably vary, and not necessarily corresponding to the maximum distal and/or proximal position that can be taken by the slider 11 .

- a hydraulic chamber 1 1 " filed with oil or other hydraulic damping fluid may be provided for inside the slider 11 .

- the hydraulic chamber 11 " may be configured according to the disclosures of the international patent application number PCT/IB2015/050603 , on behalf of the Applicant. Furthermore, such application illustrates the operation of the hydraulic chamber 11 " and the relative components.

- the hydraulic chamber 11 " may include a cylinder 60 , which may be fixed to the hinge body 10 by means of the rod 16 .

- the cylinder 60 may divide the hydraulic chamber 11 " into a first and a second variable volume compartment 12 , 13 , placed in fluid communication with each other and preferably adjacent.

- the working fluid may circulate in a hydraulic circuit inside the hydraulic chamber 11 ", and more in particular it may flow from one to the other of the compartments 12 , 13 through a calibrated passage obtained by interference between the hole 14 and valve pin 15 .

- Valve means 50 for controlling the through-flow of the working fluid between the two compartments 12 , 13 may be present.

- the hydraulic chamber 11 ' and the relative components therein may define hydraulic damping means, as better outlined hereinafter.

- elastic means 40 mutually interacting with the slider 11 may be provided for inside the hinge body 10 .

- the elastic counteracting means may include, respectively may consist of, a spiral spring 40 with predetermined diameter.

- the elastic means 40 may be recovery means, i.e. having a force such to return the slider 11 from the proximal position to the distal position but not closing or opening the door-leaf A .

- recovery elastic means 40 may advantageously be configured and/or dimensioned so as to push the door-leaf A towards the open or closed position, so as to facilitate the user opening or closing the door-leaf A manually.

- the spiral spring 40 may be fitted onto the rod 16 , which may possibly serve as a guide for the same.

- the spring 40 will remain interposed between the bottom cap 17 of the hinge body 10 and the rear face 51 of the slider 31 , which will act as an abutment face for the spring 40 .

- the slider 11 may include a cam follower element 32 ' with an operative face 32 and thus interacting with the cam element 21 so that the rotation of the latter around the axis X promotes the sliding of the slider along the axis Y .

- the cam element 21 may be substantially flat. More in particular, in the initial position for example illustrated in FIG. 1C the substantially flat cam element 21 may be substantially perpendicular to the axis Y , while in the final position illustrated for example in FIG. 4C it may be substantially parallel to the axis Y .

- the operative face 32 may have a suitable shape, which will allow to control the closing of the door-leaf A from the full opening position illustrated for example in FIG. 1A to the closing position illustrated for example in FIG. 4A .

- the door-leaf A may close at a substantially constant speed, thus that is without banging against the frame S .

- the presence of the spring 40 dimensioned as mentioned above will facilitate the opening of the door-leaf A by the user.

- the apparent weight of the opening door-leaf A will be lesser than the actual weight, i.e. the weight that the user would be required to overcome without the spring.

- the operative face 32 may have an operative portion 33 with at least one first section 35 ' and 35 ".

- the latter may be equal to each other.

- the configuration of the operative face 32 may be symmetrical with respect to the axis Y , so that the hinge 1 behaves in the same way in both directions of rotation of the pin 20 .

- the operative face 32 may include a single section 35 ' or 35 " without departing from the scope of protection of the attached claims.

- the sections 35 ', 35 " may be substantially flat and preferably inclined with respect to the axis Y . More in particular, the inclination may be divergent with respect to the axis Y in the direction of the bottom cap 17 .

- the operative portion 33 may include a second section 36 interposed between the first sections 35 ', 35 ".

- the section 36 may be substantially flat. Thus, it may cooperate with the substantially flat cam element 21 in the initial position so as to keep the hinge in the closed position, for example as illustrated in FIG. 1A .

- the portion 33 which will not necessarily be in a central position with respect to the cam follower element but for example in a peripheral position, may include only one inclined section and a top section.

- first sections and the second section may not be necessarily flat, but slightly curved for example.

- the flat or curved top section could also be absent, and it could reduce at a point.

- the cam element 21 will rotate around the axis X for a first angular section to pass from the initial position ( FIG. 1C ) to an intermediate working position ( FIG. 2C ) in which the central portion 22 thereof tilts in the central portion 33 of the operative face 32 .

- the cam element 21 will continue to rotate around the axis X for a further second angular section, which may for example be of about 40°. Such movement will bring the cam element 21 , along with the door-leaf A , from the first intermediate working position ( FIG. 2C ) to a second intermediate working position ( FIG. 3C ).

- the end portion 23 " of the cam element 21 may exclusively rest against the lateral portion 34 " of the cam element 32 ', up to impacting against the central portion 33 .

- the second rotation step of the cam element 21 will displace the slider 11 along the axis Y , promoting the through-flow of the working fluid from compartment 12 to compartment 13 through the calibrated passage defined between the hole 14 and the valve pin 15 .

- the movement of the door-leaf A around the axis X will be hydraulically damped with a first predetermined resistance strength.

- the length of the lateral portion 34 " of the cam element 32 ' against which the end portion 23 " of the cam element 21 rests i.e. substantially the distance d2 between the ends 37 ' and 37 ", may define the second angular section of the rotation of the door-leaf A .

- the cam element 21 will continue to rotate around the axis X for a further third angular section, which may for example be of about 30°. Such movement will bring the cam element 21 , along with the door-leaf A , from the second intermediate working position ( FIG. 3C ) to the final position ( FIG. 4C ).

- the end portion 23 " of the cam element 21 may exclusively rest against the central portion 33 of the cam follower element 32 ', and more in particular against the section 35 " thereof.

- the length of the latter i.e. substantially the distance d3 between the ends 37 ' and 37 "', may define the third angular section of the rotation of the door-leaf A .

- the closing rotation of the door-leaf A may occur at a substantially constant speed.

- the cam element 21 may have a predetermined distance d5 from the axis X .

- the central portion 33 in the final portion ( FIG. 4C ) will act against the cam element 21 to force the closing door-leaf A against the frame S .

- Such configuration may be particularly useful to promote the mutual interaction between the cam element 21 and the cam follower element 32' substantially for the entire opening and/or closing rotation of the door-leaf A .

- the damping means that supply the resistance strength to the weight force A during the rotation are of the hydraulic type.

- the damping means that supply the resistance strength to the weight force of the door-leaf A during the rotation may be of the mechanical type.

- such mechanical damping means may include or consist of a compression spring 40 '.

- Such spring may have characteristics such to supply the aforementioned resistance strength. More in particular, the compression spring 40 ' may have a high rigidity, for example of at least 10 Kgf / mm.

- the expression rigidity of a compression spring is used to indicate the force required to compress the length unit, for example expressed in kilogram-force per compression millimetre of the spring.

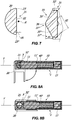

- the slider 11 may be defined by a solid cylinder which includes the cam follower element 32 '.

- the spring 40 ' may be interposed between the slider 11 and the hinge body 10 . More in particular, the spring 40 ' may be interposed between the slider 11 and the bottom cap 17 of the latter.

- the working chamber 11 ' may be without the rod 16 .

- All the other characteristics of the embodiment of the hinge 1 of FIGS. 8A and 8B may be identical to those of the embodiment of the hinge 1 of FIGS. 1A to 4C .

- the configuration of the cam element 21 and that of the cam follower element 32 ' may be identical.

- the operation may also be substantially be the same one described above, except for the fact that the resistance strength is given by the progressive compression of the spring 40 '.

Landscapes

- Closing And Opening Devices For Wings, And Checks For Wings (AREA)

- Wing Frames And Configurations (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT102018000004608A IT201800004608A1 (it) | 2018-04-17 | 2018-04-17 | Cerniera di controllo per porte o ante inclinate |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP3556980A1 true EP3556980A1 (de) | 2019-10-23 |

| EP3556980B1 EP3556980B1 (de) | 2025-06-25 |

| EP3556980C0 EP3556980C0 (de) | 2025-06-25 |

Family

ID=62875204

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19169402.5A Active EP3556980B1 (de) | 2018-04-17 | 2019-04-16 | Scharnier zur kontrolle von geneigten türen oder türblättern |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP3556980B1 (de) |

| IT (1) | IT201800004608A1 (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11261637B2 (en) * | 2016-12-15 | 2022-03-01 | In & Tec S.R.L. | Hinge for the rotatable movement of a door, a shutter or the like |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2071993A2 (de) * | 2007-12-17 | 2009-06-24 | Altura Leiden Holding B.V. | Trennwand |

| AU2010100487A4 (en) * | 2009-08-18 | 2010-07-08 | Chung Chow | Damped door hinge |

| WO2012049518A1 (en) * | 2010-10-14 | 2012-04-19 | Chung Chow | Hinge having self centering means |

| GB2525444A (en) * | 2014-04-25 | 2015-10-28 | Bestko Prec Ltd | Damped Hinge |

-

2018

- 2018-04-17 IT IT102018000004608A patent/IT201800004608A1/it unknown

-

2019

- 2019-04-16 EP EP19169402.5A patent/EP3556980B1/de active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2071993A2 (de) * | 2007-12-17 | 2009-06-24 | Altura Leiden Holding B.V. | Trennwand |

| AU2010100487A4 (en) * | 2009-08-18 | 2010-07-08 | Chung Chow | Damped door hinge |

| WO2012049518A1 (en) * | 2010-10-14 | 2012-04-19 | Chung Chow | Hinge having self centering means |

| GB2525444A (en) * | 2014-04-25 | 2015-10-28 | Bestko Prec Ltd | Damped Hinge |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11261637B2 (en) * | 2016-12-15 | 2022-03-01 | In & Tec S.R.L. | Hinge for the rotatable movement of a door, a shutter or the like |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3556980B1 (de) | 2025-06-25 |

| IT201800004608A1 (it) | 2019-10-17 |

| EP3556980C0 (de) | 2025-06-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6813504B2 (ja) | 家具のリーフ用の引き上げシステム | |

| RU2500870C2 (ru) | Предмет мебели с выталкивающим устройством для подвижных деталей мебели | |

| EP2746508A1 (de) | Türverschlussscharnier, insbesondere für Glastüren | |

| KR100835730B1 (ko) | 볼타입 클러치장치 및 이를 이용한 자동복귀 힌지장치 | |

| EP3887632B1 (de) | Möbelscharnier für nach oben öffnende schranktüren | |

| EP2909406B1 (de) | Schnappscharnier mit gedämpftem verschliessen | |

| CN109790735A (zh) | 用于提升系统的致动装置和用于家具门扇的提升系统 | |

| CN1715605B (zh) | 用于翼式和旋转翼式打开的窗和门的隐式铰接装置 | |

| JP2002227513A (ja) | 折り畳み式二枚扉用の持ち上げ装置 | |

| JP2020502404A5 (de) | ||

| EP3555399B1 (de) | Scharnier zur drehbewegung einer tür, eines verschlusses oder dergleichen | |

| EP3556980B1 (de) | Scharnier zur kontrolle von geneigten türen oder türblättern | |

| EP3795790B1 (de) | Schnappscharnier mit einer dämpfervorrichtung | |

| EP4479616A1 (de) | Scharnier für türen oder klappläden, insbesondere für kühlschränke, sowie system mit diesem scharnier | |

| EP3475509B1 (de) | Scharniermechanismus und scharniersystem | |

| DE10001424A1 (de) | Tür mit drehbar in Türbändern gelagerte Türflügel | |

| KR101784984B1 (ko) | 개폐속도조절 및 자동이송이 가능한 폴딩도어 | |

| EP4636209A2 (de) | Antriebsvorrichtung für klappbare türen von kleiderschränken, begehbaren schränken oder möbelstücken im allgemeinen | |

| EP4536927A1 (de) | Hebesystem für möbeltüren sowie stütz- und hubanordnung für möbeltüren mit dem hebesystem | |

| IT202200000212A1 (it) | Cerniera perfezionata in particolare per un elettrodomestico | |

| IT201900006586A1 (it) | Cerniera per la movimentazione girevole di una porta, un’anta o similare | |

| ITBO940148U1 (it) | Cancello a battente oscillante | |

| HK1166833B (en) | Door closing hinge, particularly for glass doors | |

| ITMI20081049A1 (it) | Dispositivo ammortizzante per cerniere di elementi di arredamento | |

| ITUA20164276A1 (it) | Dispositivo chiudiporta automatico perfezionato |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20200423 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20231026 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20250314 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602019071452 Country of ref document: DE |

|

| U01 | Request for unitary effect filed |

Effective date: 20250723 |

|

| U07 | Unitary effect registered |

Designated state(s): AT BE BG DE DK EE FI FR IT LT LU LV MT NL PT RO SE SI Effective date: 20250729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250926 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250925 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250625 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250925 |