EP3485781B2 - Suction device with function module - Google Patents

Suction device with function module Download PDFInfo

- Publication number

- EP3485781B2 EP3485781B2 EP18215339.5A EP18215339A EP3485781B2 EP 3485781 B2 EP3485781 B2 EP 3485781B2 EP 18215339 A EP18215339 A EP 18215339A EP 3485781 B2 EP3485781 B2 EP 3485781B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- suction device

- suction

- function module

- module

- electric

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000003287 optical effect Effects 0.000 claims description 7

- 239000002245 particle Substances 0.000 claims description 4

- 230000007613 environmental effect Effects 0.000 claims description 3

- 230000004308 accommodation Effects 0.000 claims 1

- 230000008878 coupling Effects 0.000 description 5

- 238000010168 coupling process Methods 0.000 description 5

- 238000005859 coupling reaction Methods 0.000 description 5

- 230000001681 protective effect Effects 0.000 description 5

- 239000004020 conductor Substances 0.000 description 3

- 230000002093 peripheral effect Effects 0.000 description 3

- 238000004140 cleaning Methods 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 230000011664 signaling Effects 0.000 description 2

- 235000014676 Phragmites communis Nutrition 0.000 description 1

- 235000004443 Ricinus communis Nutrition 0.000 description 1

- 240000000528 Ricinus communis Species 0.000 description 1

- 230000006978 adaptation Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L9/00—Details or accessories of suction cleaners, e.g. mechanical means for controlling the suction or for effecting pulsating action; Storing devices specially adapted to suction cleaners or parts thereof; Carrying-vehicles specially adapted for suction cleaners

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L7/00—Suction cleaners adapted for additional purposes; Tables with suction openings for cleaning purposes; Containers for cleaning articles by suction; Suction cleaners adapted to cleaning of brushes; Suction cleaners adapted to taking-up liquids

- A47L7/0085—Suction cleaners adapted for additional purposes; Tables with suction openings for cleaning purposes; Containers for cleaning articles by suction; Suction cleaners adapted to cleaning of brushes; Suction cleaners adapted to taking-up liquids adapted for special purposes not related to cleaning

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L7/00—Suction cleaners adapted for additional purposes; Tables with suction openings for cleaning purposes; Containers for cleaning articles by suction; Suction cleaners adapted to cleaning of brushes; Suction cleaners adapted to taking-up liquids

- A47L7/0095—Suction cleaners or attachments adapted to collect dust or waste from power tools

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L9/00—Details or accessories of suction cleaners, e.g. mechanical means for controlling the suction or for effecting pulsating action; Storing devices specially adapted to suction cleaners or parts thereof; Carrying-vehicles specially adapted for suction cleaners

- A47L9/28—Installation of the electric equipment, e.g. adaptation or attachment to the suction cleaner; Controlling suction cleaners by electric means

- A47L9/2805—Parameters or conditions being sensed

- A47L9/2821—Pressure, vacuum level or airflow

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L9/00—Details or accessories of suction cleaners, e.g. mechanical means for controlling the suction or for effecting pulsating action; Storing devices specially adapted to suction cleaners or parts thereof; Carrying-vehicles specially adapted for suction cleaners

- A47L9/28—Installation of the electric equipment, e.g. adaptation or attachment to the suction cleaner; Controlling suction cleaners by electric means

- A47L9/2805—Parameters or conditions being sensed

- A47L9/2831—Motor parameters, e.g. motor load or speed

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L9/00—Details or accessories of suction cleaners, e.g. mechanical means for controlling the suction or for effecting pulsating action; Storing devices specially adapted to suction cleaners or parts thereof; Carrying-vehicles specially adapted for suction cleaners

- A47L9/28—Installation of the electric equipment, e.g. adaptation or attachment to the suction cleaner; Controlling suction cleaners by electric means

- A47L9/2836—Installation of the electric equipment, e.g. adaptation or attachment to the suction cleaner; Controlling suction cleaners by electric means characterised by the parts which are controlled

- A47L9/2842—Suction motors or blowers

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L9/00—Details or accessories of suction cleaners, e.g. mechanical means for controlling the suction or for effecting pulsating action; Storing devices specially adapted to suction cleaners or parts thereof; Carrying-vehicles specially adapted for suction cleaners

- A47L9/28—Installation of the electric equipment, e.g. adaptation or attachment to the suction cleaner; Controlling suction cleaners by electric means

- A47L9/2857—User input or output elements for control, e.g. buttons, switches or displays

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L9/00—Details or accessories of suction cleaners, e.g. mechanical means for controlling the suction or for effecting pulsating action; Storing devices specially adapted to suction cleaners or parts thereof; Carrying-vehicles specially adapted for suction cleaners

- A47L9/28—Installation of the electric equipment, e.g. adaptation or attachment to the suction cleaner; Controlling suction cleaners by electric means

- A47L9/2894—Details related to signal transmission in suction cleaners

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/66—Structural association with built-in electrical component

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R24/00—Two-part coupling devices, or either of their cooperating parts, characterised by their overall structure

- H01R24/76—Two-part coupling devices, or either of their cooperating parts, characterised by their overall structure with sockets, clips or analogous contacts and secured to apparatus or structure, e.g. to a wall

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R27/00—Coupling parts adapted for co-operation with two or more dissimilar counterparts

- H01R27/02—Coupling parts adapted for co-operation with two or more dissimilar counterparts for simultaneous co-operation with two or more dissimilar counterparts

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R9/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, e.g. terminal strips or terminal blocks; Terminals or binding posts mounted upon a base or in a case; Bases therefor

- H01R9/22—Bases, e.g. strip, block, panel

- H01R9/24—Terminal blocks

- H01R9/2491—Terminal blocks structurally associated with plugs or sockets

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/46—Bases; Cases

- H01R13/52—Dustproof, splashproof, drip-proof, waterproof, or flameproof cases

- H01R13/5213—Covers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R2103/00—Two poles

Definitions

- the invention relates to a suction device for separating particles from a suction flow, with a suction motor for generating the suction flow and with a suction housing having a control wall for operating the suction device according to the preamble of claim 1.

- Such a suction device is, for example EP 1 955 637 A2 known.

- Such a control wall usually has an on and off switch for switching the suction device on and off. Furthermore, further controls, for example for adjusting the speed of the suction motor, can be provided at this point. Suction devices used in the workshop often have a socket for connecting an electrical tool. However, the scope of functions of the suction device is fixed.

- a basic idea of the invention is that the functional module can be replaced as required. It is therefore possible to use different functional modules with different requirements for the suction device. It goes without saying that several module holders can also be present on a suction device according to the invention.

- control wall is expediently an external wall simply because of its accessibility.

- the functional module it would be conceivable for the functional module to be placed entirely on the vacuum cleaner housing in the assembled state, i.e. not to penetrate into the vacuum cleaner housing.

- the module holder has a receiving space in which the at least one functional module is completely or partially accommodated in the assembled state.

- the recording room is advantageously accessible from the outside.

- the receiving space is a receiving chamber or a receiving shaft.

- the receiving space is so deep that a front side of the at least one functional module does not protrude, or only protrudes insignificantly, from a part of the control wall surrounding the receiving space.

- the penetration depth of the functional module therefore essentially corresponds to a depth or height of the functional module.

- the functional module does not protrude in front of the vacuum cleaner housing, which is visually appealing and provides mechanical protection for the functional module.

- a sealing arrangement that protects the functional module, the module receptacle or the electrical connection arrangement as well as corresponding contacts of the functional module from environmental influences is also advantageous.

- at least one seal can be provided on the connections of the connection arrangement. It is preferred if a seal is arranged on the outer circumference of the functional module and/or on an inner circumference of the module receptacle. The seal is preferably designed so that no dirt can penetrate into the receiving space.

- the electrical connection arrangement preferably has supply contacts for supplying electrical energy to an electrical consumer that can be connected to the suction device.

- the consumer is, for example, a power tool.

- the supply contacts can have a switchable switching supply contact that can be switched on and off by a switch on the suction device.

- This switch of the suction device can be a separate switch specifically assigned to the switching supply contact or, in a preferred embodiment of the invention, a "main switch", advantageously a switch that is provided for switching the suction motor.

- the supply contact is a permanent current contact, which is, for example, permanently connected to a power supply connection of the suction device, with which it can be connected to a power supply network. If the suction device is operated using an accumulator, the permanent current contact is permanently connected to the accumulator.

- an automatic supply contact is useful, to which a current sensor is assigned. If current flows via the automatic supply contact, this current flow is detected by the current sensor.

- One or more power supply connections in the respective supply module can be supplied with electrical energy via the supply contacts of the suction device, to which an electrical consumer, for example an electric tool, can in turn be connected.

- the functional module can be with one or several of the aforementioned supply contacts, for example the switching supply contact, the continuous current contact and the automatic supply contact, can be connected by means of a selector switch. It goes without saying that the selector switch can only allow the selection of two of the three aforementioned contacts.

- the functional module is reconfigurable in such a way that the power supply contact can be connected to at least two of the three of the aforementioned variants - switching supply contact, continuous current contact or automatic supply contact - by, for example, replugging the power connections of the functional model.

- the electrical connection arrangement of the suction device expediently also has suction device signal contacts and/or a wireless internal interface for communicating data signals and/or control signals to the functional module or from the respective functional module.

- the signal contacts are expediently potential-free, for which purpose a relay or the like can be provided.

- connection of the functional module to the suction device is expediently carried out without tools.

- Locking means for example locking hooks

- the connecting means can include, for example, one or more screws.

- a variant of the invention can provide that the functional module can deliberately only be attached to or detached from the suction device using a tool. This can, for example, represent improved theft protection or be indicated for electrical reasons, namely that the supply contacts of the suction device are not openly accessible. It goes without saying that for connecting means that can only be actuated with tools, locking means or the like can also be used, but these can advantageously only be brought into a release or release position for removing the functional module with a suitable tool.

- the functional module according to the invention provides an electrical, optical or acoustic function or any combinations thereof.

- the functional module can be, for example, a switching module.

- Display modules are also useful.

- the functional module expediently has suction device signal contacts that can connect to the module signal contacts, for example to communicate data signals or control signals.

- the data signals are expediently bus data signals.

- the functional module has an electrical switch for switching on or off the suction motor of the suction device.

- this switch is a signal switch, i.e. it outputs a switching signal for switching the suction motor on or off at a main switch arranged in the suction device.

- the switching signal can be transmitted to the suction device potential-free.

- the switching signal expediently has a lower potential than the main switch of the suction device, with which the suction motor can be switched on and off.

- the functional module can be a compressed air module.

- the functional module has, for example, a compressed air connection arrangement for connecting a compressed air tool.

- the compressed air connection arrangement expediently includes compressed air connections for looping through a compressed air line supplying the compressed air tool. At least one of the compressed air connections is expediently provided with a quick coupling and/or a counterpart for quick couplings.

- the compressed air functional module expediently includes a compressed air sensor for detecting a compressed air stream that flows through the functional module.

- the compressed air sensor contains, for example, a spring-loaded sensor body, in particular a float, which can be actuated when compressed air is actuated or when the compressed air flows through and closes a switch, preferably a reed contact.

- the float can be magnetic, for example. It goes without saying that the compressed air sensor can also be a pressure switch that can be actuated by pressure.

- the functional module has a current sensor for detecting a current flowing through the functional module.

- a potential-free switching contact is also useful. If, for example, a consumer is connected to the aforementioned power supply connection and this is switched on, i.e. for example an electric tool is switched on, the current sensor or the switching contact reports this to the suction device, which in turn then activates the suction motor.

- the respective sensor for example the compressed air sensor, the current sensor or the switching contact, are advantageously connected to the module signal contacts for transmitting data signals and control signals.

- the functional module can also include a bus coupler for connection to a data bus of the suction device.

- the functional module includes, for example, data contacts for connecting a data device to a data bus of the suction device and/or the functional module. This makes it possible, for example, to diagnose, program or calibrate the suction device and/or functional module.

- the data contacts are expediently connected to the module contacts for connection to the data bus of the suction device.

- the invention provides that the functional module has a wireless external interface for wireless communication with the functional module and/or the suction device.

- the functional module has a wireless external interface for wireless communication with the functional module and/or the suction device.

- the functional module can have optical or acoustic output means for outputting data, for example diagnostic data of the suction device, music or the like.

- data for example diagnostic data of the suction device, music or the like.

- a variant of the invention provides that the functional module has compensation for noise emissions from the suction device.

- the functional module can also have a radio receiver and/or data reading means.

- the data reading means are suitable, for example, for outputting music data stored in MP3 format or another music data format.

- a functional module according to the invention can also be a master-slave module, with the help of which a further suction device can be connected to the suction device according to the invention.

- the two suction devices can be switched on and off at the same time so that their suction power is available simultaneously.

- the current sensor in the functional module of the other suction device to which the aforementioned suction device is connected detects the current flow to the newly switched on suction device and, as a result, also switches on the suction device having the functional module according to the invention. This then forms a slave suction device.

- the suction device is a transportable, for example rollable and/or portable, suction device, according to the invention a workshop vacuum.

- a suction motor 12 is arranged to generate a suction stream 13, which can be sucked into the suction cup housing 11 via a suction inlet 14.

- a hose not shown, can be connected to the suction inlet 14.

- a receptacle 17 for receiving the suction hose and/or a connecting cable 18 with which the suction device 10 can be connected to an electrical supply network.

- the suction device 10 is a transportable suction device, on the underside of which rollers 19, 20 are arranged.

- the front castors 20 are swivel casters. Furthermore, the suction device 10 can be gripped on a carrying handle 21 on the top 16.

- a control wall 23 with control elements 24 for operating the suction device 10 extends between a front wall 22 having the suction inlet 14 and the top side 16.

- the control wall 23 is expediently inclined at an angle so that the control elements 24 can be easily operated from diagonally above at the front.

- the operating elements 24 include a switch 25, which forms a main switch, so to speak.

- the suction motor 12 can be switched on and off using the switch 25.

- an automatic mode can be set in which the suction motor 12 always runs when a connected consumer receives electrical power via the suction device 10, which will be explained later.

- a suction power or speed switch 26 With the help of a suction power or speed switch 26, the power of the suction motor 12 can be adjusted.

- An adjustment switch 27 enables electrical adjustment of the suction device 10 to a suction hose connected to a respective suction inlet 14.

- a cleaning function of the suction device 10 can be switched on and/or parameterized using a cleaning switch 28.

- a socket 29 permanently installed on the suction device 10 enables an electrical energy consumer to be plugged in. The socket 29 is electrically connected to the connection cable 18.

- the suction device 10 optionally provides additional functions that the operator can select as required: On the control wall 23 there is a module holder 30 for selectively holding functional modules 50a, 50d, which provide electrical, optical and acoustic functions.

- the module receptacle 30 is designed in the form of a receptacle shaft that is closed. Circumferential walls 32, 33 extend from the control wall 23 in the direction of the interior of the vacuum cleaner housing 11 to a bottom 31 of the module holder 30. This prevents dirt from penetrating through the module receptacle 30 into the interior of the vacuum cleaner housing 11.

- a sealing arrangement 35 with a seal 36 is provided.

- the seal 36 is, for example, an O-ring which is arranged on an edge region 34 of the receiving space 37 approximately between the operating wall 23 and the peripheral walls 32, 33.

- the module holder 30 can also be covered by a cover plate 38, the contour of which is the same as the front walls 51a - 51d ( Figure 11 ).

- the receiving space 37 forms a plug-in receptacle for receiving the functional modules 50a - 50d, which can therefore be easily inserted into the module receptacle 30.

- the functional modules 50a - 50d can be detachably connected to the suction cup housing 11.

- the receiving space 37 designed as a plug-in receptacle already forms a component of connecting means 52 with which the functional module 50a - 50d can be detachably connected to the suction cup housing 11.

- the connecting means 52 include guide ribs 39 which protrude in front of the peripheral walls 32, 33 and guide the respective functional module 50a - 50d and support it in the assembled state.

- the connecting means 52 also include screws 53 which are inserted through screw domes 65 of the functional modules 50a - 50d, which are aligned with screw receptacles 40 of the module receptacle 30 when the respective functional module 50a - 50d is mounted on the vacuum cleaner 10.

- the receiving space 37 has a depth that is sufficient so that the front wall 51a - 51d is essentially aligned with the control wall 23 when the respective functional module 50a - 50d is attached to the vacuum cleaner 11.

- the connection arrangement 41 includes supply contacts 42 with a permanent current contact 43, which is always connected to the connecting cable 18, so that, for example, a potential of 230 V is present at the continuous current contact 43 when the connecting cable 18 is connected to an electrical supply network, not shown.

- the supply contacts 42 include a switching supply contact 44, which then has a power supply potential when the switch 25 switches on the suction motor 12, and an automatic supply contact 45, to which a current sensor 46 for detecting a current flow via the automatic supply contact 45 is assigned.

- supply contacts 42a (protective conductor / PE) and 42b (ground / M) are components of the supply contacts 42.

- a data or signaling connection between the suction device and the functional module 50a - 50d is possible via suction device signal contacts 47.

- data contacts 48 are connected to a data bus of the suction device 10.

- Switching contacts 49 enable potential-free signaling of an on and off signal for switching the suction motor 12 on and off when the switch 25 is set to "automatic".

- the electrical connection arrangement 51 enables a multitude of possibilities for a wide variety of functional modules, of which the functional modules 50a - 50d are explained below as an example:

- the functional module 50a is a compressed air module for connecting a compressed air tool.

- the functional module 50a has a compressed air connection arrangement 54 with compressed air connections 55a, 55b, to which a compressed air hose can be connected.

- the compressed air connection 55a includes a quick coupling, while the compressed air connection 55b forms, so to speak, a counterpart for a quick coupling, which is arranged on a compressed air hose, not shown.

- a compressed air connection can therefore be looped through the functional module 50a via the connection arrangement 54, with a compressed air path in the functional module 50a leading via a compressed air sensor 56 to detect a compressed air flow.

- the compressed air sensor 56 actuates a switch 57 which is connected to module signal contacts 58.

- the module signal contacts 58 are electrically connected to the suction device signal contacts 47. This creates, for example, an electrical connection between the switch 57 and the switching contacts 49, so that when the compressed air tool (not shown) connected to the compressed air connection arrangement 54 is actuated, the switch 57 bridges the two switching contacts 49, which results in switching on of the suction motor 12 leads.

- the electronic or electrical components of the functional module 50a are advantageously housed in a housing 59 in a protected manner.

- the housing 59 is expediently dimensioned so that it is guided on the guide ribs 39.

- the functional module 50b is used for potential-free switching of the suction motor 12.

- a plug connector 60 for inserting a plug is arranged on its front wall 51b.

- the plug connector which in the present case is designed as a socket, can be closed by means of a cover 61 and can therefore be protected from environmental influences.

- contacts 62a, 62b of the connector 60 are connected to contacts 58b of the module signal contacts 58, so that an electrical connection between the module signal contacts 58b and the suction device signal contacts 47 on the suction device side can be established by inserting the functional module 50b into the module receptacle 30.

- a data connection for connection to a data bus of the suction device 10 would also be possible.

- contacts 62a, 62c are connected to module signal contacts 58a by means of lines 63, 64, which come into connection with the data contacts 48 on the suction cup when the functional module 50b is inserted.

- a computer is connected to the contacts 62a, 62c.

- guide projections 66 in the manner of lateral guide wings are provided on the screw domes 65 of the functional module 50b.

- the functional module 50c is used to entertain a user of the suction device 10. It has a radio receiver 67 and data reading means 68 for reading music data.

- a memory card SD card, MMC card or the like

- the data reading means 68 reads out can be inserted into a slot 72 of the data reading means 68 arranged on a front wall 51c.

- music data is stored on the card in MP3 format.

- a loudspeaker 69 i.e. an acoustic output means, is used to output music and speech from the radio receiver 67 and the data reading means.

- Optical output means 71 for example an LCD display, are also expediently present, for example to display the currently tuned station.

- the display 70 can also be used to output diagnostic data of the suction device 10, for example to display operating hours, the current suction power or the like.

- the loudspeaker 69 can also be used for diagnostic messages, for example to emit a warning tone when the filter arrangement 15 is filled to maximum capacity.

- the functional module 50d has an electrical power supply connection 73 arranged on the front wall 51d for connecting an electrical consumer, for example an electric tool.

- the power supply connection 73 includes a socket 74, preferably a protective contact socket, which can be closed by means of a cover 75.

- the lid 75 is pivotable with respect to the front wall 51d.

- Contacts 76, 77 and 78 of the socket 74 are connected to contacts 79, 80 and 81 of a plug connector 82 via lines 83.

- the plug connector 82 is used to establish electrical connections to the supply contacts 42 of the electrical connection arrangement 41 of the suction device 10.

- the contact 79 establishes a connection to the supply contact 42a, thus establishing a protective conductor connection, while the contact 80 forms a ground connection with the other supply contact 42b.

- the contact 81 is connected to the permanent current contact 43 when the functional module 50d is plugged in. You could also arrange the contact 81 at any time at one of the contact locations 84 or 85 in order to establish a connection to the switching supply contact 44 on the vacuum device side or the automatic supply contact 45 when the functional module 50d is inserted.

- the functional module 50d can therefore be reconfigured at any time.

- wiring with free lines 83 also has the advantage that different contact locations, for example the contact locations 84 or 85, can be connected to the power supply contact 78 of the socket 74 following a common parts principle.

- the term electrical connection arrangement between a suction device according to the invention and an associated functional module expediently provides electrical contacts. Electrical contact surfaces are advantageous at least for electrical power supply of the respective functional module by the suction device.

- the electrical connection arrangement can also be designed to be wireless. If the functional module then has a local energy supply, for example an accumulator, electrical line connections or contact connections between the suction device and the functional module are not even necessary.

- the functional module 50b for wireless communication with the suction device 10 could have a radio module 86 for implementing a wireless internal interface 87, which is arranged on the suction device 10 Radio module 88 communicates wirelessly, which represents a wireless internal interface 89.

- the module signal contacts 58 are then not required, at most for electrical power supply of the functional module 50b.

Description

Die Erfindung betrifft ein Sauggerät zum Absondern von Partikeln aus einem Saugstrom, mit einem Saugmotor zum Erzeugen des Saugstroms und mit einem eine Bedienwand zur Bedienung des Sauggeräts aufweisenden Saugergehäuse gemäß dem Oberbegriff des Anspruchs 1.The invention relates to a suction device for separating particles from a suction flow, with a suction motor for generating the suction flow and with a suction housing having a control wall for operating the suction device according to the preamble of claim 1.

Ein derartiges Sauggerät ist beispielsweise

An der Vorderseite eines aus

Eine solche Bedienwand weist in der Regel einen Ein- und Ausschalter zum Ein- und Ausschalten des Sauggeräts auf. Ferner können weitere Bedienelemente, beispielsweise zur Drehzahlverstellung des Saugmotors, an dieser Stelle vorgesehen sein. Im Werkstattbereich eingesetzte Sauggeräte haben häufig noch eine Steckdose zum Anschließen eines elektrischen Werkzeuges. Der Funktionsumfang des Sauggeräts ist allerdings festgelegt.Such a control wall usually has an on and off switch for switching the suction device on and off. Furthermore, further controls, for example for adjusting the speed of the suction motor, can be provided at this point. Suction devices used in the workshop often have a socket for connecting an electrical tool. However, the scope of functions of the suction device is fixed.

Es ist daher die Aufgabe der vorliegenden Erfindung, eine flexible Anpassung eines Funktionsumfangs eines Sauggeräts zu ermöglichen.It is therefore the object of the present invention to enable flexible adaptation of the functional scope of a suction device.

Zur Lösung der Aufgabe ist ein Sauggerät gemäß der technischen Lehre des Anspruchs 1 vorgesehen.To solve the problem, a suction device according to the technical teaching of claim 1 is provided.

Ein Grundgedanke der Erfindung ist, dass das Funktionsmodul je nach Bedarf austauschbar ist. Es ist also möglich, bei unterschiedlichen Anforderungen an das Sauggerät unterschiedliche Funktionsmodule zu verwenden. Es versteht sich, dass auch mehrere Modulaufnahmen an einem erfindungsgemäßen Sauggerät vorhanden sein können.A basic idea of the invention is that the functional module can be replaced as required. It is therefore possible to use different functional modules with different requirements for the suction device. It goes without saying that several module holders can also be present on a suction device according to the invention.

Zwar wäre es prinzipiell auch denkbar, das Funktionsmodul nach einem Öffnen des Sauggerätes von Innen her an der Bedienwand anzuordnen. Die Bedienwand ist schon allein wegen ihrer Zugänglichkeit zweckmäßigerweise eine Außenwand.In principle, it would also be conceivable to arrange the functional module on the control wall from the inside after opening the suction device. The control wall is expediently an external wall simply because of its accessibility.

Zwar wäre es prinzipiell denkbar, dass das Funktionsmodul im montierten Zustand ganz auf das Saugergehäuse aufgesetzt ist, d.h. nicht in das Saugergehäuse eindringt. Bevorzugt ist jedoch eine Ausführungsform, bei der die Modulaufnahme einen Aufnahmeraum aufweist, in dem das mindestens eine Funktionsmodul im montierten Zustand ganz oder teilweise aufgenommen ist. Der Aufnahmeraum ist vorteilhaft von außen zugänglich. Beispielsweise ist der Aufnahmeraum eine Aufnahmekammer oder ein Aufnahmeschacht.In principle, it would be conceivable for the functional module to be placed entirely on the vacuum cleaner housing in the assembled state, i.e. not to penetrate into the vacuum cleaner housing. However, an embodiment is preferred in which the module holder has a receiving space in which the at least one functional module is completely or partially accommodated in the assembled state. The recording room is advantageously accessible from the outside. For example, the receiving space is a receiving chamber or a receiving shaft.

Vorzugsweise ist der Aufnahmeraum derart tief, dass eine Frontseite des mindestens einen Funktionsmoduls nicht oder nur unwesentlich vor eine den Aufnahmeraum umgebende Partie der Bedienwand vorsteht. Die Eindringtiefe des Funktionsmoduls entspricht also im Wesentlichen einer Tiefe bzw. Höhe des Funktionsmoduls. Dadurch steht das Funktionsmodul nicht vor das Saugergehäuse vor, was optisch ansprechend ist und einen mechanischen Schutz für das Funktionsmodul darstellt.Preferably, the receiving space is so deep that a front side of the at least one functional module does not protrude, or only protrudes insignificantly, from a part of the control wall surrounding the receiving space. The penetration depth of the functional module therefore essentially corresponds to a depth or height of the functional module. As a result, the functional module does not protrude in front of the vacuum cleaner housing, which is visually appealing and provides mechanical protection for the functional module.

Vorteilhaft ist auch eine Dichtungsanordnung, die das Funktionsmodul, die Modulaufnahme oder auch die elektrische Anschlussanordnung sowie korrespondierende Kontakte des Funktionsmoduls vor Umwelteinflüssen schützt. Beispielsweise kann an den Anschlüssen der Anschlussanordnung mindestens eine Dichtung vorgesehen sein. Bevorzugt ist es, wenn am Außenumfang des Funktionsmoduls und/oder an einem Innenumfang der Modulaufnahme eine Dichtung angeordnet ist. Die Dichtung ist vorzugsweise so ausgestaltet, dass kein Schmutz in den Aufnahmeraum eindringen kann.A sealing arrangement that protects the functional module, the module receptacle or the electrical connection arrangement as well as corresponding contacts of the functional module from environmental influences is also advantageous. For example, at least one seal can be provided on the connections of the connection arrangement. It is preferred if a seal is arranged on the outer circumference of the functional module and/or on an inner circumference of the module receptacle. The seal is preferably designed so that no dirt can penetrate into the receiving space.

Die elektrische Anschlussanordnung weist vorzugsweise Versorgungskontakte zur elektrischen Energieversorgung eines an das Sauggerät anschließbaren elektrischen Verbrauchers auf. Der Verbraucher ist beispielsweise ein Elektrowerkzeug. Es versteht sich, dass ergänzend zu dem mindestens einen Funktionsmodul auch mindestens eine feststehende Steckdose am Sauggerät vorhanden sein kann, so dass im vorliegenden Fall zwei oder mehrere elektrische Anschlüsse für elektrische Verbraucher möglich sind.The electrical connection arrangement preferably has supply contacts for supplying electrical energy to an electrical consumer that can be connected to the suction device. The consumer is, for example, a power tool. It goes without saying that, in addition to the at least one functional module, there can also be at least one fixed socket on the suction device, so that in the present case two or more electrical connections for electrical consumers are possible.

Bei den Versorgungskontakten sind verschiedene Varianten möglich. Beispielsweise können diese einen schaltbaren Schaltversorgungskontakt aufweisen, der durch einen Schalter des Sauggerätes ein- und ausschaltbar ist. Dieser Schalter des Sauggerätes kann ein separater, speziell dem Schaltversorgungskontakt zugeordneter Schalter sein oder in einer bevorzugten Ausführungsform der Erfindung ein "Hauptschalter", vorteilhaft ein Schalter, der zum Schalten des Saugmotors vorgesehen ist.Different variants are possible for the supply contacts. For example, these can have a switchable switching supply contact that can be switched on and off by a switch on the suction device. This switch of the suction device can be a separate switch specifically assigned to the switching supply contact or, in a preferred embodiment of the invention, a "main switch", advantageously a switch that is provided for switching the suction motor.

Weiterhin ist es möglich, dass der Versorgungskontakt ein Dauerstromkontakt ist, der beispielsweise dauerhaft mit einem Stromversorgungsanschluss des Sauggerätes verbunden ist, mit welchem dieses mit einem Stromversorgungsnetz verbindbar ist. Wenn das Sauggerät mittels eines Akkumulators betrieben wird, ist der Dauerstromkontakt mit dem Akkumulator dauerhaft verbunden.Furthermore, it is possible for the supply contact to be a permanent current contact, which is, for example, permanently connected to a power supply connection of the suction device, with which it can be connected to a power supply network. If the suction device is operated using an accumulator, the permanent current contact is permanently connected to the accumulator.

Weiterhin ist ein Automatikversorgungskontakt zweckmäßig, dem ein Stromsensor zugeordnet ist. Wenn über den Automatikversorgungskontakt Strom fließt, wird dieser Stromfluss durch den Stromsensor erfasst.Furthermore, an automatic supply contact is useful, to which a current sensor is assigned. If current flows via the automatic supply contact, this current flow is detected by the current sensor.

Weitere Versorgungskontakte, die in Kombination mit sämtlichen vorgenannten Varianten zweckmäßig sind, sind beispielsweise Schutzleiterkontakte, Massekontakte und dergleichen.Other supply contacts that are useful in combination with all of the aforementioned variants are, for example, protective conductor contacts, ground contacts and the like.

Über die Versorgungskontakte des Sauggeräts können eine oder mehrere Stromversorgungsanschlüsse bei dem jeweiligen Versorgungsmodul mit elektrischer Energie versorgt werden, an die wiederum ein elektrischer Verbraucher, zum Beispiel ein Elektro-Werkzeug, anschließbar ist. Das Funktionsmodul kann mit einem oder mehreren der vorgenannten Versorgungskontakten, beispielsweise dem Verschaltversorgungskontakt, dem Dauerstromkontakt und dem Automatikversorgungskontakt mittels eines Wahlschalters verbindbar sein. Es versteht sich, dass der Wahlschalter auch nur die Auswahl zweier der drei vorgenannten Kontakte zulassen kann. Weiterhin ist gemäß einer Variante der Erfindung vorgesehen, dass das Funktionsmodul umkonfigurierbar ist derart, dass der Stromversorgungskontakt durch ein beispielsweise Umstecken vom Stromverbindungen des Funktionsmodells wahlweise mit mindestens zwei der drei der vorgenannten Varianten Schaltversorgungskontakt, Dauerstromkontakt oder Automatikversorgungskontakt verbindbar ist.One or more power supply connections in the respective supply module can be supplied with electrical energy via the supply contacts of the suction device, to which an electrical consumer, for example an electric tool, can in turn be connected. The functional module can be with one or several of the aforementioned supply contacts, for example the switching supply contact, the continuous current contact and the automatic supply contact, can be connected by means of a selector switch. It goes without saying that the selector switch can only allow the selection of two of the three aforementioned contacts. Furthermore, according to a variant of the invention, it is provided that the functional module is reconfigurable in such a way that the power supply contact can be connected to at least two of the three of the aforementioned variants - switching supply contact, continuous current contact or automatic supply contact - by, for example, replugging the power connections of the functional model.

Die elektrische Anschlussanordnung des Sauggeräts weist zweckmäßigerweise auch Sauggerät-Signalkontakte und/oder eine drahtlose Internschnittstelle zur Kommunikation von Datensignalen und/oder Steuersignalen an das Funktionsmodul oder von dem jeweiligen Funktionsmodul auf. Die Signalkontakte sind zweckmäßigerweise potenzialfrei, wozu beispielsweise ein Relais oder dergleichen vorgesehen sein kann.The electrical connection arrangement of the suction device expediently also has suction device signal contacts and/or a wireless internal interface for communicating data signals and/or control signals to the functional module or from the respective functional module. The signal contacts are expediently potential-free, for which purpose a relay or the like can be provided.

Die Verbindung des Funktionsmoduls mit dem Sauggerät erfolgt zweckmäßigerweise werkzeuglos. Zweckmäßigerweise sind Rastmittel, beispielsweise Rasthaken, vorgesehen. Weiterhin können die Verbindungsmittel beispielsweise eine oder mehrere Schrauben umfassen. Eine Variante der Erfindung kann vorsehen, dass das Funktionsmodul ganz bewusst nur mittels Werkzeug am Sauggerät befestigbar bzw. von diesem wieder lösbar ist. Dies kann beispielsweise einen verbesserten Diebstahlschutz darstellen oder aus elektrischen Gründen angezeigt sein, dass nämlich die Versorgungskontakte des Sauggerätes nicht offen zugänglich sind. Es versteht sich, dass bei Verbindungsmitteln, die nur mit Werkzeugen betätigbar sind, durchaus auch Rastmittel oder dergleichen zum Einsatz kommen können, die jedoch vorteilhaft nur mit einem geeigneten Werkzeug in eine Freigabe- oder Lösestellung zum Entfernen des Funktionsmoduls bringbar sind.The connection of the functional module to the suction device is expediently carried out without tools. Locking means, for example locking hooks, are expediently provided. Furthermore, the connecting means can include, for example, one or more screws. A variant of the invention can provide that the functional module can deliberately only be attached to or detached from the suction device using a tool. This can, for example, represent improved theft protection or be indicated for electrical reasons, namely that the supply contacts of the suction device are not openly accessible. It goes without saying that for connecting means that can only be actuated with tools, locking means or the like can also be used, but these can advantageously only be brought into a release or release position for removing the functional module with a suitable tool.

Das Funktionsmodul gemäß der Erfindung stellt eine elektrische, optische oder akustische Funktion oder beliebige Kombinationen davon zur Verfügung. Das Funktionsmodul kann beispielsweise ein Schaltmodul sein. Auch Anzeigemodule sind zweckmäßig.The functional module according to the invention provides an electrical, optical or acoustic function or any combinations thereof. The functional module can be, for example, a switching module. Display modules are also useful.

Das Funktionsmodul hat zweckmäßigerweise Sauggerät-Signalkontakte, die mit den Modul-Signalkontakten in Verbindung treten können, um beispielsweise Datensignale oder Steuersignale zu kommunizieren. Die Datensignale sind zweckmäßigerweise Busdatensignale.The functional module expediently has suction device signal contacts that can connect to the module signal contacts, for example to communicate data signals or control signals. The data signals are expediently bus data signals.

Das Funktionsmodul hat in einer bevorzugten Ausführungsform einen elektrischen Schalter zum Einschalten oder Ausschalten des Saugmotors des Sauggerätes. Diese Schalter ist in einer bevorzugten Ausführungsform ein Signalschalter, d.h. er gibt ein Schaltsignal zum Ein- oder Ausschalten des Saugmotors an einem im Sauggerät angeordneten Hauptschalter aus. Das Schaltsignal kann potenzialfrei auf das Sauggerät übertragen werden. Jedenfalls hat das Schaltsignal zweckmäßigerweise ein geringeres Potenzial als der Hauptschalter des Sauggerätes, mit dem der Saugmotor ein- und ausschaltbar ist.In a preferred embodiment, the functional module has an electrical switch for switching on or off the suction motor of the suction device. In a preferred embodiment, this switch is a signal switch, i.e. it outputs a switching signal for switching the suction motor on or off at a main switch arranged in the suction device. The switching signal can be transmitted to the suction device potential-free. In any case, the switching signal expediently has a lower potential than the main switch of the suction device, with which the suction motor can be switched on and off.

Das Funktionsmodul kann ein Druckluft-Modul sein. Das Funktionsmodul weist beispielsweise eine Druckluft-Anschlussanordnung zum Anschließen eines Druckluft-Werkzeugs auf. Die Druckluftanschlussanordnung umfasst zweckmäßigerweise Druckluftanschlüsse zum Durchschleifen einer das Druckluftwerkzeug versorgenden Druckluftleitung. Mindestens einer der Druckluftanschlüsse ist zweckmäßigerweise mit einer Schnellkupplung und/oder einem Gegenstück für Schnellkupplungen versehen. Das Druckluft-Funktionsmodul umfasst zweckmäßigerweise einen Druckluftsensor zum Erfassen eines Druckluft-Stroms, der das Funktionsmodul durchströmt. Der Druckluftsensor enthält beispielsweise einen federbelasteten Sensorkörper, insbesondere einen Schwebekörper, der bei Druckluftbetätigung bzw. beim Durchströmen der Druckluft betätigbar ist und einen Schalter schließt, vorzugsweise einen Reedkontakt. Der Schwebekörper kann beispielsweise magnetisch sein. Es versteht sich, dass der Druckluftsensor auch ein Druckschalter sein kann, der durch Druckbetätigung betätigbar ist.The functional module can be a compressed air module. The functional module has, for example, a compressed air connection arrangement for connecting a compressed air tool. The compressed air connection arrangement expediently includes compressed air connections for looping through a compressed air line supplying the compressed air tool. At least one of the compressed air connections is expediently provided with a quick coupling and/or a counterpart for quick couplings. The compressed air functional module expediently includes a compressed air sensor for detecting a compressed air stream that flows through the functional module. The compressed air sensor contains, for example, a spring-loaded sensor body, in particular a float, which can be actuated when compressed air is actuated or when the compressed air flows through and closes a switch, preferably a reed contact. The float can be magnetic, for example. It goes without saying that the compressed air sensor can also be a pressure switch that can be actuated by pressure.

Weiterhin ist es vorteilhaft, wenn das Funktionsmodul einen Stromsensor zum Erfassen eines das Funktionsmodul durchfließenden Stromflusses aufweist. Auch ein potenzialfreier Schaltkontakt ist zweckmäßig. Wenn beispielsweise and den vorgenannten Stromversorgungsanschluss ein Verbraucher angeschlossen ist und dieser eingeschaltet wird, d.h. z.B. ein Elektrowerkzeug eingeschaltet wird, meldet dies der Stromsensor oder der Schaltkontakt an das Sauggerät, das seinerseits dann den Saugmotor aktiviert. Der jeweilige Sensor, beispielsweise der Druckluftsensor, der Stromsensor oder der Schaltkontakt, sind vorteilhaft zum Übertragen von Datensignalen und Steuersignalen mit den Modul-Signalkontakten verbunden.Furthermore, it is advantageous if the functional module has a current sensor for detecting a current flowing through the functional module. A potential-free switching contact is also useful. If, for example, a consumer is connected to the aforementioned power supply connection and this is switched on, i.e. for example an electric tool is switched on, the current sensor or the switching contact reports this to the suction device, which in turn then activates the suction motor. The respective sensor, for example the compressed air sensor, the current sensor or the switching contact, are advantageously connected to the module signal contacts for transmitting data signals and control signals.

An dieser Stelle sei bemerkt, dass das Funktionsmodul auch einen Buskoppler zur Anbindung an einen Datenbus des Sauggerätes umfassen kann.It should be noted at this point that the functional module can also include a bus coupler for connection to a data bus of the suction device.

Das Funktionsmodul umfasst beispielsweise Datenkontakte zum Anschluss eines Datengerätes an einen Datenbus des Sauggeräts und/oder des Funktionsmoduls. Somit ist beispielsweise eine Diagnose, Programmierung oder Kalibrierung des Sauggeräts und/oder Funktionsmoduls möglich. Die Datenkontakte sind zweckmäßigerweise zur Verbindung mit dem Datenbus des Sauggerätes mit den Modulkontakten verbunden.The functional module includes, for example, data contacts for connecting a data device to a data bus of the suction device and/or the functional module. This makes it possible, for example, to diagnose, program or calibrate the suction device and/or functional module. The data contacts are expediently connected to the module contacts for connection to the data bus of the suction device.

Die Erfindung sieht vor, dass das Funktionsmodul eine drahtlose Extern-Schnittstelle zur drahtlosen Kommunikation mit dem Funktionsmodul und/oder dem Sauggerät aufweist. Somit ist es erfindungsgemäß möglich, mittels einer Fernsteuerung das Sauggerät ein- und auszuschalten oder dessen Saugleistung einzustellen oder dergleichen.The invention provides that the functional module has a wireless external interface for wireless communication with the functional module and/or the suction device. Thus, according to the invention, it is possible to use a remote control to switch the suction device on and off or to adjust its suction power or the like.

Weiterhin kann das Funktionsmodul optische oder akustische Ausgabemittel zur Ausgabe von Daten, beispielsweise Diagnosedaten des Sauggeräts, Musik oder dergleichen haben. Eine Variante der Erfindung sieht vor, dass das Funktionsmodul Kompensation einer Lärmemission des Sauggeräts aufweist.Furthermore, the functional module can have optical or acoustic output means for outputting data, for example diagnostic data of the suction device, music or the like. A variant of the invention provides that the functional module has compensation for noise emissions from the suction device.

Das Funktionsmodul kann auch einen Radioempfänger und/oder Datenlesemittel aufweisen. Die Datenlesemittel eignen sich beispielsweise für die Ausgabe von im MP3-Format oder einem sonstigen Musikdatenformat gespeicherten Musikdaten.The functional module can also have a radio receiver and/or data reading means. The data reading means are suitable, for example, for outputting music data stored in MP3 format or another music data format.

Ein erfindungsgemäßes Funktionsmodul kann auch ein Master-Slave-Modul sein, mit Hilfe dessen an das erfindungsgemäße Sauggerät ein weiteres Sauggerät angeschlossen werden kann. Die beiden Sauggeräte können auf diesem Wege zeitgleich ein- und ausgeschaltet werden, so dass deren Saugleistung simultan zur Verfügung steht. Wenn das eine Sauggerät eingeschaltet wird, erfasst beispielsweise der Stromsensor im Funktionsmodul des anderen Sauggeräts, an dem das vorgenannten Sauggerät angeschlossen ist, den Stromfluss zu dem neu eingeschalteten Sauggerät und schaltet in Folge dessen das das erfindungsgemäße Funktionsmodul aufweisende Sauggerät ebenfalls ein. Dieses bildet dann ein Slave-Sauggerät.A functional module according to the invention can also be a master-slave module, with the help of which a further suction device can be connected to the suction device according to the invention. In this way, the two suction devices can be switched on and off at the same time so that their suction power is available simultaneously. When one suction device is switched on, for example, the current sensor in the functional module of the other suction device to which the aforementioned suction device is connected detects the current flow to the newly switched on suction device and, as a result, also switches on the suction device having the functional module according to the invention. This then forms a slave suction device.

Es versteht sich, dass Kombinationen der vorher erläuterten Funktionsvarianten bei ein und demselben Funktionsmodul realisierbar sind.It goes without saying that combinations of the previously explained functional variants can be implemented with one and the same functional module.

Das Sauggerät ist erfindungsgemäß ein transportables, beispielsweise rollbares und/oder tragbares, Sauggerät, erfindungsgemäß ein Werkstattsauger.According to the invention, the suction device is a transportable, for example rollable and/or portable, suction device, according to the invention a workshop vacuum.

Nachfolgend werden Ausführungsbeispiele anhand der Zeichnung erläutert. Es zeigen:

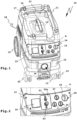

- Figur 1

- ein erfindungsgemäßes Sauggerät in einer perspektivischen Schrägansicht von schräg vorn,

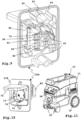

- Figur 2

- ein Detail A des Sauggeräts gemäß

Figur 1 mit einem Druckluft-Funktionsmodul, - Figur 3

- den Ausschnitt gemäß

Figur 2 , jedoch mit entferntem Funktionsmodul, - Figur 4

- eine perspektivische Schrägansicht von vorn und

- Figur 5

- eine perspektivische Schrägansicht von hinten des Druckluft-Funktionsmodul gemäß

Figuren 1, 2 , - Figur 6

- eine perspektivische Schrägansicht von vorn und

- Figur 7

- eine perspektivische Schrägansicht von schräg hinten eines Moduls mit einem potenzialfreien Schaltkontakt,

- Figur 8

- ein Funktionsmodul schräg von vorn, das einen Radioempfänger sowie einen MP3-Player umfasst,

- Figur 9

- eine perspektivische Schrägansicht von hinten und

Figur 10- eine perspektivische Schrägansicht von vorn eines elektrischen Stromversorgungsmoduls und

Figur 11- eine perspektivische Schrägansicht des Sauggeräts gemäß

Figur 1 , jedoch mit entferntem Funktionsmodul und durch eine Blende abgedeckter Modulaufnahme.

- Figure 1

- a suction device according to the invention in a perspective oblique view from the front,

- Figure 2

- a detail A of the suction device according to

Figure 1 with a compressed air function module, - Figure 3

- according to the cutout

Figure 2 , but with the functional module removed, - Figure 4

- a perspective oblique view from the front and

- Figure 5

- a perspective oblique view from behind of the compressed air functional module

Figures 1, 2 , - Figure 6

- a perspective oblique view from the front and

- Figure 7

- a perspective oblique view from the back of a module with a potential-free switching contact,

- Figure 8

- a functional module diagonally from the front, which includes a radio receiver and an MP3 player,

- Figure 9

- a perspective oblique view from behind and

- Figure 10

- a perspective oblique view from the front of an electrical power supply module and

- Figure 11

- a perspective oblique view of the suction device according to

Figure 1 , but with the functional module removed and the module holder covered by a cover.

Im Inneren eines Saugergehäuses 11 eines Sauggeräts 10 ist ein Saugmotor 12 zum Erzeugen eines Saugstroms 13 angeordnet, der über einen Saugeinlass 14 in das Saugergehäuse 11 einsaugbar ist. An den Saugeinlass 14 ist ein nicht dargestellter Schlauch anschließbar. Im Inneren des Saugergehäuses 11 befindet sich ferner eine Filteranordnung 15 zum Absondern von Partikeln aus dem Saugstrom 13.Inside a

An einer Oberseite 16 des Saugergehäuses 11 befindet sich eine Aufnahme 17 zur Aufnahme des Saugschlauches und/oder eines Anschlusskabels 18, mit dem das Sauggerät 10 an ein elektrisches Versorgungsnetz anschließbar ist. Das Sauggerät 10 ist ein transportables Sauggerät, an dessen Unterseite Fahrrollen 19, 20 angeordnet sind. Die vorderen Fahrrollen 20 sind Lenkrollen. Weiterhin kann das Sauggerät 10 an einem Tragegriff 21 an der Oberseite 16 ergriffen werden.On a

Zwischen einer den Saugeinlass 14 aufweisenden Frontwand 22 und der Oberseite 16 erstreckt sich eine Bedienwand 23 mit Bedienelementen 24 zur Bedienung des Sauggeräts 10. Die Bedienwand 23 ist zweckmäßigerweise schräg geneigt, so dass die Bedienelemente 24 von schräg oben vorn leicht bedienbar sind.A

Die Bedienelemente 24 umfassen einen Schalter 25, der sozusagen einen Hauptschalter bildet. Mit dem Schalter 25 kann der Saugmotor 12 ein- und ausgeschaltet werden. Ferner ist ein Automatikmodus einstellbar, bei dem der Saugmotor 12 immer dann läuft, wenn ein angeschlossener Verbraucher elektrischen Strom über das Sauggerät 10 erhält, was später noch erläutert wird. Mit Hilfe eines Saugleistungs- oder Drehzahlschalters 26 kann eine Leistung des Saugmotors 12 eingestellt werden. Ein Anpassungsschalter 27 ermöglicht eine elektrische Anpassung des Sauggeräts 10 an einem jeweiligen Saugeinlass 14 angeschlossenen Saugschlauch. Mit einem Reinigungsschalter 28 ist eine Reinigungsfunktion des Sauggeräts 10 einschaltbar und/oder parametrierbar. Eine fest am Sauggerät 10 installierte Steckdose 29 ermöglicht das Einstecken eines elektrischen Energieverbrauchers. Die Steckdose 29 ist mit den Anschlusskabel 18 elektrisch verbunden.The operating

Über die Bedienelemente 24 hinaus stellt das Sauggerät 10 erfindungsgemäß wahlweise weitere Funktionen bereit, die der Bediener nach Bedarf auswählen kann:

An der Bedienwand 23 ist eine Modulaufnahme 30 zur wahlweisen Aufnahme von Funktionsmodulen 50a, 50d, die elektrische, optische und akustische Funktionen bereitstellen.This is beyond the

On the

Die Modulaufnahme 30 ist in der Art eines Aufnahmeschachtes ausgestaltet, der geschlossen ist. Von der Bedienwand 23 weg erstrecken sich in Richtung des Innenraums des Saugergehäuses 11 Umfangswände 32, 33 bis zu einem Boden 31 der Modulaufnahme 30 hin. Ein Eindringen von Schmutz durch die Modulaufnahme 30 in den Innenraum des Saugergehäuses 11 ist dadurch verhindert.The

Als weitere Schutzmaßnahme gegen ein Eindringen von Schmutz in einen durch die Umfangswände 32, 33 und den Boden 31 begrenzten Aufnahmeraum 37 der Modulaufnahme 30 ist eine Dichtungsanordnung 35 mit einer Dichtung 36 vorgesehen. Die Dichtung 36 ist beispielsweise ein O-Ring, der an einem Randbereich 34 des Aufnahmeraums 37 etwa zwischen der Bedienwand 23 und den Umfangswänden 32, 33 angeordnet ist. Wenn die Funktionsmodule 50a - 50d am Saugergehäuse 11 montiert sind, liegen deren Frontwände 51a - 51d jeweils auf der Dichtung 36 auf, so dass kein Schmutz zwischen der Bedienwand 23 und der jeweiligen Frontwand 51a - 51d in den Aufnahmeraum 37 eindringt. Die Frontwände 51a - 51d decken die Modulaufnahme 30 bzw. den Aufnahmeraum 37 vollständig ab.As a further protective measure against the ingress of dirt into a receiving

Anstelle der Funktionsmodule 50a - 50d kann die Modulaufnahme 30 auch durch eine Abdeckplatte 38 abgedeckt werden, deren Kontur den Frontwänden 51a - 51d gleicht (

Der Aufnahmeraum 37 bildet eine Steckaufnahme zum Aufnehmen der Funktionsmodule 50a - 50d, die also in die Modulaufnahme 30 einfach einsteckbar sind. Jedenfalls sind die Funktionsmodule 50a - 50d lösbar mit dem Saugergehäuse 11 verbindbar. Insofern bildet der als Steckaufnahme ausgestaltete Aufnahmeraum 37 bereits einen Bestandteil von Verbindungsmitteln 52, mit denen das Funktionsmodul 50a - 50d lösbar mit dem Saugergehäuse 11 verbindbar ist.The receiving

Zudem umfassen die Verbindungsmittel 52 Führungsrippen 39, die vor die Umfangswände 32, 33 vorstehen und das jeweilige Funktionsmodul 50a - 50d führen und im montierten Zustand stützen.In addition, the connecting

Zur unverlierbaren Sicherung der Funktionsmodule 50a - 50d umfassen die Verbindungsmittel 52 weiterhin Schrauben 53, die durch Schraubdome 65 der Funktionsmodule 50a - 50d durchgesteckt sind, die mit Schraubaufnahmen 40 der Modulaufnahme 30 fluchten, wenn das jeweilige Funktionsmodul 50a - 50d am Sauger 10 montiert ist.To secure the

Der Aufnahmeraum 37 hat eine Tiefe, die ausreicht, dass die Frontwand 51a - 51d im Wesentlichen mit der Bedienwand 23 fluchtet, wenn das jeweilige Funktionsmodul 50a - 50d am Sauger 11 befestigt ist.The receiving

Weiterhin ist eine elektrische Ankopplung der Funktionsmodule 50a - 50d an das Sauggerät 10 möglich, wofür eine elektrische Anschlussanordnung 41 der Modulaufnahme 30 vorgesehen ist. Die Anschlussanordnung 41 umfasst Versorgungskontakte 42 mit einem Dauerstromkontakt 43, der stets mit dem Anschlusskabel 18 verbunden ist, so dass beispielsweise ein Potential von 230 V am Dauerstromkontakt 43 vorhanden ist, wenn das Anschlusskabel 18 mit einem nicht dargestellten elektrischen Versorgungsnetz verbunden ist. Weiterhin umfassen die Versorgungskontakte 42 einen Schaltversorgungskontakt 44, der dann ein Stromversorgungspotential hat, wenn der Schalter 25 den Saugmotor 12 einschaltet, sowie einen Automatikversorgungskontakt 45, dem ein Stromsensor 46 zum Erfassen eines Stromflusses über den Automatikversorgungskontakt 45 zugeordnet ist. Weiterhin sind Versorgungskontakte 42a (Schutzleiter / PE) sowie 42b (Masse / M) Bestandteile der Versorgungskontakte 42.Furthermore, an electrical coupling of the

Eine datentechnische bzw. signaltechnische Verbindung zwischen Sauggerät und Funktionsmodul 50a - 50d ist über Sauggerät-Signalkontakte 47 möglich. Beispielsweise sind Datenkontakte 48 mit einem Datenbus des Sauggeräts 10 verbunden. Schaltkontakte 49 ermöglichen eine potentialfreie Signalgabe eines Ein- und Aussignals zum Einschalten und Ausschalten des Saugmotors 12, wenn der Schalter 25 auf "Automatik" steht.A data or signaling connection between the suction device and the

Jedenfalls ermöglicht die elektrische Anschlussanordnung 51 eine Vielzahl von Möglichkeiten verschiedenartigster Funktionsmodule, von denen beispielhaft die Funktionsmodule 50a - 50d nachfolgend erläutert werden:

Das Funktionsmodul 50a ist ein Druckluft-Modul zum Anschließen eines Druckluft-Werkzeuges. Das Funktionsmodul 50a hat eine Druckluft-Anschlussanordnung 54 mit Druckluft-Anschlüssen 55a, 55b, an die jeweils ein Druckluftschlauch anschließbar ist. Der Druckluft-Anschluss 55a umfasst eine Schnellkupplung, während der Druckluft-Anschluss 55b sozusagen ein Gegenstück für eine Schnellkupplung bildet, die an einem nicht dargestellten Druckluftschlauch angeordnet ist. Somit kann also eine Druckluftverbindung über die Anschlussanordnung 54 durch das Funktionsmodul 50a durchgeschleift werden, wobei ein Druckluftpfad im Funktionsmodul 50a über einen Druckluftsensor 56 zum Erfassen eines Druckluftstromes führt.In any case, the electrical connection arrangement 51 enables a multitude of possibilities for a wide variety of functional modules, of which the

The

Der Druckluftsensor 56 betätigt einen Schalter 57, der mit Modulsignalkontakten 58 verbunden ist. Wenn das Funktionsmodul 50a in die Modulaufnahme 30 eingesteckt ist, sind die Modulsignalkontakte 58 mit den Sauggerät-Signalkontakten 47 elektrisch verbunden. Dadurch ist beispielsweise eine elektrische Verbindung zwischen dem Schalter 57 und den Schaltkontakten 49 realisiert, so dass beim Betätigen des nicht dargestellten, an die Druckluft-Anschlussanordnung 54 angeschlossenen Druckluft-Werkzeugs der Schalter 57 die beiden Schaltkontakte 49 überbrückt, was zum Einschalten des Saugmotors 12 führt.The

Vorteilhafterweise sind die elektronischen oder elektrischen Komponenten des Funktionsmoduls 50a in einem Gehäuse 59 geschützt untergebracht. Das Gehäuse 59 ist zweckmäßigerweise so bemessen, dass es an den Führungsrippen 39 geführt ist.The electronic or electrical components of the

Das Funktionsmodul 50b dient zum potenzialfreien Schalten des Saugmotors 12. An seiner Frontwand 51b ist ein Steckverbinder 60 zum Einstecken eines Steckers angeordnet. Der Steckverbinder, der vorliegend als Buchse ausgestaltet ist, ist mittels eines Deckels 61 verschließbar und somit vor Umwelteinflüssen schützbar.The

Beispielsweise sind Kontakte 62a, 62b des Steckverbinders 60 mit Kontakten 58b der Modul-Signalkontakte 58 verbunden, so dass eine elektrische Verbindung zwischen den Modul-Signalkontakten 58b und den saugerseitigen Sauggerät-Signalkontakten 47 durch Einstecken des Funktionsmoduls 50b in die Modulaufnahme 30 herstellbar ist.For example,

Alternativ wäre aber auch eine Datenverbindung zur Verbindung mit einem Datenbus des Sauggeräts 10 möglich. Dazu sind beispielsweise Kontakte 62a, 62c mittels Leitungen 63, 64 mit Modul-Signalkontakten 58a verbunden, die beim Einstecken des Funktionsmoduls 50b mit den saugerseitigen Datenkontakten 48 in Verbindung treten. Somit ist beispielsweise eine Parametrierung, Programmierung oder Diagnose des Sauggeräts 10 über das Funktionsmodul 50b möglich. An die Kontakte 62a, 62c wird dazu beispielsweise ein Computer angeschlossen.Alternatively, a data connection for connection to a data bus of the

Zur Führung an den Führungsrippen 39 der Modulaufnahme 30 sind an den Schraubdomen 65 des Funktionsmoduls 50b Führungsvorsprünge 66 in der Art von seitlichen Führungsflügeln vorgesehen.For guidance on the

Das Funktionsmodul 50c dient zur Unterhaltung eines Nutzers des Sauggeräts 10. Es weist einen Radioempfänger 67 sowie Datenlesemittel 68 zum Lesen von Musikdaten auf. In einen an einer Frontwand 51c angeordneten Schlitz 72 der Datenlesemittel 68 kann beispielsweise eine Speicherkarte (SD-Karte, MMC-Karte oder dergleichen) eingesteckt werden, welche die Datenlesemittel 68 auslesen. Auf der Karte sind beispielsweise Musikdaten im MP3-Format gespeichert. Zur Ausgabe von Musik und Sprache des Radioempfängers 67 sowie der Datenlesemittel dient ein Lautsprecher 69, mithin also ein akustisches Ausgabemittel.The

Zweckmäßigerweise sind auch optische Ausgabemittel 71, beispielsweise eine LCD-Anzeige, vorhanden, um zum Beispiel den aktuell eingestellten Sender anzuzeigen.Optical output means 71, for example an LCD display, are also expediently present, for example to display the currently tuned station.

Die Anzeige 70 kann aber auch zur Ausgabe von Diagnosedaten des Sauggeräts 10 dienen, beispielsweise zur Anzeige von Betriebsstunden, der momentanen Saugleistung oder dergleichen. Der Lautsprecher 69 kann auch für Diagnosemeldungen genutzt werden, z.B. um bei einer maximalen Befüllung der Filteranordnung 15 einen Warnton auszugeben.The

Das Funktionsmodul 50d weist einen an der Frontwand 51d angeordneten elektrischen Stromversorgungsanschluss 73 zum Anschluss eines elektrischen Verbrauchers, beispielsweise eines Elektro-Werkzeugs, auf. Der Stromversorgungsanschluss 73 umfasst eine Steckdose 74, vorzugsweise eine Schutzkontaktsteckdose, die mittels eines Deckels 75 ist verschließbar. Der Deckel 75 ist schwenkbar bezüglich der Frontwand 51d.The

Kontakte 76, 77 und 78 der Steckdose 74 sind über Leitungen 83 mit Kontakten 79, 80 und 81 eines Steckverbinders 82 verbunden. Der Steckverbinder 82 dient zur Herstellung elektrischer Verbindungen zu den Versorgungskontakten 42 der elektrischen Anschlussanordnung 41 des Sauggeräts 10. Beispielsweise stellt der Kontakt 79 eine Verbindung zum Versorgungskontakt 42a, mithin also eine Schutzleiterverbindung her, während der Kontakt 80 mit den anderen Versorgungskontakt 42b eine Masseverbindung bildet. Der Kontakt 81 ist im gesteckten Zustand des Funktionsmoduls 50d mit dem Dauerstromkontakt 43 verbunden. Man könnte den Kontakt 81 jederzeit auch an einem der Kontaktplätze 84 oder 85 anordnen, um beim Einstecken des Funktionsmoduls 50d eine Verbindung zu dem sauggeräteseitigen Schaltversorgungskontakt 44 oder dem Automatikversorgungskontakt 45 herzustellen. Somit ist das Funktionsmodul 50d jederzeit umkonfigurierbar. Auch bezüglich der Herstellung hat die Verdrahtung mit freien Leitungen 83 den Vorteil, dass einem Gleichteileprinzip folgend unterschiedliche Kontaktplätze, also beispielsweise die Kontaktplätze 84 oder 85, mit dem Stromversorgungskontakt 78 der Steckdose 74 verbindbar sind.

Eine höhere Flexibilität würde dadurch erreicht werden, dass man zwischen dem Kontakt 78 einerseits und dem Kontakt 81 sowie an den Kontaktplätzen 84 und 85 angeordneten, nicht dargestellten Kontakten einen Wahlschalter anordnet, der vorzugsweise an der Frontseite bzw. Frontwand 51d angeordnet ist, so dass das Funktionsmodul 50d zwischen einem Dauerstrom, einem Automatikmodus und einem Schaltmodus umschaltbar ist.Greater flexibility would be achieved by arranging a selector switch between the

Es versteht sich, dass der Begriff elektrische Anschlussanordnung zwischen einem erfindungsgemäßen Sauggerät und einem zugeordneten ebenfalls erfindungsgemäßen Funktionsmodul zweckmäßigerweise elektrische Kontakte vorsieht. Zumindest für eine elektrische Stromversorgung des jeweiligen Funktionsmoduls durch das Sauggerät sind elektrische Kontaktflächen vorteilhaft. Zu einer Datenkommunikation hingegen kann die elektrische Anschlussanordnung auch drahtlos ausgestaltet sein. Wenn das Funktionsmodul dann über eine lokale Energieversorgung verfügt, beispielsweise einen Akkumulator, sind noch nicht einmal elektrische Leitungsverbindungen oder Kontaktverbindungen zwischen Sauggerät und Funktionsmodul nötig. Beispielsweise könnte das Funktionsmodul 50b zur drahtlosen Kommunikation mit dem Sauggerät 10 ein Funkmodul 86 zur Realisierung einer drahtlosen Intern-Schnittstelle 87 aufweisen, das mit einem am Sauggerät 10 angeordneten Funkmodul 88 drahtlos kommuniziert, welches eine drahtlose InternSchnittstelle 89 darstellt. Die Modul-Signalkontakte 58 sind dann nicht erforderlich, allenfalls zur elektrischen Stromversorgung des Funktionsmoduls 50b.It is understood that the term electrical connection arrangement between a suction device according to the invention and an associated functional module, which is also according to the invention, expediently provides electrical contacts. Electrical contact surfaces are advantageous at least for electrical power supply of the respective functional module by the suction device. For data communication, however, the electrical connection arrangement can also be designed to be wireless. If the functional module then has a local energy supply, for example an accumulator, electrical line connections or contact connections between the suction device and the functional module are not even necessary. For example, the

Claims (14)

- Portable suction device for separating particles from a suction flow (13), comprising a suction motor (12) for generating the suction flow (13) and a suction device housing (11) having an operating wall (23) for operating the suction device (10), wherein the suction motor (12) is located in the interior of the suction device housing (11) and the suction flow (13) can be drawn into the suction device housing (11) via a suction inlet (14), wherein a hose can be connected to the suction inlet (14) and a filter assembly (15) is located in the interior of the suction device housing (11) for separating particles from the suction flow (13), wherein at least one module location (30) is located at the operating wall (23) for the accommodation of at least one function module (50a - 50d) providing an electric and/or optical and/or acoustic function, wherein an electric connecting assembly (41) for an electric connection of the at least one function module (50a - 50d) to the suction device (10) is located at the module location (30), and wherein the at least one function module (50a - 50d) is releasably connectable to the suction device housing (11) by means of connecting means (52), characterised in that the suction device (10) has a function module (50a - 50d), which can be located at the module location (30) of the suction device (10) and connected mechanically to the suction device (10) by means of connecting means (52) and electrically to an electric connecting assembly (41) and which provides an electric and/or optical and/or acoustic function, and in that the function module (50a - 50d) has a wireless external interface for the wireless communication with the function module (50a - 50d) and/or the suction device (10), so that it is possible to switch the suction device (10) on and off or to adjust its suction power, the suction device (10) being a workshop vacuum cleaner.

- Suction device according to claim 1, characterised in that the module location (30) has a location space (37), in which the at least one function module (50a - 50d) is at least partially accommodated when mounted on the suction device (10).

- Suction device according to claim 1 or 2, characterised in that the location space (37) is so deep that a front side of the at least one function module (50a - 50d) projects in the mounted state not at all or only marginally in front of a section of the operating wall (23) which surrounds the location space (37).

- Suction device according to any of the preceding claims, characterised in that a seal assembly (31) for protection against environmental influences is located between the suction device housing (11) and the at least one function module (50a - 50d), wherein the seal assembly (31) expediently comprises a seal (36) located between the module location (30) and the at least one function module (50a - 50d), in particular between a circumference of the at least one function module (50a - 50d) and the operating wall (23) or at a circumferential wall of the module location (30) and/or advantageously a seal located at the electric connecting assembly (41).

- Suction device according to any of the preceding claims, characterised in that the electric connecting assembly (41) has supply contacts (42) for the electric energy supply of an electric load, in particular an electric tool, connectable to the suction device (10).