EP3446367B1 - Contact enfichable - Google Patents

Contact enfichable Download PDFInfo

- Publication number

- EP3446367B1 EP3446367B1 EP17718102.1A EP17718102A EP3446367B1 EP 3446367 B1 EP3446367 B1 EP 3446367B1 EP 17718102 A EP17718102 A EP 17718102A EP 3446367 B1 EP3446367 B1 EP 3446367B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- contact

- plug

- legs

- conductor

- connection

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000004020 conductor Substances 0.000 claims description 69

- 239000000463 material Substances 0.000 claims description 18

- 238000003780 insertion Methods 0.000 claims description 12

- 230000037431 insertion Effects 0.000 claims description 12

- 238000000034 method Methods 0.000 description 7

- 238000004519 manufacturing process Methods 0.000 description 4

- 238000003825 pressing Methods 0.000 description 4

- 239000011248 coating agent Substances 0.000 description 3

- 238000000576 coating method Methods 0.000 description 3

- 238000005520 cutting process Methods 0.000 description 3

- 238000001465 metallisation Methods 0.000 description 3

- 230000005923 long-lasting effect Effects 0.000 description 2

- 230000002441 reversible effect Effects 0.000 description 2

- 238000005476 soldering Methods 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R12/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, specially adapted for printed circuits, e.g. printed circuit boards [PCB], flat or ribbon cables, or like generally planar structures, e.g. terminal strips, terminal blocks; Coupling devices specially adapted for printed circuits, flat or ribbon cables, or like generally planar structures; Terminals specially adapted for contact with, or insertion into, printed circuits, flat or ribbon cables, or like generally planar structures

- H01R12/50—Fixed connections

- H01R12/51—Fixed connections for rigid printed circuits or like structures

- H01R12/55—Fixed connections for rigid printed circuits or like structures characterised by the terminals

- H01R12/58—Fixed connections for rigid printed circuits or like structures characterised by the terminals terminals for insertion into holes

- H01R12/585—Terminals having a press fit or a compliant portion and a shank passing through a hole in the printed circuit board

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R12/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, specially adapted for printed circuits, e.g. printed circuit boards [PCB], flat or ribbon cables, or like generally planar structures, e.g. terminal strips, terminal blocks; Coupling devices specially adapted for printed circuits, flat or ribbon cables, or like generally planar structures; Terminals specially adapted for contact with, or insertion into, printed circuits, flat or ribbon cables, or like generally planar structures

- H01R12/70—Coupling devices

- H01R12/71—Coupling devices for rigid printing circuits or like structures

- H01R12/75—Coupling devices for rigid printing circuits or like structures connecting to cables except for flat or ribbon cables

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/02—Contact members

- H01R13/04—Pins or blades for co-operation with sockets

- H01R13/05—Resilient pins or blades

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/28—Clamped connections, spring connections

- H01R4/48—Clamped connections, spring connections utilising a spring, clip, or other resilient member

- H01R4/4809—Clamped connections, spring connections utilising a spring, clip, or other resilient member using a leaf spring to bias the conductor toward the busbar

- H01R4/48185—Clamped connections, spring connections utilising a spring, clip, or other resilient member using a leaf spring to bias the conductor toward the busbar adapted for axial insertion of a wire end

- H01R4/4819—Clamped connections, spring connections utilising a spring, clip, or other resilient member using a leaf spring to bias the conductor toward the busbar adapted for axial insertion of a wire end the spring shape allowing insertion of the conductor end when the spring is unbiased

- H01R4/4821—Single-blade spring

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/28—Clamped connections, spring connections

- H01R4/48—Clamped connections, spring connections utilising a spring, clip, or other resilient member

- H01R4/4809—Clamped connections, spring connections utilising a spring, clip, or other resilient member using a leaf spring to bias the conductor toward the busbar

- H01R4/4828—Spring-activating arrangements mounted on or integrally formed with the spring housing

- H01R4/4833—Sliding arrangements, e.g. sliding button

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/28—Clamped connections, spring connections

- H01R4/48—Clamped connections, spring connections utilising a spring, clip, or other resilient member

- H01R4/4809—Clamped connections, spring connections utilising a spring, clip, or other resilient member using a leaf spring to bias the conductor toward the busbar

- H01R4/4846—Busbar details

- H01R4/4852—Means for improving the contact with the conductor, e.g. uneven wire-receiving surface

Definitions

- the invention relates to a plug-in contact for electrically contacting a circuit board by inserting the plug-in contact into a contact hole in the circuit board, with two contact legs that are resilient relative to one another, a connection area and a connection area, the connection area connecting the two contact legs to one another and to the connection area, and the plug-in contact is formed from a metallic flat material.

- the invention also relates to an electrical connection terminal with a housing, with a conductor connection element and with a busbar piece, wherein a conductor to be connected can be electrically connected to the busbar piece by means of the conductor connection element and a conductor insertion opening is formed in the housing for inserting an electrical conductor to be connected.

- Plug contacts for producing electrical connections between conductors, various electrical or electronic components and busbars are known in various embodiments and for various areas of application.

- the plug contacts are inserted into corresponding receiving contacts or socket elements, whereby the receiving contacts can be openings in busbars, for example.

- the plug contacts themselves can be connected to electrical components or provided for connection to electrical conductors, for which purpose the connection area of the plug contacts is then designed accordingly.

- connection terminals have also been known in a variety of design variants for decades.

- the connection terminals can, for example, be designed as a so-called printed circuit board for connecting an electrical conductor or several conductors to a circuit board, for which purpose the connection terminals have corresponding contact pins which are pressed or soldered into corresponding holes in the circuit board.

- a screw terminal can be provided as a conductor connection element, through which a conductor to be connected can be connected to the busbar piece in an electrically conductive manner.

- the conductor connection element can also be designed as a crimp connection to which the stripped end of a conductor to be connected can be attached, the crimp connection then being formed at one end of the busbar piece and the contact pin at the other end of the busbar piece.

- a cutting connection in which an insulated end of a conductor is pressed into the cutting edges of the cutting connection, is also possible as a conductor connection element.

- Clamping springs can also be used as conductor connection elements, with both loop-shaped clamping springs, so-called tension spring clamps, as well as U-shaped or V-shaped clamping springs being used.

- Rigid conductors or conductors with a ferrule can be inserted directly into U-shaped or V-shaped clamping springs, ie without the clamping point having to be opened beforehand with a tool.

- U-shaped or V-shaped clamping springs With the known U-shaped or V-shaped clamping springs, the conductor to be connected is pressed against the busbar piece by the clamping leg of the clamping spring, whereby the electrical connection between the conductor and the busbar piece is established.

- the clamping point between the clamping leg and the busbar piece must be opened, for which purpose an actuation opening for inserting a tool, for example the tip of a screwdriver, is formed in the housing.

- the actuation opening also serves to open the terminal point in order to be able to pull a connected conductor out of the terminal again.

- a plug contact designed for use in circuit boards has been known for some time, which is designed in the manner of a spring fork and has two flat contact legs that are resilient relative to one another and which are connected to one another via a common connection area.

- the plug contact is punched out of a metallic flat material and bent, with the narrowest possible area between the contact legs being punched out to produce the two contact legs.

- the contact legs When plugged in, the contact legs each press with their outer punched edges against the inner wall of the contact hole into which the plug contact is inserted.

- the connection area opposite the contact legs is designed as a crimp connection, so that one conductor can be connected to a plug contact.

- the two contact legs In order for the two contact legs to be manufactured safely using stamping technology, their width must approximately correspond to their thickness, i.e. H. the material thickness of the flat material from which the plug contact is punched out. Since the width of the area punched out between the two contact legs also corresponds approximately to the material thickness of the flat material, it results that the width of the individual contact legs is only just under 1/3 of the total width of the plug-in contact.

- the total width of the plug contact i.e. H.

- the width of the two contact legs and the width of the area punched out between the two contact legs is determined by the diameter of the contact hole in the circuit board into which the plug contact is to be inserted. With small hole diameters, this means that the contact legs of the plug contact have to be very narrow and thin. This is initially difficult to achieve in terms of stamping technology and also means that the normal contact force that can be applied by the contact legs is only relatively low.

- a plug-in connection does not produce such an intermetallic connection.

- the contact partners ie the plug contact and the contact hole in the circuit board, press against each other with the normal contact force. This must be sufficiently large to ensure good and permanent electrical contact between the contact partners. Are the contact legs too narrow? or too thin, the contact normal force may not be large enough to ensure long-term good electrical contact.

- the US 4,384,757 discloses a plug contact with two resilient contact legs for insertion into a contact hole on a circuit board.

- the plug-in contact is bent from a flat material, with a connection area forming a U-shaped contour together with the resilient contact legs.

- the two contact legs are bent in the longitudinal direction.

- the FR 2 813 997 shows a plug contact, according to the preamble of claim 1, in which the distance between the two contact legs in the contact area is smaller than in the connection area.

- the contact legs of this plug contact are curved in cross section in the contacting area.

- connection terminal with several plug contacts described above is from the DE 10 2011 011 017 A1 known.

- the individual plug contacts are arranged next to each other in several rows in chambers of the connection housing in such a way that the plug contacts extend perpendicular to the plane of the circuit board.

- the connection areas of the individual plug contacts are designed as crimp connections. This allows several conductors to be connected to a circuit board in which the individual contact holes are at a small distance from one another. However, subsequent connection or disconnection of individual conductors is not possible with the known connection terminal.

- a fork-shaped plug contact for contacting a circuit board is also available DE 202 18 295 U1 known.

- the contact legs press with their outer punched edges against the inner wall of the contact hole, with the two contact legs each having two outer edges, which dig into the metallization of the hole wall when the plug-in contact is pressed into the contact hole of the circuit board.

- Cold welding should preferably occur between the metallization of the bore wall and the contact leg in order to ensure good electrical contact.

- a subsequent separation of the connection is then not possible or only possible with difficulty.

- the present invention is based on the object of providing a plug-in contact described above, which ensures secure contacting of the contact hole even when the material thickness of the flat material is small so that the connector ensures good and permanent electrical contact between the contact partners.

- the plug contact should also be able to be pulled out of the contact hole again.

- an electrical connection terminal is to be specified with which an electrical conductor can be easily connected to a circuit board.

- the two contact legs each have a first section and a second section adjoining it in the insertion direction of the plug-in contact.

- the two contact legs are bent out of the plane of the connection area in such a way that the connection area and the first areas of the two contact legs adjacent to the connection area together form a U-shaped contour.

- the contacting areas that contact the contact hole when the plug-in contact is inserted are formed on the outer sides of the second sections of the two contact legs facing away from one another, with each contact leg having a contacting area.

- the contact legs and the connection area do not extend in a common plane, but the contact legs are bent relative to the connection area. This results in the contact legs in the inserted state not pressing against the inner wall of the contact hole with their punched edges, but with their outer sides of the second sections facing away from one another. This ensures that the contact area of the contact legs is no longer directly dependent on the material thickness of the metallic flat material from which the plug contact is made.

- the design of the contact legs in particular their geometry and the shape of the contacting areas, there is more scope for design, so that the plug contact and in particular the contact legs can be better adapted to the respective dimensions of the contact hole.

- the contacting areas of the contact legs are not formed on their punched edges but on the rolled side of the metallic flat material, the Contacting areas can be provided with a coating in a simple manner, for example gold-plated. Since the contacting areas are not formed on the punched edges, the coating can already be applied to the metallic flat material from which the plug contacts are made, ie punched out and bent. This eliminates the need for subsequent and complex coating of the individual plug contacts that have already been punched out and possibly bent.

- the second sections of the two contact legs each have an outer contour with a rounded cross-section, at least in their contacting area.

- the edges of the contact legs are therefore machined, particularly in the area in which the contact legs contact the contact hole when inserted, so that they do not have any sharp edges that dig into the metallization of the bore wall when the plug contact is inserted into the contact hole.

- the outer contour of the contact legs can have a radius that is smaller than the radius of the contact hole. This makes it possible to insert and remove the plug contact several times without causing major damage to the inner wall of the contact hole in the circuit board.

- the contacting areas of the two contact legs are designed to be spherical. The spherical shape of the contacting areas can be easily created using a die into which the corresponding areas of the second sections of the contact legs are pressed before the contact legs are bent out of the plane of the connection area.

- the geometry of the contact legs can be more easily adapted to the respective requirements, in particular to the dimensions of the contact hole .

- the two contact legs are arranged mirror-symmetrically to one another, with a distance from one another over their entire longitudinal extent.

- the contact legs are bent in such a way that the distance between the two contact legs from one another is the smallest in the area of their free ends.

- connection area is also the same for plug-in contacts that are designed to be inserted into contact holes are provided with small diameters, can have a width that ensures sufficient stability of the plug contact.

- the two contact legs also each have a smaller width in their contacting area than in their first section. This also creates the possibility of providing a plug-in contact that can be inserted into contact holes with a small diameter , without the overall width of the contact legs having to be chosen correspondingly small. This makes the production of the plug-in contact easier because the contact legs do not have to be too narrow in the section in which they are bent away from the connection area. In addition, the normal contact force that can be applied by the contact legs is not too low, so that long-lasting, good electrical contact can be guaranteed even with low material thickness.

- the electrical connection terminal has a plug contact according to the invention, which is at least partially arranged in the housing of the connection terminal in such a way that the busbar piece is formed by the connection area or a section of the connection area of the plug contact, the contact legs of the plug contact having their second sections or their contacting areas protrude from the bottom of the housing.

- the underside of the housing is the side that faces the circuit board when the connection terminal is placed on the circuit board.

- connection terminals can be used in connection terminals with different connection techniques.

- a screw terminal or an insulation displacement terminal can be provided as a conductor connection element, through which a conductor to be connected can be electrically connected to the busbar piece.

- the conductor connection element can also be designed as a crimp connection to which the stripped end of a conductor to be connected can be attached.

- a clamping spring is provided as the conductor connection element, which has a clamping leg and a contact leg, the clamping leg together with the corresponding section of the connection area of the plug contact forming a spring-loaded clamping connection for the conductor to be connected.

- the use of a clamping spring as a conductor connection element has the additional advantage that a conductor to be connected can be connected very easily to the connection terminal and thus also to a circuit board via the spring-loaded clamp connection. If necessary, the electrical conductor can also be pulled out of the connection terminal again when the spring-loaded terminal connection is opened. The electrical connection between the conductor and the circuit board can thus be released both between the conductor and the connection area of the plug contact and between the contact legs of the plug contact and the circuit board.

- connection area of the electrical connection terminal extends in the longitudinal direction of the contact legs

- the conductor insertion opening is arranged on the top of the housing and an electrical conductor to be connected is inserted into the connection terminal perpendicular to the plane of the circuit board.

- connection area of the plug contact it is also possible for the connection area of the plug contact to be bent perpendicularly - or at an angle not equal to 90° - to the longitudinal direction of the contact legs, so that the conductor insertion opening is then arranged accordingly on an end face of the housing. In both cases, the electrical conductor is pressed from the free end of the contact leg against the corresponding section of the connection area, whereby the electrical connection between the conductor and the plug contact is established.

- connection area of the plug contact facing the clamping leg.

- connection area increases the surface pressure between the inserted conductor and the plug contact, which leads to a lower contact resistance.

- a plurality of adjusting elements are formed on the underside of the housing, which are inserted into corresponding recesses in the circuit board when the connection terminal is placed on the circuit board.

- the ends of the adjusting elements are preferably conical, which makes it easier to insert the adjusting elements into the corresponding recesses in the circuit board.

- the length of the adjusting elements is selected so that when the connection terminal is placed on the circuit board, the adjusting elements first engage with their free ends in the corresponding recesses in the circuit board before the contacting areas of the contact legs of the plug-in contact dip into the corresponding contact holes in the circuit board.

- At least two locking elements are formed on the underside of the housing, which engage in corresponding recesses in the circuit board.

- Appropriate locking projections or locking lugs can be used to ensure that the electrical connection terminal is securely attached to a circuit board after it has been placed on it.

- the latching elements are preferably designed in such a way that they can be transferred from a first, non-latching state to a second, latching state and vice versa. This makes it possible to release the latching between the housing of the electrical connection terminal and the circuit board again, so that the electrical connection terminal can be lifted off the circuit board again if necessary.

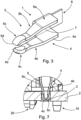

- the Fig. 1 and 2 show a preferred exemplary embodiment of a plug-in contact 1 for contacting a circuit board 2, for which purpose the plug-in contact 1 is inserted into a corresponding contact hole 3 in the circuit board 2 (cf. Fig. 6 and 7 ).

- the plug contact 1 punched out and bent from a metallic flat material, has two contact legs 4, 5 which are resilient relative to one another, a connection area 6 and a connection area 7, the two contact legs 4, 5 being connected to one another and to the connection area 6 via the connection area 7.

- the two contact legs 4, 5 each have a first section 4a, 5a and a second section 4b, 5b, which adjoins the first section 4a, 5a in the insertion direction E of the plug contact 1. How in particular Fig. 1 As can be seen, the two contact legs 4, 5 are bent out of the plane of the connection area 7, so that the connection area 7 and the adjoining first areas 4a, 5a of the two contact legs 4, 5 together form a U-shaped contour. The contact legs 4, 5 are bent approximately perpendicularly from the connection area 7, so that the connection area 7 forms the U-back and the two first sections 4a, 5a of the contact legs 4, 5 form the U-legs of the U-shaped contour.

- the contacting areas 4c, 5c are formed, which contact the contact hole 3 when the plug contact 1 is inserted.

- the contact areas 4c, 5c are spherical.

- the radius of the outer contour of the contact areas 4c, 5c is slightly smaller than the radius of the contact hole 3, so that when the contact legs 4, 5 are inserted into the contact hole 3, the metallized inner wall of the contact hole 3 is not damaged.

- the two contact legs 4, 5 are arranged mirror-symmetrically to one another and are at a distance from one another over their entire longitudinal extent.

- the distance between the contact legs 4, 5 from one another is smallest in the area of their free ends 4d, 5d, while it is greatest in the area of the first sections 4a, 5a.

- the contact legs 4, 5 are thus bent towards one another starting from the connection area 7 or from their first sections 4a, 5a, with the width of the contact legs 4, 5 also reducing in the direction of the free ends 4d, 5d.

- the contact legs 4, 5 can be inserted into a contact hole 3, the diameter of which is smaller than the distance between the first two sections 4a, 5a of the two contact legs 4, 5 or the width of the connection area 7.

- a plug-in contact 1 can thus be realized, which can be inserted into very small contact holes 3 and still has sufficient rigidity and stability so that the plug contact 1 is not deformed when the contact legs 4, 5 are inserted into the contact hole 3.

- the in Fig. 3 Plug contact 1 shown enlarged differs from that in the Fig. 1 and 2 shown plug contact 1 only by a slightly different design of the connection area 6.

- the connection area 6 is designed as a straight tongue, which, like the section 6a of the connection area 6 according to Fig. 1 and 2 serves to contact an electrical conductor.

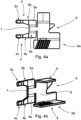

- Fig. 4 shows two intermediate steps in the production of the plug contact 1 according to the invention, where in Fig. 4a the plug contact 1 is shown after being punched out of a metallic flat material.

- the metallic flat material can have a thickness of less than 0.5 mm, for example a thickness of only 0.3 - 0.4 mm.

- the spherical shape of the contacting areas 4c, 5c was created by pressing the corresponding areas of the second sections 4b, 5b of the contact legs 4, 5 into a die.

- two sections of the connection area 6 are bent upwards, so that the connection area 6 has a U-shaped contour with a U-back 8 and two side walls 9.

- the two contact legs 4, 5 are bent essentially vertically upwards from the plane of the connection area 7 and the second sections 4b, 5b of the contact legs 4, 5 are bent towards one another, so that the in Fig. 1 shown shape of the plug contact 1 is achieved.

- the 5 and 6 show a preferred embodiment of an electrical connection terminal 10 according to the invention, which has a housing 11 generally made of plastic. A plurality of conductor insertion openings 12 and a corresponding number of clamping springs 13 and plug contacts 1 are arranged in the housing 11.

- the exemplary embodiment of the electrical connection terminal 10 shown in the figures is used to connect ten individual conductors, so that a total of ten clamping springs 13 and ten plug contacts 1 are arranged in the housing 11, with two clamping springs 13 each being arranged mirror-symmetrically opposite one another, as shown Fig. 6 is recognizable.

- the individual clamping springs 13, of which are shown in the cross-sectional view Fig. 6 two opposite each other can be seen in the connection terminal 10, each have a clamping leg 14 and a contact leg 15.

- Each clamping spring 13 is assigned a plug-in contact 1 in such a way that a section 6a of the connection area 6 of a plug-in contact 1 formed by a side wall 9, together with the free end of the clamping leg 14 of a clamping spring 13, forms a spring-loaded clamping connection for an electrical connection inserted through a conductor insertion opening 12 into the housing 11 leader forms. Since the connection terminal 10 is provided for connecting ten conductors, ten conductor insertion openings 12 and ten actuation openings 16 are also formed in the housing 11 for opening one spring-loaded terminal connection.

- the two locking elements 20 can each have locking lugs that are opposite one another. With the help of a locking pin arranged between the opposite locking lugs and designed to be displaceable in the longitudinal direction of the locking element 20, an unwanted springing back of the locking lugs can be prevented when the Locking pin is in its locking position between the two locking lugs.

- an actuation pusher 21 is displaceably arranged in each of the actuation openings 16. If the actuation pusher 21 is pressed into the actuation opening 16 of the housing 11, the actuation pusher 21 deflects the clamping leg 14 of the clamping spring 13 against its spring force, so that a connected conductor can be pulled out of the clamping point or a flexible conductor can be inserted into the clamping point.

Landscapes

- Coupling Device And Connection With Printed Circuit (AREA)

Claims (7)

- Contact enfichable (1) servant à la mise en contact électrique d'une carte de circuit imprimé (2) par enfichage du contact enfichable (1) dans un trou de contact (3) de la carte de circuit imprimé (2), comportant deux branches de contact (4, 5) élastiques l'une par rapport à l'autre, une zone de raccordement (6) et une zone de liaison (7), la zone de liaison (7) reliant les deux branches de contact (4, 5) l'une à l'autre et à la zone de raccordement (6) et le contact enfichable (1) étant formé à partir d'un matériau plat métallique,les deux branches de contact (4, 5) présentant respectivement une première partie (4a, 5a) et une deuxième partie (4b, 5b) adjacente à celle-ci dans le sens d'enfichage (E) du contact enfichable (1),les deux branches de contact (4, 5) étant courbées de sorte que la zone de liaison (7) et les premières parties (4a, 5a), adjacentes à la zone de liaison (7), des deux branches de contact (4, 5) forment conjointement un contour en forme de U, etune zone de mise en contact (4c, 5c), assurant la mise en contact du trou de contact (3) à l'état enfiché, étant formée respectivement sur les côtés extérieurs, opposés l'un à l'autre, des deuxièmes parties (4b, 5b) des deux branches de contact (4, 5),les deuxièmes parties (4b, 5b) des deux branches de contact (4, 5) présentant respectivement un contour extérieur arrondi en section transversale au moins dans leur zone de mise en contact (4c, 5c),les deux branches de contact (4, 5) étant disposées en symétrie miroir l'une par rapport à l'autre et étant situées à une distance l'une de l'autre sur toute leur étendue longitudinale, la distance des branches de contact (4, 5) étant la plus petite dans la région de leurs extrémités libres (4d, 5d) et la plus grande dans la région de leurs premières parties (4a, 5 a),caractérisé en ce queles deux branches de contact (4, 5) sont courbées hors du plan de la zone de liaison (7) eten ce que les zones de mise en contact (4c, 5c) des deux branches de contact (4, 5) sont formées de manière bombée.

- Contact enfichable (1) selon la revendication 1, caractérisé en ce que les deux branches de contact (4, 5) présentent respectivement dans leur zone de mise en contact (4c, 5c) une plus petite largeur que dans leur première partie (4a, 5a).

- Contact enfichable (1) selon la revendication 1 ou 2, caractérisé en ce que les branches de contact (4, 5) présentent respectivement une épaisseur de moins de 0,5 mm.

- Borne de raccordement électrique (10) comportant un boîtier (11), comportant un élément de raccordement de conducteur et comportant une pièce de rail de courant, un conducteur à raccorder pouvant être relié électriquement à la pièce de rail de courant au moyen de l'élément de raccordement de conducteur, et une ouverture d'insertion de conducteur (12) destinée à l'insertion du conducteur électrique à raccorder étant formée dans le boîtier (11),

caractérisée en cequ'un contact enfichable (1) selon l'une des revendications 1 à 3 est disposé dans le boîtier (11) de telle sorte que la pièce de rail de courant soit formée par la zone de raccordement (6) ou une partie (6a) de la zone de raccordement (6) du contact enfichable (1) et que les branches de contact (4, 5) fassent saillie, par leurs deuxièmes parties (4b, 5b), de la face inférieure (17) du boîtier (11) qui est tournée vers une carte de circuit imprimé (2), etet en ce qu'un ressort de serrage (13) est disposé dans le boîter (11) en tant qu'élément de raccordement de conducteur, le ressort de serrage (13) présentant une branche de serrage (14) et une branche d'appui (15) et la branche de serrage (14) formant avec la zone de raccordement (6) ou une partie (6a) de la zone de raccordement (6) du contact enfichable (1) un raccordement de serrage par force de ressort pour un conducteur électrique à raccorder et une ouverture d'actionnement (16) pour l'ouverture du raccordement de serrage par force de ressort étant formée dans le boîtier (11). - Borne de raccordement électrique (10) selon la revendication 4, caractérisée en ce que plusieurs rainures (18) ou entailles sont formées sur le côté, tourné vers la branche de serrage (14), de la zone de raccordement (6) ou de la partie (6a) de la zone de raccordement (6) du contact enfichable (1).

- Borne de raccordement électrique (10) selon la revendication 4 ou 5, caractérisée en ce que plusieurs éléments de réglage (19), destinés à être enfichés dans des évidements correspondants dans une carte de circuit imprimé (2), sont formés sur la face inférieure (17) du boîtier (11).

- Borne de raccordement électrique (10) selon l'une des revendications 4 à 6, caractérisée en ce qu'un bouton d'actionnement (21) est disposé dans l'ouverture d'actionnement (16), lequel peut être déplacé d'une première position dans laquelle le raccordement de serrage par force de ressort est fermé à une deuxième position dans laquelle le bouton d'actionnement (21), par son extrémité tournée vers la branche de serrage (14), dévie la branche de serrage (14) à l'encontre de la force de ressort du ressort de serrage (13), de sorte que le raccordement de serrage par force de ressort soit ouvert.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| LU93039A LU93039B1 (de) | 2016-04-22 | 2016-04-22 | Steckkontakt |

| PCT/EP2017/059545 WO2017182647A1 (fr) | 2016-04-22 | 2017-04-21 | Contact enfichable |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3446367A1 EP3446367A1 (fr) | 2019-02-27 |

| EP3446367B1 true EP3446367B1 (fr) | 2023-09-27 |

Family

ID=56096678

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP17718102.1A Active EP3446367B1 (fr) | 2016-04-22 | 2017-04-21 | Contact enfichable |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20190140375A1 (fr) |

| EP (1) | EP3446367B1 (fr) |

| CN (1) | CN109075473B (fr) |

| LU (1) | LU93039B1 (fr) |

| WO (1) | WO2017182647A1 (fr) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6780513B2 (ja) * | 2017-01-18 | 2020-11-04 | 株式会社オートネットワーク技術研究所 | 端子モジュール |

| DE102020121004A1 (de) * | 2019-08-15 | 2021-02-18 | Phoenix Contact Gmbh & Co. Kg | Kontaktelement und Anschlusselement |

| DE102020104077A1 (de) * | 2020-02-17 | 2021-08-19 | WAGO Verwaltungsgesellschaft mit beschränkter Haftung | Federkraftklemmanschluss |

| KR102651499B1 (ko) * | 2021-08-20 | 2024-03-27 | 현대모비스 주식회사 | 양방향 시그널핀 모듈, 이를 포함한 파워 모듈 및 이의 제조 방법 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2917723A (en) * | 1956-05-28 | 1959-12-15 | Ind Hardware Mfg Co Inc | Tube socket for printed circuits |

| DE2228953A1 (de) * | 1972-06-14 | 1974-01-31 | Siemens Ag | Stiftfoermiges anschlusselement fuer leiterplatten |

| WO2010015571A1 (fr) * | 2008-08-04 | 2010-02-11 | Tyco Electronics Amp Gmbh | Paire de contacts électriques |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4220393A (en) * | 1977-02-22 | 1980-09-02 | Elfab Corporation | Electrical connector and method of fabrication and assembly |

| US4384757A (en) * | 1980-12-18 | 1983-05-24 | Amp Incorporated | Terminal for connecting a ceramic chip to a printed circuit board |

| US5282758A (en) * | 1988-11-11 | 1994-02-01 | Amp Incorporated | Electrical contact |

| US5374204A (en) * | 1993-11-30 | 1994-12-20 | The Whitake Corporation | Electrical terminal with compliant pin section |

| FR2813997B1 (fr) * | 2000-09-14 | 2002-10-18 | Sylea | Dispositif de liaison d'un conducteur a une piste conductrice |

| DE20218295U1 (de) | 2002-11-19 | 2003-04-03 | Würth Elektronik GmbH & Co. KG, 74676 Niedernhall | Kontaktelement für Leiterplatten |

| DE102008010160A1 (de) * | 2008-02-20 | 2009-09-03 | Phoenix Contact Gmbh & Co. Kg | Leiterplattenanordnung und elektrisches Anschlussmodul |

| CN201230087Y (zh) * | 2008-04-30 | 2009-04-29 | 富士康(昆山)电脑接插件有限公司 | 电连接器 |

| CN102132460B (zh) * | 2008-08-27 | 2013-09-18 | 菲尼克斯电气公司 | 电接线端子 |

| DE102009004513A1 (de) * | 2009-01-09 | 2010-07-22 | Phoenix Contact Gmbh & Co. Kg | Klemmfeder für eine Federkraftklemme |

| DE102011011017A1 (de) | 2011-02-11 | 2012-08-16 | Würth Elektronik Ics Gmbh & Co. Kg | Direktsteckvorrichtung mit Stecker und Schürze |

| US9373588B2 (en) * | 2013-09-24 | 2016-06-21 | Intel Corporation | Stacked microelectronic dice embedded in a microelectronic substrate |

| TWI544705B (zh) * | 2014-09-05 | 2016-08-01 | 町洋企業股份有限公司 | 蝶形彈簧連接器 |

-

2016

- 2016-04-22 LU LU93039A patent/LU93039B1/de active IP Right Grant

-

2017

- 2017-04-21 CN CN201780025147.8A patent/CN109075473B/zh active Active

- 2017-04-21 EP EP17718102.1A patent/EP3446367B1/fr active Active

- 2017-04-21 US US16/095,440 patent/US20190140375A1/en not_active Abandoned

- 2017-04-21 WO PCT/EP2017/059545 patent/WO2017182647A1/fr active Application Filing

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2917723A (en) * | 1956-05-28 | 1959-12-15 | Ind Hardware Mfg Co Inc | Tube socket for printed circuits |

| DE2228953A1 (de) * | 1972-06-14 | 1974-01-31 | Siemens Ag | Stiftfoermiges anschlusselement fuer leiterplatten |

| WO2010015571A1 (fr) * | 2008-08-04 | 2010-02-11 | Tyco Electronics Amp Gmbh | Paire de contacts électriques |

Also Published As

| Publication number | Publication date |

|---|---|

| US20190140375A1 (en) | 2019-05-09 |

| EP3446367A1 (fr) | 2019-02-27 |

| CN109075473A (zh) | 2018-12-21 |

| WO2017182647A1 (fr) | 2017-10-26 |

| LU93039B1 (de) | 2017-10-27 |

| CN109075473B (zh) | 2021-05-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3446366B1 (fr) | Contact enfichable | |

| EP3375048B1 (fr) | Contact à enficher | |

| EP2430892B1 (fr) | Connexion de plaquettes | |

| WO2007104500A1 (fr) | Broche de contact et son procédé de fabrication | |

| EP3375046B1 (fr) | Borne de branchement électrique | |

| EP1391965A1 (fr) | Borne à ressort pour conducteur électrique | |

| EP2187480B1 (fr) | Douille pour carte de circuits imprimés | |

| WO2010006758A1 (fr) | Dispositif de connexion électrique | |

| EP2131449A1 (fr) | Borne unique | |

| DE102006028814A1 (de) | Kontaktelement zum Anschließen eines elektrischen Leiters | |

| EP3446367B1 (fr) | Contact enfichable | |

| EP1207588A1 (fr) | Connecteur électrique pour cable plat ou circuit imprimé flexible | |

| DE2941029A1 (de) | Zum einpressverbinden mit einem elektrischen leiter vorgesehenen elektrischen anschlussteil, verfahren zum verbinden eines anschlussteils mit einem elektrischen leiter sowie verbinder mit einer mehrzahl elektrischer anschlussteile | |

| DE112018001787T5 (de) | Elektrischer steckverbinder | |

| EP3375047B1 (fr) | Contact à insérer et méthode de fabrication d'un contact à insérer | |

| DE202016008242U1 (de) | Steckkontakt | |

| DE3925958C1 (en) | Plug connector insertable in metallised bores of PCB - has parallel rows of contact element at right angles to insertion direction of counter-plug for other appts. | |

| DE9102716U1 (de) | Vorrichtung zum Verbinden von einer Vielzahl von zumindest teilweise mit einer Isolation versehenen Leitern mit elektrischen Kontakten | |

| EP3782235A1 (fr) | Connecteur direct | |

| WO2017093457A1 (fr) | Connecteur enfichable | |

| EP3201994A1 (fr) | Barrette à broches | |

| EP1939987B1 (fr) | Dispositif de contact | |

| DE202016102148U1 (de) | Steckkontakt | |

| DE102017110621B3 (de) | Anordnung aus einer Leiterplatte und mindestens einem Steckkontakt | |

| DE69502040T2 (de) | Elektrischer Verbinder für gedruckte Leiterplatten |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: UNKNOWN |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20181029 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20190725 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20230417 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230512 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502017015421 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230927 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230927 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231227 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230927 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230927 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230927 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231228 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230927 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20230927 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230927 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230927 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230927 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230927 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240127 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230927 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230927 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230927 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240129 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230927 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230927 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502017015421 Country of ref document: DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240627 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230927 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230927 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20240423 Year of fee payment: 8 Ref country code: FR Payment date: 20240430 Year of fee payment: 8 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20240628 |