EP3299159A1 - Method and device for producing shoulder boxes - Google Patents

Method and device for producing shoulder boxes Download PDFInfo

- Publication number

- EP3299159A1 EP3299159A1 EP17001522.6A EP17001522A EP3299159A1 EP 3299159 A1 EP3299159 A1 EP 3299159A1 EP 17001522 A EP17001522 A EP 17001522A EP 3299159 A1 EP3299159 A1 EP 3299159A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- frame

- bottom part

- plane

- erecting

- station

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000000034 method Methods 0.000 title claims description 12

- 238000004519 manufacturing process Methods 0.000 claims abstract description 14

- 235000019504 cigarettes Nutrition 0.000 claims abstract description 5

- 239000003292 glue Substances 0.000 claims description 14

- 238000012546 transfer Methods 0.000 claims description 10

- 238000003780 insertion Methods 0.000 claims description 7

- 230000037431 insertion Effects 0.000 claims description 7

- 210000000056 organ Anatomy 0.000 claims description 7

- 238000012545 processing Methods 0.000 claims description 5

- 230000015572 biosynthetic process Effects 0.000 claims description 2

- 230000002093 peripheral effect Effects 0.000 claims 1

- 238000004026 adhesive bonding Methods 0.000 description 4

- 239000000463 material Substances 0.000 description 3

- 238000001035 drying Methods 0.000 description 2

- 230000002996 emotional effect Effects 0.000 description 2

- 238000012856 packing Methods 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 230000032258 transport Effects 0.000 description 2

- 239000000969 carrier Substances 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 239000002689 soil Substances 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B50/00—Making rigid or semi-rigid containers, e.g. boxes or cartons

- B31B50/74—Auxiliary operations

- B31B50/76—Opening and distending flattened articles

- B31B50/80—Pneumatically

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B50/00—Making rigid or semi-rigid containers, e.g. boxes or cartons

- B31B50/003—Straightening the side walls of boxes; Squaring collapsed folded box blanks; Deforming boxes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B50/00—Making rigid or semi-rigid containers, e.g. boxes or cartons

- B31B50/005—Making rigid or semi-rigid containers, e.g. boxes or cartons involving a particular layout of the machinery or relative arrangement of its subunits

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B50/00—Making rigid or semi-rigid containers, e.g. boxes or cartons

- B31B50/02—Feeding or positioning sheets, blanks or webs

- B31B50/04—Feeding sheets or blanks

- B31B50/042—Feeding sheets or blanks using rolls, belts or chains

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B50/00—Making rigid or semi-rigid containers, e.g. boxes or cartons

- B31B50/60—Uniting opposed surfaces or edges; Taping

- B31B50/62—Uniting opposed surfaces or edges; Taping by adhesives

- B31B50/624—Applying glue on blanks

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B50/00—Making rigid or semi-rigid containers, e.g. boxes or cartons

- B31B50/74—Auxiliary operations

- B31B50/81—Forming or attaching accessories, e.g. opening devices, closures or tear strings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B2105/00—Rigid or semi-rigid containers made by assembling separate sheets, blanks or webs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B2110/00—Shape of rigid or semi-rigid containers

- B31B2110/30—Shape of rigid or semi-rigid containers having a polygonal cross section

- B31B2110/35—Shape of rigid or semi-rigid containers having a polygonal cross section rectangular, e.g. square

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B2120/00—Construction of rigid or semi-rigid containers

- B31B2120/002—Construction of rigid or semi-rigid containers having contracted or rolled necks, having shoulders

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B2120/00—Construction of rigid or semi-rigid containers

- B31B2120/10—Construction of rigid or semi-rigid containers provided with covers, e.g. lids

- B31B2120/102—Construction of rigid or semi-rigid containers provided with covers, e.g. lids with a hinged cover

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B2120/00—Construction of rigid or semi-rigid containers

- B31B2120/30—Construction of rigid or semi-rigid containers collapsible; temporarily collapsed during manufacturing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B2120/00—Construction of rigid or semi-rigid containers

- B31B2120/50—Construction of rigid or semi-rigid containers covered or externally reinforced

Definitions

- the invention relates to (cigarette) packs of the cap box type, namely with their production using a method according to the preamble of claim 1. Furthermore, a special device is used in the implementation of the method.

- Cap boxes usually consist of a bottom part, a lid part and a fixed inside the bottom part, running around frame (also called “shoulder"), which abuts and protrudes over the bottom side walls, such that the cover part comprises the frame in the closed package.

- Bottom part and lid part can be connected to each other by a hinge strip ( US 5,938,018 ).

- a hinge strip US 5,938,018 .

- an outside impact in particular made of paper or the like, is used for the complete or partial enclosure of the bottom part and the cover part.

- the device thus operates with several, in particular with three coordinated and synchronously running production lines, each producing a cap box.

- a plug-in station ie an aggregate for merging the bottom part and the frame. This is connected after insertion into the bottom part with the erected bottom side walls, preferably by gluing.

- the bottom part and frame units then enter a merge station in which the lid part is placed on the bottom part.

- the part packs are supplied to a wrapping station for attaching a preferably complete outer wrapper or an outer wrapper.

- An innovative core of the present technology consists - preferably in connection with multi-lane manufacturing - is that the frame in flat lying, so folded formation - are fed in an upright positioning - a frame unit.

- the frame is placed in the box-like, quadrangular shape, preferably by movable (suction) members which secure the frame to two at each other pull apart the opposite frame sections, preferably in conjunction with a deformation reducing the outer dimensions.

- the frame prepared in this way is transferred by downward movement to the bottom part kept ready in a lower level.

- the bottom part of the pack has side walls, ie bottom side walls which are not (directly) connected to one another in the area of the packing corners.

- the frame is provided on the outside with glue, in particular with a circulating glue strip, which allows a permanent, dimensionally stable connection with the individual bottom side walls. The frame thus creates the three-dimensional shape of the bottom part.

- the produced cigarette packet of the cap box type consists of a bottom part 10 and a lid part 11.

- the bottom part 10 forms a bottom wall 12 and connected thereto (upright) bottom side walls 13 on the one hand and 14 on the other.

- the bottom side walls (13, 14) are pivotally connected to the bottom wall (12). To complete the bottom side walls (13, 14) are erected and stabilized in this position.

- the lid part 11 is formed with lid wall 15 and lid side walls sixteenth

- a shoulder or a ringer-around frame 17 is arranged in the bottom part 10. This consists of mutually opposite frame portions 18, 19.

- the closed frame 17 is suitably inserted into the bottom part 10 and connected by gluing to the (erected) bottom side walls (13, 14). These are fixed in the pack-like position.

- the frame 17 is provided on the outside with glue around or with a continuous glue strip 20, which establishes the connection with the inside of the bottom side walls 13, 14.

- the frame 17 is preferably made of an elongated, folded strip whose ends are connected together in the region of a frame corner by a tab 21.

- the unit of bottom part 10, cover part 11 and frame 17 is preferably completely surrounded by an outer cover 22.

- This blank made of paper or the like is connected by (full-surface) bonding with the free outer sides of bottom part 10 and lid 11.

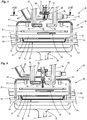

- FIG. 3 A compact, high-performance manufacturing plant is schematically in Fig. 3 shown.

- An innovative core is a (first) processing station, namely a union station 23, in which bottom part 10 and frame 17 are provided, folded in a package-like manner and connected to one another.

- the resulting units 24 of bottom part 10 and frame 17 are fed to another processing station for stabilizing the connection between the bottom part 10 and frame 17, in this case a fixing turret 25, which has the particular task, the (glue) connection between bottom wall 10 and frame 17th to stabilize.

- a cover station 26 for supplying separately prepared lid parts 11 and for uniting them with the units 24.

- the basically finished package is then transferred to a wrapping assembly 27 for attachment of the outer wrap 22 to the packs.

- the unit 27 consists of organs for attaching the outer panels 22 to the packages, in particular by placing them on the cover wall 15 by means of transfer rollers 28.

- the outer wrap packs 22 are fed to a folding station 32, in which the outer wrap 22 is completed, so that a cap box in the embodiment according to Fig. 2 arises.

- the finished packages are then transferred to drying units, in particular to dry turrets 33 and transported away after leaving the same on a package track 34.

- the manufacturing device is designed so that the individual folding and working steps for several packages are performed simultaneously in the range of several, preferably three parallel production lines.

- the processing units namely in particular folding and conveying members are arranged in a corresponding number next to each other, driven coaxially and synchronously with rotating organs. Accordingly, several, in particular three, packages are completed at each power stroke.

- the material to be processed namely bottom part 10, cover part 11 and frame 17, is Preferably, in the axial or axis-parallel conveying direction, ie transversely to the (three) production lines, the respective units in the same number of cycles processed supplied.

- the union station 23 consists of two special units, namely a frame assembly 35 and a ground assembly 36.

- the frame assembly 35 is used to prepare the frame 17 and to transfer the same to a prepared bottom part 10, in particular by downward movement of the frame 17.

- the ground assembly 36 is used for preparation of soil parts 10.

- the blanks for the bottom part 10 are removed from a bottom magazine 37 and - conveyed by a bottom conveyor 38 to the ground assembly 36 - transverse to the direction of the production lines.

- the blanks of the bottom part 10 taken from the bottom magazine 37 by a removal device are fed (firstly) to a folding unit.

- This consists essentially of a folding shaft 39 and a punch 40.

- the punch 40 By downward movement of the punch 40, the blank (10) is pushed by the correspondingly formed folding shaft 39 down, wherein the bottom side walls 13, 14 are erected.

- the thus prepared bottom part 10 is deposited on the bottom conveyor 38, namely between suitably arranged drivers 41 of a belt conveyor.

- the drivers 41 stabilize the transverse direction to the conveying direction, upright bottom side walls 13th

- the prefolded floor parts 10 are taken over by a preferably similarly designed transfer conveyor 42 and fed to the union station 23.

- the transfer conveyor 42 is disposed above the plane of action of the bottom conveyor 38 and thus detects the bottom parts 10 with a lower run.

- the bottom parts 10 are transferred to a main conveyor 44, which is also designed as a belt conveyor and has spaced apart drivers 41.

- the main conveyor 44 extends in the direction of the production lines for the packages.

- a corresponding number (three) of main conveyors 44 are arranged parallel next to each other, each with the same number of matching and synchronously operating units.

- the bottom part 10 is removed in the union station 23 from the conveyor 42 and in particular transmitted by downward movement to the main conveyor 44.

- up-and-down movable punches 45 are effective which engage with elongated pressure ridges by downward movement of the bottom wall 12 of the bottom portion 10 respectively on both sides of the belt of the transfer conveyor 42, decrease by downward movement from the transfer conveyor 42 and transferred to the main conveyor 44.

- the main conveyor 44 transports the prepared floor parts 10 into the area of the frame assembly 35.

- the frame 17 are separately and independently of the bottom parts 10 of the union station 23 and the frame assembly 35, respectively. The movements are coordinated.

- the closed frame 17 are folded, ie lying flat, fed by a frame conveyor, namely a frame belt 46, the unit 35.

- the conveyor 46 preferably consists of a single belt which rotates in a horizontal plane with upright belt position and correspondingly arranged carriers 47. These each convey a frame 17 also positioned in an upright position in the region of the unit 35.

- the conveyor 46 is a gluing station 47 shown schematically upstream, in the area of glue is applied to the flat folded frame 17 outside, namely in particular the glue strip 20th

- the guide rails 48 are arranged or dimensioned so that they are outside or above the area of the glue strips 20 ( Fig. 5 ).

- the drive of the frame belt 46 is controlled so that a frame 17 is provided in the region of the frame assembly 35 in the horizontal plane and aligned with a bottom part 10 in a downwardly offset plane ( Fig. 5 ).

- the frame 17 rests on a movable (horizontal) pad, in this case on a (divided) table 49.

- the frame 17 from the feeder level ( Fig. 5 ) into an erecting plane ( Fig. 6 ) moves or lowered.

- the pad or the table 49 is withdrawn.

- the frame 17 becomes out of the region of the frame belt 46 moved out, by downward movement by means of movable up and down pressure member 50, which has a fork-shaped head and detects the frame 17 at an upper, free edge.

- the pressure member 50 is formed so that on both sides of the elongated frame 17 guide webs 51 are arranged.

- the frame 17 is inserted during transport into the frame assembly 35 in a position between the guide webs 51 ( Fig. 7 ). Above the guide webs 51 is the actual pressure member 50th

- Each suction head 54 is formed as an elongated, web-like suction member having a plurality of juxtaposed - in series - lying suction holes 55. These are connected via connection channels and connection channels with a vacuum source. By means of the suction head 54 thus formed, the relevant frame section 18 is grasped and held on a larger, preferably central, length.

- the suction heads 54 are preferably connected as a web projecting on one side with a holding and actuating member, in the present case with an upright supporting rod 56. This is connected to a rotary drive (not shown). By rotating the upright support rod 56, a pivoting movement of the suction head 54 is effected, namely from a receiving position (dash-dotted lines in FIG Fig. 10 ) in the holding or end position (also Fig. 10 ). In this case, the frame 17 is folded in the quadrangular position.

- the support rod 56 also includes a longitudinally extending connection bore for the suction holes 55.

- the suction heads 54 are thus initially brought into a starting position (dash-dotted lines in Fig. 8 . Fig. 10 ). Then, the suction heads 54 after detecting the frame portions 18 in opposite pivotal movements in the end position according to Fig. 10 emotional.

- the (deformed) frame 17 can be so zwfitungsok introduced into the bottom part 10.

- the deformation in the present case consists in that the free frame sections 19 are deformed inwards, that is to say an inwardly shaped arc-shaped structure is obtained ( Fig. 10 ).

- free end portions of the frame portion 18, in particular outside the range of action of the suction cups 54 arcuately drawn inward, including the corners formed between the sections 18 and 19 with a corresponding reduction in the outer contour of the frame 17th

- the aforesaid deformation is effected by moldings acting on the outside of the frame sections 19, in particular by (upright) stop pins 57 on both (outer) sides of the frame 17 and the sections 19.

- the action of the stop pins 57 is preferably such that in the opening or folding movement of the frame 17 by the action of the suction cups 54, the frame portions 19 are pressed against the - inwardly offset - stop pin 57, so until reaching the end position according to Fig. 10 the deformation takes place by the unfolding process.

- the stop pins 57 are movable downwards with the frame 17 into a lower position for transferring the (deformed) frame 17 to the bottom part 10 (FIG. Fig. 11 ). Thereafter, the stop bolts 57 return by upward movement into the starting position accordingly FIG. 8, Fig. 9 back, so in the plane for the folding of a (subsequent) frame 17.

- the recessed in the bottom part frame 17 obtained by the restoring forces in the material of the frame 17, the final, rectangular shape to rest against the erected bottom side walls 13, 14th

- the stop pins 57 are arranged on a common, up and down movable support, preferably on a frame-shaped lifting support 58. This is attached to a common lifting rod 59 below the path of movement of the bottom part 10.

- the lifting beam 58 consists of two lateral, bow-shaped support arms 60, each with a horizontal support leg 61, on the underside of each a (downwardly directed) stop pin 57 is attached.

- the downward movement of the frame 17, preferably in the contour according to Fig. 10 is effected by the lifting support 58 - while maintaining the shape of the stop pin 57.

- the frame 17 is moved down to the end position within the bottom part 10 (FIGS. Fig. 11 ).

- the frame 17 is now released.

- the suction cups 54 are vented and then return to the (upper) initial position.

- the lifting carrier 58 with the stop pin 57 in the upper starting position ( Fig. 8, Fig. 9 . Fig. 12 ) moved back by corresponding upward movement of the Hubismes 58.

- the upward movement of the Hubanis or the stop pin 57 of the (deformed) frame 17 is released. This now takes due to the existing material tension the correct, in particular rectangular shape (dash-dotted representation in Fig. 13 ).

- movable abutment pieces 62 are moved to a holding position under abutment with an upper, free edge of the frame 17 ( Fig. 13 ).

- the stop pieces 62 are preferably in the region of the frame portions 18 to the effect after the suction cups 54 are retracted from the holding position.

- the stop pieces 62 are by rotational movement (about a vertical axis) in the operative position, preferably in the region of the frame portions 18 ( Fig. 13 , solid lines) and moved out of this operative position (dash-dotted lines in Fig. 13 ).

- the rotational movement is effected by belt drive or by (tooth) belt 63, which are driven synchronously with the other movements and cause a corresponding rotational movement of the stop pieces 62.

- the units 24 formed in the frame unit 35 from the bottom part 10 and frame 17 can be completed in this area by pressing together frame sections 18, 19 and associated bottom side walls 13, 14.

- the bottom side walls 13, 14 during this phase in an inclined position ( Fig. 11, Fig. 12 ).

- Between the frame sections 18, 19 on the one hand and the side walls 13, 14 on the other hand creates a wedge-shaped gap.

- the slightly oblique Projection 65 is adapted to support free edges of the (obliquely directed) bottom side walls 13, 14.

- the units 24 are subsequently - after leaving the main conveyor 44 - completed by pressing the bottom side walls 13, 14 to the frame sections 18, 19, in particular in the fixing turret 25th

Landscapes

- Making Paper Articles (AREA)

- Supplying Of Containers To The Packaging Station (AREA)

Abstract

Verfahren zum Herstellen von Zigaretten-Packungen des Typs Kappenschachtel mit einem Bodenteil (10) und einem innerhalb des Bodenteils (10) angeordneten, ringsherum laufenden, an Boden-Seitenwänden (13, 14) anliegenden Rahmen (17). Der in der Endstellung eckige Rahmen (17) wird in flach zusammengefaltetem Zustand einem Rahmenaggregat (35) zugeführt und durch Aufrichtorgane, z.B. Saugköpfe (54), durch Erfassen an der Außenseite von Rahmenabschnitten (18) aufgerichtet und zugleich mit Hilfe von Anschlagbolzen (57) derart verformt, dass die Außenkonturen des Rahmens (17) kleiner sind als die Fläche einer Bodenwand (12). Der so verformte Rahmen (17) wird in das Bodenteil (10) abgesenkt und dort in die eckige Endform gebracht.A method for producing cap-type cigarette packs having a bottom part (10) and a frame (17) arranged around the bottom part (10) and running around on bottom side walls (13, 14). The end frame rectangular frame (17) is supplied in a flat collapsed condition a frame assembly (35) and by Aufrichtorgane, e.g. Suction heads (54), raised by detecting on the outside of frame portions (18) and at the same time deformed by means of stop pins (57) such that the outer contours of the frame (17) are smaller than the surface of a bottom wall (12). The thus deformed frame (17) is lowered into the bottom part (10) and placed there in the square end shape.

Description

Die Erfindung befasst sich mit (Zigaretten-)Packungen des Typs Kappenschachtel, nämlich mit deren Herstellung unter Anwendung eines Verfahrens gemäß Oberbegriff des Anspruchs 1. Weiterhin kommt eine besondere Vorrichtung bei der Umsetzung des Verfahrens zum Einsatz.The invention relates to (cigarette) packs of the cap box type, namely with their production using a method according to the preamble of

Kappenschachteln bestehen üblicherweise aus einem Bodenteil, einem Deckelteil und einem innerhalb des Bodenteils fixierten, ringsherum laufenden Rahmen (auch "Schulter" genannt), der an Boden-Seitenwänden anliegt und über diese hinwegragt, derart, dass das Deckelteil den Rahmen bei geschlossener Packung umfasst. Bodenteil und Deckelteil können durch einen Gelenkstreifen miteinander verbunden sein (

Im Vordergrund steht vorliegend die Zusammenführung von Bodenteil und Rahmen. Es geht darum, das Herstellungsverfahren und die Vorrichtung zur Umsetzung desselben hinsichtlich der Leistungsfähigkeit zu erhöhen, sodass eine ausreichende Anzahl von Packungen in der Zeiteinheit gefertigt werden können.In the foreground here is the merging of bottom part and frame. The aim is to increase the manufacturing process and the device for implementing the same in terms of performance, so that a sufficient number of packages can be made in the unit time.

Zur Lösung dieser Aufgabe wird ein Verfahren mit den Merkmalen des Anspruchs 1 angewendet.To achieve this object, a method with the features of

Die Vorrichtung arbeitet demnach mit mehreren, insbesondere mit drei aufeinander abgestimmten und synchron laufenden Fertigungsbahnen, die je eine Kappenschachtel herstellen. Von Bedeutung sind dabei Aufbau und Arbeitsweise einer Einschubstation, also eines Aggregats zum Zusammenführen des Bodenteils und des Rahmens. Dieser wird nach Einsetzen in das Bodenteil mit den aufgerichteten Boden-Seitenwänden verbunden, vorzugsweise durch Klebung. Die Einheiten aus Bodenteil und Rahmen gelangen sodann in eine Zusammenführungsstation, in der das Deckelteil auf den Bodenteil aufgesetzt wird. Sodann werden die Teilpackungen einer Umhüllungsstation zugeführt zum Anbringen einer vorzugsweise kompletten Außenumhüllung bzw. eines Außeneinschlags.The device thus operates with several, in particular with three coordinated and synchronously running production lines, each producing a cap box. Of importance are the structure and operation of a plug-in station, ie an aggregate for merging the bottom part and the frame. This is connected after insertion into the bottom part with the erected bottom side walls, preferably by gluing. The bottom part and frame units then enter a merge station in which the lid part is placed on the bottom part. Then, the part packs are supplied to a wrapping station for attaching a preferably complete outer wrapper or an outer wrapper.

Ein innovativer Kern der vorliegenden Technologie besteht - vorzugsweise in Verbindung mit mehrbahnigen Fertigung - darin, dass die Rahmen in flach liegender, also zusammengefalteter Formation - bei aufrechter Positionierung - einem Rahmenaggregat zugeführt werden. Während der Stillstandsphase des Rahmens, vorzugsweise in einer gegenüber der Ebene der Zuführung nach unten versetzten Aufrichtebene, wird der Rahmen in die packungsgemäße, viereckige Form gebracht, vorzugsweise durch bewegbare (Saug-)Organe, die den Rahmen durch Erfassen (außen) an zwei einander gegenüberliegenden Rahmenabschnitten auseinanderziehen, vorzugsweise in Verbindung mit einer die Außenabmessungen vermindernden Verformung. Der so vorbereitete Rahmen wird durch Abwärtsbewegung an das in einer unteren Ebene bereitgehaltene Bodenteil übergeben.An innovative core of the present technology consists - preferably in connection with multi-lane manufacturing - is that the frame in flat lying, so folded formation - are fed in an upright positioning - a frame unit. During the standstill phase of the frame, preferably in a set-up plane offset from the feed level, the frame is placed in the box-like, quadrangular shape, preferably by movable (suction) members which secure the frame to two at each other pull apart the opposite frame sections, preferably in conjunction with a deformation reducing the outer dimensions. The frame prepared in this way is transferred by downward movement to the bottom part kept ready in a lower level.

Eine Besonderheit besteht darin, dass das Bodenteil der Packung Seitenwände aufweist, also Boden-Seitenwände, die im Bereich der Packungsecken nicht (unmittelbar) miteinander verbunden sind. Vielmehr ist der Rahmen an der Außenseite mit Leim, insbesondere mit einem ringsherumlaufenden Leimstreifen versehen, der eine dauerhafte, formstabile Verbindung mit den einzelnen Boden-Seitenwänden ermöglicht. Der Rahmen schafft demnach die dreidimensionale Form des Bodenteils.A special feature is that the bottom part of the pack has side walls, ie bottom side walls which are not (directly) connected to one another in the area of the packing corners. Rather, the frame is provided on the outside with glue, in particular with a circulating glue strip, which allows a permanent, dimensionally stable connection with the individual bottom side walls. The frame thus creates the three-dimensional shape of the bottom part.

Einzelheiten der Packung, des Herstellungsverfahrens und der Vorrichtung werden nachfolgend anhand der Zeichnungen näher erläutert. Es zeigt:

- Fig. 1

- ein Schema der Teile einer Kappenschachtel hinsichtlich der Zusammensetzbarkeit,

- Fig. 2

- eine komplette Kappenschachtel in Außenansicht,

- Fig. 3

- eine Herstellungsvorrichtung für Kappenschachtel in schematischer Perspektive,

- Fig. 4

- einen Ausschnitt IV der Vorrichtung gemäß

Fig. 3 in vergrößertem Maßstab, - Fig. 5

- die Einzelheit gemäß

Fig. 4 in Queransicht bzw. im Querschnitt der Ebene V-V derFig. 4 , - Fig. 6

- die Einzelheit gemäß

Fig. 5 bei veränderter Darstellung von Einzelheiten, - Fig. 7

- das Detail gemäß

Fig. 5 im Horizontalschnitt der Ebene VII-VII, - Fig.8

- eine Darstellung der Einzelheit gemäß

Fig. 5, Fig. 6 bei fortgesetztem Arbeitsverfahren, - Fig. 9

- die Einzelheit gemäß

Fig. 8 in Queransicht bzw. in einem quergerichteten Schnitt, - Fig. 10

- die Vorrichtung gemäß

Fig. 9 im Horizontalschnitt in der Schnittebene X-X, - Fig. 11

- eine Darstellung der Einzelheit gemäß

Fig. 9 bei Übergabe eines Rahmens an ein Bodenteil, - Fig. 12

- die Vorrichtung gemäß

Fig. 8 nach Übergabe eines Rahmens an ein Bodenteil, - Fig. 13

- die Vorrichtung gemäß

Fig. 11 in horizontaler Schnittebene XIII-XIII.

- Fig. 1

- a schematic of the parts of a cap box in terms of composability,

- Fig. 2

- a complete cap box in exterior view,

- Fig. 3

- a cap box manufacturing apparatus in a schematic perspective,

- Fig. 4

- a section IV of the device according to

Fig. 3 on an enlarged scale, - Fig. 5

- the detail according to

Fig. 4 in transverse view or in the cross section of the plane VV ofFig. 4 . - Fig. 6

- the detail according to

Fig. 5 with altered presentation of details, - Fig. 7

- the detail according to

Fig. 5 in the horizontal section of the plane VII-VII, - Figure 8

- a representation of the detail according to

Fig. 5, Fig. 6 with continued work procedure, - Fig. 9

- the detail according to

Fig. 8 in transverse view or in a transverse section, - Fig. 10

- the device according to

Fig. 9 in horizontal section in the section plane XX, - Fig. 11

- a representation of the detail according to

Fig. 9 when transferring a frame to a floor part, - Fig. 12

- the device according to

Fig. 8 after transfer of a frame to a bottom part, - Fig. 13

- the device according to

Fig. 11 in horizontal sectional plane XIII-XIII.

Die herzustellende Zigarettenpackung des Typs Kappenschachtel besteht aus einem Bodenteil 10 und einem Deckelteil 11. Das Bodenteil 10 bildet eine Bodenwand 12 und mit dieser verbundene (aufrechte) Boden-Seitenwände 13 einerseits und 14 andererseits. Die Boden-Seitenwände (13, 14) sind schwenkbar mit der Bodenwand (12) verbunden. Zur Komplettierung werden die Boden-Seitenwände (13, 14) aufgerichtet und in dieser Position stabilisiert.The produced cigarette packet of the cap box type consists of a

In analoger Weise ist das Deckelteil 11 ausgebildet mit Deckelwand 15 und Deckel-Seitenwänden 16.In an analogous manner, the

Zur Komplettierung der Packung ist im Bodenteil 10 eine Schulter bzw. ein ringerherum laufender Rahmen 17 angeordnet. Dieser besteht aus jeweils einander gegenüberliegenden Rahmenabschnitten 18, 19. Der geschlossene Rahmen 17 wird passend in das Bodenteil 10 eingesetzt und durch Klebung mit den (aufgerichteten) Boden-Seitenwänden (13, 14) verbunden. Diese werden so in der packungsgemäßen Position fixiert. Vorliegend ist der Rahmen 17 an der Außenseite ringsherum mit Leim versehen bzw. mit einem durchgehenden Leimstreifen 20, der die Verbindung mit der Innenseite der Boden-Seitenwände 13, 14 herstellt. Der Rahmen 17 besteht vorzugsweise aus einem langgestreckten, gefalteten Streifen, dessen Enden im Bereich einer Rahmenecke durch eine Lasche 21 miteinander verbunden sind.To complete the pack a shoulder or a ringer-around

Zur Verbindung von Bodenteil 10 und Deckelteil 11 wird die Einheit aus Bodenteil 10, Deckelteil 11 und Rahmen 17 von einem Außeneinschlag 22 vorzugsweise vollständig umgeben. Dieser aus Papier oder dergleichen bestehende Zuschnitt wird durch (vollflächige) Klebung mit den freien Außenseiten von Bodenteil 10 und Deckel 11 verbunden.To connect the

Eine im Aufbau kompakte, leistungsfähige Fertigungsanlage ist schematisch in

Die im Prinzip fertiggestellte Packung wird sodann einem Umhüllungsaggregat 27 übergeben zur Anbringung des Außeneinschlags 22 an den Packungen. Das Aggregat 27 besteht aus Organen zur Anbringung der Außenzuschnitte 22 an den Packungen, insbesondere durch Auflegen auf die Deckelwand 15 mittels Übertragungswalzen 28. Diesen sind Zuschnittmagazine 29 für die Außenzuschnitte 22 zugeordnet mit Vereinzelungsorganen 30 und Leimaggregaten 31 zum Aufbringen von Leim auf die Zuschnitte 22. Danach werden die Packungen mit Außeneinschlag 22 einer Faltstation 32 zugeführt, in der der Außeneinschlag 22 fertiggestellt wird, sodass eine Kappenschachtel in der Ausführung gemäß

Die Fertigungseinrichtung ist so ausgebildet, dass die einzelnen Falt- und Arbeitsschritte für mehrere Packungen zeitgleich im Bereich von mehreren, vorzugsweise von drei parallelen Fertigungsbahnen vollzogen werden. Die Bearbeitungsaggregate, nämlich insbesondere Falt- und Förderorgane, sind in entsprechender Anzahl nebeneinander angeordnet, bei umlaufenden Organen gleichachsig und synchron angetrieben. Es werden demnach bei jedem Arbeitstakt mehrere, insbesondere drei Packungen fertiggestellt. Das zu verarbeitende Material, nämlich Bodenteil 10, Deckelteil 11 und Rahmen 17, wird vorzugsweise in axialer bzw. achsparalleler Förderrichtung, also quer zu den (drei) Fertigungsbahnen, den jeweiligen Aggregaten in der taktgleich verarbeitenden Anzahl zugeführt.The manufacturing device is designed so that the individual folding and working steps for several packages are performed simultaneously in the range of several, preferably three parallel production lines. The processing units, namely in particular folding and conveying members are arranged in a corresponding number next to each other, driven coaxially and synchronously with rotating organs. Accordingly, several, in particular three, packages are completed at each power stroke. The material to be processed, namely

Die Vereinigungsstation 23 besteht aus zwei besonderen Einheiten, nämlich einem Rahmenaggregat 35 und einem Bodenaggregat 36. Das Rahmenaggregat 35 dient zur Vorbereitung der Rahmen 17 und zur Übergabe derselben an ein bereitgehaltenes Bodenteil 10, insbesondere durch Abwärtsbewegung des Rahmens 17. Das Bodenaggregat 36 dient zur Vorbereitung von Bodenteilen 10.The

Die Zuschnitte für das Bodenteil 10 werden einem Bodenmagazin 37 entnommen und - quer zur Richtung der Fertigungsbahnen - durch einen Bodenförderer 38 dem Bodenaggregat 36 zugefördert. Die durch ein Entnahmeorgan dem Bodenmagazin 37 entnommenen Zuschnitte des Bodenteils 10 werden (zuerst) einem Faltaggregat zugeführt. Dieses besteht im Wesentlichen aus einem Faltschacht 39 und einem Stempel 40. Durch Abwärtsbewegung des Stempels 40 wird der Zuschnitt (10) durch den entsprechend ausgebildeten Faltschacht 39 nach unten geschoben, wobei die Boden-Seitenwände 13, 14 aufgerichtet werden. Das so vorbereitete Bodenteil 10 wird auf dem Bodenförderer 38 abgelegt, nämlich zwischen passend angeordneten Mitnehmern 41 eines Gurtförderers. Die Mitnehmer 41 stabilisieren die quer zur Förderrichtung weisenden, aufgerichteten Boden-Seitenwände 13.The blanks for the

Die vorgefalteten Bodenteile 10 werden im Anschluss an den Bodenförderer 38 von einem vorzugsweise gleichartig ausgebildeten Übergabeförderer 42 übernommen und der Vereinigungsstation 23 zugeführt. Der Übergabeförderer 42 ist oberhalb der Wirkungsebene des Bodenförderers 38 angeordnet und erfasst demnach die Bodenteile 10 mit einem Untertrum.Following the

In der Vereinigungsstation 23 werden die Bodenteile 10 an einen Hauptförderer 44 übergeben, der ebenfalls als Gurtförderer ausgebildet ist und in exakten Abständen voneinander angeordnete Mitnehmer 41 aufweist. Der Hauptförderer 44 erstreckt sich in Richtung der Fertigungsbahnen für die Packungen. Vorliegend ist eine entsprechende Anzahl (drei) von Hauptförderern 44 parallel nebeneinander angeordnet, jeweils mit der gleichen Anzahl von übereinstimmenden und synchron arbeitenden Aggregaten.In the

Das Bodenteil 10 wird in der Vereinigungsstation 23 vom Förderer 42 abgenommen und insbesondere durch Abwärtsbewegung an den Hauptförderer 44 übertragen. In der Vereinigungsstation 23 sind auf- und abbewegbare Stempel 45 wirksam, die mit langgestreckten Druckstegen durch Abwärtsbewegung die Bodenwand 12 des Bodenteils 10 jeweils zu beiden Seiten des Gurts des Übergabeförderers 42 erfassen, durch Abwärtsbewegung vom Übergabeförderer 42 abnehmen und an den Hauptförderer 44 übergeben. Der Hauptförderer 44 transportiert die vorbereiteten Bodenteile 10 in den Bereich des Rahmenaggregats 35.The

Die Rahmen 17 werden gesondert und unabhängig von den Bodenteilen 10 der Vereinigungsstation 23 bzw. dem Rahmenaggregat 35 zugeführt. Die Bewegungen sind aufeinander abgestimmt.The

Die geschlossenen Rahmen 17 werden zusammengefaltet, also flachliegend, durch einen Rahmenförderer, nämlich einen Rahmengurt 46, dem Aggregat 35 zugeführt. Der Förderer 46 besteht vorzugsweise aus einem Einzelgurt, der in horizontaler Ebene umläuft mit aufrechter Gurtstellung und entsprechend angeordneten Mitnehmern 47. Diese fördern jeweils einen ebenfalls in aufrechter Ebene positionierten Rahmen 17 in den Bereich des Aggregats 35. Dem Förderer 46 ist eine schematisch gezeigte Beleimungsstation 47 vorgeordnet, in deren Bereich Leim auf die flach zusammengelegten Rahmen 17 außen aufgebracht wird, nämlich insbesondere der Leimstreifen 20.The

Teil der Förderstrecke für den (beleimten) Rahmen 17 sind feststehende Führungsschienen 48 zu beiden Seiten der Bewegungsbahn der Rahmen 17. Die Führungsschienen 48 sind so angeordnet bzw. bemessen, dass sie sich außerhalb bzw. oberhalb des Bereichs der Leimstreifen 20 befinden (

Der Antrieb des Rahmengurts 46 ist so gesteuert, dass ein Rahmen 17 im Bereich des Rahmenaggregats 35 in horizontaler Ebene und ausgerichtet auf ein Bodenteil 10 in einer nach unten versetzten Ebene bereitgehalten wird (

Für die weitere Bearbeitung wird der Rahmen 17 aus der Zuförderebene (

In der Aufrichtebene des Rahmens 17 (

In der - vorliegend durch die Anschlagplatte 52 definierten - Verformungsebene für den Rahmen 17 werden Formgebungsorgane wirksam. Zum Aufrichten bzw. Auffalten des Rahmens 17 in die funktionsgerechte, dreidimensionale Struktur werden Aufrichtorgane wirksam, die zwei einander gegenüberliegende Rahmenabschnitte erfassen und auseinanderziehen, vorliegend die längeren Rahmenabschnitte 18. Diese werden jeweils an der Außenseite durch bewegbare Faltorgane erfasst und durch entsprechende Bewegung in eine Stellung mit Abstand voneinander gezogen, wodurch der Rahmen 17 in die viereckige Kontur bewegt wird. Bei diesen Faltorganen handelt es sich vorzugsweise um Saugköpfe 54, die an den Rahmenabschnitten 18 an deren Außenseite angreifen. Durch Saugluft werden die betreffenden Abschnitte 18 an den Saugköpfen 54 gehalten. Diese werden von einer Aufnahmestellung (

Jeder Saugkopf 54 ist als langgestrecktes, stegartiges Saugorgan ausgebildet mit einer Mehrzahl von nebeneinander - in Reihe - liegenden Saugbohrungen 55. Diese sind über Verbindungskanäle und Anschlusskanäle mit einer Unterdruckquelle verbunden. Durch den so ausgebildeten Saugkopf 54 wird der betreffende Rahmenabschnitt 18 auf einer größeren, vorzugsweise mittigen Länge erfasst und gehalten.Each

Die Saugköpfe 54 sind - vorzugsweise als einseitig abstehender Steg - mit einem Halte- und Betätigungsorgan verbunden, vorliegend mit einer aufrechten Tragstange 56. Diese ist mit einem (nicht dargestellten) Drehantrieb verbunden. Durch Drehen der aufrechten Tragstange 56 wird eine Schwenkbewegung des Saugkopfes 54 bewirkt, und zwar aus einer Aufnahmestellung (strichpunktiert in

Beim Aufrichten des Rahmens 17 in die packungsgemäße Gestalt findet eine Verformung des Rahmens 17 statt, derart, dass die Außenkonturen kleiner sind als die entsprechenden Abmessungen des Bodenteils 10. Der (verformte) Rahmen 17 kann so zwängungsfrei in das Bodenteil 10 eingeführt werden.When erecting the

Die Verformung besteht vorliegend darin, dass die freien Rahmenabschnitte 19 nach innen verformt werden, also eine nach innen geformte bogenförmige Struktur erhalten (

Die vorgenannte Verformung wird durch Formstücke bewirkt, die an der Außenseite der Rahmenabschnitte 19 wirksam sind, insbesondere durch (aufrechte) Anschlagbolzen 57 an beiden (Außen-)Seiten des Rahmens 17 bzw. der Abschnitte 19. Die Wirkung der Anschlagbolzen 57 ist vorzugsweise derart, dass bei der Öffnungs- bzw. Faltbewegung des Rahmens 17 durch die Wirkung der Saugköpfe 54 die Rahmenabschnitte 19 gegen die - nach innen versetzten - Anschlagbolzen 57 gedrückt werden, sodass bis zum Erreichen der Endstellung gemäß

Die Anschlagbolzen 57 sind mit dem Rahmen 17 abwärts bewegbar in eine untere Stellung zur Übergabe des (verformten) Rahmens 17 an das Bodenteil 10 (

Die Anschlagbolzen 57 sind an einem gemeinsamen, auf- und abbewegbaren Träger angeordnet, vorzugsweise an einem rahmenförmigen Hubträger 58. Dieser ist an einer gemeinsamen Hubstange 59 unterhalb der Bewegungsbahn des Bodenteils 10 angebracht. Vorzugsweise besteht der Hubträger 58 aus zwei seitlichen, bügelartigen Tragarmen 60, jeweils mit einem horizontalen Tragschenkel 61, an dessen Unterseite jeweils ein (nach unten gerichteter) Anschlagbolzen 57 angebracht ist.The stop pins 57 are arranged on a common, up and down movable support, preferably on a frame-shaped

Die Abwärtsbewegung des Rahmens 17, vorzugsweise in der Kontur gemäß

Bei der Aufwärtsbewegung der Anschlagbolzen 57 wird sichergestellt, dass der Rahmen 17 in der Position im Bodenteil 10 gehalten wird. Zu diesem Zweck werden bewegbare Anschlagstücke 62 in eine Halteposition unter Anlage an einer oberen, freien Kante des Rahmens 17 bewegt (

Die in dem Rahmenaggregat 35 gebildeten Einheiten 24 aus Bodenteil 10 und Rahmen 17 können in diesem Bereich durch Aneinanderdrücken von Rahmenabschnitten 18, 19 und zugeordneten Boden-Seitenwände 13, 14 fertiggestellt werden. Bei dem vorliegenden Ausführungsbeispiel befinden sich die Boden-Seitenwände 13, 14 während dieser Phase in einer Schrägstellung (

Die Einheiten 24 werden nachfolgend - nach Verlassen des Hauptförderers 44 - komplettiert durch Andrücken der Boden-Seitenwände 13, 14 an die Rahmenabschnitte 18, 19, und zwar insbesondere in dem Fixierrevolver 25.The

Eine innovative Besonderheit ist das Rahmenaggregat 35 mit den (Saug-)Organen zum Aufrichten des Rahmens 17 durch Erfassen der Rahmenabschnitte 18 an deren Außenseite.

Claims (15)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102016011458.4A DE102016011458A1 (en) | 2016-09-23 | 2016-09-23 | Method and device for producing cap boxes |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3299159A1 true EP3299159A1 (en) | 2018-03-28 |

| EP3299159B1 EP3299159B1 (en) | 2020-01-08 |

Family

ID=59914247

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP17001522.6A Active EP3299159B1 (en) | 2016-09-23 | 2017-09-12 | Method and device for producing shoulder boxes |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP3299159B1 (en) |

| CN (1) | CN107867011B (en) |

| DE (1) | DE102016011458A1 (en) |

| ZA (1) | ZA201706344B (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3599088A2 (en) | 2018-07-25 | 2020-01-29 | Focke & Co. (GmbH & Co. KG) | Method and device for handling blanks made of packaging material |

| CN111267401A (en) * | 2020-04-13 | 2020-06-12 | 广东壮丽彩印股份有限公司 | Outer box forming production line of pull cigarette case |

| CN111346782A (en) * | 2018-12-20 | 2020-06-30 | 广东高堡实业有限公司 | Paste feeding machine |

| CN118544636A (en) * | 2024-06-06 | 2024-08-27 | 江苏天之泽生态科技有限公司 | Automatic conveying device for cutlery box |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108750177B (en) * | 2018-05-25 | 2020-05-05 | 广东恒信源智能装备有限公司 | Cigarette boxing machine |

| CN110561830B (en) * | 2018-06-11 | 2024-01-02 | 枣阳徳立智机械制造有限公司 | Automatic assembling equipment for barrel bottom of paperboard barrel |

| DE102021124939A1 (en) | 2021-09-27 | 2023-03-30 | Focke & Co. (Gmbh & Co. Kg) | Method and apparatus for feeding a group of cigarette industry products as pack contents to a blank for a pack of cigarette industry products |

| CN114347558B (en) * | 2022-01-10 | 2024-06-04 | 中科天工(广东)智能技术有限公司 | Surrounding strip assembling process |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE568652C (en) * | 1928-04-26 | 1933-01-24 | Muller J C & Co | Method and device for inserting necks into shell parts |

| DE591742C (en) * | 1931-06-09 | 1934-02-08 | Richard Krautwald Fa | Device for the production of boxes, in particular neck boxes |

| DE657061C (en) * | 1935-08-18 | 1938-02-24 | Jagenberg Werke Ag | Device for inserting the neck into the bottom part of the box |

| GB838385A (en) * | 1958-08-14 | 1960-06-22 | Liesbeth Schwarz | Improvements in shoulder box machinery |

| US5938018A (en) | 1997-04-15 | 1999-08-17 | Rothmans, Benson & Hedges Inc. | Cigarette or tobacco package with re-usable aroma releasant for multiple package openings |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE526234C (en) | 1929-05-30 | 1931-06-04 | Jagenberg Werke Ag | Method and device for the production of box parts with neck inserts |

| DE613792C (en) | 1932-05-15 | 1935-05-27 | Jagenberg Werke Ag | Method and device for attaching the neck in the base of neck boxes |

| DE692179C (en) | 1936-11-18 | 1940-07-02 | Muller J C & Co | Device for opening and inserting box handles into box parts |

| DE102006024559A1 (en) * | 2006-05-23 | 2007-11-29 | Focke & Co.(Gmbh & Co. Kg) | Method and device for producing cigarette packets |

| ITBO20070300A1 (en) * | 2007-04-23 | 2008-10-24 | Gd Spa | PACKAGING MACHINE AND WRAPPING METHOD FOR THE PRODUCTION OF CIGARETTE PACKAGES WITH SLIDING OPENING. |

-

2016

- 2016-09-23 DE DE102016011458.4A patent/DE102016011458A1/en not_active Withdrawn

-

2017

- 2017-09-12 EP EP17001522.6A patent/EP3299159B1/en active Active

- 2017-09-20 ZA ZA201706344A patent/ZA201706344B/en unknown

- 2017-09-22 CN CN201710862507.1A patent/CN107867011B/en active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE568652C (en) * | 1928-04-26 | 1933-01-24 | Muller J C & Co | Method and device for inserting necks into shell parts |

| DE591742C (en) * | 1931-06-09 | 1934-02-08 | Richard Krautwald Fa | Device for the production of boxes, in particular neck boxes |

| DE657061C (en) * | 1935-08-18 | 1938-02-24 | Jagenberg Werke Ag | Device for inserting the neck into the bottom part of the box |

| GB838385A (en) * | 1958-08-14 | 1960-06-22 | Liesbeth Schwarz | Improvements in shoulder box machinery |

| US5938018A (en) | 1997-04-15 | 1999-08-17 | Rothmans, Benson & Hedges Inc. | Cigarette or tobacco package with re-usable aroma releasant for multiple package openings |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3599088A2 (en) | 2018-07-25 | 2020-01-29 | Focke & Co. (GmbH & Co. KG) | Method and device for handling blanks made of packaging material |

| DE102018005838A1 (en) * | 2018-07-25 | 2020-01-30 | Focke & Co. (Gmbh & Co. Kg) | Method and device for handling blanks from packaging material |

| CN111346782A (en) * | 2018-12-20 | 2020-06-30 | 广东高堡实业有限公司 | Paste feeding machine |

| CN111267401A (en) * | 2020-04-13 | 2020-06-12 | 广东壮丽彩印股份有限公司 | Outer box forming production line of pull cigarette case |

| CN118544636A (en) * | 2024-06-06 | 2024-08-27 | 江苏天之泽生态科技有限公司 | Automatic conveying device for cutlery box |

Also Published As

| Publication number | Publication date |

|---|---|

| CN107867011B (en) | 2020-11-13 |

| ZA201706344B (en) | 2019-11-27 |

| DE102016011458A1 (en) | 2018-03-29 |

| CN107867011A (en) | 2018-04-03 |

| EP3299159B1 (en) | 2020-01-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3299159A1 (en) | Method and device for producing shoulder boxes | |

| DE3522614C2 (en) | ||

| DE68907622T2 (en) | Method and machine for the production of polygonal boxes from sheet material and box made therefrom. | |

| EP0925173B1 (en) | Folding machine and process for automatic folding of a folding box | |

| EP3169592B1 (en) | Method and apparatus for producing packages, especially packages for cigarettes | |

| EP2377764B1 (en) | Carton folding device and method for folding a carton | |

| EP3003870B1 (en) | Method and device for producing packs, especially cigarette packs | |

| EP3299158B1 (en) | Method and device for producing shoulder boxes | |

| EP2819924B1 (en) | Device and method for reducing restoring forces of packaging sleeves in a filling machine | |

| DE10359310A1 (en) | Apparatus and method for producing container packaging | |

| EP0113899A2 (en) | Method and device for closing boxes | |

| DE4027395C2 (en) | ||

| EP2647576B2 (en) | Apparatus and method for producing cigarette packets | |

| DE19904443A1 (en) | Method and device for feeding package blanks | |

| DE2645095A1 (en) | MACHINE FOR THE MAKING OF BOXES FROM SEMI-SHAPED CUTTINGS | |

| DE4209141C2 (en) | Device for the production of packaging, in particular cardboard boxes, from flat blanks | |

| DE102015010493A1 (en) | Method and device for producing (cigarette) packs of the cap box type | |

| EP3476752A1 (en) | Device and method for manufacturing cigarette packages | |

| DE2228396C3 (en) | Machine for the production of drawn cardboard packaging | |

| DE4105973A1 (en) | Object positioner in storage and transport container - uses flat blank with middle plane as object receptacle aperture with peripheral edges, and holding lugs | |

| DE3417154C2 (en) | ||

| DE29512459U1 (en) | Device for producing a box from a blank | |

| DE2731900A1 (en) | DEVICE AND METHOD OF PACKING UNITS IN CONTAINERS | |

| DE2612458A1 (en) | Box erection and packing system - applies glue strips to ribbed cardboard sheets which are held stationary prior to sidewall formation | |

| DE2940796A1 (en) | MACHINE FOR COVERING BOXES WITH A CARDBOARD OR FILM CUT |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20180508 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20190121 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B31B 50/80 20170101AFI20190712BHEP Ipc: B31B 120/50 20170101ALN20190712BHEP Ipc: B31B 50/81 20170101ALI20190712BHEP Ipc: B31B 110/35 20170101ALN20190712BHEP Ipc: B31B 105/00 20170101ALN20190712BHEP Ipc: B31B 120/10 20170101ALN20190712BHEP Ipc: B31B 50/04 20170101ALI20190712BHEP Ipc: B31B 50/62 20170101ALN20190712BHEP Ipc: B31B 120/30 20170101ALN20190712BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20190909 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: STORCKS, ANDREAS Inventor name: VUJEVIC, ALEKSANDAR Inventor name: ALBRECHT, PETER |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502017003398 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1222172 Country of ref document: AT Kind code of ref document: T Effective date: 20200215 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20200108 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200531 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200508 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200409 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502017003398 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20201009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20200930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200912 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200930 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200912 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200930 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200930 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20210912 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200108 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210912 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230517 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20230810 Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 1222172 Country of ref document: AT Kind code of ref document: T Effective date: 20220912 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220912 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240828 Year of fee payment: 8 |