EP3130809B1 - Optimized efficiency actuating unit of the articulated lever type - Google Patents

Optimized efficiency actuating unit of the articulated lever type Download PDFInfo

- Publication number

- EP3130809B1 EP3130809B1 EP16182930.4A EP16182930A EP3130809B1 EP 3130809 B1 EP3130809 B1 EP 3130809B1 EP 16182930 A EP16182930 A EP 16182930A EP 3130809 B1 EP3130809 B1 EP 3130809B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- equal

- clamping

- rod

- pneumatic cylinder

- bar

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B15/00—Fluid-actuated devices for displacing a member from one position to another; Gearing associated therewith

- F15B15/02—Mechanical layout characterised by the means for converting the movement of the fluid-actuated element into movement of the finally-operated member

- F15B15/06—Mechanical layout characterised by the means for converting the movement of the fluid-actuated element into movement of the finally-operated member for mechanically converting rectilinear movement into non- rectilinear movement

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25B—TOOLS OR BENCH DEVICES NOT OTHERWISE PROVIDED FOR, FOR FASTENING, CONNECTING, DISENGAGING OR HOLDING

- B25B5/00—Clamps

- B25B5/06—Arrangements for positively actuating jaws

- B25B5/12—Arrangements for positively actuating jaws using toggle links

- B25B5/122—Arrangements for positively actuating jaws using toggle links with fluid drive

Definitions

- the present invention relates to an articulated lever actuation unit with optimized efficiency.

- the present invention relates to an actuation unit of the above optimized efficiency type in terms of energy consumption and overall dimensions.

- Articulated lever actuation units such as locking unit and pivot units, are typically used for handling and/or clamping elements during sheet metal processing.

- clamping units for keeping the metal sheets into position during mechanical processes (such as welding, crimping or other technique for joining metal sheets).

- clamping units comprise a closing device able to cause the rotation of a clamping arm, connected to such a closing device, up to an exact operating angular position of closure and, once achieved, keep it in such a position, triggering an irreversibility mechanism able to guarantee the position even in the absence of control (for example, in the absence of air in the case of pneumatic control).

- the stroke of the closing device which generally corresponds to a rotation of 135° of the clamping arm, is usually controlled through a pneumatic or electrical actuation, depending on the specific embodiment.

- the closing device comprises a piston which acts on a toggle mechanism to which the clamping arm is in turn constrained.

- the toggle mechanism consists of a connecting rod and a crank rod, where the connecting rod is pivoted at the ends thereof to the piston rod and to the crank rod, respectively, and the crank rod sets the clamping arm in rotation.

- the connecting rod and the crank rod are typically made of multiple parts or as a single part, for example by means of a fork.

- pneumatic actuation of the piston feeding of pressurized fluid, usually compressed air, is required for generating the thrust force required.

- pressurized fluid usually compressed air

- the generation of compressed air has a very low yield, typically less than 3%.

- pneumatic actuations are generally characterized by high losses which lead to an increase in the consumption of compressed air, in addition to that strictly necessary for control. This source of energy is therefore particularly inefficient and expensive.

- Actuation units designed to optimize air consumption are known in the art. They use complex pneumatic circuits that allow a partial air recovery. In this way, keeping the other features of the actuation unit unchanged, the pneumatic cylinder is able to operate and produce the same thrust force on the piston through a reduced supply of compressed air.

- An example of a clamping unit that uses such a solution is described in patent EP 2016290 .

- actuation units available on the market are made according to predetermined and by the industrial standards specifically defined "models" in terms of both clamping moment and actuation, which in the specific case of pneumatic actuation translates into "sizes" of the actuation cylinders.

- a known model of clamping unit currently widespread on the market is actuated by means of a ⁇ 50 mm pneumatic cylinder, offering a clamping moment of a value comprised between 180 N m and 230 N m.

- a further widespread model of clamping unit is actuated by means of a ⁇ 63 mm pneumatic cylinder, offering a clamping moment of a value comprised between 375 N m and 425 N m.

- Such pneumatic cylinders when supplied at a pressure of 5 bar, generate a thrust force equal to 981.75 N and 1558.62 N, respectively, consuming a volume of compressed air at each cycle substantially proportional to the respective thrust force.

- the Applicant has therefore identified a need to operate the articulated lever actuation unit through a lower thrust force, while keeping the clamping moment and the overall dimensions substantially unchanged in order to satisfy the industrial standards of the field.

- k is calculated with respect to a position of the pivotable arm other than the closed position and has to be considered invariable with respect to the plurality of physical characteristics which determine the geometry of the actuating unit defined by the industrial standards since, in turn, these physical characteristics are considered to be predefined by the standards.

- Such factor k has furthermore to be considered substantially invariable also with respect to the first rod length BA (also known as connecting rod) which just negligibly contributes to the generation of clamping moment at the output, by substantially working along the horizontal.

- the Applicant has first noted that, in order to keep the clamping moment unchanged while reducing the thrust force P exerted on the piston by the (either pneumatic or electric) actuator to achieve energy saving, the length of the second rod needs to be increased.

- the Applicant has, in fact, found that, near to such condition, such a proportionality factor is strongly influenced by the energy typically dissipated by the system, releasing the thrust force exerted on the articulated lever mechanism on contrast elements.

- the contrast elements for example are the walls of the body against which the articulated lever mechanism rests during the movement caused by the translation of the piston rod, rather than the rods (connecting rod and crank) themselves. These elements are able, by deforming, to absorb part of the thrust force exerted on the same.

- the Applicant has found that, advantageously, the dissipation incurred by the system is considerably lower in proportion for lower thrust forces, thereby allowing a same clamping moment to be obtained with crank lengths well lower than those theoretically calculated. This at the same time allows a considerable energy saving to be obtained while keeping the current overall dimensions unchanged.

- the Applicant has unexpectedly found that the proportionality factor k that binds the clamping moment to the product between thrust force and length of the second lever is comprised between 6.8 and 10.0 for clamping moments comprised between 180 N m and 230 N m, allowing energy saving to be obtained while keeping the length of the second rod AO equal to or less than 32 mm and therefore not changing the current overall dimensions of the corresponding clamping units known to date, able to offer the same clamping moments.

- the Applicant has surprisingly found that the proportionality factor k that binds the clamping moment to the product between thrust force and length of the second lever is comprised between 8.0 and 12.2 for a clamping moment comprised between 375 N m and 425 N m, allowing energy saving to be obtained while keeping the length of the second rod AO equal to or less than 35.5 mm and therefore not changing the current overall dimensions of the corresponding clamping units known to date, able to offer the same clamping moments.

- the Applicant has surprisingly found that the proportionality factor k that binds the clamping moment to the product between thrust force and length of the second lever is comprised between 6.8 and 11.4 for a clamping moment comprised between 830 N m and 880 N m, allowing energy saving to be obtained while keeping the length of the second rod AO equal to or less than 56.5 mm and therefore not changing the current overall dimensions of the corresponding clamping units known to date, able to offer the same clamping moments.

- the Applicant has surprisingly found that the proportionality factor k that binds the clamping moment to the product between thrust force and length of the second lever is comprised between 8.0 and 13.8 for a clamping moment comprised between 115 N m and 145 N m, allowing energy saving to be obtained while keeping the length of the second rod AO equal to or less than 30.5 mm and therefore not changing the current overall dimensions of the corresponding clamping units known to date, able to offer the same clamping moments.

- the Applicant has surprisingly succeeded in obtaining articulated lever actuation units able to provide, for equal overall dimensions, same clamping moments with an optimization of the energy saving of up to about 46%.

- the optimization of the geometry of the articulated lever mechanism of the actuation unit with reference to the thrust force applied allows energy saving to be obtained also in the presence of an electric or combined pneumatic-manual or electric-manual actuation, it being possible to significantly reduce the thrust force required to generate the desired clamping moment without it being necessary to modify the current overall dimensions.

- an articulated lever actuation unit is shown according to the present invention, indicated overall with reference numeral 10, in particular a clamping unit.

- the clamping unit 10 comprises a body 11 within which a control piston 12 is arranged, comprising a rod 12a which can slide within body 11 along a sliding axis A.

- Rod 12a of piston 12 is connected to an articulated lever mechanism 13, specifically comprising a toggle mechanism consisting of a pair of rods 13a, 13b.

- a first rod 13a also called connecting rod, is pivoted at the ends thereof to the piston rod 12a and to the second rod 13b, called crank rod 13b, respectively.

- the crank rod 13b is rotatably connected to body 11 and, at the axis of revolution B thereof, it sets a clamping arm 14 in rotation.

- the control piston 12 is coupled to a pneumatic cylinder 15 able to exert a thrust force P on the control piston when supplied with compressed air.

- Figure 2 schematically shows the articulated lever mechanism 13 in a different configuration compared to the irreversibility condition shown in figure 1b .

- rod AO corresponds to the crank rod 13b

- rod AB corresponds to the connecting rod 13a

- the third rod schematizes rod 12a of piston 12.

- a known clamping unit was considered, characterized by the following parameters:

- a clamping unit was implemented characterized by the following parameters:

- the energy consumption of the clamping unit according to the embodiment of the present example in line with the invention therefore was 213.13 cm 3 , i.e. more than 30% lower than the consumption of the clamping unit of the prior art described in the comparative Example 1.

- crank rod it was sufficient to extend the crank rod by only 4 mm, obtaining the same torque equal to 186 N m with a pneumatic actuation carried out with a cylinder having section ⁇ equal to 40 mm.

- such an increase in length is not compatible with the requirement of keeping the overall dimensions of the starting clamping unit unchanged.

- a clamping unit was implemented characterized by the following parameters:

- the energy consumption of the clamping unit according to the embodiment of the present example in line with the invention therefore was 360.39 cm 3 , i.e. more than 32% lower than the consumption of the clamping unit of the prior art described in the comparative Example 2.

- crank rod it was sufficient to extend the crank rod by only 3.5 mm, obtaining the same torque equal to 390 N m with a pneumatic actuation carried out with a cylinder having section ⁇ equal to 50 mm.

- such an increase in length is not compatible with the requirement of keeping the overall dimensions of the starting clamping unit unchanged.

- a clamping unit was implemented characterized by the following parameters:

- the energy consumption of the clamping unit according to the embodiment of the present example in line with the invention therefore was 123.85 cm 3 , i.e. more than 30% lower than the consumption of the clamping unit of the prior art described in the comparative Example 3.

- such an increase in length is not compatible with the requirement of keeping the overall dimensions of the starting clamping unit unchanged.

- a clamping unit was implemented characterized by the following parameters:

- the energy consumption of the clamping unit according to the embodiment of the present example in line with the invention therefore was 902.13 cm 3 , i.e. more than 33% lower than the consumption of the clamping unit of the prior art described in the comparative Example 4.

- crank rod it was sufficient to extend the crank rod by only 5 mm, obtaining the same torque equal to 850 N m with a pneumatic actuation carried out with a cylinder having section ⁇ equal to 63 mm.

- the Applicant has also found that, in clamping units according to the industrial standards that provide an output clamping moment comprised between 375 N m and 425 N m, the length of the crank rod, amounting today to 31.5 mm, can be incremented by nevertheless remaining under or equal to 35.5 mm so as to keep the current overall dimensions unchanged.

- the Applicant has also found that, in clamping units according to the industrial standards that provide an output clamping moment comprised between 115 N m and 145 N m, the length of the crank rod, amounting today to 26 mm, can be incremented by nevertheless remaining under or equal to 30.5 mm so as to keep the current overall dimensions unchanged.

- the Applicant has also found that, in clamping units according to the industrial standards that provide an output clamping moment comprised between 830 N m and 880 N m, the length of the crank rod, amounting today to 50 mm, can be incremented by nevertheless remaining under or equal to 56.5 mm so as to keep the current overall dimensions unchanged.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- General Engineering & Computer Science (AREA)

- Jigs For Machine Tools (AREA)

- Transmission Devices (AREA)

Description

- The present invention relates to an articulated lever actuation unit with optimized efficiency. In particular, the present invention relates to an actuation unit of the above optimized efficiency type in terms of energy consumption and overall dimensions.

- Articulated lever actuation units, such as locking unit and pivot units, are typically used for handling and/or clamping elements during sheet metal processing. For example, within the scope of making motor vehicle bodies, it is known to use clamping units for keeping the metal sheets into position during mechanical processes (such as welding, crimping or other technique for joining metal sheets).

- Such mechanical processes require extremely accurate positioning of the elements to be machined and that such a positioning is kept over time. To this end, clamping units comprise a closing device able to cause the rotation of a clamping arm, connected to such a closing device, up to an exact operating angular position of closure and, once achieved, keep it in such a position, triggering an irreversibility mechanism able to guarantee the position even in the absence of control (for example, in the absence of air in the case of pneumatic control).

- The stroke of the closing device, which generally corresponds to a rotation of 135° of the clamping arm, is usually controlled through a pneumatic or electrical actuation, depending on the specific embodiment. In both cases, the closing device comprises a piston which acts on a toggle mechanism to which the clamping arm is in turn constrained. In particular, the toggle mechanism consists of a connecting rod and a crank rod, where the connecting rod is pivoted at the ends thereof to the piston rod and to the crank rod, respectively, and the crank rod sets the clamping arm in rotation. The connecting rod and the crank rod are typically made of multiple parts or as a single part, for example by means of a fork.

- In case of pneumatic actuation of the piston, feeding of pressurized fluid, usually compressed air, is required for generating the thrust force required. The generation of compressed air has a very low yield, typically less than 3%. Moreover, pneumatic actuations are generally characterized by high losses which lead to an increase in the consumption of compressed air, in addition to that strictly necessary for control. This source of energy is therefore particularly inefficient and expensive.

- Considering that normally, 3500 to 4000 clamping units plus about 60-80 pneumatic control pivot units are used in production lines of motor vehicle bodies, it goes without saying that in the field of articulated lever actuation units for use in such production lines there is a high interest in an optimization of the efficiency in terms of energy consumption, for example to reduce the amount of compressed air required for the actuation. Clearly, the optimization of energy consumption must be subject to the conditions dictated by the already existing production lines which require other operating parameters, such as the overall dimensions of the actuation units and the output clamping moment provided by the same, to be kept unchanged. Furthermore, these physical characteristics are determined by industrial standards and cannot be varied.

- Actuation units designed to optimize air consumption are known in the art. They use complex pneumatic circuits that allow a partial air recovery. In this way, keeping the other features of the actuation unit unchanged, the pneumatic cylinder is able to operate and produce the same thrust force on the piston through a reduced supply of compressed air. An example of a clamping unit that uses such a solution is described in patent

EP 2016290 . - The Applicant started from the observation that, to date, the actuation units available on the market are made according to predetermined and by the industrial standards specifically defined "models" in terms of both clamping moment and actuation, which in the specific case of pneumatic actuation translates into "sizes" of the actuation cylinders. For example, a known model of clamping unit currently widespread on the market is actuated by means of a Ø 50 mm pneumatic cylinder, offering a clamping moment of a value comprised between 180 N m and 230 N m. Likewise, a further widespread model of clamping unit is actuated by means of a Ø 63 mm pneumatic cylinder, offering a clamping moment of a value comprised between 375 N m and 425 N m. Such pneumatic cylinders, when supplied at a pressure of 5 bar, generate a thrust force equal to 981.75 N and 1558.62 N, respectively, consuming a volume of compressed air at each cycle substantially proportional to the respective thrust force.

- Analogously, another known model of clamping unit currently widespread on the market is actuated by means of a Ø 40 mm pneumatic cylinder, offering a clamping moment of a value comprised between 115 N m and 145 N m. Not least, a still further widespread model of clamping unit is actuated by means of a Ø 80 mm pneumatic cylinder, offering a clamping moment of a value comprised between 830 N m and 880 N m. Such pneumatic cylinders, when supplied at a pressure of 5 bar, generate a thrust force equal to 628,32 N and 2513,27 N, respectively, consuming a volume of compressed air at each cycle substantially proportional to the respective thrust force.

- In the present description and in the following claims, where reference is made to a pneumatic cylinder with "standardized size" it is meant a cylinder having features according to what defined in the international standard ISO 15552 - Pneumatic fluid power - Cylinders with detachable mountings as regards each specific size.

- In order to obtain energy saving, the Applicant has therefore identified a need to operate the articulated lever actuation unit through a lower thrust force, while keeping the clamping moment and the overall dimensions substantially unchanged in order to satisfy the industrial standards of the field.

- In the field of the articulated lever actuating units, such as clamping and pivot units for use in the automotive sector, there are indeed industrial standards which define the physical characteristics of such units based on the cylinder sizes. In detail, such industrial standards define the dimensions of the units in terms of volumes and position of the unit axis (which coincides with the axis along which the rod translates inside the unit) with respect to the rotating axis given at the output of the unit.

- In theoretical terms, torque M is defined by a relationship of direct proportionality with both the thrust force P and with the length of the second rod

AO (also known as crank) according to the following variability law (with respect to a configuration of the articulated lever system other than the closed position in which the system has reached the condition of irreversibility):

where k is calculated with respect to a position of the pivotable arm other than the closed position and has to be considered invariable with respect to the plurality of physical characteristics which determine the geometry of the actuating unit defined by the industrial standards since, in turn, these physical characteristics are considered to be predefined by the standards. Such factor k has furthermore to be considered substantially invariable also with respect to the first rod lengthBA (also known as connecting rod) which just negligibly contributes to the generation of clamping moment at the output, by substantially working along the horizontal. - Starting from this theoretical law, the Applicant has first noted that, in order to keep the clamping moment unchanged while reducing the thrust force P exerted on the piston by the (either pneumatic or electric) actuator to achieve energy saving, the length of the second rod needs to be increased.

- Applying this theoretical law, the Applicant has noted that in order to reduce the size of the pneumatic cylinders currently used in the known articulated lever actuation units to obtain a significant reduction of the thrust force exerted on the piston and a consequent energy saving, it is necessary to increase the crank length not compatible with the need of keeping the current overall dimensions substantially unchanged.

- Still according to the theoretical law of variability, the Applicant has also noted that reductions in the volume of the cylinder such as to result in an increase of the crank length compatible with keeping the overall dimensions unchanged would lead to a negligible energy saving, in particular well below 10%.

- The Applicant has surprisingly found that, contrary to what the theoretical laws lead to conclude, the relation between torque, thrust force and length of the second rod is not bound by a constant proportionality factor but conversely, such a proportionality factor varies as a function of the thrust force exerted. Such different relation between torque, thrust force and length of the second rod particularly applies when the articulated lever system is approaching or has substantially reached its irreversibility condition.

- The Applicant has, in fact, found that, near to such condition, such a proportionality factor is strongly influenced by the energy typically dissipated by the system, releasing the thrust force exerted on the articulated lever mechanism on contrast elements. The contrast elements for example are the walls of the body against which the articulated lever mechanism rests during the movement caused by the translation of the piston rod, rather than the rods (connecting rod and crank) themselves. These elements are able, by deforming, to absorb part of the thrust force exerted on the same.

- The Applicant has found that, advantageously, the dissipation incurred by the system is considerably lower in proportion for lower thrust forces, thereby allowing a same clamping moment to be obtained with crank lengths well lower than those theoretically calculated. This at the same time allows a considerable energy saving to be obtained while keeping the current overall dimensions unchanged.

- Specifically, the Applicant has unexpectedly found that the proportionality factor k that binds the clamping moment to the product between thrust force and length of the second lever is comprised between 6.8 and 10.0 for clamping moments comprised between 180 N m and 230 N m, allowing energy saving to be obtained while keeping the length of the second rod

AO equal to or less than 32 mm and therefore not changing the current overall dimensions of the corresponding clamping units known to date, able to offer the same clamping moments. - Likewise, the Applicant has surprisingly found that the proportionality factor k that binds the clamping moment to the product between thrust force and length of the second lever is comprised between 8.0 and 12.2 for a clamping moment comprised between 375 N m and 425 N m, allowing energy saving to be obtained while keeping the length of the second rod

AO equal to or less than 35.5 mm and therefore not changing the current overall dimensions of the corresponding clamping units known to date, able to offer the same clamping moments. - Similarly, the Applicant has surprisingly found that the proportionality factor k that binds the clamping moment to the product between thrust force and length of the second lever is comprised between 6.8 and 11.4 for a clamping moment comprised between 830 N m and 880 N m, allowing energy saving to be obtained while keeping the length of the second rod

AO equal to or less than 56.5 mm and therefore not changing the current overall dimensions of the corresponding clamping units known to date, able to offer the same clamping moments. - Again, the Applicant has surprisingly found that the proportionality factor k that binds the clamping moment to the product between thrust force and length of the second lever is comprised between 8.0 and 13.8 for a clamping moment comprised between 115 N m and 145 N m, allowing energy saving to be obtained while keeping the length of the second rod

AO equal to or less than 30.5 mm and therefore not changing the current overall dimensions of the corresponding clamping units known to date, able to offer the same clamping moments. - By selecting the crank length and the thrust force according to the above parameters, the Applicant has surprisingly succeeded in obtaining articulated lever actuation units able to provide, for equal overall dimensions, same clamping moments with an optimization of the energy saving of up to about 46%.

- Moreover, the optimization of the geometry of the articulated lever mechanism of the actuation unit with reference to the thrust force applied, in accordance with the parameters defined above, allows energy saving to be obtained also in the presence of an electric or combined pneumatic-manual or electric-manual actuation, it being possible to significantly reduce the thrust force required to generate the desired clamping moment without it being necessary to modify the current overall dimensions.

- Last but not least, the possibility of using cylinders of a smaller size also positively affects the sizing of the valves and of the fittings of the pneumatic circuit, allowing an additional cost saving to be obtained.

- Preferred embodiments of the present invention are defined in the dependent claims.

- Further features and advantages of the present invention will appear more clearly from the following detailed description of some preferred embodiments thereof, made with reference to the accompanying drawings.

- The different features in the single configurations may be combined with one another as desired according to the description above, to make use of the advantages resulting in a specific way from a particular combination.

- In such drawings,

-

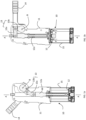

figures 1a and 1b are schematic side sectional views of a clamping unit according to the present invention in the non-operating open position and in the operating closed position, respectively. -

figure 2 is a schematic representation of an articulated lever mechanism included in an actuation unit according to the present invention in a configuration other than the irreversibility condition. - With reference to

figures 1a and 1b , an articulated lever actuation unit is shown according to the present invention, indicated overall withreference numeral 10, in particular a clamping unit. - The

clamping unit 10 comprises abody 11 within which acontrol piston 12 is arranged, comprising arod 12a which can slide withinbody 11 along a sliding axis A. -

Rod 12a ofpiston 12 is connected to an articulatedlever mechanism 13, specifically comprising a toggle mechanism consisting of a pair ofrods first rod 13a, also called connecting rod, is pivoted at the ends thereof to thepiston rod 12a and to thesecond rod 13b, calledcrank rod 13b, respectively. Thecrank rod 13b is rotatably connected tobody 11 and, at the axis of revolution B thereof, it sets aclamping arm 14 in rotation. - The

control piston 12 is coupled to apneumatic cylinder 15 able to exert a thrust force P on the control piston when supplied with compressed air. -

Figure 2 schematically shows the articulatedlever mechanism 13 in a different configuration compared to the irreversibility condition shown infigure 1b . In particular, rod AO corresponds to the crankrod 13b, rod AB corresponds to the connectingrod 13a and the third rod schematizesrod 12a ofpiston 12. -

-

- The following is a comparative example to illustrate the present invention. The scope of protection defined by the appended claims, however, is not to be considered limited only to the specific example.

- A known clamping unit was considered, characterized by the following parameters:

- length of the crank arm equal to 28 mm;

- piston stroke equal to 78 mm;

- size of the pneumatic cylinder equal to Ø 50 mm operated at 5 bar; and

- output clamping moment equal to 186 N m.

- It was measured that such a clamping unit requires an air consumption equal to about 306.31 cm3 for each cycle defined as a forward and backward stroke of the cylinder.

- In particular, the cylinder having section Ø equal to 50 mm, when operated with compressed air at 5 bar, generates a thrust force P equal to about 981.75 N. From the proportionality relation discussed above it is therefore inferred that the proportionality constant of such a clamping unit is about k = 6.77.

- Theoretically, this means that, in order to scale the size of the cylinder, using one having section Ø equal to 40 mm, therefore able to develop a thrust force at 5 bar equal to about P = 628.32 N, it would be necessary to bring the length of the crank rod to about AO = 44 mm. However, such an increase in length is not compatible with the requirement of keeping the overall dimensions of the starting clamping unit unchanged.

- According to the present invention, a clamping unit was implemented characterized by the following parameters:

- length of the crank arm equal to 32 mm;

- piston stroke equal to 84.8 mm;

- size of the pneumatic cylinder equal to Ø 40 mm operated at 5 bar,

- In particular, the increase in the piston stroke was selected based on the fact that it is proportional to the increase in the length of the crank rod according to the following law Δcorsa = Δ

AO ∗ (1 + sin 45°), applicable in the operating range of the device suitable for ensuring an opening angle equal to 135° (opening angle characteristic of the applications on production lines of motor vehicle bodies). - The energy consumption of the clamping unit according to the embodiment of the present example in line with the invention therefore was 213.13 cm3, i.e. more than 30% lower than the consumption of the clamping unit of the prior art described in the comparative Example 1.

- In practice, it was sufficient to extend the crank rod by only 4 mm, obtaining the same torque equal to 186 N m with a pneumatic actuation carried out with a cylinder having section Ø equal to 40 mm.

- Such a configuration led to a reduced energy dissipation and therefore to an increase in the proportionality constant. Specifically, in the configuration described, the proportionality constant surprisingly reached a value of about k = 9.25.

- With a known clamping unit, characterized by the following parameters:

- length of the crank arm equal to 31.5 mm;

- piston stroke equal to 85.8 mm;

- size of the pneumatic cylinder equal to Ø 63 mm operated at 5 bar; and

- output clamping moment equal to 390 N m.

- It was measured that such a clamping unit requires an air consumption equal to about 534.92 cm3 for each cycle defined as a forward and backward stroke of the cylinder.

- In particular, the cylinder having section Ø equal to 63 mm, when operated with compressed air at 5 bar, generates a thrust force P equal to about 1558.62 N. From the proportionality relation discussed above it is therefore inferred that the proportionality constant of such a clamping unit is about k = 7.94.

- Theoretically, this for example means that, in order to scale the size of the cylinder, using one having section Ø equal to 50 mm, therefore able to develop a thrust force at 5 bar equal to about P = 981.75 N, it would be necessary to bring the length of the crank rod to about AO = 50 mm. However, such an increase in length is not compatible with the requirement of keeping the overall dimensions of the starting clamping unit unchanged.

- According to the present invention, a clamping unit was implemented characterized by the following parameters:

- length of the crank arm equal to 35 mm;

- piston stroke equal to 91.77 mm;

- size of the pneumatic cylinder equal to Ø 50 mm operated at 5 bar,

- In particular, the increase in the piston stroke was selected based on the fact that it is proportional to the increase in the length of the crank rod according to the following law Δcorsa = Δ

AO ∗ (1 + sin 45°), applicable in the operating range of the device suitable for ensuring an opening angle equal to 135° (opening angle characteristic of the applications on production lines of motor vehicle bodies). - The energy consumption of the clamping unit according to the embodiment of the present example in line with the invention therefore was 360.39 cm3, i.e. more than 32% lower than the consumption of the clamping unit of the prior art described in the comparative Example 2.

- In practice, it was sufficient to extend the crank rod by only 3.5 mm, obtaining the same torque equal to 390 N m with a pneumatic actuation carried out with a cylinder having section Ø equal to 50 mm.

- Such a configuration led to a reduced energy dissipation and therefore to an increase in the proportionality constant. Specifically, in the configuration described, the proportionality constant surprisingly reached a value of about k = 11.28.

- With a known clamping unit, characterized by the following parameters:

- length of the crank arm equal to 26 mm;

- piston stroke equal to 71.22 mm;

- size of the pneumatic cylinder equal to Ø 40 mm operated at 5 bar; and

- output clamping moment equal to 130 N m.

- It was measured that such a clamping unit requires an air consumption equal to about 178.99 cm3 for each cycle defined as a forward and backward stroke of the cylinder.

- In particular, the cylinder having section Ø equal to 40 mm, when operated with compressed air at 5 bar, generates a thrust force P equal to about 628.32 N. From the proportionality relation discussed above it is therefore inferred that the proportionality constant of such a clamping unit is about k = 7.95.

- Theoretically, this for example means that, in order to scale the size of the cylinder, using one having section Ø equal to 32 mm, therefore able to develop a thrust force at 5 bar equal to about P = 402.12 N, it would be necessary to bring the length of the crank rod to about AO = 40 mm. However, such an increase in length is not compatible with the requirement of keeping the overall dimensions of the starting clamping unit unchanged.

- According to the present invention, a clamping unit was implemented characterized by the following parameters:

- length of the crank arm equal to 29 mm;

- piston stroke equal to 77 mm;

- size of the pneumatic cylinder equal to Ø 32 mm operated at 5 bar,

- In particular, the increase in the piston stroke was selected based on the fact that it is proportional to the increase in the length of the crank rod according to the following law Δcorsa = Δ

AO ∗ (1 + sin 45°), applicable in the operating range of the device suitable for ensuring an opening angle equal to 135° (opening angle characteristic of the applications on production lines of motor vehicle bodies). - The energy consumption of the clamping unit according to the embodiment of the present example in line with the invention therefore was 123.85 cm3, i.e. more than 30% lower than the consumption of the clamping unit of the prior art described in the comparative Example 3.

- In practice, it was sufficient to extend the crank rod by only 3 mm, obtaining the same torque equal to 130 N m with a pneumatic actuation carried out with a cylinder having section Ø equal to 32 mm.

- Such a configuration led to a reduced energy dissipation and therefore to an increase in the proportionality constant. Specifically, in the configuration described, the proportionality constant surprisingly reached a value of about k = 11.15.

- With a known clamping unit, characterized by the following parameters:

- length of the crank arm equal to 50 mm;

- piston stroke equal to 135.2 mm;

- size of the pneumatic cylinder equal to Ø 80 mm operated at 5 bar; and

- output clamping moment equal to 850 N m.

- It was measured that such a clamping unit requires an air consumption equal to about 1359.17 cm3 for each cycle defined as a forward and backward stroke of the cylinder.

- In particular, the cylinder having section Ø equal to 80 mm, when operated with compressed air at 5 bar, generates a thrust force P equal to about 2513.27 N. From the proportionality relation discussed above it is therefore inferred that the proportionality constant of such a clamping unit is about k = 6.76.

- Theoretically, this for example means that, in order to scale the size of the cylinder, using one having section Ø equal to 63 mm, therefore able to develop a thrust force at 5 bar equal to about P = 1558.62 N, it would be necessary to bring the length of the crank rod to about AO = 80 mm. However, such an increase in length is not compatible with the requirement of keeping the overall dimensions of the starting clamping unit unchanged.

- According to the present invention, a clamping unit was implemented characterized by the following parameters:

- length of the crank arm equal to 55 mm;

- piston stroke equal to 144.7 mm;

- size of the pneumatic cylinder equal to Ø 63 mm operated at 5 bar,

- In particular, the increase in the piston stroke was selected based on the fact that it is proportional to the increase in the length of the crank rod according to the following law Δcorsa = Δ

AO ∗ (1 + sin 45°), applicable in the operating range of the device suitable for ensuring an opening angle equal to 135° (opening angle characteristic of the applications on production lines of motor vehicle bodies). - The energy consumption of the clamping unit according to the embodiment of the present example in line with the invention therefore was 902.13 cm3, i.e. more than 33% lower than the consumption of the clamping unit of the prior art described in the comparative Example 4.

- In practice, it was sufficient to extend the crank rod by only 5 mm, obtaining the same torque equal to 850 N m with a pneumatic actuation carried out with a cylinder having section Ø equal to 63 mm.

- Such a configuration led to a reduced energy dissipation and therefore to an increase in the proportionality constant. Specifically, in the configuration described, the proportionality constant surprisingly reached a value of about k = 9.92.

- The Applicant has in fact found that, in clamping units according to the industrial standards that provide an output clamping moment comprised between 180 N m and 230 N m, the length of the crank rod, amounting today to 28 mm, can be incremented by nevertheless remaining under or equal to 32.8 mm so as to keep unchanged the current overall dimensions deriving from the standards.

- Likewise, the Applicant has also found that, in clamping units according to the industrial standards that provide an output clamping moment comprised between 375 N m and 425 N m, the length of the crank rod, amounting today to 31.5 mm, can be incremented by nevertheless remaining under or equal to 35.5 mm so as to keep the current overall dimensions unchanged.

- Similarly, the Applicant has also found that, in clamping units according to the industrial standards that provide an output clamping moment comprised between 115 N m and 145 N m, the length of the crank rod, amounting today to 26 mm, can be incremented by nevertheless remaining under or equal to 30.5 mm so as to keep the current overall dimensions unchanged.

- Not least, the Applicant has also found that, in clamping units according to the industrial standards that provide an output clamping moment comprised between 830 N m and 880 N m, the length of the crank rod, amounting today to 50 mm, can be incremented by nevertheless remaining under or equal to 56.5 mm so as to keep the current overall dimensions unchanged.

- The configuration of maximum optimization of the energy saving is carried at said crank lengths identified by the Applicant as the maximum allowable.

- Accordingly, in case of clamping units with a clamping moment comprised between 180 N m and 230 N m, it is possible to bring the energy saving up to 36.2%, while in case of clamping units with a clamping moment comprised between 375 N m and 425 N m, it is possible to bring the energy saving of up to 37.3%.

- Furthermore, in case of clamping units with a clamping moment comprised between 115 N m and 145 N m, it is possible to bring the energy saving up to 45.7%, while in case of clamping units with a clamping moment comprised between 830 N m and 880 N m, it is possible to bring the energy saving of up to 43.3%.

- The features of the articulated lever actuation unit object of the present invention as well as the relevant advantages are clear from the above description.

- Additional variations of the embodiments described above are possible without departing from the teaching of the invention as defined by the claims.

- Finally, it is clear that several changes and variations may be made to the articulated lever actuation unit thus conceived, all falling within the invention; moreover, all details can be replaced with technically equivalent elements. In the practice, the materials used can be any according to the technical requirements.

Claims (5)

- An articulated lever actuation unit (10) for handling and/or clamping elements during metal sheet processing for making motor vehicle bodies comprising a body (11), inside of which a control piston (12) is slidably associated to the body (11) along a sliding axis (A), the control piston (12) being connected or coupled to actuation means (15) able to exert a thrust force (P) on the control piston (12), wherein- the control piston (12) is operatively coupled to a pivotable arm (14) with the interposition of an articulated lever mechanism (13) in order to induce a rotational movement to the pivotable arm (14) about an axis of rotation (B) perpendicular to the sliding axis (A) following a sliding motion of the control piston (12), the pivotable arm (14) being moved between an open or non-operating position and a closed or operating position,- the articulated lever mechanism (13) comprises a first (13a) and a second (13b) rod, the first rod (13a) being pivoted to a rod (12a) of the control piston (12) and to the second rod (13b), respectively, and the second rod (13b) being pivoted to the body (11) and setting the pivotable arm (14) in rotation,- for each position of the pivotable arm other than the closed position, the thrust force (P) exerted by the control piston (12) determines a clamping moment (M) at the axis of rotation (B),wherein the actuation means are of the pneumatic type, comprising a pneumatic cylinder (15), andwherein the actuating unit is a clamping unit or a pivot unit,characterized in thatsaid clamping moment (M) at the axis of rotation (B) is variable according to law M = k ∗ P ∗

AO whereAO is the length of the second rod and k is a proportionality factor which is variable as a function of the thrust force (P),and wherein:- the pneumatic cylinder is of the standard size type having section Ø equal to 40 mm as defined in international standard ISO 15552, the length of the second rod (AO) is equal to about 32 mm, wherein the piston stroke is equal to about 84.8 mm, and wherein the proportionality factor (k) is a value of about 9.25 and the clamping moment is comprised between 185 Nm and 190 Nm when the pneumatic cylinder is operated at about 5 bar; or- the pneumatic cylinder is of the standard size type having section Ø equal to 50 mm as defined in international standard ISO 15552, the length of the second rod (AO) is equal to about 35 mm, wherein the piston stroke is equal to about 91.77 mm, and wherein the proportionality factor is a value of about 11.28 and the clamping moment is comprised between 380 Nm and 400 Nm when the pneumatic cylinder is operated at about 5 bar; or- the pneumatic cylinder is of the standard size type having section Ø equal to 32 mm as defined in international standard ISO 15552, the length of the second rod (AO) is equal to about 29 mm, wherein the piston stroke is equal to about 77 mm, and wherein the proportionality factor (k) is a value of about 11.15 and the clamping moment is comprised between 125 Nm and 132 Nm when the pneumatic cylinder is operated at about 5 bar; or- the pneumatic cylinder is of the standard size type having section Ø equal to 63 mm as defined in international standard ISO 15552, the length of the second rod (AO) is equal to about 55 mm, wherein the piston stroke is equal to about 144.7 mm, and wherein the proportionality factor is a value of about 9.92 and the clamping moment is comprised between 845 Nm and 855 Nm when the pneumatic cylinder is operated at about 5 bar. - Actuation unit (10) according to claim 1, wherein for pneumatic cylinder of the standard size type having section Ø equal to 40 mm as defined in international standard ISO 15552 and operated at about 5 bar, the clamping moment (M) is substantially equal to 186 N m.

- Actuation unit (10) according to claim any one of the preceding claims, wherein for pneumatic cylinder of the standard size type having section Ø equal to 50 mm as defined in international standard ISO 15552 and operated at about 5 bar, the clamping moment (M) is substantially equal to 390 N m.

- Actuation unit (10) according to claim any one of the preceding claims, wherein for pneumatic cylinder of the standard size type having section Ø equal to 63 mm as defined in international standard ISO 15552 and operated at about 5 bar the clamping moment (M) is substantially equal to 850 N m.

- Actuation unit (10) according to claim any one of the preceding claims, wherein for pneumatic cylinder of the standard size type having section Ø equal to 32 mm as defined in international standard ISO 15552 and operated at about 5 bar, the clamping moment (M) is substantially equal to 130 N m.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ITUB2015A003120A ITUB20153120A1 (en) | 2015-08-13 | 2015-08-13 | ACTUATION TYPE ACTUATED UNIT WITH OPTIMIZED EFFICIENCY |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3130809A1 EP3130809A1 (en) | 2017-02-15 |

| EP3130809B1 true EP3130809B1 (en) | 2023-08-02 |

Family

ID=54477183

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP16182930.4A Active EP3130809B1 (en) | 2015-08-13 | 2016-08-05 | Optimized efficiency actuating unit of the articulated lever type |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP3130809B1 (en) |

| IT (1) | ITUB20153120A1 (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2018210398A1 (en) * | 2017-05-15 | 2018-11-22 | Olaf Und André Tünkers Gbr | Toggle clamp device for use in vehicle body manufacturing in the automotive industry |

| US11199248B2 (en) * | 2019-04-30 | 2021-12-14 | Woodward, Inc. | Compact linear to rotary actuator |

| IT202000003805A1 (en) * | 2020-02-24 | 2021-08-24 | Pneumax S P A | ACTUATION UNIT OF THE TYPE WITH ARTICULATED LEVER OR ELECTRICALLY OPERATED CAM |

| IT202000003784A1 (en) * | 2020-02-24 | 2021-08-24 | Pneumax S P A | ACTUATION UNIT OF THE TYPE WITH ARTICULATED LEVER OR ELECTRICALLY OPERATED CAM |

Citations (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0341155A1 (en) | 1988-05-06 | 1989-11-08 | Genus International | Device for clamping plates or sectional steels against each other |

| DE29713944U1 (en) | 1997-08-05 | 1997-10-02 | Tünkers Maschinenbau GmbH, 40880 Ratingen | Fluid-operated knee lever clamping device |

| DE29811331U1 (en) | 1997-10-08 | 1998-10-08 | Genus Technologies, Chatillon | Device for holding, positioning and tensioning |

| EP0894573A2 (en) | 1997-07-29 | 1999-02-03 | Benteler Ag | Workpiece clamp |

| EP1088623A2 (en) | 1999-10-01 | 2001-04-04 | SMC Kabushiki Kaisha | Electric clamp apparatus |

| EP1149665A2 (en) | 2000-04-28 | 2001-10-31 | SMC Kabushiki Kaisha | Electric clamp apparatus |

| EP1179394A2 (en) | 2000-08-03 | 2002-02-13 | Norgren Automotive Inc. | Over-center power clamp toggle mechanism |

| US6416045B1 (en) | 2000-07-25 | 2002-07-09 | Norgren Automotive, Inc. | Rotary clamp having predetermined adjustable clamping angles |

| DE10136057C1 (en) | 2001-07-25 | 2002-10-02 | Tuenkers Maschinenbau Gmbh | Knee-lever clamping, especially for use in body structure of motor vehicles, has clamping head and a drive which is axially connected to it |

| EP1262285A2 (en) | 2001-04-30 | 2002-12-04 | Btm Corporation | Adjustable stroke clamp |

| EP1310332A2 (en) | 2001-11-05 | 2003-05-14 | Luciano Migliori | Electrically operated clamping device |

| DE102004007346B3 (en) | 2003-11-04 | 2005-04-21 | Tünkers Maschinenbau Gmbh | Road vehicle bodywork manufacturing tool with knee joint clamping system and point welding tool has cylinder with working piston and braking piston with piston rod fitting in bore in working piston rod |

| DE102006022950A1 (en) | 2006-05-17 | 2007-11-22 | De-Sta-Co Europe Gmbh | Clamping device for fixing workpieces |

| DE102006041707B4 (en) | 2006-05-10 | 2009-01-02 | Tünkers Maschinenbau Gmbh | Piston-cylinder unit (working cylinder) for clamping, and / or pressing, and / or joining, and / or punching, and / or embossing, and / or punching and / or welding, for example, with the interposition of a toggle joint arrangement |

| EP1878539B1 (en) | 2006-06-26 | 2009-04-15 | UNIVER S.p.A. | Clamping and/or centering device for work pieces, with manually settable operative positions |

| DE202009002141U1 (en) | 2009-02-14 | 2009-04-23 | Tünkers Maschinenbau Gmbh | Device with a via an actuator and a toggle joint assembly driven by a drive in opposite directions lever, the one or more masses is assigned or are, in particular for use in the bodywork of the automotive industry |

| EP2055430B1 (en) | 2007-10-29 | 2009-06-10 | UNIVER S.p.A. | Toggle joint clamping device |

| EP1849559B1 (en) | 2006-04-27 | 2009-08-05 | UNIVER S.p.A. | Positioning and/or clamping apparatus, with adjustable opening position of the working arm |

| DE102008007256B3 (en) | 2008-02-01 | 2009-08-20 | Tünkers Maschinenbau Gmbh | Working cylinder for e.g. manufacturing vehicle body in motor vehicle industry, has valves that are formed as manifold valves and arranged inside working cylinder together with channels and/or lines, in structurally unified manner |

| EP2177320A1 (en) | 2008-10-15 | 2010-04-21 | UNIVER S.p.A. | Irreversible-type toggle-lever drive device |

| DE202015004786U1 (en) | 2014-10-06 | 2015-08-14 | Olaf Und André Tünkers Gbr (Vertretungsberechtigter Gesellschafter: Dipl.-Ing. Olaf Tünkers, 40885 Ratingen) | Toggle clamping device, in particular for use in the bodywork of the automotive industry |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19846951A1 (en) | 1998-10-12 | 2000-04-20 | Strip S D O O Podjetje Za Svet | Press with elbow lever drive has triangular guide rod connected to crank drive at one end and fitted with drive arm and support arm spaced from each other at other end and adjustable in length between elbow joint and crank drive |

-

2015

- 2015-08-13 IT ITUB2015A003120A patent/ITUB20153120A1/en unknown

-

2016

- 2016-08-05 EP EP16182930.4A patent/EP3130809B1/en active Active

Patent Citations (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0341155A1 (en) | 1988-05-06 | 1989-11-08 | Genus International | Device for clamping plates or sectional steels against each other |

| EP0894573A2 (en) | 1997-07-29 | 1999-02-03 | Benteler Ag | Workpiece clamp |

| DE29713944U1 (en) | 1997-08-05 | 1997-10-02 | Tünkers Maschinenbau GmbH, 40880 Ratingen | Fluid-operated knee lever clamping device |

| DE29811331U1 (en) | 1997-10-08 | 1998-10-08 | Genus Technologies, Chatillon | Device for holding, positioning and tensioning |

| EP1088623A2 (en) | 1999-10-01 | 2001-04-04 | SMC Kabushiki Kaisha | Electric clamp apparatus |

| EP1149665A2 (en) | 2000-04-28 | 2001-10-31 | SMC Kabushiki Kaisha | Electric clamp apparatus |

| US6416045B1 (en) | 2000-07-25 | 2002-07-09 | Norgren Automotive, Inc. | Rotary clamp having predetermined adjustable clamping angles |

| EP1179394A2 (en) | 2000-08-03 | 2002-02-13 | Norgren Automotive Inc. | Over-center power clamp toggle mechanism |

| EP1262285A2 (en) | 2001-04-30 | 2002-12-04 | Btm Corporation | Adjustable stroke clamp |

| DE10136057C1 (en) | 2001-07-25 | 2002-10-02 | Tuenkers Maschinenbau Gmbh | Knee-lever clamping, especially for use in body structure of motor vehicles, has clamping head and a drive which is axially connected to it |

| EP1310332A2 (en) | 2001-11-05 | 2003-05-14 | Luciano Migliori | Electrically operated clamping device |

| DE102004007346B3 (en) | 2003-11-04 | 2005-04-21 | Tünkers Maschinenbau Gmbh | Road vehicle bodywork manufacturing tool with knee joint clamping system and point welding tool has cylinder with working piston and braking piston with piston rod fitting in bore in working piston rod |

| EP1849559B1 (en) | 2006-04-27 | 2009-08-05 | UNIVER S.p.A. | Positioning and/or clamping apparatus, with adjustable opening position of the working arm |

| DE102006041707B4 (en) | 2006-05-10 | 2009-01-02 | Tünkers Maschinenbau Gmbh | Piston-cylinder unit (working cylinder) for clamping, and / or pressing, and / or joining, and / or punching, and / or embossing, and / or punching and / or welding, for example, with the interposition of a toggle joint arrangement |

| DE102006022950A1 (en) | 2006-05-17 | 2007-11-22 | De-Sta-Co Europe Gmbh | Clamping device for fixing workpieces |

| EP1878539B1 (en) | 2006-06-26 | 2009-04-15 | UNIVER S.p.A. | Clamping and/or centering device for work pieces, with manually settable operative positions |

| EP2055430B1 (en) | 2007-10-29 | 2009-06-10 | UNIVER S.p.A. | Toggle joint clamping device |

| DE102008007256B3 (en) | 2008-02-01 | 2009-08-20 | Tünkers Maschinenbau Gmbh | Working cylinder for e.g. manufacturing vehicle body in motor vehicle industry, has valves that are formed as manifold valves and arranged inside working cylinder together with channels and/or lines, in structurally unified manner |

| EP2177320A1 (en) | 2008-10-15 | 2010-04-21 | UNIVER S.p.A. | Irreversible-type toggle-lever drive device |

| DE202009002141U1 (en) | 2009-02-14 | 2009-04-23 | Tünkers Maschinenbau Gmbh | Device with a via an actuator and a toggle joint assembly driven by a drive in opposite directions lever, the one or more masses is assigned or are, in particular for use in the bodywork of the automotive industry |

| DE202009008068U1 (en) | 2009-02-14 | 2009-08-27 | Tünkers Maschinenbau Gmbh | Device for clamping and / or joining and / or punching and / or embossing and / or welding and / or punching and / or clinching and / or pivoting, in particular for use in the bodywork of the motor vehicle industry and control for such a device and the use Such a device, primarily for the bodywork of the automotive industry |

| EP2218549A1 (en) | 2009-02-14 | 2010-08-18 | TÜNKERS MASCHINENBAU GmbH | Device with a lever drivable in opposing directions with a position member and a knee lever joint assembly by means of a drive |

| DE202015004786U1 (en) | 2014-10-06 | 2015-08-14 | Olaf Und André Tünkers Gbr (Vertretungsberechtigter Gesellschafter: Dipl.-Ing. Olaf Tünkers, 40885 Ratingen) | Toggle clamping device, in particular for use in the bodywork of the automotive industry |

| DE102014014857B3 (en) | 2014-10-06 | 2015-11-12 | Olaf Und André Tünkers Gbr (Vertretungsberechtigter Gesellschafter: Dipl.-Ing. Olaf Tünkers, 40885 Ratingen) | Toggle clamping device, in particular for use in the bodywork of the automotive industry |

| WO2016055138A1 (en) * | 2014-10-06 | 2016-04-14 | Olaf Und Andre Tünkers Gbr | Toggle clamp device, in particular for use in vehicle body manufacturing in the automotive industry |

Non-Patent Citations (6)

| Title |

|---|

| ANONYMOUS: "Catalogue General", GENUSTECH BROCHURE, 1 June 2000 (2000-06-01), pages 109pp, XP055961341 |

| ANONYMOUS: "Dispositifs de serrage", UNIVER BROCHURE, 28 June 2011 (2011-06-28), pages 14pp, XP055961468 |

| ANONYMOUS: "Kompaktzylinder ADN/AEN, ISO 21287", FESTO, 1 November 2010 (2010-11-01), XP093186052 |

| ANONYMOUS: "Kraftspanner selbsthaltend, einstellbarer Oeffnungswinkel, geschl. Bauform, Spannarm universell, 20 mm breit / Power clamp selflocking, adjustable opening angle, enclosed form, clamp arm universal, 20 mm wide - Masse/DIM's in mm", FORD MANUFACTURING STANDARDS / FERTIGUNGS-NORMEN, 1 December 2006 (2006-12-01), XP093185040 |

| ANONYMOUS: "Serrages Pneumatiques CNOMO, Serie CP-01", GENUSTECH BROCHURE, 1 July 2006 (2006-07-01), pages 1 - 20, XP055961338 |

| ANONYMOUS: "SOUDAGE ELECTRIQUE PAR RESISTANCE DISPOSITlF DE MAINTIEN OU DE SERRAGE DES PIECES DE CARROSSERIE ANALYSE FONCTIONNELLE DU BESOIN ", CNOMO STANDARD E34.41.105N, 1 April 1998 (1998-04-01), XP093185037 |

Also Published As

| Publication number | Publication date |

|---|---|

| ITUB20153120A1 (en) | 2017-02-13 |

| EP3130809A1 (en) | 2017-02-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3130809B1 (en) | Optimized efficiency actuating unit of the articulated lever type | |

| US4411148A (en) | Press brake | |

| CN105937592B (en) | Double-cam crank mechanism | |

| US10933487B2 (en) | Spot welding apparatus | |

| CA2722009C (en) | Method of activating a mountable hydraulic appliance, and such mountable hydraulic appliance, in particular for demolition, comminution or recycling | |

| US20090126438A1 (en) | Device for bending tubes or profiled sections with symmetrical structure for two-way bending and machine equipped with same | |

| EP0811437A1 (en) | Hydraulic device for bending work and a bending device with the hydraulic device mounted thereon | |

| CN105782154B (en) | The control method of hydraulic pressure processing machine and its hydraulic system and the hydraulic system | |

| CN106180243B (en) | Variable extrusion die device | |

| CN202239110U (en) | U-shaped beam bender | |

| CN105269337B (en) | A kind of microscope carrier mechanism of the universal translation of energy | |

| US3322008A (en) | Toggle-actuated hand tool with full stroke-compelling mechanism | |

| CN106989073B (en) | Electrohydraulic controlling mechanism | |

| CN104976188B (en) | Actuator assembly, engineering machinery and arm support control device and method thereof | |

| CN209831691U (en) | Single-action three-jaw mechanical clamping mechanism | |

| CA2842490A1 (en) | Manually operated press | |

| US3125000A (en) | Airfoil controlling actuator | |

| CN105291125A (en) | Screw driving hand mechanism of robot and clamping method | |

| CN109915424A (en) | A lever-type solenoid valve-controlled hydraulic transformer with adjustable lever arm | |

| CN109649482A (en) | Vehicle hydraulic steering system | |

| CN205669596U (en) | An electric screw hydraulic valve | |

| US11454258B2 (en) | Fluid-driven drive | |

| GB1163814A (en) | Improvements in or relating to Bending and Cutting Machines | |

| US20200331121A1 (en) | Toggle clamp device, in particular for use in vehicle body manufacturing in the automotive industry | |

| Gharat et al. | Design and Fabrication of Pneumatic Punching and Bending Machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20170630 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20191001 |

|

| TPAC | Observations filed by third parties |

Free format text: ORIGINAL CODE: EPIDOSNTIPA |

|

| TPAC | Observations filed by third parties |

Free format text: ORIGINAL CODE: EPIDOSNTIPA |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20230412 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230329 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602016081533 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20230802 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 1595054 Country of ref document: AT Kind code of ref document: T Effective date: 20230802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231103 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231202 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231204 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231102 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231202 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231103 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 602016081533 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| 26 | Opposition filed |

Opponent name: OLAF UND ANDRE TUENKERS GBR Effective date: 20240226 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230805 |

|

| R26 | Opposition filed (corrected) |

Opponent name: OLAF UND ANDRE TUENKERS GBR Effective date: 20240226 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230805 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230831 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20230831 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230805 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20231102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230805 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20231002 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230831 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20231102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20231102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: OLAF UND ANDRE TUENKERS GBR Effective date: 20240226 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20160805 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20160805 |

|

| PLCK | Communication despatched that opposition was rejected |

Free format text: ORIGINAL CODE: EPIDOSNREJ1 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R100 Ref document number: 602016081533 Country of ref document: DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250828 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230802 |

|

| PLBN | Opposition rejected |

Free format text: ORIGINAL CODE: 0009273 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |