EP3099841B1 - Système de capotage pour cuve d'électrolyse - Google Patents

Système de capotage pour cuve d'électrolyse Download PDFInfo

- Publication number

- EP3099841B1 EP3099841B1 EP15740112.6A EP15740112A EP3099841B1 EP 3099841 B1 EP3099841 B1 EP 3099841B1 EP 15740112 A EP15740112 A EP 15740112A EP 3099841 B1 EP3099841 B1 EP 3099841B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- electrolytic cell

- hoods

- covers

- sealing

- lids

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000007789 sealing Methods 0.000 claims description 45

- 238000000034 method Methods 0.000 claims description 27

- 238000000429 assembly Methods 0.000 claims description 22

- 230000000712 assembly Effects 0.000 claims description 22

- 239000000463 material Substances 0.000 claims description 22

- 239000000843 powder Substances 0.000 claims description 15

- 238000009413 insulation Methods 0.000 claims description 6

- 238000005452 bending Methods 0.000 claims description 5

- 230000001174 ascending effect Effects 0.000 claims description 3

- 230000000284 resting effect Effects 0.000 claims 1

- 238000005868 electrolysis reaction Methods 0.000 description 76

- 239000007789 gas Substances 0.000 description 50

- 206010039509 Scab Diseases 0.000 description 18

- 230000008859 change Effects 0.000 description 11

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 8

- 239000004020 conductor Substances 0.000 description 8

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 7

- 229910052782 aluminium Inorganic materials 0.000 description 7

- 238000009792 diffusion process Methods 0.000 description 7

- 230000008901 benefit Effects 0.000 description 5

- 238000012423 maintenance Methods 0.000 description 5

- 239000011810 insulating material Substances 0.000 description 4

- 238000013519 translation Methods 0.000 description 4

- 238000003780 insertion Methods 0.000 description 3

- 230000037431 insertion Effects 0.000 description 3

- 229910000831 Steel Inorganic materials 0.000 description 2

- 239000003463 adsorbent Substances 0.000 description 2

- 230000004888 barrier function Effects 0.000 description 2

- 230000015556 catabolic process Effects 0.000 description 2

- 238000006731 degradation reaction Methods 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 230000007613 environmental effect Effects 0.000 description 2

- 238000000605 extraction Methods 0.000 description 2

- 230000008595 infiltration Effects 0.000 description 2

- 238000001764 infiltration Methods 0.000 description 2

- 239000011490 mineral wool Substances 0.000 description 2

- 239000011819 refractory material Substances 0.000 description 2

- 230000003014 reinforcing effect Effects 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 description 1

- 238000009626 Hall-Héroult process Methods 0.000 description 1

- 241000920340 Pion Species 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 239000003575 carbonaceous material Substances 0.000 description 1

- 230000009194 climbing Effects 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 239000003546 flue gas Substances 0.000 description 1

- 238000002955 isolation Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000003032 molecular docking Methods 0.000 description 1

- 238000004321 preservation Methods 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

- 230000002195 synergetic effect Effects 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25C—PROCESSES FOR THE ELECTROLYTIC PRODUCTION, RECOVERY OR REFINING OF METALS; APPARATUS THEREFOR

- C25C3/00—Electrolytic production, recovery or refining of metals by electrolysis of melts

- C25C3/06—Electrolytic production, recovery or refining of metals by electrolysis of melts of aluminium

- C25C3/22—Collecting emitted gases

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25C—PROCESSES FOR THE ELECTROLYTIC PRODUCTION, RECOVERY OR REFINING OF METALS; APPARATUS THEREFOR

- C25C3/00—Electrolytic production, recovery or refining of metals by electrolysis of melts

- C25C3/06—Electrolytic production, recovery or refining of metals by electrolysis of melts of aluminium

- C25C3/08—Cell construction, e.g. bottoms, walls, cathodes

Definitions

- the present invention relates to an electrolytic cell comprising a cowling system and a method of changing an anode assembly.

- Aluminum is conventionally produced in aluminum smelters, by electrolysis, according to the Hall-Héroult process.

- An aluminum smelter traditionally comprises several hundred electrolytic cells connected in series and traversed by an electrolysis current whose intensity can reach several hundreds of thousands of amperes. It is known to arrange the electrolytic cells transversely with respect to the flow direction of the electrolysis current at the scale of the series.

- Electrolysis tanks conventionally comprise a steel box inside which is arranged a coating of refractory materials, a cathode of carbon material, crossed by cathode conductors for collecting the electrolysis current at the cathode to conduct it up to cathode outlets passing through the bottom or sides of the box, routing conductors extending substantially horizontally to the next tank from the cathode outlets, an electrolytic bath in which the alumina is dissolved, at least one set anode having at least one anode immersed in said electrolytic bath and an anode rod sealed in the anode, an anode frame to which the anode assembly is suspended via the anode rod, and electrolytic current rise conductors, extending from bottom to top, connected to the routing conductors of the preceding electrolytic cell to convey electrolysis current e from the cathode outlets to the anode frame and the anode assembly and the anode of the next vessel.

- the anodes are more particularly of anode type precooked with precooked carbon blocks,

- the anode assemblies are consumed during the electrolysis reaction and must therefore be regularly replaced by new anode assemblies.

- the sides of the electrolytic cell define an opening through which the anode assemblies are introduced into the electrolytic cell to be immersed in the electrolytic bath or removed from the electrolytic cell for replacement.

- tank gases gases generated during the electrolysis reaction

- Known rollover systems such as those disclosed in patent documents US4043892 and WO2007067061 , include side caps, removable, inclined compared to the horizontal. These covers rest on the one hand on one side of the electrolytic cell and on the other hand against a part of superstructure, intended to support the anode assemblies, extending in a longitudinal direction of the electrolytic cell, to above the opening defined by the sides of the tank, that is to say, in line with the anode assemblies and the electrolytic bath.

- the covers thus form a containment chamber limiting the diffusion of the tank gases when the rollover system is completely closed. This also limits heat losses.

- cowling systems offer a limited response to the problem of diffusion of tank gas out of the electrolysis cell and preservation of the thermal equilibrium of the electrolysis cell.

- hoods are removed to create an opening through the rollover system.

- This opening necessary, allows access to the interior of the tank, in particular to remove a spent anode assembly.

- the opening thus created provides the opportunity for the cell gases to diffuse out of the containment. This opening can also disturb the thermal equilibrium of the tank.

- the hoods having been removed to create the opening required for the intervention are often placed next to the electrolysis cell, in particular in an inter-cell space separating two adjacent tanks. This can pose a congestion problem, and this congestion problem can slow down the intervention, that is to say, increase the duration during which the rollover system is open. This can also pose a safety problem, as an operator may trip over.

- hoods of known rollover systems are designed to have their adjacent edges superimposed on each other. This superposition makes it possible to limit the leakage of vat gas and the energetic losses at the interface between two adjacent covers.

- hoods of traditional rollover systems are similar, especially in terms of dimensions, so that the only possibility of selecting an opening surface through the rollover system is the selection of the number of covers to remove. This does not allow a fine adjustment of the opening surface, that is to say the selection of a minimum opening area but sufficient to perform a maintenance intervention to achieve.

- the presence of the superstructure and electrolytic current rise conductors above the opening defined by the sides of the tank make it difficult the crust breaking operation being formed between the anode assemblies because the access under the superstructure and climbing conductors is particularly small. It follows that the crust breaking operation, traditionally carried out with a jack hammer mounted on an arm with an angular inclination, requires more time than if there were no such obstacles, which increases the duration opening of the cowling. In addition, because of this problem of accessibility, the crust breaking is sometimes incomplete at the periphery of the anode assembly and the extracted anode assembly comprises solid crust pieces that increase its passage section, its size and can damage adjacent covers still in place.

- hoods rest in the lower part on the top of the box on which collapses the cover product of the anodes, so that the supports of the hoods are unstable and their positioning is not accurate. They are also exposed at the bottom to flames and hot spots related to discontinuities of the anode cover, resulting in their rapid degradation.

- the present invention aims at overcoming all or part of these disadvantages by proposing a rollover system, an electrolysis cell comprising this cowling system and a method of changing an anode assembly, offering the possibility of effectively containing the diffusion tank gas and maintain thermal equilibrium, especially during a maintenance intervention.

- This electrolytic cell has a stable thermal equilibrium and limits the gas discharges from tanks, including during the intervention as an anode assembly replacement.

- the rollover system offers the possibility to access the inside of the electrolysis cell by removing only one of the blanking covers, without moving or removing the covers.

- opposite sides of the electrolytic cell is meant sides located on either side of a median plane, in particular a longitudinal median plane, of the electrolytic cell.

- each cover is intended to extend on both sides of this median plane to rest simultaneously on these two opposite sides.

- the covers and shutter covers have a vertical assembly stroke, which is an important advantage to automate the introduction of the covers, because there is no complex angular movements to achieve unlike the state of the art.

- the closure covers have longitudinal edges which are intended to rest each on one of the covers.

- the seal at the junction between the closure covers and the covers is ensured over the entire length of the covers, respectively the closure covers, by superimposing an edge of the closure cover over a cover. hood edge.

- the closure covers have a T-shaped cross-section defining two longitudinal returns, the covers have an inverted T-shaped cross-section delimiting two longitudinal returns, each return of one of the closure covers being based on one of the returns of an adjacent cowl, so that the rollover system has an alternation of covers and nested sealing lids.

- This configuration offers both a simple solution to allow the shutter covers to be removed without interference with the covers on which they rest and the other shutter covers, and at the same time to improve the tightness of the rollover system. This thus makes it possible to limit tank gas leaks and heat losses.

- the returns of the covers and the closure covers have an L-shaped section, so that the engagement of a cover and a closure cover forms a sealing baffle.

- This feature also offers the advantage of improved sealing, to contain tank gas leaks and heat losses.

- the rollover system comprises sealing means interposed between the returns of each closure cover and the returns of the adjacent covers on which each closure cover rests.

- the covers and lids extend horizontally and the longitudinal returns of the hoods comprise chutes containing a powdery material and having an upper opening, the longitudinal returns of the lids having an L-shaped section, so that end portion of the L-section of the lid is pressed into the powder material via the upper opening in the chute when the cover and the cover are nested.

- the powdery material contains alumina.

- the pulverulent material may be formed of alumina or crushed electrolysis bath which comprises alumina. These materials have the advantage of being available in an aluminum smelter and are further introduced into the electrolysis tanks so that they do not risk polluting the electrolytic cell in case of accidental spillage into the tank.

- alumina is a very good adsorbent for the HF and SO2 released by the electrolytic cell so that any infiltration of vat gas through the powder material will have a lower environmental impact.

- the covers and / or the covers comprise a shutter arranged to close the opening of the chute when the cover and the cover are nested.

- This flap that can be fixed or mobile, including pivoting is intended to retain the powder material in the chute.

- the sealing means comprise elastic seals intended to compensate for a difference in relative deformation between two consecutive covers of the cowling system between which is intended to extend a closure cover in position. shutter.

- the space or clearance between covers and closure covers is side so that the crushing of the seals separating them, taking into account the deflection of the covers and the closure covers, is in the range elastic crushing seals.

- the seal is improved.

- the covers comprise a face provided with at least one reinforcing rib intended to limit the bending of the covers.

- the covers comprise a face provided with thermal insulation means.

- the isolation means are arranged on the underside of the covers so as to limit the warpage and therefore the degradation of the covers.

- the covers comprise a substantially longitudinal tubular body, the tubular body defining a cavity inside which is arranged a thermally insulating material.

- the covers comprise a bottom face provided with deflection means for deflecting a flow of vat gas.

- the tank gases can be diverted towards a capture system that can equip the electrolysis tank, so that the tank gas leaks are limited.

- the closure covers comprise gripping means designed to allow a substantially vertical lifting of each shutter cover without moving the covers and independently of the other sealing covers.

- a substantially vertical withdrawal of the closure covers limits the risk of moving the adjacent covers during removal and is the simplest solution to implement a sealing system between the closure covers and covers that they are adjacent.

- the closure covers comprise a lower bearing surface designed to allow the closure covers to rest stably on one of the covers or on another closure cover.

- closure covers when removed, can be stacked on an adjacent hood or other close shutter cover. Consequently, the trajectories described by the electrolysis service machine during an intervention are minimal, so that the duration of opening of the intervention window is also minimal. This results in a decrease in the leakage of the tank gas and thermal losses that may occur during an intervention.

- the covers comprise a bottom support face designed to allow the covers to rest stably on one of the closure covers.

- the hoods when removed, can be stacked on an adjacent hood or a close shutter cover. This reduces the trajectories of the electrolysis service machine, thus the opening time of the intervention window. Tank gas leaks and heat losses during the intervention, in particular an anode assembly change, are less.

- the covers and the closure covers extend in a substantially horizontal plane.

- the intervention window has a width less than that of the covers that the intervention window separates.

- This small opening area of the cowling allows to create in combination with the traditional suction of the tank gases a suction effect of the outside air to the inside of the tank, against the movement of the tank gases. Tank gas leaks are thus limited.

- each shutter cover has a width less than the width of the covers.

- the hoods have a bending stiffness greater than that of the closure covers.

- the hoods deform more difficultly than the shutter covers, and the shutter caps deform more easily than the hoods under the effect of their weight, so that the shutter covers can deform to compensate the deformations, the least, of the hoods on which they rest. This improves the seal.

- the electrolytic cell comprises sealing means interposed between the support edges of the covers and the sides of the electrolytic cell on which the support edges rest.

- the sealing means interposed between the support edges of the covers and the sides of the tank on which the support edges rest, comprise a seal

- the electrolysis cell comprises means pinching the seal

- each shutter cover extends above and all along a subjacent interanode space separating two adjacent anode assemblies from the electrolytic cell.

- inter-anode space space separating anodes from two adjacent anode sets.

- each cap extends above and along an anode assembly subjacent to the electrolytic cell.

- the electrolysis cell comprises indexing means adapted to indicate a predetermined position of the covers such that the covers extend to the right of the anode assemblies.

- This feature allows fast, repeatable and accurate placement of covers, to quickly close the opening and prevent them from moving.

- covers extending to the right of the anode assemblies is meant that under each cover extends a single anode assembly.

- the electrolytic cell comprises means for capturing the bottom gases, designed to capture and collect the cell gases emitted during the electrolysis reaction.

- the capturing means comprise suction holes arranged under the hoods and the closure covers.

- the capturing means comprise a diaphragm for modifying an air passage section in order to modify a capture rate of the tank gases.

- This characteristic offers the possibility of increasing the capture rate when a cover and / or a shutter cover are removed, for example during an anode assembly change.

- the diffusion of vat gas during an intervention is substantially limited.

- the width of each cap is less than the width of an anode assembly of the electrolytic cell.

- This method provides the possibility of providing access to the interior of the electrolytic cell with a minimum opening area, and thus breaking or sawing the crust formed during the electrolysis reaction with a minimum of gas leaks and thermal losses. During the change of anode assembly, the diffusion of vat gas and heat losses are therefore substantially limited.

- the method comprises a step of placing the first closure cover on one of the covers adjacent to the first closure cover.

- the method comprises a step of moving a second shutter cover, from the shut-off position to the intervention position, without moving the covers of the rollover system and the other covers.

- shutter the second shutter cover being arranged on the other side of one of the covers beside which was arranged the first shutter cover, so as to release a second passage on the other side of this cover, and a step of breaking or sawing a crust formed on the surface of an electrolytic bath, by inserting a tool adapted to break or saw the crust through this second passage.

- the method comprises a step of placing the second closure cover on the first closure cover.

- the stacking of the closure covers limits the paths of the electrolysis service machine, thus the duration during which the corresponding intervention windows are open.

- the method comprises a step of removing a cover initially adjacent to the first closure cover.

- the method according to the invention limits the leakage of vat gas and preserves the thermal equilibrium of an electrolytic cell during an anode assembly change.

- the method comprises a step of stacking said cover on the first shutter cover or, if appropriate, on the second shutter cover.

- the method may then comprise a step of extracting the spent anode assembly, underlying the cap previously removed, and then a step of inserting the new anode assembly inside the electrolytic cell.

- steps can be performed by substantially vertical upward or downward translation, respectively of the used anode assembly and the new anode assembly.

- the method may comprise a step of repositioning the cover previously removed, then the first and second closure cover.

- the figure 1 shows, according to one embodiment of the invention, an electrolysis tank 100, intended to produce aluminum by electrolysis, and a rollover system 1 for closing an opening of the electrolytic cell.

- the electrolysis tank 100 can equip an electrolysis plant, such as an aluminum smelter.

- the electrolysis plant may comprise a plurality of electrolytic cells 100 aligned and electrically connected to each other to form a line or series of electrolysis cells.

- the electrolytic tanks 100 are intended to be traversed by an electrolysis current of up to several hundreds of thousands of amperes.

- the electrolysis tanks 100 may be arranged transversely with respect to the direction of the line or series, that is to say substantially perpendicularly to the overall direction of flow of electrolysis current at the scale of the line or from the Serie.

- the electrolysis tank 100 may comprise two opposite longitudinal sides 101 which may be substantially parallel to each other and two opposite transverse sides 103 which may be substantially parallel to each other and perpendicular to the longitudinal sides 101, so that the electrolysis tank 100 may have a substantially rectangular shape.

- the electrolysis tank 100 comprises a fixed structure.

- the fixed structure comprises a box 102 and / or a side wall 105 of a gas containment enclosure.

- the box 102 may contain a bottom 104 of refractory materials, a plurality of cathode blocks 106 and conductors 108 for collecting an electrolysis current passing through the cathode blocks 106.

- the electrolytic cell 100 also comprises a plurality of anode assemblies 109 that are movable in a substantially vertical translation relative to the fixed structure of the electrolytic cell so that they can be immersed in an electrolytic bath 110 as they progress. consumption.

- the anode assemblies 109 herein comprise a plurality of carbonaceous blocks 112, supported by an electrically conductive anode crosshead 114.

- the anode cross-member 114 advantageously extends in a substantially transverse direction Y of the electrolytic cell, in a substantially horizontal plane.

- the ends of this crosspiece 114 are electrically connected to routing conductors (not shown) for routing the electrolysis current from a previous electrolysis tank.

- the sides of the electrolysis tank 100 define an opening 116 which is intended for insertion or extraction of the anode assemblies 109 respectively inside or outside the electrolysis tank 100.

- this opening 116 is adapted to allow this insertion or extraction by substantially vertical displacement, respectively descending or ascending, of the assembly 109 anodic.

- the electrolysis tank 100 further comprises the cowling system 1.

- the rollover system 1 is intended to seal the opening 116, to prevent the diffusion of tank gases generated during the electrolysis reaction, out of the electrolysis tank 100.

- the rollover system 1 also makes it possible to limit heat losses.

- the rollover system 1 extends above the anode assemblies 109 in order to completely cover the opening 116.

- the rollover system 1 comprises a plurality of covers 2.

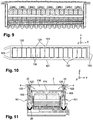

- the covers 2 are self-supporting. Each cover 2 comprises two opposite support edges 4, visible in particular on the figure 11 , intended to rest on two opposite sides of the electrolysis tank 100, in particular on an upper edge of the two longitudinal sides 101 of the electrolysis tank 100.

- Each cover 2 thus rests integrally on the electrolytic cell 100, extending between the two longitudinal sides 101, above the opening 116.

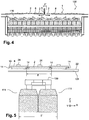

- the cowling system 1 is also designed to present, substantially parallel to the cowls 2, longitudinal intervention windows 6, as is visible for example on the figure 4 .

- Each intervention window 6 makes it possible to release a predetermined passage through the plurality of covers 2.

- the intervention windows 6 extend longitudinally between two adjacent covers 2.

- the rollover system 1 further comprises closure caps 8, each intended to close a window 6 intervention.

- Each shutter cover 8 is movable relative to the covers 2 between a closed position, in which each shutter cover 8 closes one of the intervention windows 6, and an intervention position, in which each cover Shutter 8 releases a passage through the rollover system 1 via one of the intervention windows 6.

- closure caps 8 are intended to rest at least partly on the covers 2, as can be seen for example on the figure 5 .

- the closure caps 8 have longitudinal edges which are intended to rest each on one of the covers 2 and have side edges which can rest on an upper edge of the longitudinal sides 101 of the electrolysis tank 100, and.

- closure lids 8 can rest straddling two adjacent covers 2 and extend between these two adjacent covers 2.

- shutter covers 8 are designed to be moved from the shutter position to the intervention position without moving the covers 2 on which the shutter covers 8 rest.

- the shutter covers 8 can also be moved from the shutter position to the intervention position independently of each other, that is to say without the movement of one of the closure lids 8 involves that of another cover 8 shutter.

- the covers 2 and, if appropriate, the closure covers 8 advantageously extend in one piece from one longitudinal side to the other of the electrolysis tank 100.

- the covers 2 and, if applicable, the closure covers 8 extend substantially parallel to a transverse direction Y of the electrolytic cell 100.

- covers 2 and the closure lids 8 extend in a substantially horizontal plane.

- the covers 2 and the closure covers 8 preferably extend above the working floor, which limits the risk of falling in the tank of the operating personnel.

- covers 2 and the closing lids 8 are intended to extend above the electrolytic bath, the temperature of which can reach about 1000 ° C.

- the covers 2 and the closure lids 8 must therefore be adapted to withstand a temperature of the order of several hundred degrees Celsius, without prejudice to their mechanical properties and, where appropriate, thermal insulation.

- the closing lids 8 have a T-shaped cross section defining two longitudinal returns 10.

- the covers 2 have in turn an inverted T cross section delimiting two longitudinal returns 12.

- Each return 10 of one of the closure lids 8 rests on one of the returns 12 of an adjacent cover 2.

- the rollover system 1 has an alternation of T right and inverted T formed by an alternation of covers 2 and nested closure caps 8.

- the returns 10, 12 of the covers 2 and the closure lids 8 have an L-shaped section.

- the cowling system 1 advantageously also comprises sealing means interposed between the returns 10 of each closure cover 8 and the returns 12 adjacent covers 2.

- the sealing means comprise, for example, elastic seals 14.

- the elastic sealing seals 14 are intended to compensate for a difference in relative deformation between two consecutive covers 2 between which a closure cover 8 extends.

- the returns 12 of the covers have chutes having an upper opening and containing a powder material 31.

- the returns 10 of the lids have an L-shaped section and an end portion of the L-shaped section of the lid is pressed into the powder material 31 via the upper opening in the chute when the cover and the cover are nested.

- the realization of such a seal by means of a powder material is possible because the covers and covers extend horizontally so that the powder material remains distributed with a uniform height over the entire length of the chute.

- the powder material serves as a sealing means to form a barrier which prevents the vent gases from escaping.

- the pulverulent material may in particular comprise alumina or crushed electrolysis bath which comprises alumina.

- alumina is a very good adsorbent for the HF and SO2 released by the electrolytic cell so that any infiltration of vat gas through the powder material will have a lower environmental impact.

- the cover further comprises on its upper face pivoting flaps 32 arranged to close the opening of the chute when the cover and the cover are nested. These flaps are intended to retain the powder material in the chute. Flaps may alternatively be arranged on the lid and be fixed.

- the covers 2 have a lower face 16, visible in particular on the figure 8 .

- the lower face 16 may be provided with at least one reinforcing rib 18 intended to limit the bending of the hoods 2.

- the covers 2 may comprise two crossed ribs 18.

- the lower face 16 may be provided with thermal insulation means.

- the thermal insulation means comprise for example rock wool, advantageously maintained and protected by a steel plate.

- the covers 2 and the closure covers 8 comprise a substantially flat plate-like main body.

- This body 20 is intended to extend longitudinally along a transverse direction Y of the electrolysis tank 100.

- the body 20 may be tubular.

- the body 20 advantageously delimits a cavity inside which can be arranged a thermally insulating material, such as rock wool.

- the body 20 may be alternately full, so that the mass of the covers 2 is larger. This allows compression or pinching of a seal 22, visible on the figure 5 and on the figure 11 extending between the support edges 4 of the covers 2 and the part of the electrolysis tank 100 on which these support edges 4 rest, in order to improve the sealing.

- the lower face 16 of the hoods 2 may be provided with deflection means for diverting a flow of tank gas to holes 120 of a tank gas collection system that can equip the tank 100 electrolysis, as will be described in more detail below.

- the closure lids 8 advantageously comprise gripping means, such as a handle 24.

- the gripping means are designed to allow a substantially vertical lift of each closure cover 8 by an electrolysis service machine, such as a bridge. handling, without having to move caps 2 or other caps 8 shutter.

- the lower face 16 may also be designed to allow the covers 2 to rest stably on one of the closure lids 8, to allow the stacking of covers 2 on closure lids 8.

- the lower surface 16 may have a housing (not shown) adapted to receive the gripping means 8 shutter covers.

- the closure caps 8 may also have a bottom face 26 designed to allow the closure caps 8 to rest stably on one of the covers 2, or on another cover 8 shutter.

- the lower surface 26 may have a housing (not shown) adapted to receive gripping means of the hoods 2, these gripping means being intended to allow lifting of the hoods 2 by an electrolysis service machine.

- this cover 8 shutter can be placed on one of the adjacent covers 2.

- the lower face 26 of the closure lids 8 may also be provided with thermal insulation means and / or means for deflecting the vat gases.

- the hoods 2 advantageously have a greater bending stiffness than that of the closing lids 8. In other words, the hoods 2 are more rigid than the closure lids 8.

- the intervention window 6 has a width less than that of the covers 2 that it separates.

- the closure caps 8 may also have a width less than the width of the covers 2.

- the opening formed by the withdrawal of a closure cover 8 is small, the function of the closure lids 8 being able to provide access to the interior of the electrolysis tank 100 with a surface open minimum.

- the invention also relates to the electrolysis tank 100 comprising the cowling system 1.

- This electrolysis tank 100 advantageously comprises sealing means interposed between the support edges 4 of the covers 2 and the sides of the electrolysis tank 101 on which the support edges 4 rest.

- These sealing means comprise for example the seal 22, which extends along the longitudinal sides 101, that is to say in a longitudinal direction X of the electrolytic cell.

- the electrolysis tank 100 advantageously comprises means for clamping this seal 22.

- the clamping means may comprise a screw pressing the support edges 4 of the covers 2 against the upper edge of the longitudinal sides 101, where the seal 22 is located.

- the clamping means may comprise a ballast equipping the covers 2 and / or the closure caps 8, the weight of the covers 2 and / or the closure covers 8 compressing the seal 22.

- each closure cover 8 advantageously extends above and all along a space 111 inter-anodes subjacent. This inter-anode gap separates two adjacent anode assemblies 109 from the electrolytic cell 100.

- Each cover 2 extends above and all along an assembly 109 anode subjacent electrolytic tank 100.

- the electrolysis tank 100 may comprise indexing means adapted to indicate a predetermined position of the hoods 2, this predetermined position being such that the hoods 2 extend to the right of the anode assemblies 109, that is to say to the above sets 109 and parallel to these sets 109 anode.

- the indexing means comprise, for example, lugs, pions or crenellations.

- the electrolysis tank 100 comprises means for capturing the tank gases. These tank gas collection means are designed to capture and collect the tank gases emitted during the electrolysis reaction.

- the capturing means here comprise suction holes 120, represented on the Figures 10 and 11 , arranged under the hoods 2 and the closure lids 8.

- the suction holes 120 allow an air communication between the inside of the electrolysis tank 100 and a collection duct 122 which is intended to conduct the sucked tank gases to a collector where these tank gases will be treated.

- the sheath 122 extends along the longitudinal sides 101 of the electrolytic tank 100.

- the sheath 122 may also be along the transverse sides 103.

- the capturing means may also comprise a diaphragm (not shown), arranged for example at the connection between the capture sheath and the collector.

- the diaphragm is intended to modify an air passage section in order to modify a capture rate of the tank gases.

- each cap 2 is smaller than the width 1 'of the underlying anode assembly 109.

- the intervention window 6 may have a width l "of the order of 350-480 mm, in particular 360 mm, and each bonnet has a width I less than a width of 700 mm. 2000mm.

- the invention also relates to a method of changing a used anode assembly 130 of an electrolytic cell, in particular of the electrolytic cell 100 described above, with a new anode assembly.

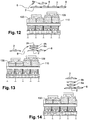

- the method comprises a step of moving a first closure cover 8a among the closure caps 8 of a rollover system 1 as described above, from the shut-off position to the intervention position, as shown in FIG. is represented on the figure 12 .

- This step is performed without moving the covers 2 and the other covers 8 shutter. Thus, a passage is released through the rollover system 1 via one of the intervention windows 6.

- the method advantageously comprises a step of placing the first closure cover 8a on one of the covers 2 adjacent to this first closure cover 8a, as shown in FIG. figure 13 .

- the method also comprises a step of breaking or sawing a crust formed on the surface of the electrolytic bath, by inserting a tool adapted to break or saw the crust through the passage previously released.

- the method comprises a step of moving a second closure cover 8b shutter, the shutter position to the intervention position, without moving the covers 2 and the other covers 8 shutter.

- the second closure cover 8b is initially arranged on the other side of one of the covers 2, in particular the cover 2, where the first shutter cover 8a is not placed, next to which was arranged the first cover 8a shutter, so that a second passage is released on the other side of the cover 2.

- the method comprises a step of breaking or sawing the crust formed on the surface of the electrolytic bath, by inserting a tool adapted to break or saw the crust through this second passage.

- the method may comprise a step of placing the second closure cover 8b on the first closure cover 8a, as is more particularly visible on the figure 13 .

- the method further comprises a step of removing one of the covers 2 initially arranged next to the first 8a shutter cover, in particular the cover 2 which is not posed if necessary the first cover 8a shutter.

- the method may comprise an additional step of stacking this cover on the second closure cover 8b.

- first and optionally the second cover 8a, 8b shutter and the cover 2 are stacked above an anodic assembly 109 unchanged.

- the method may then comprise a step of extracting the spent anode assembly 130, underlying the cap 2 previously removed, and then inserting the new anode assembly inside the electrolysis cell.

- steps can be performed by substantially vertical upward or downward translation, respectively of the used anode assembly 130 and the new anode assembly.

- the method may comprise a step of repositioning the cover 2 previously removed, then the first and second closure cover 8a, 8b.

- first shutter cover 8a and the second shutter cover 8b are displaced by means of an electrolysis service machine, such as a handling bridge, suitable for docking these caps 8 shutter and the cover by their gripping means.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Electrolytic Production Of Metals (AREA)

- Electrolytic Production Of Non-Metals, Compounds, Apparatuses Therefor (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR1400177A FR3016890B1 (fr) | 2014-01-27 | 2014-01-27 | Systeme de capotage pour cuve d'electrolyse |

| PCT/IB2015/000070 WO2015110903A1 (fr) | 2014-01-27 | 2015-01-23 | Système de capotage pour cuve d'électrolyse |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP3099841A1 EP3099841A1 (fr) | 2016-12-07 |

| EP3099841A4 EP3099841A4 (fr) | 2017-11-08 |

| EP3099841B1 true EP3099841B1 (fr) | 2019-07-24 |

Family

ID=50489286

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP15740112.6A Active EP3099841B1 (fr) | 2014-01-27 | 2015-01-23 | Système de capotage pour cuve d'électrolyse |

Country Status (9)

| Country | Link |

|---|---|

| EP (1) | EP3099841B1 (pt) |

| CN (1) | CN105934537B (pt) |

| AU (1) | AU2015208857B2 (pt) |

| BR (1) | BR112016015587B1 (pt) |

| CA (1) | CA2935478C (pt) |

| DK (1) | DK179126B1 (pt) |

| FR (1) | FR3016890B1 (pt) |

| RU (1) | RU2682498C2 (pt) |

| WO (1) | WO2015110903A1 (pt) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107099821B (zh) * | 2017-06-23 | 2023-07-25 | 重庆科技学院 | 一种预焙阳极铝电解槽上部全密封装置 |

| EP4174216A1 (en) * | 2021-10-27 | 2023-05-03 | Dubai Aluminium PJSC | Protection device for anodes of an electrolytic cell, comprising movable panels, and its implementation method |

| CN114318366B (zh) * | 2021-12-02 | 2024-01-30 | 珠海格力电器股份有限公司 | 电解发生装置 |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2822328A (en) * | 1953-07-20 | 1958-02-04 | Henry J Kaiser Company | Bifurcated self-baking anode and gas collection means |

| US3935090A (en) * | 1974-03-15 | 1976-01-27 | Dmitry Pavlovich Petrusenko | Covering of an aluminum-producing electrolysis cell |

| US4043892A (en) * | 1975-12-15 | 1977-08-23 | Reynolds Metals Company | Aluminum reduction cell having a lateral enclosure system |

| DE2841459A1 (de) * | 1978-08-24 | 1980-03-06 | Alusuisse | Abdeckung einer schmelzflusselektrolysezelle |

| NO168542C (no) * | 1989-05-24 | 1992-03-04 | Elkem Aluminium | Anordning for gassoppsamling i ovner for smelteelektrolytisk fremstilling av aluminium. |

| NO172250C (no) * | 1990-05-07 | 1993-06-23 | Elkem Aluminium | Anordning for lukking av anodetoppen paa en soederberganodei en elektrolysecelle for fremstilling av aluminium |

| DE4118304A1 (de) * | 1991-06-04 | 1992-12-24 | Vaw Ver Aluminium Werke Ag | Elektrolysezelle zur aluminiumgewinnung |

| CN2114667U (zh) * | 1992-02-15 | 1992-09-02 | 贾石明 | 安全密封铝电解槽罩门 |

| NO179415C (no) * | 1994-02-21 | 1996-10-02 | Elkem Aluminium | Fremgangsmåte og anordning for lukking og kjöling av toppen av anodemantelen på en Söderberganode i en elektrolysecelle for fremstilling av aluminium |

| NO310730B1 (no) * | 1999-11-17 | 2001-08-20 | Norsk Hydro As | Fremgangsmåte og anordning for drift av elektrolysecelle |

| US6723221B2 (en) * | 2000-07-19 | 2004-04-20 | Alcoa Inc. | Insulation assemblies for metal production cells |

| RU2294407C1 (ru) * | 2005-06-08 | 2007-02-27 | Открытое акционерное общество "Всероссийский алюминиево-магниевый институт" | Укрытие алюминиевого электролизера с обожженными анодами |

| NO328467B1 (no) * | 2005-12-09 | 2010-02-22 | Norsk Hydro As | Fremgangsmate og anordning for innkapsling av en elektrolysecelle |

| RU2385974C2 (ru) * | 2007-10-19 | 2010-04-10 | РУСАЛ АйПи ХОЛДИНГ ЛИМИТЕД | Укрытие алюминиевого электролизера с обожженными анодами |

| FR2953223B1 (fr) * | 2009-12-02 | 2012-01-27 | Alcan Int Ltd | Procede de changement d'une anode usee et support et systeme pour le stockage temporaire d'une telle anode usee |

-

2014

- 2014-01-27 FR FR1400177A patent/FR3016890B1/fr not_active Expired - Fee Related

-

2015

- 2015-01-23 CA CA2935478A patent/CA2935478C/fr active Active

- 2015-01-23 CN CN201580005849.0A patent/CN105934537B/zh active Active

- 2015-01-23 RU RU2016134372A patent/RU2682498C2/ru active

- 2015-01-23 BR BR112016015587-4A patent/BR112016015587B1/pt active IP Right Grant

- 2015-01-23 EP EP15740112.6A patent/EP3099841B1/fr active Active

- 2015-01-23 AU AU2015208857A patent/AU2015208857B2/en active Active

- 2015-01-23 WO PCT/IB2015/000070 patent/WO2015110903A1/fr active Application Filing

-

2016

- 2016-07-19 DK DKPA201670545A patent/DK179126B1/en active

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| CN105934537A (zh) | 2016-09-07 |

| EP3099841A1 (fr) | 2016-12-07 |

| BR112016015587A2 (pt) | 2017-08-08 |

| FR3016890A1 (fr) | 2015-07-31 |

| WO2015110903A1 (fr) | 2015-07-30 |

| AU2015208857B2 (en) | 2018-08-16 |

| CA2935478C (fr) | 2021-11-23 |

| CN105934537B (zh) | 2018-01-05 |

| EP3099841A4 (fr) | 2017-11-08 |

| DK179126B1 (en) | 2017-11-20 |

| RU2016134372A (ru) | 2018-03-02 |

| FR3016890B1 (fr) | 2016-01-15 |

| BR112016015587B1 (pt) | 2022-01-25 |

| CA2935478A1 (fr) | 2015-07-30 |

| RU2682498C2 (ru) | 2019-03-19 |

| RU2016134372A3 (pt) | 2018-10-04 |

| AU2015208857A1 (en) | 2016-07-28 |

| DK201670545A1 (en) | 2016-09-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2459777B1 (fr) | Anode rainuree de cuve d'electrolyse | |

| EP3099841B1 (fr) | Système de capotage pour cuve d'électrolyse | |

| EP3099844B1 (fr) | Cuve d'electrolyse comportant un ensemble anodique contenu dans une enceinte de confinement | |

| WO2009066025A2 (fr) | Anode rainuree de cuve d'εlectrolyse | |

| WO2016103020A1 (fr) | Systeme de confinement pour un ensemble anodique | |

| EP3099843B1 (fr) | Dispositif de stockage d'une charge au-dessus d'une cuve d'électrolyse | |

| FR3012473A1 (fr) | Dispositif d'etancheite pour capot de cellule d'electrolyse | |

| EP3099842B1 (fr) | Caisson de cuve d'électrolyse | |

| FR3016892A1 (fr) | Dispositif de prechauffage d'un ensemble anodique. | |

| FR3032457A1 (fr) | Module de service pour l'exploitation d'une installation de production d'aluminium | |

| FR3032456B1 (fr) | Machine de service pour l'exploitation d'une installation de production d'aluminium | |

| EP3099846A1 (fr) | Dispositif de perçage d'une croûte de bain cryolithaire apte à être positionné en périphérie d'une cuve d'électrolyse | |

| FR3016893A1 (fr) | Cuve d'electrolyse comprenant une paroi de cloisonnement | |

| WO2016128634A1 (fr) | Unité pour l'exploitation d'une installation de production d'aluminium | |

| FR3032454A1 (fr) | Systeme d'etancheite pour une cuve d'electrolyse | |

| FR3016901A1 (fr) | Cuve d'electrolyse pour la production d'aluminium comprenant un dispositif de collecte de gaz. | |

| BE458281A (pt) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20160804 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| A4 | Supplementary search report drawn up and despatched |

Effective date: 20171010 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: C25C 3/22 20060101AFI20171004BHEP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 602015034311 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: C25C0003080000 Ipc: C25C0003220000 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: C25C 3/22 20060101AFI20190301BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20190325 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602015034311 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1158306 Country of ref document: AT Kind code of ref document: T Effective date: 20190815 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20190724 |

|

| REG | Reference to a national code |

Ref country code: NO Ref legal event code: T2 Effective date: 20190724 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 1158306 Country of ref document: AT Kind code of ref document: T Effective date: 20190724 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191024 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191125 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191025 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191124 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200224 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602015034311 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG2D | Information on lapse in contracting state deleted |

Ref country code: IS |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602015034311 Country of ref document: DE |

|

| 26N | No opposition filed |

Effective date: 20200603 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20200123 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20200131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200123 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200123 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200801 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200131 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200131 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200123 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190724 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20231222 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NO Payment date: 20240108 Year of fee payment: 10 |