EP3043960B1 - Flexibler schleifartikel und verfahren zur verwendung davon - Google Patents

Flexibler schleifartikel und verfahren zur verwendung davon Download PDFInfo

- Publication number

- EP3043960B1 EP3043960B1 EP15786616.1A EP15786616A EP3043960B1 EP 3043960 B1 EP3043960 B1 EP 3043960B1 EP 15786616 A EP15786616 A EP 15786616A EP 3043960 B1 EP3043960 B1 EP 3043960B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- abrasive article

- backing

- layer

- flexible abrasive

- mpa

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 238000000034 method Methods 0.000 title claims description 16

- 239000002245 particle Substances 0.000 claims description 47

- 239000002243 precursor Substances 0.000 claims description 47

- NIXOWILDQLNWCW-UHFFFAOYSA-M Acrylate Chemical compound [O-]C(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 claims description 39

- 229920000647 polyepoxide Polymers 0.000 claims description 26

- 229920002803 thermoplastic polyurethane Polymers 0.000 claims description 13

- 239000004433 Thermoplastic polyurethane Substances 0.000 claims description 12

- 239000007795 chemical reaction product Substances 0.000 claims description 7

- 229910052751 metal Inorganic materials 0.000 claims description 5

- 239000002184 metal Substances 0.000 claims description 5

- 239000002023 wood Substances 0.000 claims description 5

- 239000010410 layer Substances 0.000 description 94

- -1 acryl Chemical group 0.000 description 24

- 239000000203 mixture Substances 0.000 description 17

- 229920005989 resin Polymers 0.000 description 17

- 239000011347 resin Substances 0.000 description 17

- XEEYBQQBJWHFJM-UHFFFAOYSA-N iron Substances [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 15

- 238000012360 testing method Methods 0.000 description 14

- 239000000463 material Substances 0.000 description 13

- 230000005855 radiation Effects 0.000 description 13

- 238000000576 coating method Methods 0.000 description 12

- 229920002635 polyurethane Polymers 0.000 description 12

- 239000004814 polyurethane Substances 0.000 description 12

- 150000003839 salts Chemical class 0.000 description 12

- IISBACLAFKSPIT-UHFFFAOYSA-N bisphenol A Chemical compound C=1C=C(O)C=CC=1C(C)(C)C1=CC=C(O)C=C1 IISBACLAFKSPIT-UHFFFAOYSA-N 0.000 description 11

- 125000003118 aryl group Chemical group 0.000 description 10

- 239000011230 binding agent Substances 0.000 description 10

- 239000007787 solid Substances 0.000 description 10

- 239000004593 Epoxy Substances 0.000 description 9

- 239000011248 coating agent Substances 0.000 description 9

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 9

- RTZKZFJDLAIYFH-UHFFFAOYSA-N Diethyl ether Chemical compound CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 8

- 150000001875 compounds Chemical class 0.000 description 8

- 239000007788 liquid Substances 0.000 description 7

- 239000011941 photocatalyst Substances 0.000 description 7

- 239000000126 substance Substances 0.000 description 7

- 150000001252 acrylic acid derivatives Chemical class 0.000 description 6

- 238000001723 curing Methods 0.000 description 6

- 238000000227 grinding Methods 0.000 description 6

- 239000004721 Polyphenylene oxide Substances 0.000 description 5

- 239000000654 additive Substances 0.000 description 5

- 229940106691 bisphenol a Drugs 0.000 description 5

- 229920003986 novolac Polymers 0.000 description 5

- 229920000570 polyether Polymers 0.000 description 5

- 239000000047 product Substances 0.000 description 5

- YIMQCDZDWXUDCA-UHFFFAOYSA-N [4-(hydroxymethyl)cyclohexyl]methanol Chemical compound OCC1CCC(CO)CC1 YIMQCDZDWXUDCA-UHFFFAOYSA-N 0.000 description 4

- 230000008901 benefit Effects 0.000 description 4

- 238000009826 distribution Methods 0.000 description 4

- 125000003700 epoxy group Chemical group 0.000 description 4

- 239000003822 epoxy resin Substances 0.000 description 4

- 239000003999 initiator Substances 0.000 description 4

- 238000000465 moulding Methods 0.000 description 4

- 125000002524 organometallic group Chemical group 0.000 description 4

- ARCGXLSVLAOJQL-UHFFFAOYSA-N trimellitic acid Chemical compound OC(=O)C1=CC=C(C(O)=O)C(C(O)=O)=C1 ARCGXLSVLAOJQL-UHFFFAOYSA-N 0.000 description 4

- 239000008096 xylene Substances 0.000 description 4

- KWVGIHKZDCUPEU-UHFFFAOYSA-N 2,2-dimethoxy-2-phenylacetophenone Chemical compound C=1C=CC=CC=1C(OC)(OC)C(=O)C1=CC=CC=C1 KWVGIHKZDCUPEU-UHFFFAOYSA-N 0.000 description 3

- OECTYKWYRCHAKR-UHFFFAOYSA-N 4-vinylcyclohexene dioxide Chemical compound C1OC1C1CC2OC2CC1 OECTYKWYRCHAKR-UHFFFAOYSA-N 0.000 description 3

- LYCAIKOWRPUZTN-UHFFFAOYSA-N Ethylene glycol Chemical compound OCCO LYCAIKOWRPUZTN-UHFFFAOYSA-N 0.000 description 3

- PEDCQBHIVMGVHV-UHFFFAOYSA-N Glycerine Chemical compound OCC(O)CO PEDCQBHIVMGVHV-UHFFFAOYSA-N 0.000 description 3

- MUBZPKHOEPUJKR-UHFFFAOYSA-N Oxalic acid Chemical compound OC(=O)C(O)=O MUBZPKHOEPUJKR-UHFFFAOYSA-N 0.000 description 3

- DAKWPKUUDNSNPN-UHFFFAOYSA-N Trimethylolpropane triacrylate Chemical compound C=CC(=O)OCC(CC)(COC(=O)C=C)COC(=O)C=C DAKWPKUUDNSNPN-UHFFFAOYSA-N 0.000 description 3

- MCMNRKCIXSYSNV-UHFFFAOYSA-N ZrO2 Inorganic materials O=[Zr]=O MCMNRKCIXSYSNV-UHFFFAOYSA-N 0.000 description 3

- 125000001931 aliphatic group Chemical group 0.000 description 3

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 3

- LSQZJLSUYDQPKJ-NJBDSQKTSA-N amoxicillin Chemical compound C1([C@@H](N)C(=O)N[C@H]2[C@H]3SC([C@@H](N3C2=O)C(O)=O)(C)C)=CC=C(O)C=C1 LSQZJLSUYDQPKJ-NJBDSQKTSA-N 0.000 description 3

- ISAOCJYIOMOJEB-UHFFFAOYSA-N benzoin Chemical compound C=1C=CC=CC=1C(O)C(=O)C1=CC=CC=C1 ISAOCJYIOMOJEB-UHFFFAOYSA-N 0.000 description 3

- 239000011246 composite particle Substances 0.000 description 3

- 229910001610 cryolite Inorganic materials 0.000 description 3

- 238000005520 cutting process Methods 0.000 description 3

- 125000005520 diaryliodonium group Chemical group 0.000 description 3

- 238000010894 electron beam technology Methods 0.000 description 3

- 150000002148 esters Chemical class 0.000 description 3

- 238000011156 evaluation Methods 0.000 description 3

- 239000000945 filler Substances 0.000 description 3

- LNEPOXFFQSENCJ-UHFFFAOYSA-N haloperidol Chemical compound C1CC(O)(C=2C=CC(Cl)=CC=2)CCN1CCCC(=O)C1=CC=C(F)C=C1 LNEPOXFFQSENCJ-UHFFFAOYSA-N 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- 238000002360 preparation method Methods 0.000 description 3

- RUOJZAUFBMNUDX-UHFFFAOYSA-N propylene carbonate Chemical compound CC1COC(=O)O1 RUOJZAUFBMNUDX-UHFFFAOYSA-N 0.000 description 3

- 239000000758 substrate Substances 0.000 description 3

- RWSOTUBLDIXVET-UHFFFAOYSA-O sulfonium Chemical compound [SH3+] RWSOTUBLDIXVET-UHFFFAOYSA-O 0.000 description 3

- 229920001169 thermoplastic Polymers 0.000 description 3

- 239000004416 thermosoftening plastic Substances 0.000 description 3

- CQGDBBBZCJYDRY-UHFFFAOYSA-N 1-methoxyanthracene-9,10-dione Chemical compound O=C1C2=CC=CC=C2C(=O)C2=C1C=CC=C2OC CQGDBBBZCJYDRY-UHFFFAOYSA-N 0.000 description 2

- KUBDPQJOLOUJRM-UHFFFAOYSA-N 2-(chloromethyl)oxirane;4-[2-(4-hydroxyphenyl)propan-2-yl]phenol Chemical compound ClCC1CO1.C=1C=C(O)C=CC=1C(C)(C)C1=CC=C(O)C=C1 KUBDPQJOLOUJRM-UHFFFAOYSA-N 0.000 description 2

- XMLYCEVDHLAQEL-UHFFFAOYSA-N 2-hydroxy-2-methyl-1-phenylpropan-1-one Chemical compound CC(C)(O)C(=O)C1=CC=CC=C1 XMLYCEVDHLAQEL-UHFFFAOYSA-N 0.000 description 2

- YXALYBMHAYZKAP-UHFFFAOYSA-N 7-oxabicyclo[4.1.0]heptan-4-ylmethyl 7-oxabicyclo[4.1.0]heptane-4-carboxylate Chemical compound C1CC2OC2CC1C(=O)OCC1CC2OC2CC1 YXALYBMHAYZKAP-UHFFFAOYSA-N 0.000 description 2

- KWOLFJPFCHCOCG-UHFFFAOYSA-N Acetophenone Chemical compound CC(=O)C1=CC=CC=C1 KWOLFJPFCHCOCG-UHFFFAOYSA-N 0.000 description 2

- 229910052582 BN Inorganic materials 0.000 description 2

- ADAHGVUHKDNLEB-UHFFFAOYSA-N Bis(2,3-epoxycyclopentyl)ether Chemical compound C1CC2OC2C1OC1CCC2OC21 ADAHGVUHKDNLEB-UHFFFAOYSA-N 0.000 description 2

- LCFVJGUPQDGYKZ-UHFFFAOYSA-N Bisphenol A diglycidyl ether Chemical compound C=1C=C(OCC2OC2)C=CC=1C(C)(C)C(C=C1)=CC=C1OCC1CO1 LCFVJGUPQDGYKZ-UHFFFAOYSA-N 0.000 description 2

- PZNSFCLAULLKQX-UHFFFAOYSA-N Boron nitride Chemical compound N#B PZNSFCLAULLKQX-UHFFFAOYSA-N 0.000 description 2

- FBPFZTCFMRRESA-FSIIMWSLSA-N D-Glucitol Natural products OC[C@H](O)[C@H](O)[C@@H](O)[C@H](O)CO FBPFZTCFMRRESA-FSIIMWSLSA-N 0.000 description 2

- FBPFZTCFMRRESA-JGWLITMVSA-N D-glucitol Chemical compound OC[C@H](O)[C@@H](O)[C@H](O)[C@H](O)CO FBPFZTCFMRRESA-JGWLITMVSA-N 0.000 description 2

- JOYRKODLDBILNP-UHFFFAOYSA-N Ethyl urethane Chemical compound CCOC(N)=O JOYRKODLDBILNP-UHFFFAOYSA-N 0.000 description 2

- TWRXJAOTZQYOKJ-UHFFFAOYSA-L Magnesium chloride Chemical compound [Mg+2].[Cl-].[Cl-] TWRXJAOTZQYOKJ-UHFFFAOYSA-L 0.000 description 2

- CERQOIWHTDAKMF-UHFFFAOYSA-M Methacrylate Chemical compound CC(=C)C([O-])=O CERQOIWHTDAKMF-UHFFFAOYSA-M 0.000 description 2

- WCUXLLCKKVVCTQ-UHFFFAOYSA-M Potassium chloride Chemical compound [Cl-].[K+] WCUXLLCKKVVCTQ-UHFFFAOYSA-M 0.000 description 2

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical compound [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 description 2

- 244000028419 Styrax benzoin Species 0.000 description 2

- 235000000126 Styrax benzoin Nutrition 0.000 description 2

- 235000008411 Sumatra benzointree Nutrition 0.000 description 2

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 2

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 2

- ZJCCRDAZUWHFQH-UHFFFAOYSA-N Trimethylolpropane Chemical compound CCC(CO)(CO)CO ZJCCRDAZUWHFQH-UHFFFAOYSA-N 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 2

- 230000001070 adhesive effect Effects 0.000 description 2

- 150000004056 anthraquinones Chemical class 0.000 description 2

- 239000003963 antioxidant agent Substances 0.000 description 2

- 229960002130 benzoin Drugs 0.000 description 2

- LMMDJMWIHPEQSJ-UHFFFAOYSA-N bis[(3-methyl-7-oxabicyclo[4.1.0]heptan-4-yl)methyl] hexanedioate Chemical compound C1C2OC2CC(C)C1COC(=O)CCCCC(=O)OCC1CC2OC2CC1C LMMDJMWIHPEQSJ-UHFFFAOYSA-N 0.000 description 2

- PXKLMJQFEQBVLD-UHFFFAOYSA-N bisphenol F Chemical compound C1=CC(O)=CC=C1CC1=CC=C(O)C=C1 PXKLMJQFEQBVLD-UHFFFAOYSA-N 0.000 description 2

- 239000000919 ceramic Substances 0.000 description 2

- 239000003086 colorant Substances 0.000 description 2

- 230000000052 comparative effect Effects 0.000 description 2

- 238000007766 curtain coating Methods 0.000 description 2

- 125000004386 diacrylate group Chemical group 0.000 description 2

- 229910003460 diamond Inorganic materials 0.000 description 2

- 239000010432 diamond Substances 0.000 description 2

- 239000012955 diaryliodonium Substances 0.000 description 2

- 238000007607 die coating method Methods 0.000 description 2

- 238000004090 dissolution Methods 0.000 description 2

- 229920001971 elastomer Polymers 0.000 description 2

- 238000001125 extrusion Methods 0.000 description 2

- 238000009472 formulation Methods 0.000 description 2

- 239000012949 free radical photoinitiator Substances 0.000 description 2

- 230000004927 fusion Effects 0.000 description 2

- 239000002223 garnet Substances 0.000 description 2

- 235000019382 gum benzoic Nutrition 0.000 description 2

- 230000006872 improvement Effects 0.000 description 2

- MGFYSGNNHQQTJW-UHFFFAOYSA-N iodonium Chemical compound [IH2+] MGFYSGNNHQQTJW-UHFFFAOYSA-N 0.000 description 2

- 229910052742 iron Inorganic materials 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- 239000000178 monomer Substances 0.000 description 2

- 150000002896 organic halogen compounds Chemical class 0.000 description 2

- WXZMFSXDPGVJKK-UHFFFAOYSA-N pentaerythritol Chemical compound OCC(CO)(CO)CO WXZMFSXDPGVJKK-UHFFFAOYSA-N 0.000 description 2

- 229920001568 phenolic resin Polymers 0.000 description 2

- 125000001997 phenyl group Chemical group [H]C1=C([H])C([H])=C(*)C([H])=C1[H] 0.000 description 2

- 150000003014 phosphoric acid esters Chemical class 0.000 description 2

- 239000000049 pigment Substances 0.000 description 2

- 229920000768 polyamine Polymers 0.000 description 2

- 229920000728 polyester Polymers 0.000 description 2

- 229920005862 polyol Polymers 0.000 description 2

- 150000003077 polyols Chemical class 0.000 description 2

- CYIDZMCFTVVTJO-UHFFFAOYSA-N pyromellitic acid Chemical compound OC(=O)C1=CC(C(O)=O)=C(C(O)=O)C=C1C(O)=O CYIDZMCFTVVTJO-UHFFFAOYSA-N 0.000 description 2

- 239000007870 radical polymerization initiator Substances 0.000 description 2

- 230000000717 retained effect Effects 0.000 description 2

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 2

- 229910010271 silicon carbide Inorganic materials 0.000 description 2

- 239000000600 sorbitol Substances 0.000 description 2

- 238000001228 spectrum Methods 0.000 description 2

- 238000005507 spraying Methods 0.000 description 2

- 238000010998 test method Methods 0.000 description 2

- 229910052719 titanium Inorganic materials 0.000 description 2

- 239000010936 titanium Substances 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 239000001993 wax Substances 0.000 description 2

- XOOUIPVCVHRTMJ-UHFFFAOYSA-L zinc stearate Chemical compound [Zn+2].CCCCCCCCCCCCCCCCCC([O-])=O.CCCCCCCCCCCCCCCCCC([O-])=O XOOUIPVCVHRTMJ-UHFFFAOYSA-L 0.000 description 2

- MXFQRSUWYYSPOC-UHFFFAOYSA-N (2,2-dimethyl-3-prop-2-enoyloxypropyl) prop-2-enoate Chemical compound C=CC(=O)OCC(C)(C)COC(=O)C=C MXFQRSUWYYSPOC-UHFFFAOYSA-N 0.000 description 1

- LEECYHUVEPKMQZ-UHFFFAOYSA-N (5-methyl-7-oxabicyclo[4.1.0]heptan-4-yl)methyl 5-methyl-7-oxabicyclo[4.1.0]heptane-4-carboxylate Chemical compound C1CC2OC2C(C)C1C(=O)OCC1CCC2OC2C1C LEECYHUVEPKMQZ-UHFFFAOYSA-N 0.000 description 1

- JRZKNHITLINYHV-UHFFFAOYSA-N 1,2,3,4,5-pentachloronaphthalene Chemical compound ClC1=CC=CC2=C(Cl)C(Cl)=C(Cl)C(Cl)=C21 JRZKNHITLINYHV-UHFFFAOYSA-N 0.000 description 1

- NAQWICRLNQSPPW-UHFFFAOYSA-N 1,2,3,4-tetrachloronaphthalene Chemical compound C1=CC=CC2=C(Cl)C(Cl)=C(Cl)C(Cl)=C21 NAQWICRLNQSPPW-UHFFFAOYSA-N 0.000 description 1

- MYWOJODOMFBVCB-UHFFFAOYSA-N 1,2,6-trimethylphenanthrene Chemical compound CC1=CC=C2C3=CC(C)=CC=C3C=CC2=C1C MYWOJODOMFBVCB-UHFFFAOYSA-N 0.000 description 1

- DVFAVJDEPNXAME-UHFFFAOYSA-N 1,4-dimethylanthracene-9,10-dione Chemical compound O=C1C2=CC=CC=C2C(=O)C2=C1C(C)=CC=C2C DVFAVJDEPNXAME-UHFFFAOYSA-N 0.000 description 1

- BOCJQSFSGAZAPQ-UHFFFAOYSA-N 1-chloroanthracene-9,10-dione Chemical compound O=C1C2=CC=CC=C2C(=O)C2=C1C=CC=C2Cl BOCJQSFSGAZAPQ-UHFFFAOYSA-N 0.000 description 1

- 239000012956 1-hydroxycyclohexylphenyl-ketone Substances 0.000 description 1

- SMZOUWXMTYCWNB-UHFFFAOYSA-N 2-(2-methoxy-5-methylphenyl)ethanamine Chemical compound COC1=CC=C(C)C=C1CCN SMZOUWXMTYCWNB-UHFFFAOYSA-N 0.000 description 1

- NIXOWILDQLNWCW-UHFFFAOYSA-N 2-Propenoic acid Natural products OC(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 1

- TXBCBTDQIULDIA-UHFFFAOYSA-N 2-[[3-hydroxy-2,2-bis(hydroxymethyl)propoxy]methyl]-2-(hydroxymethyl)propane-1,3-diol Chemical compound OCC(CO)(CO)COCC(CO)(CO)CO TXBCBTDQIULDIA-UHFFFAOYSA-N 0.000 description 1

- DZZAHLOABNWIFA-UHFFFAOYSA-N 2-butoxy-1,2-diphenylethanone Chemical compound C=1C=CC=CC=1C(OCCCC)C(=O)C1=CC=CC=C1 DZZAHLOABNWIFA-UHFFFAOYSA-N 0.000 description 1

- KMNCBSZOIQAUFX-UHFFFAOYSA-N 2-ethoxy-1,2-diphenylethanone Chemical compound C=1C=CC=CC=1C(OCC)C(=O)C1=CC=CC=C1 KMNCBSZOIQAUFX-UHFFFAOYSA-N 0.000 description 1

- GTELLNMUWNJXMQ-UHFFFAOYSA-N 2-ethyl-2-(hydroxymethyl)propane-1,3-diol;prop-2-enoic acid Chemical class OC(=O)C=C.OC(=O)C=C.OC(=O)C=C.CCC(CO)(CO)CO GTELLNMUWNJXMQ-UHFFFAOYSA-N 0.000 description 1

- SJEBAWHUJDUKQK-UHFFFAOYSA-N 2-ethylanthraquinone Chemical compound C1=CC=C2C(=O)C3=CC(CC)=CC=C3C(=O)C2=C1 SJEBAWHUJDUKQK-UHFFFAOYSA-N 0.000 description 1

- CKKQLOUBFINSIB-UHFFFAOYSA-N 2-hydroxy-1,2,2-triphenylethanone Chemical compound C=1C=CC=CC=1C(C=1C=CC=CC=1)(O)C(=O)C1=CC=CC=C1 CKKQLOUBFINSIB-UHFFFAOYSA-N 0.000 description 1

- YOJAHTBCSGPSOR-UHFFFAOYSA-N 2-hydroxy-1,2,3-triphenylpropan-1-one Chemical compound C=1C=CC=CC=1C(=O)C(C=1C=CC=CC=1)(O)CC1=CC=CC=C1 YOJAHTBCSGPSOR-UHFFFAOYSA-N 0.000 description 1

- LRRQSCPPOIUNGX-UHFFFAOYSA-N 2-hydroxy-1,2-bis(4-methoxyphenyl)ethanone Chemical compound C1=CC(OC)=CC=C1C(O)C(=O)C1=CC=C(OC)C=C1 LRRQSCPPOIUNGX-UHFFFAOYSA-N 0.000 description 1

- RZCDMINQJLGWEP-UHFFFAOYSA-N 2-hydroxy-1,2-diphenylpent-4-en-1-one Chemical compound C=1C=CC=CC=1C(CC=C)(O)C(=O)C1=CC=CC=C1 RZCDMINQJLGWEP-UHFFFAOYSA-N 0.000 description 1

- DIVXVZXROTWKIH-UHFFFAOYSA-N 2-hydroxy-1,2-diphenylpropan-1-one Chemical compound C=1C=CC=CC=1C(O)(C)C(=O)C1=CC=CC=C1 DIVXVZXROTWKIH-UHFFFAOYSA-N 0.000 description 1

- BQZJOQXSCSZQPS-UHFFFAOYSA-N 2-methoxy-1,2-diphenylethanone Chemical compound C=1C=CC=CC=1C(OC)C(=O)C1=CC=CC=C1 BQZJOQXSCSZQPS-UHFFFAOYSA-N 0.000 description 1

- LWRBVKNFOYUCNP-UHFFFAOYSA-N 2-methyl-1-(4-methylsulfanylphenyl)-2-morpholin-4-ylpropan-1-one Chemical compound C1=CC(SC)=CC=C1C(=O)C(C)(C)N1CCOCC1 LWRBVKNFOYUCNP-UHFFFAOYSA-N 0.000 description 1

- MSXVEPNJUHWQHW-UHFFFAOYSA-N 2-methylbutan-2-ol Chemical compound CCC(C)(C)O MSXVEPNJUHWQHW-UHFFFAOYSA-N 0.000 description 1

- GRWFFFOEIHGUBG-UHFFFAOYSA-N 3,4-Epoxy-6-methylcyclohexylmethyl-3,4-epoxy-6-methylcyclo-hexanecarboxylate Chemical compound C1C2OC2CC(C)C1C(=O)OCC1CC2OC2CC1C GRWFFFOEIHGUBG-UHFFFAOYSA-N 0.000 description 1

- ZRYCRPNCXLQHPN-UHFFFAOYSA-N 3-hydroxy-2-methylbenzaldehyde Chemical compound CC1=C(O)C=CC=C1C=O ZRYCRPNCXLQHPN-UHFFFAOYSA-N 0.000 description 1

- QGHDLJAZIIFENW-UHFFFAOYSA-N 4-[1,1,1,3,3,3-hexafluoro-2-(4-hydroxy-3-prop-2-enylphenyl)propan-2-yl]-2-prop-2-enylphenol Chemical group C1=C(CC=C)C(O)=CC=C1C(C(F)(F)F)(C(F)(F)F)C1=CC=C(O)C(CC=C)=C1 QGHDLJAZIIFENW-UHFFFAOYSA-N 0.000 description 1

- HVMHLMJYHBAOPL-UHFFFAOYSA-N 4-[2-(7-oxabicyclo[4.1.0]heptan-4-yl)propan-2-yl]-7-oxabicyclo[4.1.0]heptane Chemical compound C1CC2OC2CC1C(C)(C)C1CC2OC2CC1 HVMHLMJYHBAOPL-UHFFFAOYSA-N 0.000 description 1

- YMRDPCUYKKPMFC-UHFFFAOYSA-N 4-hydroxy-2,2,5,5-tetramethylhexan-3-one Chemical compound CC(C)(C)C(O)C(=O)C(C)(C)C YMRDPCUYKKPMFC-UHFFFAOYSA-N 0.000 description 1

- UULBKYXWPANSHS-UHFFFAOYSA-N 6-[bis(4-methyl-7-oxabicyclo[4.1.0]heptan-3-yl)methoxy]-6-oxohexanoic acid Chemical compound C1C2OC2CC(C)C1C(OC(=O)CCCCC(O)=O)C1CC2OC2CC1C UULBKYXWPANSHS-UHFFFAOYSA-N 0.000 description 1

- NHJIDZUQMHKGRE-UHFFFAOYSA-N 7-oxabicyclo[4.1.0]heptan-4-yl 2-(7-oxabicyclo[4.1.0]heptan-4-yl)acetate Chemical compound C1CC2OC2CC1OC(=O)CC1CC2OC2CC1 NHJIDZUQMHKGRE-UHFFFAOYSA-N 0.000 description 1

- QGZKDVFQNNGYKY-UHFFFAOYSA-O Ammonium Chemical compound [NH4+] QGZKDVFQNNGYKY-UHFFFAOYSA-O 0.000 description 1

- 229910021630 Antimony pentafluoride Inorganic materials 0.000 description 1

- 241000842962 Apoda limacodes Species 0.000 description 1

- QYEXBYZXHDUPRC-UHFFFAOYSA-N B#[Ti]#B Chemical compound B#[Ti]#B QYEXBYZXHDUPRC-UHFFFAOYSA-N 0.000 description 1

- 229910052580 B4C Inorganic materials 0.000 description 1

- OYPRJOBELJOOCE-UHFFFAOYSA-N Calcium Chemical compound [Ca] OYPRJOBELJOOCE-UHFFFAOYSA-N 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 239000004970 Chain extender Substances 0.000 description 1

- 229920001634 Copolyester Polymers 0.000 description 1

- ZMDDERVSCYEKPQ-UHFFFAOYSA-N Ethyl (mesitylcarbonyl)phenylphosphinate Chemical compound C=1C=CC=CC=1P(=O)(OCC)C(=O)C1=C(C)C=C(C)C=C1C ZMDDERVSCYEKPQ-UHFFFAOYSA-N 0.000 description 1

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 1

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 1

- 239000006057 Non-nutritive feed additive Substances 0.000 description 1

- CTQNGGLPUBDAKN-UHFFFAOYSA-N O-Xylene Chemical compound CC1=CC=CC=C1C CTQNGGLPUBDAKN-UHFFFAOYSA-N 0.000 description 1

- ZLMJMSJWJFRBEC-UHFFFAOYSA-N Potassium Chemical compound [K] ZLMJMSJWJFRBEC-UHFFFAOYSA-N 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- 108091092920 SmY RNA Proteins 0.000 description 1

- 241001237710 Smyrna Species 0.000 description 1

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 1

- 229910033181 TiB2 Inorganic materials 0.000 description 1

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 1

- 239000013036 UV Light Stabilizer Substances 0.000 description 1

- 229920001807 Urea-formaldehyde Polymers 0.000 description 1

- VZTQQYMRXDUHDO-UHFFFAOYSA-N [2-hydroxy-3-[4-[2-[4-(2-hydroxy-3-prop-2-enoyloxypropoxy)phenyl]propan-2-yl]phenoxy]propyl] prop-2-enoate Chemical compound C=1C=C(OCC(O)COC(=O)C=C)C=CC=1C(C)(C)C1=CC=C(OCC(O)COC(=O)C=C)C=C1 VZTQQYMRXDUHDO-UHFFFAOYSA-N 0.000 description 1

- 239000003082 abrasive agent Substances 0.000 description 1

- 239000006061 abrasive grain Substances 0.000 description 1

- 238000009825 accumulation Methods 0.000 description 1

- 239000003377 acid catalyst Substances 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 239000002390 adhesive tape Substances 0.000 description 1

- 229920000180 alkyd Polymers 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 150000001408 amides Chemical class 0.000 description 1

- 229920003180 amino resin Polymers 0.000 description 1

- PYKYMHQGRFAEBM-UHFFFAOYSA-N anthraquinone Natural products CCC(=O)c1c(O)c2C(=O)C3C(C=CC=C3O)C(=O)c2cc1CC(=O)OC PYKYMHQGRFAEBM-UHFFFAOYSA-N 0.000 description 1

- 229910052787 antimony Inorganic materials 0.000 description 1

- WATWJIUSRGPENY-UHFFFAOYSA-N antimony atom Chemical compound [Sb] WATWJIUSRGPENY-UHFFFAOYSA-N 0.000 description 1

- 239000002216 antistatic agent Substances 0.000 description 1

- 150000004982 aromatic amines Chemical class 0.000 description 1

- UHOVQNZJYSORNB-UHFFFAOYSA-N benzene Substances C1=CC=CC=C1 UHOVQNZJYSORNB-UHFFFAOYSA-N 0.000 description 1

- RWCCWEUUXYIKHB-UHFFFAOYSA-N benzophenone Chemical compound C=1C=CC=CC=1C(=O)C1=CC=CC=C1 RWCCWEUUXYIKHB-UHFFFAOYSA-N 0.000 description 1

- 239000012965 benzophenone Substances 0.000 description 1

- AIKZXVUWCRXZFS-UHFFFAOYSA-N bis(2-methylbutan-2-yl) oxalate Chemical compound CCC(C)(C)OC(=O)C(=O)OC(C)(C)CC AIKZXVUWCRXZFS-UHFFFAOYSA-N 0.000 description 1

- JRPRCOLKIYRSNH-UHFFFAOYSA-N bis(oxiran-2-ylmethyl) benzene-1,2-dicarboxylate Chemical compound C=1C=CC=C(C(=O)OCC2OC2)C=1C(=O)OCC1CO1 JRPRCOLKIYRSNH-UHFFFAOYSA-N 0.000 description 1

- ZXOATMQSUNJNNG-UHFFFAOYSA-N bis(oxiran-2-ylmethyl) benzene-1,3-dicarboxylate Chemical compound C=1C=CC(C(=O)OCC2OC2)=CC=1C(=O)OCC1CO1 ZXOATMQSUNJNNG-UHFFFAOYSA-N 0.000 description 1

- NEPKLUNSRVEBIX-UHFFFAOYSA-N bis(oxiran-2-ylmethyl) benzene-1,4-dicarboxylate Chemical compound C=1C=C(C(=O)OCC2OC2)C=CC=1C(=O)OCC1CO1 NEPKLUNSRVEBIX-UHFFFAOYSA-N 0.000 description 1

- MQDJYUACMFCOFT-UHFFFAOYSA-N bis[2-(1-hydroxycyclohexyl)phenyl]methanone Chemical compound C=1C=CC=C(C(=O)C=2C(=CC=CC=2)C2(O)CCCCC2)C=1C1(O)CCCCC1 MQDJYUACMFCOFT-UHFFFAOYSA-N 0.000 description 1

- 229910052797 bismuth Inorganic materials 0.000 description 1

- JCXGWMGPZLAOME-UHFFFAOYSA-N bismuth atom Chemical compound [Bi] JCXGWMGPZLAOME-UHFFFAOYSA-N 0.000 description 1

- 239000004841 bisphenol A epoxy resin Substances 0.000 description 1

- INAHAJYZKVIDIZ-UHFFFAOYSA-N boron carbide Chemical compound B12B3B4C32B41 INAHAJYZKVIDIZ-UHFFFAOYSA-N 0.000 description 1

- CDQSJQSWAWPGKG-UHFFFAOYSA-N butane-1,1-diol Chemical compound CCCC(O)O CDQSJQSWAWPGKG-UHFFFAOYSA-N 0.000 description 1

- 229910052793 cadmium Inorganic materials 0.000 description 1

- BDOSMKKIYDKNTQ-UHFFFAOYSA-N cadmium atom Chemical compound [Cd] BDOSMKKIYDKNTQ-UHFFFAOYSA-N 0.000 description 1

- 239000011575 calcium Substances 0.000 description 1

- 229910052791 calcium Inorganic materials 0.000 description 1

- CJZGTCYPCWQAJB-UHFFFAOYSA-L calcium stearate Chemical compound [Ca+2].CCCCCCCCCCCCCCCCCC([O-])=O.CCCCCCCCCCCCCCCCCC([O-])=O CJZGTCYPCWQAJB-UHFFFAOYSA-L 0.000 description 1

- 239000008116 calcium stearate Substances 0.000 description 1

- 235000013539 calcium stearate Nutrition 0.000 description 1

- 239000003054 catalyst Substances 0.000 description 1

- 238000010538 cationic polymerization reaction Methods 0.000 description 1

- 150000001768 cations Chemical class 0.000 description 1

- 229920006217 cellulose acetate butyrate Polymers 0.000 description 1

- CETPSERCERDGAM-UHFFFAOYSA-N ceric oxide Chemical compound O=[Ce]=O CETPSERCERDGAM-UHFFFAOYSA-N 0.000 description 1

- 229910000422 cerium(IV) oxide Inorganic materials 0.000 description 1

- 239000011362 coarse particle Substances 0.000 description 1

- 229910017052 cobalt Inorganic materials 0.000 description 1

- 239000010941 cobalt Substances 0.000 description 1

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000010924 continuous production Methods 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 239000007822 coupling agent Substances 0.000 description 1

- XLJMAIOERFSOGZ-UHFFFAOYSA-M cyanate Chemical compound [O-]C#N XLJMAIOERFSOGZ-UHFFFAOYSA-M 0.000 description 1

- 230000007812 deficiency Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- KORSJDCBLAPZEQ-UHFFFAOYSA-N dicyclohexylmethane-4,4'-diisocyanate Chemical compound C1CC(N=C=O)CCC1CC1CCC(N=C=O)CC1 KORSJDCBLAPZEQ-UHFFFAOYSA-N 0.000 description 1

- BQQUFAMSJAKLNB-UHFFFAOYSA-N dicyclopentadiene diepoxide Chemical compound C12C(C3OC33)CC3C2CC2C1O2 BQQUFAMSJAKLNB-UHFFFAOYSA-N 0.000 description 1

- 235000014113 dietary fatty acids Nutrition 0.000 description 1

- GYZLOYUZLJXAJU-UHFFFAOYSA-N diglycidyl ether Chemical compound C1OC1COCC1CO1 GYZLOYUZLJXAJU-UHFFFAOYSA-N 0.000 description 1

- 239000003085 diluting agent Substances 0.000 description 1

- 150000002009 diols Chemical class 0.000 description 1

- LTYMSROWYAPPGB-UHFFFAOYSA-O diphenylsulfanium Chemical compound C=1C=CC=CC=1[SH+]C1=CC=CC=C1 LTYMSROWYAPPGB-UHFFFAOYSA-O 0.000 description 1

- RYEOCIUXFIZXNC-UHFFFAOYSA-L dipotassium;docosyl phosphate Chemical compound [K+].[K+].CCCCCCCCCCCCCCCCCCCCCCOP([O-])([O-])=O RYEOCIUXFIZXNC-UHFFFAOYSA-L 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 239000000975 dye Substances 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000005670 electromagnetic radiation Effects 0.000 description 1

- 229910001651 emery Inorganic materials 0.000 description 1

- 150000002118 epoxides Chemical class 0.000 description 1

- 230000032050 esterification Effects 0.000 description 1

- 238000005886 esterification reaction Methods 0.000 description 1

- 150000002170 ethers Chemical class 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 239000000194 fatty acid Substances 0.000 description 1

- 229930195729 fatty acid Natural products 0.000 description 1

- 150000004665 fatty acids Chemical class 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 239000003063 flame retardant Substances 0.000 description 1

- SLGWESQGEUXWJQ-UHFFFAOYSA-N formaldehyde;phenol Chemical compound O=C.OC1=CC=CC=C1 SLGWESQGEUXWJQ-UHFFFAOYSA-N 0.000 description 1

- 239000003205 fragrance Substances 0.000 description 1

- 229940083124 ganglion-blocking antiadrenergic secondary and tertiary amines Drugs 0.000 description 1

- 125000003055 glycidyl group Chemical group C(C1CO1)* 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 238000007756 gravure coating Methods 0.000 description 1

- ACCCMOQWYVYDOT-UHFFFAOYSA-N hexane-1,1-diol Chemical compound CCCCCC(O)O ACCCMOQWYVYDOT-UHFFFAOYSA-N 0.000 description 1

- 229930195733 hydrocarbon Natural products 0.000 description 1

- 150000003949 imides Chemical class 0.000 description 1

- 239000004615 ingredient Substances 0.000 description 1

- 229910052500 inorganic mineral Inorganic materials 0.000 description 1

- 230000005865 ionizing radiation Effects 0.000 description 1

- 239000012948 isocyanate Substances 0.000 description 1

- 150000002513 isocyanates Chemical class 0.000 description 1

- 238000003698 laser cutting Methods 0.000 description 1

- 238000010330 laser marking Methods 0.000 description 1

- 239000011968 lewis acid catalyst Substances 0.000 description 1

- 239000004611 light stabiliser Substances 0.000 description 1

- 238000011068 loading method Methods 0.000 description 1

- 239000000314 lubricant Substances 0.000 description 1

- 239000011777 magnesium Substances 0.000 description 1

- 229910052749 magnesium Inorganic materials 0.000 description 1

- 229910001629 magnesium chloride Inorganic materials 0.000 description 1

- 238000010128 melt processing Methods 0.000 description 1

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 description 1

- 229910052753 mercury Inorganic materials 0.000 description 1

- AUHZEENZYGFFBQ-UHFFFAOYSA-N mesitylene Substances CC1=CC(C)=CC(C)=C1 AUHZEENZYGFFBQ-UHFFFAOYSA-N 0.000 description 1

- 229910044991 metal oxide Inorganic materials 0.000 description 1

- 150000004706 metal oxides Chemical class 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 125000005641 methacryl group Chemical group 0.000 description 1

- YDKNBNOOCSNPNS-UHFFFAOYSA-N methyl 1,3-benzoxazole-2-carboxylate Chemical compound C1=CC=C2OC(C(=O)OC)=NC2=C1 YDKNBNOOCSNPNS-UHFFFAOYSA-N 0.000 description 1

- 235000010755 mineral Nutrition 0.000 description 1

- 239000011707 mineral Substances 0.000 description 1

- 239000002480 mineral oil Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000003607 modifier Substances 0.000 description 1

- SLCVBVWXLSEKPL-UHFFFAOYSA-N neopentyl glycol Chemical compound OCC(C)(C)CO SLCVBVWXLSEKPL-UHFFFAOYSA-N 0.000 description 1

- 239000002667 nucleating agent Substances 0.000 description 1

- 238000010899 nucleation Methods 0.000 description 1

- 229940078552 o-xylene Drugs 0.000 description 1

- 150000002898 organic sulfur compounds Chemical class 0.000 description 1

- 235000006408 oxalic acid Nutrition 0.000 description 1

- 239000005011 phenolic resin Substances 0.000 description 1

- 150000002989 phenols Chemical class 0.000 description 1

- 238000000016 photochemical curing Methods 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 239000004014 plasticizer Substances 0.000 description 1

- 229940113115 polyethylene glycol 200 Drugs 0.000 description 1

- 229940068918 polyethylene glycol 400 Drugs 0.000 description 1

- 229920000139 polyethylene terephthalate Polymers 0.000 description 1

- 239000005020 polyethylene terephthalate Substances 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 239000002685 polymerization catalyst Substances 0.000 description 1

- 230000000379 polymerizing effect Effects 0.000 description 1

- 229920000193 polymethacrylate Polymers 0.000 description 1

- 229920001296 polysiloxane Polymers 0.000 description 1

- 229920006295 polythiol Polymers 0.000 description 1

- 229920006264 polyurethane film Polymers 0.000 description 1

- 229920005749 polyurethane resin Polymers 0.000 description 1

- 239000004800 polyvinyl chloride Substances 0.000 description 1

- 229920000915 polyvinyl chloride Polymers 0.000 description 1

- 238000011417 postcuring Methods 0.000 description 1

- 239000011591 potassium Substances 0.000 description 1

- 229910052700 potassium Inorganic materials 0.000 description 1

- 239000001103 potassium chloride Substances 0.000 description 1

- 235000011164 potassium chloride Nutrition 0.000 description 1

- 150000003141 primary amines Chemical class 0.000 description 1

- 238000007639 printing Methods 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 229920003987 resole Polymers 0.000 description 1

- 229920006395 saturated elastomer Polymers 0.000 description 1

- 150000004756 silanes Chemical class 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- ABTOQLMXBSRXSM-UHFFFAOYSA-N silicon tetrafluoride Chemical class F[Si](F)(F)F ABTOQLMXBSRXSM-UHFFFAOYSA-N 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 239000000344 soap Substances 0.000 description 1

- 239000011734 sodium Substances 0.000 description 1

- 229910052708 sodium Inorganic materials 0.000 description 1

- 239000011780 sodium chloride Substances 0.000 description 1

- 229910001495 sodium tetrafluoroborate Inorganic materials 0.000 description 1

- 239000002904 solvent Substances 0.000 description 1

- 238000007655 standard test method Methods 0.000 description 1

- 239000011593 sulfur Substances 0.000 description 1

- 229910052717 sulfur Inorganic materials 0.000 description 1

- 239000004094 surface-active agent Substances 0.000 description 1

- 239000000375 suspending agent Substances 0.000 description 1

- 238000010345 tape casting Methods 0.000 description 1

- 150000003509 tertiary alcohols Chemical class 0.000 description 1

- 150000003568 thioethers Chemical class 0.000 description 1

- 230000009974 thixotropic effect Effects 0.000 description 1

- 150000003608 titanium Chemical class 0.000 description 1

- 239000004408 titanium dioxide Substances 0.000 description 1

- YXFVVABEGXRONW-UHFFFAOYSA-N toluene Substances CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 1

- 238000011282 treatment Methods 0.000 description 1

- 125000005409 triarylsulfonium group Chemical group 0.000 description 1

- ZIBGPFATKBEMQZ-UHFFFAOYSA-N triethylene glycol Chemical compound OCCOCCOCCO ZIBGPFATKBEMQZ-UHFFFAOYSA-N 0.000 description 1

- 238000009966 trimming Methods 0.000 description 1

- 239000011800 void material Substances 0.000 description 1

- 239000000080 wetting agent Substances 0.000 description 1

- 229910052724 xenon Inorganic materials 0.000 description 1

- FHNFHKCVQCLJFQ-UHFFFAOYSA-N xenon atom Chemical compound [Xe] FHNFHKCVQCLJFQ-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D3/00—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents

- B24D3/02—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents the constituent being used as bonding agent

- B24D3/20—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents the constituent being used as bonding agent and being essentially organic

- B24D3/28—Resins or natural or synthetic macromolecular compounds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D11/00—Constructional features of flexible abrasive materials; Special features in the manufacture of such materials

- B24D11/02—Backings, e.g. foils, webs, mesh fabrics

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D3/00—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents

- B24D3/001—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents the constituent being used as supporting member

- B24D3/002—Flexible supporting members, e.g. paper, woven, plastic materials

Definitions

- Sandpaper is widely sold in home improvement and hardware stores for household sanding applications.

- Common household substrates to be sanded include, for example, moldings, raised panels, carvings, and flutings. It is common practice for users to fold and/or wrap the sandpaper around their finger tip for greater control and ability to get into tight spots. However, such practices may be less than ideal due to stiffness of typical paper-backed sandpaper; indeed, the sandpaper may crack thereby causing reduced product life.

- a coated abrasive article comprising a backing having a major surface, an abrasive layer secured to at least a portion of the major surface, the abrasive layer comprising a make layer comprising a first binder, abrasive particles at least partially embedded in the make layer and a size layer comprising a second binder, at least partially covering the abrasive layer.

- the present inventors have overcome the above-mentioned deficiencies by making a flexible abrasive article that includes a flexible and durable backing comprising polyurethane.

- the flexible abrasive products may outlast commercial sandpaper sold into the home improvement market by up to 1600 percent.

- the flexible abrasive articles are sufficiently flexible that they are well-suited for sanding intricate details in wooden architectural element such as moldings, raised panels, carvings, flutings, etc., and can be easily and comfortably be rolled, folded, or wrapped around the user's fingertip for superior control and ability to get into tight spots.

- the present invention provides a flexible abrasive article according to claim 1. Further embodiments are outlined in the dependent claims.

- the present disclosure provides a method of abrading a workpiece, the method comprising:

- elongation at break and tensile strength are to be determined according to ASTM International Test Method D882-12"Standard Test Method for Tensile Properties of Thin Plastic Sheeting", published September 2012 by ASTM International, West Conshohocken, Pennsylvania, using an extension rate of ten percent of the gauge length per minute.

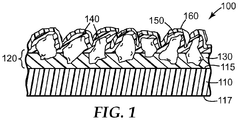

- FIG. 1 is a schematic side view of a flexible abrasive article 100 according to the present disclosure.

- flexible abrasive article 100 comprises unitary polyurethane backing 110 having first and second opposed major surfaces 115, 117.

- Abrasive layer 120 is disposed on and secured to first major surface 115 of unitary polyurethane backing 110.

- Abrasive layer 120 comprises make layer 130, abrasive particles 140, and size layer 150 which is disposed on make layer 130 and abrasive particles 140.

- Optional supersize layer 160 is disposed on size layer 150.

- the backing may have a number of physical properties that collectively impart flexibility and durability to the flexible abrasive articles.

- the backing may have an average thickness of 4 to 6 mils (102 to 152 microns), preferably 4.5 to 6.5 mils (114 to 165 microns), and more preferably 4.8 to 6.2 mils (122 to 157 microns).

- the backing may have a tensile strength in the range of from 500 to 3200 psi (3.4 to 22.1 MPa), preferably 1000 to 2500 psi (6.9 to 17.2 MPa), more preferably 1600 to 2100 psi (11.0 to 14.5 MPa), and an ultimate elongation (i.e., elongation at break) of 230 to 530 percent, preferably300 to 460 percent, and more preferably 350 to 410 percent.

- the backing may have an average thickness of 4 to 6 mils (102 to 152 microns), preferably 4.5 to 6.5 mils (114 to 165 microns), and more preferably 4.8 to 6.2 mils (122 to 157 microns).

- the backing may have an average tensile strength in the range of from 500 to 3200 pounds per square inch (psi) (3.4 to 22.1 MPa), preferably 1000 to 2500 psi (6.9 to 17.2 MPa), more preferably 1600 to 2100 psi (11.0 to 14.5 MPa), and an average ultimate elongation (i.e., elongation at break) of 230 to 530 percent, preferably300 to 460 percent, and more preferably 350 to 410 percent.

- the backing may have an average thickness of 4 to 6 mils (102 to 152 microns), preferably 4.5 to 6.5 mils (114 to 165 microns), and more preferably 4.8 to 6.2 mils (122 to 157 microns).

- the backing may have a maximum, and optionally minimum, tensile strength in the range of from 500 to 3200 pounds per square inch (psi) (3.4 to 22.1 MPa), preferably 1000 to 2500 psi (6.9 to 17.2 MPa), more preferably 1600 to 2100 psi (11.0 to 14.5 MPa), and a maximum, and optionally minimum, ultimate elongation (i.e., elongation at break) of 230 to 530 percent, preferably300 to 460 percent, and more preferably 350 to 410 percent.

- psi pounds per square inch

- the backing may have an average thickness of 4 to 6 mils (102 to 152 microns), preferably 4.5 to 6.5 mils (114 to 165 microns), and more preferably 4.8 to 6.2 mils (122 to 157 microns).

- the flexible abrasive article may have a tensile strength of from at least 400 psi (2.8 MPa), at least 500 psi (3.4 MPa), at least 600 psi (4.1MPa), at least 700 psi (4.8 MPa), at least 800 psi (5.5 MPa), at least 900 psi (6.2 MPa), at least 1000 psi (6.9 MPa), at least 1100 psi (7.6 MPa), at least 1200 psi (8.3 MPa), or even at least 1300 psi (9.0 MPa) up to 1500 psi (10.3 MPa), 1600 psi (11.0 MPa), 1700 psi (11.7 MPa), 1800 psi (12.4 MPa), 1900 psi (13.1 MPa), 2000 psi (13.8 MPa), 2100 psi (14.5 MPa), 2200 psi (15.1 MPa), 2300 psi (15.9 MPa), or even up to 2

- the backing may have an average thickness of 4 to 6 mils (102 to 152 microns), preferably 4.5 to 6.5 mils (114 to 165 microns), and more preferably 4.8 to 6.2 mils (122 to 157 microns).

- the flexible abrasive article may have an average tensile strength of from at least 400 psi (2.8 MPa), at least 500 psi (3.4 MPa), at least 600 psi (4.1MPa), at least 700 psi (4.8 MPa), at least 800 psi (5.5 MPa), at least 900 psi (6.2 MPa), at least 1000 psi (6.9 MPa), at least 1100 psi (7.6 MPa), at least 1200 psi (8.3 MPa), or even at least 1300 psi (9.0 MPa) up to 1500 psi (10.3 MPa), 1600 psi (11.0 MPa), 1700 psi (11.7 MPa), 1800 psi (12.4 MPa), 1900 psi (13.1 MPa), 2000 psi (13.8 MPa), 2100 psi (14.5 MPa), 2200 psi (15.1 MPa), 2300 psi (15.9 MPa), or even up to 2

- the backing may have an average thickness of 4 to 6 mils (102 to 152 microns), preferably 4.5 to 6.5 mils (114 to 165 microns), and more preferably 4.8 to 6.2 mils (122 to 157 microns).

- the flexible abrasive article may have an average maximum and/or minimum tensile strength of from at least 400 psi (2.8 MPa), at least 500 psi (3.4 MPa), at least 600 psi (4.1MPa), at least 700 psi (4.8 MPa), at least 800 psi (5.5 MPa), at least 900 psi (6.2 MPa), at least 1000 psi (6.9 MPa), at least 1100 psi (7.6 MPa), at least 1200 psi (8.3 MPa), or even at least 1300 psi (9.0 MPa) up to 1500 psi (10.3 MPa), 1600 psi (11.0 MPa), 1700 psi (11.7 MPa), 1800 psi (12.4 MPa), 1900 psi (13.1 MPa), 2000 psi (13.8 MPa), 2100 psi (14.5 MPa), 2200 psi (15.1 MPa), 2300 psi (15.9 MPa),

- the backing may be unitary; that is, it may consist of a single layer, although in certain embodiments it may be a composite backing, if desired.

- the backing is at least substantially homogeneous, although this is not a requirement.

- the backing may be perforated; however, if perforated, the average thickness is not determined using areas of the perforations where the thickness would, of course, be zero as no backing is present there.

- the backing is impermeable to liquid water and substantially free of void space, although minor amounts of porosity may be acceptable.

- the backing may have less than 10 percent, less than 2 percent, less than 1 percent, or even less than 0.01 percent of intrinsic voids (i.e., voids that are not deliberately added, but are an intrinsic property of the material making up the backing), based on the total volume of the backing.

- intrinsic voids i.e., voids that are not deliberately added, but are an intrinsic property of the material making up the backing

- the backing may comprise one or more polyurethanes.

- the polyurethane comprises, or at least consists essentially of, at least one thermoplastic polyurethane (TPU).

- TPU thermoplastic polyurethane

- additive compounds e.g., fragrances, colorants, antioxidants, UV light stabilizers, and/or fillers

- the additives may have less than a 5 percent, preferably less than 1 percent, effect on tensile strength and ultimate elongation.

- the backing comprises a single thermoplastic polyurethane or a combination of thermoplastic polyurethanes.

- One preferred class of polyurethanes is aromatic polyether- based polyurethanes, preferably thermoplastic polyether-based polyurethanes.

- the thermoplastic polyether-bases polyurethanes are derived from 4,4'-methylenedicyclohexyl diisocyanate (MDI), a polyether polyol, and butanediol.

- Thermoplastic polyurethanes are well known and can be made according to many known techniques, or they may be obtained for commercial suppliers.

- Lubrizol Corp. Cleveland, Ohio

- the backing may be cast (e.g., from solvent or water) or extruded. It may contain one or more additives such as fillers, melt processing aids, antioxidants, flame retardants, colorants, or ultraviolet light stabilizers.

- the make and size layers can be prepared by curing a respective make or size layer precursor.

- the make and size layer precursors may have the same or different compositions, and may be applied at the same or different coat weights.

- the make and size layer comprise at least one polyepoxide and at least one polyfunctional (meth)acrylate, a curative (e.g., polyamine, polythiol, acid catalyst, or photocatalyst) for the polyepoxide and a free-radical initiator (photoinitiator and/or thermal initiator).

- a curative e.g., polyamine, polythiol, acid catalyst, or photocatalyst

- a free-radical initiator photoinitiator and/or thermal initiator.

- Monofunctional epoxides and polyols e.g., diols used as chain extenders

- Useful polyepoxides may be aromatic or aliphatic polyepoxide(s), or a combination thereof.

- Useful polyepoxides may be liquid or solid, but are typically liquid for ease of handling. Whether liquid or solid, the polyepoxide(s) should generally be selected such that it can be dissolved in the precursor composition (e.g., make or size layer precursor composition). In some instances, heating may be useful to facilitate dissolution of the polyepoxide.

- aromatic polyepoxides include: polyglycidyl ethers of polyhydric phenols such as such as bisphenol A diglycidyl ether (commonly referred to in the art as DGEBA) and commercially available bisphenol A-derived and bisphenol F-derived epoxy resins having the trade designation "EPON” (for example, EPON RESIN 825, EPON RESIN 828, EPON RESIN 1001F, EPON RESIN 1002F, EPON RESIN 1004F, EPON RESIN 1007F, and EPON RESIN 1009F), marketed by Hexion Specialty Chemicals, Columbus, Ohio, and bisphenol A-derived epoxy resins having the trade designation "DER” (for example, DER 332, DER 337, DER 362, and DER 364), marketed by Dow Chemical Company, Midland, Michigan; epoxy cresol-novolac resins; epoxy phenol-novolac resins; and glycidyl esters of aromatic carboxylic acids (e.g.,

- Examples of useful aliphatic polyepoxides include epoxycyclohexanecarboxylates (e.g., 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexanecarboxylate (e.g., as available as ERL-4221 from Dow Chemical Co.); 3,4-epoxy-2-methylcyclohexylmethyl 3,4-epoxy-2-methylcyclohexanecarboxylate; bis(3,4-epoxy-6-methylcyclohexylmethyl) adipate; 3,4-epoxy-6-methylcyclohexylmethyl 3,4-epoxy-6-methylcyclohexanecarboxylate (e.g., as available as ERL-4201 from Dow Chemical Co.); vinylcyclohexene dioxide (e.g., as available as ERL-4206 from Dow Chemical Co.); bis(2,3-epoxycyclopentyl) ether (e.g., as available as ERL-0400 from Dow Chemical

- the amount of polyepoxide present in the make layer precursor typically ranges from about 40 to 70 percent by weight, preferably 50 to 60 percent by weight, based on the total weight of solids (i.e., nonvolatile components) in the make layer precursor, although amounts outside this range may also be used.

- Useful polyfunctional (meth)acrylates may be liquid or solid, but are typically liquid for ease of handling. Whether liquid or solid, the polyfunctional (meth)acrylates should generally be selected such that it can be dissolved in the precursor composition. In some instances, heating may be useful to facilitate dissolution of the polyfunctional (meth)acrylate.

- Exemplary useful polyfunctional (meth)acrylates include (meth)acrylate monomers, (meth)acrylate oligomers, (meth)acrylated polymers, and combinations thereof.

- polyfunctional (meth)acrylate(s) are readily commercially available; for example, from such vendors as Sartomer Co., Exton, Pennsylvania, and UCB Chemicals Corp., Smyrna, Georgia.

- Exemplary polyfunctional (meth)acrylate(s) include ethylene glycol di(meth)acrylate, hexanediol di(meth)acrylate, triethylene glycol di(meth)acrylate and methacrylate, trimethylolpropane tri(meth)acrylate, glycerol tri(meth)acrylate, pentaerythritol tri(meth)acrylate and methacrylate, ethoxylated trimethylolpropane tri(meth)acrylate and trimethacrylate, neopentyl glycol di(meth)acrylate and dimethacrylate, pentaerythritol tetra(meth)acrylate and tetramethacrylate, dipentaerythritol penta(meth)acrylate, sorbitol tri(meth)acrylate, sorbitol hexa(meth)acrylate, Bisphenol A di(meth)acrylate, ethoxylated

- Example of useful polyfunctional (meth)acrylate monomers include trimethylolpropane triacrylate, available, for example, from Sartomer Co. as SR 351; ethoxylated trimethylolpropane triacrylate, available, for example, from Sartomer Co. as SR 454; pentaerythritol tetraacrylate, available, for example, from Sartomer Co. as SR 295; and neopentyl glycol diacrylate, available, for example, from Sartomer Co. as SR 247.

- the polyfunctional acrylate may comprise at least one (meth)acrylate oligomer.

- exemplary (meth)acrylate oligomers include (meth)acrylated epoxy oligomers (e.g., Bisphenol-A based epoxy (meth)acrylate oligomers), aliphatic urethane (meth)acrylate oligomers, and aromatic urethane (meth)acrylate oligomers.

- Additional useful polyfunctional (meth)acrylate oligomers include polyether oligomers such as a polyethylene glycol 200 diacrylate, available, for example, from Sartomer Co. as SR 259 and a polyethylene glycol 400 diacrylate available from Sartomer Co. as SR 344; and acrylated epoxies including those available as EBECRYL 3500, EBECRYL 3600, and EBECRYL 3700, from UCB Chemicals Corp.

- the, polyfunctional (meth)acrylate whether present as a blend of polymerizable (meth)acrylates or as a single component, has an average (meth)acryloxy group functionality of at least 2.2., at least 2.5, or even at least 3.

- the amount of polyfunctional (meth)acrylate(s) present in the make layer precursor typically ranges from about 5 to about 20 percent by weight, preferably from about 5 to about 15 percent by weight, and even more desirably from about 8 to about 12 percent by weight, based on the total weight of solids (i.e., nonvolatile components) in the make layer precursor, although amounts outside this range may also be used.

- the make and size layer precursors may further comprise an optional bireactive polymerizable component, for example, a compound having at least one free-radically polymerizable group, and at least one cationically polymerizable group.

- Bireactive compounds can be made, for example, by introducing at least one ethylenically-unsaturated group into a compound that already contains one or more epoxy groups, or, conversely, by introducing at least one epoxy group into a compound that already contains one or more ethylenically-unsaturated group.

- Exemplary bireactive polymerizable compounds include those contained in the reaction products of 0.4 to 0.6 weight equivalent of an acrylic acid and one mole of diglycidyl ether of Bisphenol A, polyglycidyl ether of phenol-formaldehyde novolac, polyglycidyl ether of cresol-formaldehyde novolac, diglycidyl terephthalate, triglycidyl ester of trimellitic acid, dicyclopentadiene dioxide, vinylcyclohexene dioxide, bis(2,3-epoxycyclopentyl)ether, 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexanecarboxylate, and bis(3,4-epoxy-6-methylcyclohexyl)methyl adipate.

- optional bireactive materials are desirably selected such that they do not significantly inhibit the cure of cationically polymerizable resin.

- exemplary groups that may interfere with such cure include primary, secondary and tertiary amines, amides, and imides.

- the make and size layer precursor typically contain an effective amount of curative for the polyepoxide curative (e.g., a polyamine or a Lewis acid catalyst) and free-radical polymerization initiator (preferably a free-radical photoinitiator) for the polyfunctional (meth)acrylate; however, depending on curing conditions this is not a requirement.

- curative for the polyepoxide curative e.g., a polyamine or a Lewis acid catalyst

- free-radical polymerization initiator preferably a free-radical photoinitiator

- Suitable curative(s) include those that are photosensitive and/or thermally-sensitive, and desirably comprise at least one free-radical polymerization initiator and at least one cationic polymerization catalyst, which may be the same or different.

- the precursors are preferably photocurable and comprise a photoinitiator and/or a photocatalyst.

- Photocatalysts as defined herein are materials that form active species that, if exposed to actinic radiation, are capable of at least partially polymerizing polyepoxides employed in practice of the present disclosure.

- the binder precursor may comprise at least one photocatalyst (e.g., an onium salt and/or cationic organometallic salt).

- onium salt photocatalysts comprise iodonium complex salts and/or sulfonium complex salts.

- Useful aromatic onium complex salts are further described, for example, in U.S. Pat. No. 4,256,828 (Smith ).

- Exemplary aromatic iodonium complex salts include diaryliodonium hexafluorophosphate or a diaryliodonium hexafluoroantimonate.

- Exemplary aromatic sulfonium complex salts include as triphenylsulfonium hexafluoroantimonate and p-phenyl(thiophenyl)diphenylsulfonium hexafluoroantimonate.

- Aromatic onium salts useful in practice of the present disclosure, are typically photosensitive only in the ultraviolet region of the spectrum; however, they can be sensitized to the near ultraviolet and the visible range of the spectrum by sensitizers for known photolyzable organic halogen compounds.

- exemplary sensitizers include aromatic amines and colored aromatic polycyclic hydrocarbons, as described, for example, in U.S. Pat. No. 4,250,053 (Smith ).

- Suitable photoactivatable organometallic complex salts useful in the present disclosure include those described, for example, in U.S. Pat. Nos. 5,059,701 (Keipert ); 4,751,138 (Tumey ); 4,985,340 (Palazzotto ); 5,191,101 (Palazzotto et al. ); and 5,252,694 (Willett et al. ).

- organometallic complex cations useful as photoactivatable catalysts include:

- organometallic salt initiators can be accompanied by an accelerator such as an oxalate ester of a tertiary alcohol.

- the accelerator desirably comprises from about 0.1 to about 4 percent by weight of the total binder precursor, more desirably about 60 percent of the weight of the organometallic salt initiator.

- Useful commercially available photocatalysts include an aromatic sulfonium complex salt available as UVI-6974 from Dow Chemical Co.

- Useful free-radical photoinitiators include, for example, those known as useful for photocuring free-radically polyfunctional acrylates.

- Exemplary photoinitiators include benzoin and its derivatives such as ⁇ -methylbenzoin; ⁇ -phenylbenzoin; ⁇ -allylbenzoin; ⁇ -benzylbenzoin; benzoin ethers such as benzil dimethyl ketal; benzoin methyl ether; benzoin ethyl ether; benzoin n-butyl ether; acetophenone and its derivatives such as 2-hydroxy-2-methyl-1-phenyl-1-propanone and 1-hydroxycyclohexyl phenyl ketone; 2-methyl-1-[4-(methylthio)phenyl]-2-(4-morpholinyl)-1-propanone; 2-benzyl-2-(dimethlamino)-1-[4-(4-morpholinyl)phenyl]-1-butanone; pivaloin

- Photoinitiators and photocatalysts useful in the present disclosure can be present in an affect amount, generally in the range of 0.01 to 10 weight percent, more typically 0.01 to 5, or even 0.1 to 2 weight percent, based on the total solids of the make and size/layer precursors amount of photocurable (i.e., crosslinkable by electromagnetic radiation) components of the binder precursor, although amounts outside of these ranges may also be useful.

- an affect amount generally in the range of 0.01 to 10 weight percent, more typically 0.01 to 5, or even 0.1 to 2 weight percent, based on the total solids of the make and size/layer precursors amount of photocurable (i.e., crosslinkable by electromagnetic radiation) components of the binder precursor, although amounts outside of these ranges may also be useful.

- thermal curative may be included in the binder precursor.

- such thermal curative is thermally stable at temperatures at which mixing of the components takes place.

- Exemplary thermal curatives for epoxy resins and acrylates are well known in the art, and are described, for example, in U.S. Pat. No. 6,258,138 (DeVoe et al. ).

- Thermal curative may be present in the make and/or size layer precursors in any effective amount. Such amounts are typically in the range of about 0.01 parts to 5 parts, desirably in the range from about 0.025 to 2 parts by weight, based on the total solids of the make and size/layer precursors, although amounts outside of these ranges may also be useful.

- the make, size, and optional supersize layer precursors used to make flexible abrasive articles according to the present disclosure may optionally contain additional curable components such as, for example, phenolic resins (novolac or resole), aminoplasts, cyanate resins, isocyanate resins, and/or alkyd resins.

- additional curable components such as, for example, phenolic resins (novolac or resole), aminoplasts, cyanate resins, isocyanate resins, and/or alkyd resins.

- the make, size, and optional supersize layers, of flexible abrasive articles according to the present disclosure may contain optional additives, for example, to modify performance and/or appearance.

- optional additives include grinding aids, fillers, plasticizers, wetting agents, surfactants, pigments, coupling agents, fibers, lubricants, thixotropic materials, antistatic agents, suspending agents, pigments, and dyes.

- Exemplary grinding aids which may be organic or inorganic, include waxes, halogenated organic compounds such as chlorinated waxes like tetrachloronaphthalene, pentachloronaphthalene, and polyvinyl chloride; halide salts such as sodium chloride, potassium cryolite, sodium cryolite, ammonium cryolite, potassium tetrafluoroborate, sodium tetrafluoroborate, silicon fluorides, potassium chloride, magnesium chloride; and metals and their alloys such as tin, lead, bismuth, cobalt, antimony, cadmium, iron, and titanium; and the like.

- Examples of other grinding aids include sulfur, organic sulfur compounds, graphite, and metallic sulfides.

- a combination of different grinding aids can be used such as that described, for example, in U.S. Pat. No. 5,552,225 (Ho ).

- the basis weight of the make layer may depend, for example, on the intended use(s), type(s) of abrasive particles, and nature of the coated abrasive article being prepared, but generally will be in the range of from about 1 to about 30 grams per square meter (i.e., gsm), preferably from about 10 to about 25 gsm, and more desirably from about 10 to about 20 gsm.

- the make layer can be formed by coating the make layer precursor on a major surface of the backing

- the make layer precursor may be applied, for example, by any known coating method for applying a make layer to a backing including, for example, roll coating, extrusion die coating, curtain coating, knife coating, gravure coating, and spray coating.

- the abrasive particles can be applied to make layer precursor and then the make layer precursor can be optionally partially cured (e.g., to an a-stage or b-stage).

- Abrasive particles suitable for use in abrasive layers utilized in practice of the present disclosure include any abrasive particles known in the abrasive art.

- Exemplary useful abrasive particles include fused aluminum oxide based materials such as aluminum oxide, ceramic aluminum oxide (which may include one or more metal oxide modifiers and/or seeding or nucleating agents), and heat-treated aluminum oxide, silicon carbide, co-fused alumina-zirconia, diamond, ceria, titanium diboride, cubic boron nitride, boron carbide, garnet, flint, emery, sol-gel derived abrasive particles, and blends thereof.

- fused aluminum oxide based materials such as aluminum oxide, ceramic aluminum oxide (which may include one or more metal oxide modifiers and/or seeding or nucleating agents), and heat-treated aluminum oxide, silicon carbide, co-fused alumina-zirconia, diamond, ceria, titanium diboride, cubic boron nitride,

- the abrasive particles comprise fused aluminum oxide, heat-treated aluminum oxide, ceramic aluminum oxide, silicon carbide, alumina zirconia, garnet, diamond, cubic boron nitride, sol-gel derived abrasive particles, or mixtures thereof.

- sol-gel abrasive particles include those described U.S. Pat. Nos. 4,314,827 (Leitheiser et al. ); 4,518,397 (Leitheiser et al. ); 4,623,364 (Cottringer et al. ); 4,744,802 (Schwabel ); 4,770,671 (Monroe et al. ); 4,881,951 (Wood et al.

- the abrasive particles may be in the form of, for example, individual particles, agglomerates, abrasive composite particles, alpha alumina abrasive shards, and mixtures thereof.

- Exemplary agglomerates are described, for example, in U.S. Pat. Nos. 4,652,275 (Bloecher et al. ) and 4,799,939 (Bloecher et al. ). It is also within the scope of the present disclosure to use diluent erodible agglomerate grains as described, for example, in U.S. Pat. No. 5,078,753 (Broberg et al. ).

- Abrasive composite particles comprise abrasive grains in a binder.

- Exemplary abrasive composite particles are described, for example, in U.S. Pat. No. 5,549,962 (Holmes et al. ).

- Alpha alumina abrasive shards are described in U.S. Pat. Appln. Publ. 2011/0314746 A1 (Erickson et al. ).

- the abrasive particles typically have an average diameter of from about 0.1 to about 2000 micrometers, more desirably from about 1 to about 1300 micrometers.

- Abrasive particles are generally graded to a given particle size distribution before use. Such distributions typically have a range of particle sizes, from coarse particles to fine particles. In the abrasive art this range is sometimes referred to as a "coarse”, "control”, and "fine” fractions.

- Abrasive particles graded according to abrasive industry accepted grading standards specify the particle size distribution for each nominal grade within numerical limits.

- Such industry accepted grading standards include those known as the American National Standards Institute, Inc. (ANSI) standards, Federation of European Producers of Abrasive Products (FEPA) standards, and Japanese Industrial Standard (JIS) standards.

- ANSI grade designations include: ANSI 4, ANSI 6, ANSI 8, ANSI 16, ANSI 24, ANSI 36, ANSI 40, ANSI 50, ANSI 60, ANSI 80, ANSI 100, ANSI 120, ANSI 150, ANSI 180, ANSI 220, ANSI 240, ANSI 280, ANSI 320, ANSI 360, ANSI 400, and ANSI 600.

- FEPA grade designations include P8, P12, P16, P24, P36, P40, P50, P60, P80, P100, P120, P150, P180, P220, P320, P400, P500, P600, P800, P1000, and P1200.

- JIS grade designations include JIS8, JIS12, JIS16, JIS24, JIS36, JIS46, JIS54, JIS60, JIS80, JIS100, JIS150, JIS180, JIS220, JIS240, JIS280, JIS320, JIS360, JIS400, JIS600, JIS800, JIS1000, JIS1500, JIS2500, JIS4000, JIS6000, JIS8000, and JIS10,000.

- the abrasive particles have a size distribution falling within the range of ANSI grades P100 to P320, inclusive.

- the abrasive particles can graded to a nominal screened grade using U.S.A. Standard Test Sieves conforming to ASTM E-11 "Standard Specification for Wire Cloth and Sieves for Testing Purposes".

- ASTM E-11 proscribes the requirements for the design and construction of testing sieves using a medium of woven wire cloth mounted in a frame for the classification of materials according to a designated particle size.

- a typical designation may be represented as -18+20 meaning that abrasive particles pass through a test sieve meeting ASTM E-11 specifications for the number 18 sieve and are retained on a test sieve meeting ASTM E-11 specifications for the number 20 sieve.

- the abrasive particles have a particle size such that most of the abrasive particle pass through an 18 mesh test sieve and can be retained on a 20, 25, 30, 35, 40, 45, or 50 mesh test sieve.

- the abrasive particles can have a nominal screened grade comprising: -18+20, -20+25, -25+30, -30+35, -35+40, -40+45, -45+50, -50+60, -60+70, -70+80, - 80+100, -100+120, -120+140, -140+170, -170+200, -200+230, -230+270, -270+325, -325+400, - 400+450, -450+500, or -500+635.

- Coating weights for the abrasive particles may depend, for example, on the binder precursor used, the process for applying the abrasive particles, and the size of the abrasive particles, but typically range from about 5 to about 250 grams per square meter (gsm), preferably from 20 to 100 gsm, more preferably 30 to 80 gsm, and more preferably 45 to 65 gsm; although other amounts may also be used.

- gsm grams per square meter

- the size layer precursor can be applied over the make layer precursor and abrasive particles and the make and size layer precursors sufficiently cured to form a useable coated abrasive article. Curing may be accomplished using thermal and/or photochemical methods.

- the size layer can be likewise formed from a precursor composition (i.e., size layer precursor).

- the size layer can be include any of the components listed hereinabove for use in the make layer precursor.

- the amount of polyepoxide present in the size layer precursor typically ranges from about 40 to 80 percent by weight, preferably 50 to 70 percent by weight, and more preferably 55 to 65 percent by weight, based on the total weight of solids (i.e., nonvolatile components) in the make layer precursor, although amounts outside this range may also be used.

- the amount of polyfunctional (meth)acrylate(s) present in the size layer precursor typically ranges from about 5 to about 50 percent by weight, preferably from about 15 to about 40 percent by weight, and even more desirably from about 25 to about 35 percent by weight, based on the total weight of solids (i.e., nonvolatile components) in the make layer precursor, although amounts outside this range may also be used.

- the basis weight of the size layer (i.e., after curing) will also necessarily vary depending on the intended use(s), type(s) of abrasive particles, and nature of the coated abrasive article being prepared, but generally will be in the range of from 10 to 150 gsm, preferably from 20 to 80 gsm, and more preferably from 35 to 55 gsm.

- the size layer may be applied, for example, by any known coating method for applying a size layer to a backing, including, for example, roll coating, extrusion die coating, curtain coating, and spray coating.

- this curing step involves thermal and/or radiation energy (e.g., ultraviolet and/or visible actinic radiation or electron beam radiation), but this is not a requirement.

- thermal energy include, for example, heat and infrared radiation.

- sources of thermal energy include ovens (for example, festoon ovens), heated rolls, hot air blowers.

- sources of radiation energy include, for example, electron beam, ultraviolet light (e.g., from a medium pressure mercury bulb, a xenon flashlamp, or a type H or type D microwave-driven bulb), and visible light.

- Other sources of radiation energy include infrared and microwave.

- Electron beam radiation which is also known as ionizing radiation, can be used at a dosage of about 0.1 to about 10 megarads (Mrad0, preferably at a dosage of about 1 to about 10 Mrad.

- Ultraviolet radiation refers to non-particulate radiation having a wavelength within the range of about 200 to about 400 nanometers (nm), preferably within the range of about 250 to 400 nm. In certain embodiments, the ultraviolet radiation can be provided by ultraviolet lights at a dosage of 100 to 300 Watts/cm. Visible radiation refers to non-particulate radiation having a wavelength within the range of about 400 to about 800 nm, and in certain embodiments, within the range of about 400 to about 550 nm.

- a supersize layer may be applied to at least a portion of the size layer.

- the supersize typically includes grinding aids and/or anti-loading materials.

- the optional supersize layer may serve to prevent or reduce the accumulation of swarf (the material abraded from a workpiece) between abrasive particles, which can dramatically reduce the cutting ability of the coated abrasive article.

- Useful supersize layers typically include a grinding aid (for example, potassium tetrafluoroborate), metal salts of fatty acids (for example, zinc stearate or calcium stearate), salts of phosphate esters (for example, potassium behenyl phosphate), phosphate esters, urea-formaldehyde resins, mineral oils, crosslinked silanes, crosslinked silicones, and/or fluorochemicals.

- a grinding aid for example, potassium tetrafluoroborate

- metal salts of fatty acids for example, zinc stearate or calcium stearate

- salts of phosphate esters for example, potassium behenyl phosphate

- phosphate esters for example, potassium behenyl phosphate

- phosphate esters for example, potassium behenyl phosphate

- the basis weight of the supersize layer can be from 1 to 50 gsm, more preferably 5 to 30 gsm, more preferably from about 10 to about 20 gsm.

- the supersize may contain a binder such as for example, those used to prepare the size or make layer, but it need not contain any binder resin.

- the supersize layer is generally dried and/or cured to provide a flexible abrasive article, which may be in sheet of web form, for example. Converting into particular shapes (e.g., rectangular sheets or discs) can be accomplished using conventional methods such as, for example die cutting, knife cutting, and laser cutting.

- the resulting flexible abrasive article may be subjected to further conventional treatments such as, for example, printing, laser marking, trimming, perforating, flexing, post-curing, or a combination thereof.

- indicia or other markings can be disposed (e.g., printed) on the first major surface of the backing prior to coating the make layer precursor, although it can be placed on the second major surface of the backing as well.

- the various components are selected such that the flexible abrasive article is sufficiently translucent or transparent that a user can visually perceive the workpiece while abrading without removing the flexible abrasive article from the surface of the workpiece. This offers an advantage as compared with paper-backed abrasive products.

- Flexible abrasive articles according to the present disclosure are typically well-suited for use in hand sanding applications to painted or unpainted wood or metal workpieces (e.g., furniture and architectural trim such as moldings, handrails, or cabinetry), especially involving curved and/or complex surface shapes.

- Advantages of flexible abrasive products according to the present disclosure for this use may include one or more of excellent hand feel, hand grip, see-through translucency, and flexibility and conformability to workpiece surfaces comprises architectural trim having three-dimensional detail.

- the present disclosure provides a flexible abrasive article comprising:

- the present disclosure provides a flexible abrasive article according to the first embodiment, the present disclosure provides a flexible abrasive article according to the first or second embodiment, wherein the abrasive particles have a nominal size grade of less than or equal to an ANSI grade P80 and greater than or equal to ANSI grade P320.

- the present disclosure provides a flexible abrasive article according to the first embodiment, wherein the abrasive particles have a nominal size grade of less than or equal to an ANSI grade P180 and greater than or equal to ANSI grade P320.

- the present disclosure provides a flexible abrasive article according to any one of the first to third embodiments, wherein the average thickness of the backing is from 4.5 to 5.5 mils.

- the present disclosure provides a flexible abrasive article according to any one of the first to fourth embodiments, wherein the backing comprises a thermoplastic polyurethane.

- the present disclosure provides a flexible abrasive article according to any one of the first to fifth embodiments, wherein the flexible abrasive article is translucent.

- the present disclosure provides a flexible abrasive article according to any one of the first to sixth embodiments, further comprising a supersize layer disposed on at least a portion of the size layer.

- the present disclosure provides a flexible abrasive article according to any one of the first to seventh embodiments, wherein the backing has a maximum tensile strength of 1000 to 2500 psi and a maximum ultimate elongation of 300 to 460 percent.

- the present disclosure provides a flexible abrasive article according to any one of the first to seventh embodiments, wherein the backing has a maximum tensile strength of 1600 to 2100 psi and a maximum ultimate elongation of 350 to 410 percent.

- the present disclosure provides a flexible abrasive article comprising:

- the present disclosure provides a method of abrading a workpiece, the method comprising:

- the present disclosure provides a method according to the tenth embodiment, wherein the workpiece comprises painted or unpainted wood or metal.

- the present disclosure provides a method according to the eleventh or twelfth embodiment, wherein the workpiece comprises architectural trim having three-dimensional detail.

- the present disclosure provides a flexible abrasive article according to any one of the eleventh to thirteenth embodiments, wherein the flexible abrasive article is hand held.

- ACR refers to trimethylolpropane triacrylate.

- ABR refers to a P320 semi-friable blend of mineral abrasive particles consisting of 96% by weight of aluminum oxide, 3 percent by weight of titanium dioxide, and less than 1% by weight total of other oxides (silicon, magnesium, calcium, iron) available as ARTIRUNDUM SFB from Art Abrasives Limited, Suzhou, China.

- AMOX refers to di-t-amyl oxalate, which can be made by esterification of oxalic acid with t-amyl alcohol as described in Example 11 of U.S. Pat. No. 4,904,814 (Frei et al. ).

- CHDM refers to 1,4-cyclohexanedimethanol.

- EP1 refers to a Bisphenol-A epichlorohydrin based epoxy resin having an epoxy equivalent weight of 525-550 g/eq, an average epoxy functionality of 2, available as EPON 1001F from Momentum Specialty Chemicals, Inc., Columbus, Ohio.