EP3032003B1 - Safety fence comprising a plurality of panels attached to a framework - Google Patents

Safety fence comprising a plurality of panels attached to a framework Download PDFInfo

- Publication number

- EP3032003B1 EP3032003B1 EP15196188.5A EP15196188A EP3032003B1 EP 3032003 B1 EP3032003 B1 EP 3032003B1 EP 15196188 A EP15196188 A EP 15196188A EP 3032003 B1 EP3032003 B1 EP 3032003B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- plates

- fence

- phase

- panels

- panel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000007704 transition Effects 0.000 claims description 17

- 238000010292 electrical insulation Methods 0.000 claims description 5

- 238000007373 indentation Methods 0.000 claims description 2

- 210000000056 organ Anatomy 0.000 description 4

- 239000003292 glue Substances 0.000 description 2

- 238000002955 isolation Methods 0.000 description 2

- 238000012423 maintenance Methods 0.000 description 2

- 230000007257 malfunction Effects 0.000 description 2

- 230000000149 penetrating effect Effects 0.000 description 2

- 230000001681 protective effect Effects 0.000 description 2

- 230000004888 barrier function Effects 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 238000010616 electrical installation Methods 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 230000002452 interceptive effect Effects 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000000615 nonconductor Substances 0.000 description 1

- 230000008439 repair process Effects 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04H—BUILDINGS OR LIKE STRUCTURES FOR PARTICULAR PURPOSES; SWIMMING OR SPLASH BATHS OR POOLS; MASTS; FENCING; TENTS OR CANOPIES, IN GENERAL

- E04H17/00—Fencing, e.g. fences, enclosures, corrals

- E04H17/14—Fences constructed of rigid elements, e.g. with additional wire fillings or with posts

- E04H17/16—Fences constructed of rigid elements, e.g. with additional wire fillings or with posts using prefabricated panel-like elements, e.g. wired frames

- E04H17/165—Fences constructed of rigid elements, e.g. with additional wire fillings or with posts using prefabricated panel-like elements, e.g. wired frames using panels with rigid filling and frame

-

- G—PHYSICS

- G08—SIGNALLING

- G08B—SIGNALLING OR CALLING SYSTEMS; ORDER TELEGRAPHS; ALARM SYSTEMS

- G08B13/00—Burglar, theft or intruder alarms

- G08B13/02—Mechanical actuation

- G08B13/12—Mechanical actuation by the breaking or disturbance of stretched cords or wires

- G08B13/122—Mechanical actuation by the breaking or disturbance of stretched cords or wires for a perimeter fence

Definitions

- the invention relates to the technical field of protection fences for detecting an intrusion attempt inside a perimeter delimited by the fence. More particularly, it relates to the field of protective fences comprising panels mounted on a frame comprising fixing posts.

- a protection fence firstly comprises a frame which consists of structural elements. These structural elements comprise fixing posts, generally vertical and, where appropriate, generally horizontal crosspieces which connect two adjacent posts. This fence further comprises various fence panels mounted on this frame, by means of fixing means, typically by screwing. The fence panels at least partially delineate an enclosure so as to form a physical barrier to prevent a person from entering the perimeter of the enclosure.

- each panel comprises two parallel plates, which are separated by electrical insulation means.

- These plates can be rigid, semi-rigid or flexible. They can be full or at least partially openwork. Within the meaning of the invention, they may be formed by a lattice, in particular a wire mesh.

- the aforementioned insulation means which are typically formed by a layer of glue, allow the two plates not to be in mutual electrical contact.

- the two constituent plates of a given panel are connected respectively, one to the ground and the other to the phase. Therefore, if one of the plates is pierced or sawed, during an intrusion attempt, at least a temporary short circuit is formed with the tool or with metal chips, which will be detected.

- the security fence described in this document has a relatively large thickness.

- this fence has a complex mechanical structure, particularly in the area of attachment of the panels on the pole. Then, the need for bare areas at the panel overlap area complicates corrosion protection and fence assembly. Finally, the maintenance of this fence can be inconvenient, especially during a mechanical breakage of the fastening means and / or a malfunction in the electrical continuity.

- the security fence according to the invention is advantageous, compared to the teaching of FR 2,937,360 . Indeed, since the adjacent panels do not overlap, the overall thickness of the fence can be reduced compared to the prior art. In this respect, it should be noted that FR 2,937,360 this overall thickness is necessarily increased by the sum of the two thicknesses of the panels.

- the structure of the fixing means used in the enclosure of the invention can be simplified.

- the adjacent panels extend in two parallel main planes, and in particular the two adjacent panels extend in the same plane. This is advantageous as regards the overall compactness of the fence, especially its thickness.

- edges of the two adjacent panels extend on either side of the structural element. This reduces the mechanical interaction between the two panels, which allows for example an intervention on one of these panels, without having to interfere with the attachment of the other of these panels on the frame.

- the main planes of the two adjacent panels pass through the structural element.

- the extra thickness due to the presence of the panels is therefore limited or non-existent.

- all the ground plates are arranged on a first side of the fence, while all the phase plates are arranged on the opposite side of the fence. This makes it possible to limit the risks of electrical malfunction.

- the connecting means comprise a connecting member comprising a first mounting zone, in particular of a removable mounting, on a ground or phase plate belonging to a first panel, as well as a second mounting zone, in particular of removable mounting, on a ground or phase plate belonging to a second panel.

- the connecting member further comprises a transition zone between said mounting zones, this transition zone extending away from the walls facing the structural element.

- the transition zone has a shape adapted to bypass the structural element, in particular a U or L shape. This measure finds its application, particularly in the case where the element of structure is a pole.

- the connecting member is a bar whose transition zone passes through a recess formed in the structural element. This measure finds its application, especially in the case where the structural element is a cross.

- This enclosure in accordance with this other object of the invention may include all or some of the above features, to the extent that they are technically compatible.

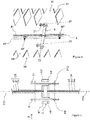

- the figure 1 illustrates a security fence according to the invention.

- this fence is intended to protect a transformer type electrical installation.

- the fence firstly comprises, in a conventional manner, a framework which consists of different structural elements. More precisely, there are posts 1, substantially vertical, which are supported by crossbars 2 substantially horizontal.

- This fence further comprises panels referenced 31 to 39, also of a type known per se. Each panel has two opposing plates extending parallel to each other.

- the figures 3 and 5 illustrate some of these plates, which are respectively referenced 41, 42 and 44, as well as 51, 52 and 54.

- the plates located on one side of the fence are called “mass” , while those on the opposite side are called “live”.

- each plate has a rigid structure, while being perforated.

- these plates are solid, or they are semi-flexible or flexible. They may for example be constituted by a wire mesh.

- ground plates including those 41, 42 and 44, are electrically connected to each other.

- various connecting members 7 and 8 the structure and function of which will be described in more detail in the following. These organs are visible on details II and IV of the figure 1 .

- the ground circuit formed by these plates is connected to a mass not shown, by connection means of a type known per se, which are not represented either.

- phase plates including those 51, 52 and 54, are electrically connected to one another.

- different connecting members 9 and 10 are provided, which are not visible on the figure 1 because they are placed on the opposite, not visible, side of the fence.

- the structure and function of these other organs 9 and 10 will be described in more detail in the following.

- the phase circuit formed by these plates is connected to a phase not shown, by connection means of a type known per se, which are not represented either.

- each linkage member 7, Omega-shaped has a central core 71 extended by two wings 72 and 73, which are terminated by respective tabs 74 and 75.

- each connecting member 9 has a central core 91 extended by two wings 92 and 93, which are terminated by respective tabs 94 and 95.

- the tabs form zones, allowing the removable assembly of the organs on two adjacent panels, while the assembly formed by the core and the two wings defines a transition zone between these mounting areas.

- each plate 41 or 42 is provided with a rod 11 or 12, penetrating into an orifice 74 'or 75' formed in a respective tab 74 or 75.

- Two washers 13 or 14, placed on either side of a nut 15 or 16, are interposed between the facing faces of each plate and each leg.

- solidarity is ensured by an additional nut 17 or 18, in particular of the "indessible" type, provided on the opposite face of each leg.

- Each connecting member 8 or 10 has the shape of an elongate bar, the two ends of which are pierced with orifices. These bars extend through passages P8 and P10, which are formed by indentations formed successively in the different flanges and crossbar 2. The skilled person will spacing the walls opposite the connecting bars, compared to those rims and the crossbar, at a sufficient distance to avoid any risk of inadvertent contact may cause a short circuit.

- each plate 41 or 44 is provided with a rod 21 or 22, penetrating into a respective orifice of the bar 8.

- a rod 21 or 22 penetrating into a respective orifice of the bar 8.

- two washers placed on either side of a nut are interposed between the facing faces of each plate and the bar.

- the securing is provided by an additional nut 27 or 28, particularly of the "indssérable" type, provided on the opposite face of each leg.

- each plate 51 and 54 The fixing of the bar 10 on each plate 51 and 54 is performed in a manner similar to that just described above for the bar 8.

- the fastening of the connecting members is shown schematically, so as not to weigh down the drawing.

- the two longitudinal ends of each bar form removable mounting areas on a respective plate, while the middle region of this bar forms a transition zone between these mounting areas.

- connecting members 7 are provided between the plates 41 and 42, between those 42 and 43, and between those 44 and 45.

- connecting members 9 are provided between the plates 41 and 44, between those 43 and 46, between those 45 and 48, as well as between those 46 and 49.

- complementary members 8 and 10 are provided between the opposing plates that are not visible on the figure 1 .

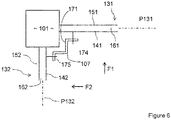

- FIG 6 illustrates an alternative embodiment of the invention.

- mechanical elements similar to those of Figures 2 and 3 are assigned the same reference numbers, increased by 100.

- the closing of the figure 6 differs from that of the preceding figures, in that the two adjacent panels 131 and 132 are not parallel, but perpendicular to each other. These panels are fixed on a pole 101, by means of conventional type which are not described in more detail.

- Each connecting member 107 has two tabs 174 and 175, allowing mounting on a respective plate 141 and 142. This attachment, which is schematically illustrated on this figure 6 , is carried out analogously to what has just been described immediately above for the member 7.

- the two lugs 174 and 175 are connected by an L-shaped transition zone 171, which bypasses the pole 101.

- P131 and P132 respectively denote the main planes of the panels 131 and 132. Within the meaning of the invention, there is no overlap between these two panels 131 and 132. In other words, the latter do not overlap when they are seen, firstly along the arrow F1 perpendicular to the main plane P131 and, secondly, according to the arrow F2 perpendicular to the main plane P132.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Fencing (AREA)

Description

L'invention se rapporte au domaine technique des clôtures de protection permettant de détecter une tentative d'intrusion à l'intérieur d'un périmètre délimité par la clôture. Plus particulièrement elle se rapport au domaine des clôtures de protection comportant des panneaux montés sur une ossature comportant des poteaux de fixation.The invention relates to the technical field of protection fences for detecting an intrusion attempt inside a perimeter delimited by the fence. More particularly, it relates to the field of protective fences comprising panels mounted on a frame comprising fixing posts.

Une clôture de protection comprend tout d'abord une ossature qui se compose d'éléments de structure. Ces éléments de structure comportent des poteaux de fixation, généralement verticaux et, le cas échéant, des traverses généralement horizontales qui relient deux poteaux voisins. Cette clôture comprend en outre différents panneaux de clôture montés sur cette ossature, par l'intermédiaire de moyens de fixation, typiquement par vissage. Les panneaux de clôture délimitent au moins en partie un enclos, de manière à former une barrière physique destinée à empêcher une personne de pénétrer dans le périmètre de cet enclos.A protection fence firstly comprises a frame which consists of structural elements. These structural elements comprise fixing posts, generally vertical and, where appropriate, generally horizontal crosspieces which connect two adjacent posts. This fence further comprises various fence panels mounted on this frame, by means of fixing means, typically by screwing. The fence panels at least partially delineate an enclosure so as to form a physical barrier to prevent a person from entering the perimeter of the enclosure.

L'invention vise plus particulièrement une telle clôture de protection, dans laquelle chaque panneau comprend deux plaques parallèles, qui sont séparées par des moyens d'isolation électrique. Ces plaques peuvent être rigides, semi-rigides ou flexibles. Elles peuvent être pleines ou au moins partiellement ajourées. Au sens de l'invention, elles peuvent être formées par un treillis, notamment un treillis métallique.The invention relates more particularly to such a protective fence, wherein each panel comprises two parallel plates, which are separated by electrical insulation means. These plates can be rigid, semi-rigid or flexible. They can be full or at least partially openwork. Within the meaning of the invention, they may be formed by a lattice, in particular a wire mesh.

Les moyens d'isolation précités, qui sont typiquement formés par une couche de colle, permettent aux deux plaques de ne pas être en contact électrique mutuel. Les deux plaques constitutives d'un panneau donné sont raccordées respectivement, l'une à la masse et l'autre à la phase. Par conséquent, si l'une des plaques est percée ou sciée, lors d'une tentative d'intrusion, il se forme au moins temporairement un court-circuit avec l'outil ou avec des copeaux métalliques, lequel sera détecté.The aforementioned insulation means, which are typically formed by a layer of glue, allow the two plates not to be in mutual electrical contact. The two constituent plates of a given panel are connected respectively, one to the ground and the other to the phase. Therefore, if one of the plates is pierced or sawed, during an intrusion attempt, at least a temporary short circuit is formed with the tool or with metal chips, which will be detected.

Lorsque la clôture est formée de plusieurs panneaux, toutes les plaques de masse sont reliées électriquement entre elles, alors que toutes les plaques de phase sont reliées électriquement entre elles. Ces deux ensembles de plaques forment donc deux circuits dits respectivement « de masse » et « de phase », reliés aux pôles d'un système d'alarme qui détecte le court-circuit entre ces deux circuits.When the fence is formed of several panels, all the ground plates are electrically connected to each other, while all the phase plates are electrically connected to each other. These two sets of plates thus form two so-called "ground" and "phase" circuits, connected to the poles of an alarm system which detects the short circuit between these two circuits.

On conçoit que, afin d'assurer un fonctionnement optimal de la clôture de sécurité, les circuits respectifs de masse et de phase doivent être isolés mutuellement. Il convient en particulier de prendre des dispositions constructives, afin que les moyens de fixation des panneaux sur le bâti ne soient pas la cause d'un court-circuit.It is conceivable that, in order to ensure optimum operation of the safety fence, the respective circuits of mass and phase must be mutually isolated. In particular, it is necessary to make constructive arrangements, so that the means of fixing the panels on the frame are not the cause of a short circuit.

On connaît de

Cette solution connue présente cependant certains inconvénients. En effet, la clôture de sécurité décrite dans ce document possède une épaisseur relativement importante. De plus, cette clôture présente une structure mécanique complexe, en particulier dans la zone de fixation des panneaux sur le poteau. Puis, le besoin d'avoir des zones dénudées au niveau de la zone de recouvrement des panneaux complique la protection contre la corrosion et l'assemblage de la clôture. Enfin, la maintenance de cette clôture peut se révéler peu commode, en particulier lors d'une rupture mécanique des moyens de fixation et / ou d'un disfonctionnement dans la continuité électrique.This known solution, however, has certain disadvantages. Indeed, the security fence described in this document has a relatively large thickness. In addition, this fence has a complex mechanical structure, particularly in the area of attachment of the panels on the pole. Then, the need for bare areas at the panel overlap area complicates corrosion protection and fence assembly. Finally, the maintenance of this fence can be inconvenient, especially during a mechanical breakage of the fastening means and / or a malfunction in the electrical continuity.

Il existe par conséquent un besoin manifeste de clôtures, permettant de remédier aux inconvénients de l'art antérieur évoqués ci-dessus.There is therefore a clear need for fencing, to overcome the disadvantages of the prior art mentioned above.

Un premier objet de l'invention est une clôture de sécurité comprenant

- une ossature comportant des éléments de structure,

- au moins deux panneaux, chaque panneau comportant au moins une première et une seconde plaques assemblées l'une au voisinage de l'autre, ainsi que des moyens d'isolation électrique entre les deux plaques,

- des moyens de fixation de chaque panneau sur au moins un élément de structure,

- des premiers moyens de liaison électrique entre les premières plaques d'au moins deux panneaux adjacents, ces panneaux adjacents s'étendant selon deux plans principaux, ainsi que des seconds moyens de liaison électrique entre les secondes plaques desdits au moins deux panneaux adjacents,

- des moyens de raccordement à une masse des premières plaques, dites plaques de masse, ainsi que des moyens de raccordement à une phase des secondes plaques, dites plaques de phase,

- a framework comprising structural elements,

- at least two panels, each panel comprising at least a first and a second assembled plate one in the vicinity of the other, as well as electrical insulation means between the two plates,

- means for fixing each panel on at least one structural element,

- first electrical connection means between the first plates of at least two adjacent panels, these adjacent panels extending in two main planes, as well as second electrical connection means between the second plates of said at least two adjacent panels,

- means for connection to a mass of the first plates, called ground plates, as well as connection means to a phase of the second plates, called phase plates,

La clôture de sécurité conforme à l'invention est avantageuse, par rapport à l'enseignement de

De plus la structure des moyens de fixation, utilisés dans la clôture de l'invention, peut être simplifiée. En particulier, il n'est pas nécessaire de prévoir des moyens uniques, assurant la fixation simultanée des deux plaques sur l'élément de structure. De ce fait, il est possible de démonter un panneau par rapport à l'élément de structure, sans interférer sur la fixation de l'autre de ces panneaux.In addition, the structure of the fixing means used in the enclosure of the invention can be simplified. In particular, it is not necessary to provide unique means, ensuring the simultaneous fixing of the two plates on the structural element. Therefore, it is possible to disassemble a panel relative to the structural element, without interfering on the attachment of the other of these panels.

Selon un mode de réalisation de l'invention, les panneaux adjacents s'étendent selon deux plans principaux parallèles, et en particulier les deux panneaux adjacents s'étendent dans le même plan. Ceci est avantageux en ce qui concerne la compacité globale de la clôture, notamment son épaisseur.According to one embodiment of the invention, the adjacent panels extend in two parallel main planes, and in particular the two adjacent panels extend in the same plane. This is advantageous as regards the overall compactness of the fence, especially its thickness.

De façon avantageuse, les chants des deux panneaux adjacents s'étendent de part et d'autre de l'élément de structure. Ceci permet de réduire l'interaction mécanique entre les deux panneaux, ce qui permet par exemple une intervention sur l'un de ces panneaux, sans avoir à interférer sur la fixation de l'autre de ces panneaux sur le bâti.Advantageously, the edges of the two adjacent panels extend on either side of the structural element. This reduces the mechanical interaction between the two panels, which allows for example an intervention on one of these panels, without having to interfere with the attachment of the other of these panels on the frame.

De façon avantageuse, les plans principaux des deux panneaux adjacents traversent l'élément de structure. La surépaisseur due à la présence des panneaux est donc limitée, voire inexistante.Advantageously, the main planes of the two adjacent panels pass through the structural element. The extra thickness due to the presence of the panels is therefore limited or non-existent.

De façon avantageuse, toutes les plaques de masse sont disposées d'un premier côté de la clôture, alors que toutes les plaques de phase sont disposées du côté opposé de la clôture. Ceci permet de limiter les risques de disfonctionnement électrique.Advantageously, all the ground plates are arranged on a first side of the fence, while all the phase plates are arranged on the opposite side of the fence. This makes it possible to limit the risks of electrical malfunction.

Selon un mode de réalisation avantageux de l'invention, les moyens de liaison comprennent un organe de liaison comportant une première zone de montage, en particulier de montage amovible, sur une plaque de masse ou de phase appartenant à un premier panneau, ainsi qu'une seconde zone de montage, en particulier de montage amovible, sur une plaque de masse ou de phase appartenant à un second panneau. Selon un mode de réalisation de l'invention, l'organe de liaison comporte en outre une zone de transition entre lesdites zones de montage, cette zone de transition s'étendant à distance des parois en regard de l'élément de structure. Le fait de prévoir un organe de liaison électrique spécifique, dédié uniquement à cette fonction, permet de dissocier celle-ci par rapport à la fonction de fixation mécanique du panneau sur l'ossature. Ceci assure notamment la simplification de la maintenance de la clôture, en particulier d'éventuelles réparations.According to an advantageous embodiment of the invention, the connecting means comprise a connecting member comprising a first mounting zone, in particular of a removable mounting, on a ground or phase plate belonging to a first panel, as well as a second mounting zone, in particular of removable mounting, on a ground or phase plate belonging to a second panel. According to one embodiment of the invention, the connecting member further comprises a transition zone between said mounting zones, this transition zone extending away from the walls facing the structural element. The fact of providing a specific electrical connection member, dedicated solely to this function, allows to dissociate it with respect to the mechanical fastening function of the panel on the frame. This ensures in particular the simplification of the maintenance of the fence, in particular any repairs.

Selon un premier mode de réalisation de l'invention, la zone de transition présente une forme adaptée pour contourner l'élément de structure, notamment une forme de U ou de L. Cette mesure trouve son application, notamment dans le cas où l'élément de structure est un poteau.According to a first embodiment of the invention, the transition zone has a shape adapted to bypass the structural element, in particular a U or L shape. This measure finds its application, particularly in the case where the element of structure is a pole.

Selon un mode de réalisation alternatif de l'invention, l'organe de liaison est une barrette dont la zone de transition traverse une échancrure ménagée dans l'élément de structure. Cette mesure trouve son application, notamment dans le cas où l'élément de structure est une traverse.According to an alternative embodiment of the invention, the connecting member is a bar whose transition zone passes through a recess formed in the structural element. This measure finds its application, especially in the case where the structural element is a cross.

Un autre objet de l'invention est une clôture de sécurité comprenant

- une ossature comportant des éléments de structure,

- au moins deux panneaux, chaque panneau comportant au moins une première et une seconde plaques assemblées l'une au voisinage de l'autre, ainsi que des moyens d'isolation électrique entre les deux plaques,

- des moyens de fixation de chaque panneau sur au moins un élément de structure

- des premiers moyens de liaison électrique entre les premières plaques d'au moins deux panneaux adjacents, ainsi que des seconds moyens de liaison électrique entre les secondes plaques desdits au moins deux panneaux adjacents,

- des moyens de raccordement à une masse des premières plaques, dites plaques de masse, ainsi que des moyens de raccordement à une phase des secondes plaques, dites plaques de phase,

- a framework comprising structural elements,

- at least two panels, each panel comprising at least a first and a second assembled plate one in the vicinity of the other, as well as electrical insulation means between the two plates,

- means for fixing each panel on at least one structural element

- first electrical connection means between the first plates of at least two adjacent panels, and second electrical connection means between the second plates of said at least two adjacent panels,

- means for connection to a mass of the first plates, called ground plates, as well as connection means to a phase of the second plates, called phase plates,

Cette clôture conforme à cet autre objet de l'invention peut comprendre tout ou partie des caractéristiques ci-dessus, dans la mesure où elles sont techniquement compatibles.This enclosure in accordance with this other object of the invention may include all or some of the above features, to the extent that they are technically compatible.

L'invention va être décrite ci-après, en référence aux dessins annexés, donnés à titre d'exemples non limitatifs, dans lesquels :

- la

figure 1 est une vue de face, illustrant une clôture de sécurité conforme à l'invention ; - la

figure 2 est une vue de face, illustrant de façon plus précise la liaison entre deux panneaux parallèles appartenant à la clôture de sécurité conforme à l'invention ; - la

figure 3 est une vue de dessus, illustrant sous un autre angle la liaison entre les deux panneaux de lafigure 2 ; - la

figure 4 est une vue de face, analogue à lafigure 2 , illustrant la liaison entre deux autres panneaux parallèles appartenant à la clôture de sécurité conforme à l'invention ; - la

figure 5 est une vue de côté, illustrant sous un autre angle la liaison entre les deux panneaux de lafigure 4 ; et - la

figure 6 est une vue de dessus, analogue à lafigure 3 , illustrant la liaison entre deux panneaux perpendiculaires appartenant à une clôture de sécurité conforme à une variante de l'invention.

- the

figure 1 is a front view, illustrating a security fence according to the invention; - the

figure 2 is a front view, illustrating more precisely the connection between two parallel panels belonging to the security fence according to the invention; - the

figure 3 is a view from above, illustrating in another angle the connection between the two panels of thefigure 2 ; - the

figure 4 is a front view, similar to thefigure 2 illustrating the connection between two other parallel panels belonging to the security fence according to the invention; - the

figure 5 is a side view, illustrating from another angle the connection between the two panels of thefigure 4 ; and - the

figure 6 is a view from above, similar to thefigure 3 , illustrating the connection between two perpendicular panels belonging to a security fence according to a variant of the invention.

La

Cette clôture comprend en outre des panneaux référencés 31 à 39, également de type connu en soi. Chaque panneau comprend deux plaques opposées, s'étendant parallèlement l'une de l'autre. Les

Les deux plaques opposées d'un même panneau sont séparées par un isolant électrique 61, 62 et 64 représenté de façon schématique sur les

Les différentes plaques de masse, dont celles 41, 42 et 44, sont reliées électriquement les unes aux autres. A cet effet, il est prévu différents organes de liaison 7 et 8, dont la structure et la fonction seront décrites plus en détail dans ce qui suit. Ces organes sont visibles sur les détails II et IV de la

De manière analogue les différentes plaques de phase, dont celles 51, 52 et 54, sont reliées électriquement les unes aux autres. A cet effet, il est prévu différents organes de liaison 9 et 10, qui ne sont pas visibles sur la

On va maintenant décrire, en référence aux

Comme montré en

La fixation de l'organe de liaison 9 sur chaque plaque 51 et 52 est réalisée de façon analogue à ce qui vient d'être décrit immédiatement ci-dessus pour l'organe 7. Sur la

Comme le montre plus particulièrement la

De plus, on notera que ces plans P31 et P32 sont confondus, à savoir que les panneaux sont disposés dans le prolongement l'un de l'autre. Ces plans s'étendent en outre à travers le poteau 1, ce qui permet de conférer une valeur très faible à l'épaisseur locale de la clôture. Cette épaisseur est définie comme la distance, selon la direction de la flèche F, entre les âmes 71 et 91 des organes de liaison 7 et 9.In addition, note that these plans P31 and P32 are confused, namely that the panels are arranged in the extension of one another. These planes further extend through the

On va maintenant décrire, en référence aux

Chaque organe de liaison 8 ou 10 présente la forme d'une barrette allongée, dont les deux extrémités sont percées d'orifices. Ces barrettes s'étendent à des travers des passages P8 et P10, qui sont formés par des échancrures ménagées successivement dans les différents rebords et la traverse 2. L'homme du métier espacera les parois en regard des barrettes de liaison, par rapport à celles des rebords et de la traverse, selon une distance suffisante pour éviter tout risque de contact intempestif susceptible de provoquer un court-circuit.Each connecting

Comme montré en

La fixation de la barrette 10 sur chaque plaque 51 et 54 est réalisée de façon analogue à ce qui vient d'être décrit immédiatement ci-dessus pour la barrette 8. Comme en

Comme le montre plus particulièrement la

De plus, on notera que ces plans P31 et P34 sont confondus, à savoir que les panneaux sont disposés dans le prolongement l'un de l'autre. Ces plans s'étendent en outre à travers la traverse 2, ce qui permet de conférer une valeur très faible à l'épaisseur locale de la clôture. Cette épaisseur est définie comme la distance, selon la direction F', entre les faces opposées de la traverse 2.In addition, note that these plans P31 and P34 are confused, namely that the panels are arranged in the extension of one another. These planes further extend through the

L'homme du métier pourra prévoir autant d'organes de liaison que nécessaire entre les plaques, situés d'un même côté de la clôture, afin d'assurer la continuité électrique entre elles. Sur la

La

La clôture de la

On note respectivement P131 et P132 les plans principaux des panneaux 131 et 132. Au sens de l'invention, il n'y a pas de recouvrement entre ces deux panneaux 131 et 132. En d'autres termes ces derniers ne se superposent pas lorsqu'ils sont vus, d'une part selon la flèche F1 perpendiculaire au plan principal P131 et, d'autre part, selon la flèche F2 perpendiculaire au plan principal P132.P131 and P132 respectively denote the main planes of the

Claims (10)

- Security fence comprising- a frame comprising structural elements (1, 2; 101),- at least two panels (31 - 39; 131, 132), with each panel comprising at least one first (41, 42, 44; 141, 142) and one second (51, 52, 54; 151, 152) plate assembled in the vicinity of one other, as well as means (61, 62, 64; 161, 162) of electrical insulation between the two plates,- means (MF) for fastening each panel onto at least one structural element,- first means (7, 9; 107) of electrical connection between the first plates (41, 42, 44; 141, 142) of at least two adjacent panels (31, 32, 34; 131, 132), with these adjacent panels extending along two main planes (P31, P32, P34; P131, P132), as well as second means (8, 10) of electrical connection between the second plates (51, 52, 54) of said at least two adjacent panels,- means for connecting to a ground of the first plates, with these plates being referred to as ground plates,as well as means for connecting to a phase of the second plates, with these plates being referred to as phase plates,

said fence characterised in that said panels do not overlap, when they are viewed according to a direction (F, F'; F1, F2) perpendicular to one or the other of their main planes (P31, P32, P34; P131, P132). - Fence according to claim 1, wherein the adjacent panels extend according to two main parallel planes (P31, P32, P34), and in particular the two adjacent panels extend in the same plane.

- Fence according to claim 1 or 2, wherein the edges (31', 32', 41', 51', 44', 54') of the two adjacent panels extend on either side of the structural element.

- Fence according to one of the preceding claims, wherein the main planes (P31, P32, P34) of the two adjacent panels (31, 32, 34) pass through the structural element (1, 2).

- Fence according to one of the preceding claims, wherein all of the ground plates (41, 42, 44; 141, 142) are arranged on a first side of the fence, while all of the phase plates (51, 52, 54; 151, 152) are arranged on the opposite side of the fence.

- Fence according to one of the preceding claims, wherein the means of connection comprise a connecting member (7, 8, 9, 10; 107) comprising a first zone for assembly (74, 94; 174), in particular with removable mounting, onto a ground plate (41; 141) or phase plate (51) belonging to a first panel (31; 131), as well as a second zone for assembly (75, 95; 175), in particular with removable mounting, onto a ground plate (42; 142) or phase plate (52) belonging to a second panel (32; 132).

- Fence according to claim 6, wherein the connecting member (7, 8 , 9, 10; 107) further comprises a transition zone (71, 72, 73; 171) between said zones for assembly, with this transition zone extending at a distance from the walls facing the structural element (1, 2; 101).

- Fence according to claim 7, wherein the transition zone (71, 72, 73; 171) has a shape that is adapted to circumvent the structural element (1; 2), in particular in the shape of a U or of an L.

- Fence according to claim 7, wherein the connecting member is a bar (8, 10) of which the transition zone passes through an indentation (P8, P10) arranged in the structural element (2).

- Security fence comprising- a frame comprising structural elements (1, 2; 101),- at least two panels (31-39; 131, 132),with each panel comprising at least one first (41, 42, 44; 141, 142) and one second (51, 52, 54; 151, 152) plate assembled in the vicinity of one other, as well as means (61, 62, 64; 161, 162) of electrical insulation between the two plates,- means (MF) for fastening each panel onto at least one structural element- first means (7, 9; 107) of electrical connection between the first plates (41, 42, 44; 141, 142) of at least two adjacent panels (31, 32, 34; 131, 132), as well as second means (8, 10) of electrical connection between the second plates (51, 52, 54) of said at least two adjacent panels,- means for connecting to a ground of the first plates, with these plates being referred to as ground plates,as well as means for connecting to a phase of the second plates, with these plates being referred to as phase plates,

characterised in that the means of connections comprise a connecting member (10) comprising a first zone for assembly, in particular with removable mounting, onto a phase or ground plate belonging to a first panel, a second zone for assembly, in particular with removable mounting, onto a phase or ground plate belonging to a second panel, as well as a transition zone between these zones for assembly, with this transition zone extending at a distance from the structural element.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR1462148A FR3029956B1 (en) | 2014-12-10 | 2014-12-10 | SAFETY CLOSURE COMPRISING SEVERAL PANELS FIXED ON A FRAMEWORK |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3032003A1 EP3032003A1 (en) | 2016-06-15 |

| EP3032003B1 true EP3032003B1 (en) | 2017-05-31 |

Family

ID=52737236

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP15196188.5A Active EP3032003B1 (en) | 2014-12-10 | 2015-11-25 | Safety fence comprising a plurality of panels attached to a framework |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP3032003B1 (en) |

| FR (1) | FR3029956B1 (en) |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH643077A5 (en) * | 1979-08-07 | 1984-05-15 | Ci Ka Ra Srl | ANTI-BREAK-IN FENCE NET, PROCEDURE AND DEVICE FOR ITS MANUFACTURE. |

| FR2592512A1 (en) * | 1985-12-31 | 1987-07-03 | Cogny Systems | Urban type electric fencing |

| FR2762919B1 (en) * | 1997-04-30 | 1999-08-06 | Yves Guerineau | SECURITY FENCE CONSISTING OF CONDUCTIVE MESH |

| FR2937360B1 (en) | 2008-10-20 | 2010-12-24 | Eurocloture | SAFETY CLOSURE PANEL AND SAFETY CLOSURE WHICH CONSISTS OF AT LEAST ONE SUCH PANEL |

| WO2012048371A1 (en) * | 2010-10-12 | 2012-04-19 | Queensland Security Fencing | Rapid deployment high security electric fencing |

-

2014

- 2014-12-10 FR FR1462148A patent/FR3029956B1/en not_active Expired - Fee Related

-

2015

- 2015-11-25 EP EP15196188.5A patent/EP3032003B1/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| EP3032003A1 (en) | 2016-06-15 |

| FR3029956A1 (en) | 2016-06-17 |

| FR3029956B1 (en) | 2016-12-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2250667B1 (en) | Assembly including a wire member and a microelectronic chip with a notch, including at least one stud for holding the wire member | |

| EP3323171B1 (en) | Insulator for a pivotable electrical connection | |

| EP2993745B1 (en) | Structure for an electrical installation of a rail vehicle and associated rail vehicle | |

| EP1793659B1 (en) | Electrical cabinet comprising a wiring bracket | |

| FR3018088A1 (en) | DEVICE FOR SOLIDARIZING A RIGID WINDING PANEL TO A GROOVED POST, AND SAID DEVICE COMPRISING A SOLIDARIZATION MEMBER COMPRISING A LOCKOUT IN TRANSLATION ALONG THE LONGITUDINAL AXIS OF THE GROOVE | |

| FR3064207B1 (en) | ANCHOR STRUCTURE FOR ANTI-EROSION COATING, ESPECIALLY FOR PROTECTION OF A WALL OF FCC UNIT. | |

| EP3032003B1 (en) | Safety fence comprising a plurality of panels attached to a framework | |

| EP2508837B1 (en) | Ballistic protection grid comprising an access door | |

| WO2013088052A1 (en) | Equipotential connection system for panel | |

| EP3006650B1 (en) | Screen device for making a fence and fence without posts made using such a device | |

| EP3997759B1 (en) | Connection device for grounding an electrical apparatus and/or creating an equipotential link between conductive elements | |

| EP2428449B1 (en) | Thermal insulation device and manufacturing method | |

| FR3023310A1 (en) | THERMALLY BRIDGE BREAKING DETECTOR FOR CONSTRUCTION DEVICE, USE THEREOF AND CORRESPONDING CONSTRUCTION DEVICE | |

| EP3238977A1 (en) | Power supply assembly intended for recharging electric batteries of electric vehicles | |

| EP4092226B1 (en) | Element for railing and corresponding fence | |

| EP3483993A1 (en) | Base for electrical cabinet | |

| EP2186956A1 (en) | Assembly piece for assembling a module, in particular a habitable module, assembly, kit and module | |

| WO2006108932A1 (en) | Prefabricated building and a framing therefor | |

| EP2178055A1 (en) | Secure enclosing panel and secure enclosure made up of at least one such panel | |

| EP3490086B1 (en) | Support system for an electrical cabinet | |

| FR3038638A1 (en) | CHAINING DEVICE, AS WELL AS A CHAINING DEVICE COMPRISING TWO SUCH DEVICES | |

| WO2015082776A1 (en) | Fire-stop wall partition device, and wall partition assembly having a pre-hung door and including such a device | |

| FR2963492A1 (en) | Fixation panel i.e. S81 panel, for fixing e.g. smart electricity meter on wall, has intermediate zone defined such that connectors are located at equidistance from terminals with tolerance of specific value relative to position | |

| FR2962604A1 (en) | False interruption grid for use in multipurpose grid of connection box in electrical network, has optional electrically conducting bars allowing electric connection of independent and interchangeable low voltage modules | |

| EP3063346B1 (en) | Edge-protection strip for a plate and use thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| 17P | Request for examination filed |

Effective date: 20161215 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: G08B 13/12 20060101ALI20170112BHEP Ipc: E04H 17/16 20060101AFI20170112BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20170130 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 897625 Country of ref document: AT Kind code of ref document: T Effective date: 20170615 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602015002919 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20170531 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 897625 Country of ref document: AT Kind code of ref document: T Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170831 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170901 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170831 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170930 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602015002919 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20180301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171125 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20151125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170531 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20191125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191125 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20241206 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20241126 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20241118 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20241201 Year of fee payment: 10 |