EP2995293A1 - Flacons d'alimentation - Google Patents

Flacons d'alimentation Download PDFInfo

- Publication number

- EP2995293A1 EP2995293A1 EP15174097.4A EP15174097A EP2995293A1 EP 2995293 A1 EP2995293 A1 EP 2995293A1 EP 15174097 A EP15174097 A EP 15174097A EP 2995293 A1 EP2995293 A1 EP 2995293A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- bottle

- nutritional

- vial according

- threaded neck

- thread

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 235000016709 nutrition Nutrition 0.000 title claims description 32

- 230000035764 nutrition Effects 0.000 title description 2

- 239000011521 glass Substances 0.000 claims abstract description 14

- 235000013305 food Nutrition 0.000 claims description 6

- 239000005388 borosilicate glass Substances 0.000 claims description 4

- 235000015097 nutrients Nutrition 0.000 claims description 4

- 210000002445 nipple Anatomy 0.000 description 10

- 239000011324 bead Substances 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 6

- 239000000463 material Substances 0.000 description 4

- 230000035622 drinking Effects 0.000 description 3

- 239000012535 impurity Substances 0.000 description 2

- 239000005361 soda-lime glass Substances 0.000 description 2

- 101001019455 Homo sapiens ICOS ligand Proteins 0.000 description 1

- 102100034980 ICOS ligand Human genes 0.000 description 1

- CDBYLPFSWZWCQE-UHFFFAOYSA-L Sodium Carbonate Chemical compound [Na+].[Na+].[O-]C([O-])=O CDBYLPFSWZWCQE-UHFFFAOYSA-L 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000003670 easy-to-clean Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000005489 elastic deformation Effects 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61J—CONTAINERS SPECIALLY ADAPTED FOR MEDICAL OR PHARMACEUTICAL PURPOSES; DEVICES OR METHODS SPECIALLY ADAPTED FOR BRINGING PHARMACEUTICAL PRODUCTS INTO PARTICULAR PHYSICAL OR ADMINISTERING FORMS; DEVICES FOR ADMINISTERING FOOD OR MEDICINES ORALLY; BABY COMFORTERS; DEVICES FOR RECEIVING SPITTLE

- A61J9/00—Feeding-bottles in general

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61J—CONTAINERS SPECIALLY ADAPTED FOR MEDICAL OR PHARMACEUTICAL PURPOSES; DEVICES OR METHODS SPECIALLY ADAPTED FOR BRINGING PHARMACEUTICAL PRODUCTS INTO PARTICULAR PHYSICAL OR ADMINISTERING FORMS; DEVICES FOR ADMINISTERING FOOD OR MEDICINES ORALLY; BABY COMFORTERS; DEVICES FOR RECEIVING SPITTLE

- A61J9/00—Feeding-bottles in general

- A61J9/08—Protective covers for bottles

- A61J9/085—Lids for closing the bottle

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61J—CONTAINERS SPECIALLY ADAPTED FOR MEDICAL OR PHARMACEUTICAL PURPOSES; DEVICES OR METHODS SPECIALLY ADAPTED FOR BRINGING PHARMACEUTICAL PRODUCTS INTO PARTICULAR PHYSICAL OR ADMINISTERING FORMS; DEVICES FOR ADMINISTERING FOOD OR MEDICINES ORALLY; BABY COMFORTERS; DEVICES FOR RECEIVING SPITTLE

- A61J11/00—Teats

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61J—CONTAINERS SPECIALLY ADAPTED FOR MEDICAL OR PHARMACEUTICAL PURPOSES; DEVICES OR METHODS SPECIALLY ADAPTED FOR BRINGING PHARMACEUTICAL PRODUCTS INTO PARTICULAR PHYSICAL OR ADMINISTERING FORMS; DEVICES FOR ADMINISTERING FOOD OR MEDICINES ORALLY; BABY COMFORTERS; DEVICES FOR RECEIVING SPITTLE

- A61J11/00—Teats

- A61J11/04—Teats with means for fastening to bottles

Definitions

- the invention relates to a feeding bottle for infants and toddlers.

- Nutritional bottles are vessels for nourishing a child by means of a nourishing teat (also called a “teat”) or a drinking aid (eg a nipple or drinking spout).

- Nutritional vials are preferably graduated for visual metering and picking up a liquid.

- Nutritional bottles, feeding teat and drinking aids are the subject of European standard EN14350-1.

- Nutritional bottles are made of plastic and glass. Glass vials are durable, hygienic, environmentally friendly and easy to clean. Multi-use glass vials are made of borosilicate glass.

- Known baby bottles made of glass have a long threaded neck with an external thread for screwing on a mounting ring for a food teat. Below the thread profile runs on the threaded neck an outwardly projecting annular bead.

- the annular bead is used to attach a gripper in the manufacture of the glass bottle.

- the tightening of the fastening ring is limited by the annular bead.

- the torus can be easily damaged during manufacture or use.

- the threaded neck sits on a bottle shoulder, whose diameter gradually increases downwards and is connected at the bottom over a large radius with the bottle body.

- the angle of the bottle shoulder to the horizontal above the radius is 55 ° and the radius in the transition to the bottle body 15 mm.

- the bottle shoulder requires a corresponding use of material and leads to a corresponding total length of the feeding bottle.

- Single use glass baby bottles are especially for clinics. They are made of soda lime glass and are not as strong as baby glass bottles for multiple use.

- a known disposable baby soda bottle made of soda-lime glass has a groove below the threaded neck for attaching a gripper during production. This is followed by a bottleneck over a large inner radius (5 mm), which runs down over an even larger outer radius (23.5 mm) towards the body of the bottle.

- the long bottle shoulder with gradually widening diameter requires a high material usage and a large length of the baby bottle.

- the present invention seeks to provide a glass jar, which is less susceptible to damage, allows for shorter design with less material and allows improved feel and an improved appearance.

- the glass feeding vial according to the invention comprises a bottle body which has a bottle bottom at the bottom and is connected at the top by a bottle shoulder with an upwardly projecting threaded neck, wherein the threaded neck forms the top as a circular cylindrical hollow body is, on which an outwardly projecting thread profile of an external thread rotates and the threaded neck down has a circumferential annular groove which is bounded above by the lower end side of the hollow body and below by the bottle shoulder and between bottle shoulder and bottle body an outer radius of 7.5 mm is available.

- the feeding bottle instead of the annular bead below the external thread, there is a circumferential annular groove into which a gripper for moving the bottle during production can intervene.

- the threaded neck can be made shorter than conventional glass jars, so that the screw ring can be screwed close to the bottle shoulder.

- the radius of maximum 7.5 mm between the bottle shoulder and the bottle body allows very short or almost square bottle shoulders. As a result, a gap between the screw ring and the bottle body can be greatly reduced, whereby the penetration of impurities can be avoided and the feel and external appearance of the feeding bottle can be improved.

- the outer radius between the bottle shoulder and bottle body is a maximum of 5 mm, preferably 2 to 4 mm, more preferably 3 mm.

- the advantageous effects of the invention are particularly pronounced.

- the bottle shoulder between the inner radius and the outer radius has a shoulder portion at an angle to the horizontal of a maximum of 30 °, preferably of at most 20 °, more preferably of 15 °.

- the invention further includes embodiments with a flat shoulder portion between inner and outer radius, so that the angle between the horizontal and the shoulder portion is 0 °.

- the bottle shoulder becomes all the more angular, the smaller the outer radius and the inner radius and the flatter the angle between the outer and inner radius and the horizontal.

- the external thread has 0.75 to 1.5 turns, preferably one turn. This promotes a particularly short bottleneck.

- the external thread is catchy.

- there is external thread a trapezoidal thread, round thread, pointed thread or flat thread.

- the external thread is preferably a thread GL50 DIN168

- the outer circular cylindrical hollow body has a height of 7.5 to 12.5 mm, preferably of 10.2 mm and / or an outer diameter of 40 to 60 mm, preferably 45 to 50 mm, further preferably 47, 3 mm.

- the external thread has a pitch of 3 to 5 mm, preferably 4 mm and / or an outer diameter of 45 to 55 mm, preferably 50 mm.

- the annular groove at the bottom has a diameter of 40 to 50 mm, preferably 44.5 mm and / or a width of 1.5 to 3 mm, preferably of 2 mm.

- the lower end face of the outer circular cylindrical hollow body is a downwardly tapered truncated cone.

- the angle between the side of the truncated cone shape and the horizontal is preferably at most 20 °, more preferably 15 °.

- the invention includes embodiments in which the lower end face of the hollow body is flat, d. H. encloses an angle of 0 ° with the horizontal.

- the outer radius is preferably 0.5 to 2 mm, more preferably 1 mm, and / or the inner radius is preferably 1 to 3 mm, preferably 1.5 mm.

- the diameter of the opening of the bottle neck at the upper end face is 35 to 45 mm, preferably 35.6 mm.

- the neck of the bottle is conically tapered downwards, the inner flank of the neck of the bottle enclosing a vertical angle of 5 to 20 °, preferably 10 °.

- the hollow body is internally conical.

- the invention includes alternatives in which the hollow body is circular cylindrical inside and outside.

- the bottleneck at the narrowest point has a diameter of 30 to 40 mm, preferably 36.5 mm.

- the nutritional vial is a multi-use nutritional vial.

- the feeding bottle is made of borosilicate glass or another glass suitable for multiple use. The use of borosilicate glass is particularly advantageous for the production of the feeding vial according to the invention, in particular the production of a bottle shoulder with an approximately angular shape.

- the nutrient bottle has a threaded ring having a hollow cylindrical body with an internal thread, with which it is screwed onto the external thread and the top of a circular ring-shaped annular flange for reaching over the top of a voltage applied to the underside on the upper end of the bottle neck Saugerflansches a Teat has.

- the lateral surface of the screwed onto the bottle neck screw ring is aligned with the lateral surface of the bottle body.

- the screw ring can be screwed onto the bottle neck at least until the complete external overlap of the external thread.

- the screw ring covers at least the outer circular cylindrical hollow body from the side. As a result, the gap between screw ring and bottle body is greatly reduced.

- the feeding bottle comprises a food teat clamped with a suction flange on the upper end face of the bottle neck.

- the feeding bottle comprises a cap held on the screw ring for covering a nutrient sucker held by the screw ring on the bottle neck.

- the lower edge of the cap covers at least the threaded ring from the side.

- the cap covers at least the hollow body laterally. As a result, a gap between the cap and bottle body is further reduced.

- top and bottom and “horizontal” and “vertical” refer to a vertical orientation of the outer circular cylindrical hollow body of the feeding bottle, wherein the threaded neck is located above the bottle body.

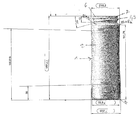

- the feeding bottle 1 comprises a bottle body 2, which has a bottom of the bottle 3 with nubs 4 on a circular ring surface and is connected at the top by a bottle shoulder 5 with an upwardly projecting threaded neck 6.

- the bottle body 2 is substantially hollow cylindrical, wherein it is preferably made slightly waisted.

- the threaded neck 5 is formed on the outside as a circular cylindrical hollow body 7, on which an outwardly projecting thread profile 8 of an external thread 9 rotates.

- Outer circular cylindrical means that the hollow body is circular cylindrical on the outside.

- the external thread 9 is catchy and has in the example a single turn, d. H. Run around once around the hollow body 7.

- the external thread 9 is formed as a trapezoidal thread.

- the threaded neck 6 has below the hollow body a circumferential annular groove 10 which is bounded above by the lower end face 11 of the circular cylindrical hollow body 7 and below by the bottle shoulder 5.

- the lower end face 11 of the circular cylindrical hollow body 7 is formed as a downwardly tapering truncated cone.

- an outer radius Ra of preferably 3 mm is formed between the bottle shoulder 5 and the shell 12 of the bottle body 2. Between the threaded neck and the annular groove 10, an inner radius Ri of preferably 2 mm is formed between the threaded neck and the annular groove 10, an inner radius Ri of preferably 2 mm is formed between the inner radius Ri and the outer radius Ra. Between the inner radius Ri and the outer radius Ra, the bottle shoulder 5 has a conical shoulder portion 13, the flank of which preferably encloses an angle of 15 ° with the horizontal.

- the height of the hollow body 7 is preferably 10.2 mm and the outer diameter is preferably 50 mm.

- the annular groove 10 preferably has a diameter of 44.5 mm at the bottom. These and other dimensions are in the Fig. 6 and 7 shown. In Fig. 7 is also shown that the hollow body 7 at the upper end outside an outer radius Ra of preferably 1 mm and inside an inner radius Ri of preferably 1.5 mm.

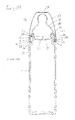

- a screw ring 14 According to Fig. 8 to 10 is screwed onto the threaded neck 6, a screw ring 14.

- the threaded ring 14 has a wood-cylindrical base body 15 with an internal thread 16, which is in engagement with the external thread 9 of the threaded neck 6.

- the screw ring 14 has a circular ring-shaped annular flange 17.

- Fig. 10 is by means of the screw ring 14, a nutrient sucker 18 and a blind cover 19 fixed to the threaded neck 6.

- the food vacuum cleaner 18 has a suction part 20 with a suction flange 21 at the lower edge.

- the blind cover 19 has a bottom 22 and a blind deck flange 23 at the outer edge.

- the Blinddeckelflansch 23 sits on the upper end face 24 of the hollow body 7 and the Saugerflansch 21 sits on the top of the blind cover flange 23.

- the annular flange 17 of the screw ring 14 presses the suction flange 21 and blind cover flange 23 sealingly against the upper end face 24 of the threaded neck 6.

- a cup-shaped cap 25 is clamped on the screw ring 14 .

- the cap 25 has a cap base 26 and a cap skirt 27, which has on the inner circumference a circumferential latching bead 28 which is snapped behind the lower edge of the base body 15.

- the cap 25 laterally covers the hollow body 7.

- Screw ring 14 and cap 25 extend close to the bottle body 2, so that the gap between them can be kept small. A further reduction of the gap width is possible by tightening the screw ring 14 under elastic deformation of the suction flange 21 or by removing the blind cover 19.

- the lateral surface 29 of the screw ring 14 and the lateral surface 30 of the cap 25 are approximately aligned with the lateral surface 12 of the bottle body second

- the feeding bottle 1 according to the invention has a comparatively low use of material and a short length. She has a particularly appealing appearance. By reducing the gap between screw ring 14 or cap 25 and bottle body 2 impurities can be avoided.

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Containers Having Bodies Formed In One Piece (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE202014104284.9U DE202014104284U1 (de) | 2014-09-10 | 2014-09-10 | Ernährungsfläschchen |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP2995293A1 true EP2995293A1 (fr) | 2016-03-16 |

Family

ID=53540594

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP15174097.4A Withdrawn EP2995293A1 (fr) | 2014-09-10 | 2015-06-26 | Flacons d'alimentation |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP2995293A1 (fr) |

| DE (1) | DE202014104284U1 (fr) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES1228596Y (es) | 2019-03-29 | 2019-07-25 | Partner Local Grup S L | Botella o recipiente con boca cortada |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE69309813T2 (de) * | 1992-09-04 | 1997-07-24 | Dart Ind Inc | Saugflasche |

| WO2006135947A1 (fr) * | 2005-06-21 | 2006-12-28 | Bamed Ag | Biberon |

| US20070045216A1 (en) * | 2005-08-03 | 2007-03-01 | Graham Packaging Company, L.P. | Plastic container finish with structural rib |

| WO2011059852A1 (fr) * | 2009-11-13 | 2011-05-19 | The Coca-Cola Company | Procédé d'isolement d'un chargement en colonne et atténuation d'une déformation de récipients métalliques formés |

| WO2014053212A1 (fr) * | 2012-10-04 | 2014-04-10 | Alpla Werke Alwin Lehner Gmbh & Co. Kg | Réceptacle en plastique sans bague de support, notamment bouteille en plastique |

-

2014

- 2014-09-10 DE DE202014104284.9U patent/DE202014104284U1/de not_active Expired - Lifetime

-

2015

- 2015-06-26 EP EP15174097.4A patent/EP2995293A1/fr not_active Withdrawn

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE69309813T2 (de) * | 1992-09-04 | 1997-07-24 | Dart Ind Inc | Saugflasche |

| WO2006135947A1 (fr) * | 2005-06-21 | 2006-12-28 | Bamed Ag | Biberon |

| US20070045216A1 (en) * | 2005-08-03 | 2007-03-01 | Graham Packaging Company, L.P. | Plastic container finish with structural rib |

| WO2011059852A1 (fr) * | 2009-11-13 | 2011-05-19 | The Coca-Cola Company | Procédé d'isolement d'un chargement en colonne et atténuation d'une déformation de récipients métalliques formés |

| WO2014053212A1 (fr) * | 2012-10-04 | 2014-04-10 | Alpla Werke Alwin Lehner Gmbh & Co. Kg | Réceptacle en plastique sans bague de support, notamment bouteille en plastique |

Also Published As

| Publication number | Publication date |

|---|---|

| DE202014104284U1 (de) | 2015-12-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| AT392211B (de) | Saugflasche | |

| DE102004023796A1 (de) | Dose | |

| EP2182910B1 (fr) | Tétine de biberon | |

| EP2494950A2 (fr) | Tétine | |

| EP2818153A1 (fr) | Réservoir de boisson doté d'un récipient pour boire et d'un appendice de prélèvement | |

| WO2009015499A1 (fr) | Fermeture pour la distribution dosée d'adhésif à partir d'un récipient | |

| EP3019412A1 (fr) | Contenant en matière plastique pourvu d'une capsule quart de tour | |

| EP2995293A1 (fr) | Flacons d'alimentation | |

| EP2607252A1 (fr) | Agencement d'un récipient en verre tubulaire et d'une fermeture en une pièce pour le récipient, ainsi que récipient en verre tubulaire destiné à la réception d'une fermeture | |

| DE102014014110A1 (de) | Flaschenverschluss zum Verschließen einer Flasche | |

| EP3191072B1 (fr) | Tétine | |

| WO2016045653A2 (fr) | Embout verseur | |

| WO2006002710A1 (fr) | Fermeture pour un recipient | |

| EP3544902B1 (fr) | Bouteille munie d'un bec verseur et d'un godet doseur | |

| EP2698323B1 (fr) | Récipient de stérilisation notamment pour nourriture pour bébé | |

| EP0215202A1 (fr) | Procédé pour la fabrication d'un couvercle en matière synthétique pour récipients en forme de bouteille | |

| EP2661399B1 (fr) | Système de fermeture à encliquetage | |

| DE102009047449B4 (de) | Aufsetzeinheit für Getränkeflaschen | |

| CH409667A (de) | Flaschenverschluss | |

| DE1404104A1 (de) | Isolierflasche | |

| CN204427513U (zh) | 一种吸管杯子 | |

| DE2461557A1 (de) | Isolierkannenverschluss | |

| CH717644B1 (de) | Flaschenhalter zur Halterung einer Flasche. | |

| CH279583A (de) | Flasche. | |

| DE102020125742A1 (de) | Behältereinheit |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| 17P | Request for examination filed |

Effective date: 20160914 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| TPAC | Observations filed by third parties |

Free format text: ORIGINAL CODE: EPIDOSNTIPA |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: A61J 9/00 20060101AFI20170713BHEP Ipc: A61J 11/00 20060101ALI20170713BHEP Ipc: B65D 1/02 20060101ALI20170713BHEP Ipc: A61J 9/08 20060101ALI20170713BHEP |

|

| 17Q | First examination report despatched |

Effective date: 20170816 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20180112 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20180523 |