EP2931962B1 - Appareil de traitement de linge à pompe à chaleur - Google Patents

Appareil de traitement de linge à pompe à chaleur Download PDFInfo

- Publication number

- EP2931962B1 EP2931962B1 EP13803033.3A EP13803033A EP2931962B1 EP 2931962 B1 EP2931962 B1 EP 2931962B1 EP 13803033 A EP13803033 A EP 13803033A EP 2931962 B1 EP2931962 B1 EP 2931962B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- basement

- heat pump

- pin

- compressing device

- treatment apparatus

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000003507 refrigerant Substances 0.000 claims description 38

- 238000000034 method Methods 0.000 claims description 15

- 238000001035 drying Methods 0.000 claims description 14

- 238000013016 damping Methods 0.000 claims description 12

- 239000000463 material Substances 0.000 claims description 5

- 230000002787 reinforcement Effects 0.000 claims description 3

- 238000005406 washing Methods 0.000 claims description 3

- 239000012530 fluid Substances 0.000 claims description 2

- 230000003134 recirculating effect Effects 0.000 description 12

- 239000002184 metal Substances 0.000 description 4

- 238000001816 cooling Methods 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- 238000001746 injection moulding Methods 0.000 description 3

- 230000000284 resting effect Effects 0.000 description 3

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- 239000006096 absorbing agent Substances 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F58/00—Domestic laundry dryers

- D06F58/20—General details of domestic laundry dryers

- D06F58/206—Heat pump arrangements

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F58/00—Domestic laundry dryers

- D06F58/20—General details of domestic laundry dryers

Definitions

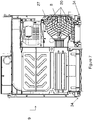

- a heat pump system includes a closed refrigerant loop, a first heat exchanger acting as evaporator for evaporating the refrigerant and cooling process air, a compressing device, a second heat exchanger acting as condenser for cooling the refrigerant and heating the process air, and an expansion device from where the refrigerant is returned to the first heat exchanger.

- a heat-pump system in which the compressing device is mounted, through first fastening means, on a bottom base element and a reinforcing plate made of metal that remains interposed between the compressing device and the bottom base element.

- Such bottom base element is in turn attached to the machine casing bottom portion with further second fastening means.

- a noise reduction cover is further placed onto the bottom base element for covering the compressing device.

- EP 2 341 179 A1 provides vibration dampers for a heat pump laundry dryer.

- the dryer has a heat pump system arranged in a basement and having a compressor.

- the compressor is supported by the dampers which support the compressor at its base plate.

- a hollow buckle is inserted into an aperture at the bottom wall of the basement.

- the hollow buckle has a radially protruding rim at the outer side of the aperture and a shaft extending through the aperture to a predefined height.

- the hollow vibration damper is placed over the shaft and a bolt (retaining rod) is screwed into the shaft. Between the lower surface of a screw head of the bolt and the upper end of the shaft the vibration damper is radially supported or stabilized by the bolt.

- the hollow buckle may be formed in single piece construction with the bottom wall.

- Said fastening device is a screw threadly engaged in said housing.

- said basement comprises seats for receiving a portion of the cabinet front wall.

- the centrifugal fan 13 is preferably located on the back of the lower supporting basement 9, at the exit end-opening or outlet of the central/intermediate segment 12c of the air recirculating conduit 12, i.e. downstream of both evaporator 15 and condenser 16 of the heat-pump assembly 14.

- Each of the pins 20 comprises a housing 32 for receiving a fastening device 22, the housing 32 extending along the longitudinal axis of the pin 20.

- the fastening device 22 comprises a screw threadly engaged or engageable in said housing 32.

- the fastening device 22 may also comprise a washer.

- the housing 32 contains an internally threaded portion threadly engaging with the fastening device 22.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Detail Structures Of Washing Machines And Dryers (AREA)

Claims (7)

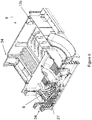

- Appareil (1) de traitement de linge à pompe de chaleur, en particulier un séchoir pour blanchisserie à pompe de chaleur ou une machine à laver séchante à pompe de chaleur, comprenant :une carrosserie (2) qui loge un tambour rotatif (3) à linge pour traiter le linge au moyen d'air de traitement, le tambour (3) étant accessible à un utilisateur par une porte (4) de l'appareil (1), un socle (9) qui constitue la partie de fond de ladite carrosserie (2) pour soutenir les composants opérationnels nécessaires pour effectuer sur le linge un processus de séchage,un circuit (12) d'air de traitement pour faire circuler l'air de traitement à travers le tambour (3),un ensemble pompe de chaleur (14) comportant une boucle de fluide frigorigène, dans laquelle le fluide frigorigène traverse un premier et un second échangeur thermique (15, 16), l'ensemble pompe de chaleur (14) comprenant un dispositif de compression (17) qui se loge dans une assise (8) constituée dans le socle (9) et qui y est fixé de façon amovible, etun élément amortisseur de vibrations (23),le dispositif de compression (17) étant fixé à la paroi de fond (31) dudit socle (9) par une clavette (20) qui est formé d'un seul tenant avec la paroi de fond (31) du socle (9) ;ladite clavette (20) servant de support à l'élément amortisseur de vibrations (23) s'étendant autour de la clavette (20) et interposé entre la clavette (20) elle-même et une partie de base (24) du dispositif de compression (17) ;ladite clavette (20) comprenant un logement (32) pour recevoir une vis (22) en prise filetée dans ledit logement (32), le logement (32) s'étendant le long de l'axe longitudinal de la clavette (20) ; etledit élément amortisseur de vibrations (23) comprenant une première extrémité (25) en contact avec la partie de base (24) du dispositif de compression (17) et une seconde extrémité (26) en contact avec une surface supérieure de la paroi de fond (31) du socle (9) portant la clavette (20) ;caractérisé en ce quela partie de base (24) du dispositif de compression (17) présente une ouverture,la clavette (20) et l'élément amortisseur de vibrations (23) s'étendent à travers l'ouverture, etune rondelle est interposée entre la surface inférieure d'une tête de vis de la vis (22) et la surface supérieure de la clavette (20) et de l'élément amortisseur de vibrations (23) et est en contact avec celles-ci.

- Appareil de traitement de linge à pompe de chaleur selon la revendication 1, dans lequel ladite paroi de fond (31) du socle (9) comprend une surface supérieure (21) et une surface inférieure (30), ladite clavette (20) faisant saillie de la surface supérieure (21) et/ou de la surface inférieure (30).

- Appareil de traitement de linge à pompe de chaleur selon la revendication 1 ou 2, dans lequel ladite clavette (20) est faite du même matériau que celui dans lequel ledit socle (9) est fait.

- Appareil de traitement de linge à pompe de chaleur selon l'une ou plusieurs des revendications précédentes, dans lequel ladite paroi de fond (31) du socle (9) comprend une surface inférieure (30) qui sépare la carrosserie (2) de l'environnement où l'appareil (1) est placé.

- Appareil de traitement de linge à pompe de chaleur selon l'une ou plusieurs des revendications précédentes, dans lequel, dans ladite assise de dispositif de compression (8), ledit socle (9) comprend des nervures de renforcement (27) qui sont formées pour retenir la partie de base (24) dudit dispositif de compression (17) dans une position stable.

- Appareil de traitement de linge à pompe de chaleur selon l'une ou plusieurs des revendications précédentes, dans lequel ledit socle (9) comprend des assises (34) pour recevoir une partie de la paroi avant de la carrosserie (2).

- Appareil de traitement de linge à pompe de chaleur selon l'une ou plusieurs des revendications précédentes,

dans lequel ledit socle (9) comprend une coque inférieure (9a) et une coque supérieure (9b) associées l'une à l'autre,

dans lequel ladite coque supérieure (9b) comprend des logements pour recevoir des moyens de support (11) de tambour (3).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP13803033.3A EP2931962B1 (fr) | 2012-12-14 | 2013-12-12 | Appareil de traitement de linge à pompe à chaleur |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP12197293.9A EP2743395A1 (fr) | 2012-12-14 | 2012-12-14 | Appareil de traitement de linge à pompe thermique |

| PCT/EP2013/076441 WO2014090962A1 (fr) | 2012-12-14 | 2013-12-12 | Appareil de traitement de linge à pompe de chaleur |

| EP13803033.3A EP2931962B1 (fr) | 2012-12-14 | 2013-12-12 | Appareil de traitement de linge à pompe à chaleur |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2931962A1 EP2931962A1 (fr) | 2015-10-21 |

| EP2931962B1 true EP2931962B1 (fr) | 2020-04-08 |

Family

ID=47563042

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12197293.9A Withdrawn EP2743395A1 (fr) | 2012-12-14 | 2012-12-14 | Appareil de traitement de linge à pompe thermique |

| EP13803033.3A Active EP2931962B1 (fr) | 2012-12-14 | 2013-12-12 | Appareil de traitement de linge à pompe à chaleur |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12197293.9A Withdrawn EP2743395A1 (fr) | 2012-12-14 | 2012-12-14 | Appareil de traitement de linge à pompe thermique |

Country Status (3)

| Country | Link |

|---|---|

| EP (2) | EP2743395A1 (fr) |

| AU (1) | AU2013357254A1 (fr) |

| WO (1) | WO2014090962A1 (fr) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102016206525A1 (de) * | 2016-04-19 | 2017-10-19 | BSH Hausgeräte GmbH | Wäschetrocknungsgerät mit Wärmepumpe und zugehörigem Antrieb |

| US20170342636A1 (en) * | 2016-05-31 | 2017-11-30 | Wuxi Little Swan Co., Ltd. | Heat pump module for laundry treatment device and laundry treatment device |

| CN106087364A (zh) * | 2016-07-29 | 2016-11-09 | 无锡小天鹅股份有限公司 | 热泵式干衣机和用于热泵式干衣机的底座组件 |

| DE102017104023A1 (de) * | 2017-02-27 | 2018-08-30 | Miele & Cie. Kg | Stationäres Haushaltsgerät mit Bodenmodul |

| CN110359249A (zh) * | 2018-03-26 | 2019-10-22 | 青岛海尔滚筒洗衣机有限公司 | 一种支撑组件及具有该支撑组件的衣物处理设备 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS58187635A (ja) * | 1982-04-26 | 1983-11-01 | Matsushita Electric Ind Co Ltd | 密閉型電動圧縮機の防振装置 |

| JP3021355B2 (ja) * | 1996-05-20 | 2000-03-15 | オリオン機械株式会社 | 冷凍装置 |

| KR100638938B1 (ko) * | 2005-03-31 | 2006-10-25 | 엘지전자 주식회사 | 의류 건조기의 습도 센서 장착 구조 |

| JP2010057545A (ja) * | 2008-09-01 | 2010-03-18 | Toshiba Corp | 洗濯乾燥機 |

| US8424834B2 (en) * | 2009-06-24 | 2013-04-23 | Magna International | Composite appliance base |

| EP2341179B1 (fr) * | 2009-12-29 | 2017-04-19 | Electrolux Home Products Corporation N.V. | Séchoir à linge pour usage domestique |

| EP2540900B1 (fr) * | 2011-06-28 | 2014-09-10 | Electrolux Home Products Corporation N.V. | Séchoir à linge pour usage domestique |

-

2012

- 2012-12-14 EP EP12197293.9A patent/EP2743395A1/fr not_active Withdrawn

-

2013

- 2013-12-12 AU AU2013357254A patent/AU2013357254A1/en not_active Abandoned

- 2013-12-12 WO PCT/EP2013/076441 patent/WO2014090962A1/fr active Application Filing

- 2013-12-12 EP EP13803033.3A patent/EP2931962B1/fr active Active

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2931962A1 (fr) | 2015-10-21 |

| EP2743395A1 (fr) | 2014-06-18 |

| WO2014090962A1 (fr) | 2014-06-19 |

| AU2013357254A1 (en) | 2015-07-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2743394A1 (fr) | Appareil de traitement de linge à pompe thermique | |

| AU2012265068B2 (en) | Rotary-drum laundry dryer | |

| EP2931962B1 (fr) | Appareil de traitement de linge à pompe à chaleur | |

| EP2990519A1 (fr) | Sèche-linge | |

| EP2990524B1 (fr) | Sèche-linge à pompe à chaleur | |

| EP2990521B1 (fr) | Sèche-linge | |

| EP2843114B1 (fr) | Sèche-linge à tambour rotatif | |

| EP2631353B1 (fr) | Sèche-linge à tambour rotatif | |

| EP2527523B1 (fr) | Sèche-linge à tambour rotatif | |

| EP2592184A1 (fr) | Sèche-linge à tambour rotatif | |

| EP2527527B1 (fr) | Sèche-linge à tambour rotatif | |

| EP3039180B1 (fr) | Sèche-linge à tambour rotatif et à pompe à chaleur | |

| EP2527525B1 (fr) | Sèche-linge à tambour rotatif | |

| EP3124679B1 (fr) | Machine à traiter le linge | |

| EP2843112B1 (fr) | Sèche-linge à tambour rotatif | |

| EP2631356B1 (fr) | Sèche-linge à tambour rotatif | |

| EP2631357B1 (fr) | Sèche-linge à tambour rotatif | |

| RU2452804C2 (ru) | Бытовое сушильное устройство для белья | |

| EP2843115A1 (fr) | Sèche-linge à tambour rotatif | |

| EP3039181A1 (fr) | Sèche-linge à tambour rotatif | |

| EP2527524B1 (fr) | Sèche-linge à tambour rotatif | |

| EP2631352B1 (fr) | Sèche-linge à tambour rotatif |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20150714 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20190604 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20191108 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1254518 Country of ref document: AT Kind code of ref document: T Effective date: 20200415 Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602013067743 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20200408 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200817 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200808 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200709 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200708 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 1254518 Country of ref document: AT Kind code of ref document: T Effective date: 20200408 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200708 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 602013067743 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 |

|

| 26 | Opposition filed |

Opponent name: BSH BOSCH UND SIEMENS HAUSGERAETE GMBH Effective date: 20210108 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20201212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20201231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201212 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201231 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201231 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201212 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201231 |

|

| PLBD | Termination of opposition procedure: decision despatched |

Free format text: ORIGINAL CODE: EPIDOSNOPC1 |

|

| PLBP | Opposition withdrawn |

Free format text: ORIGINAL CODE: 0009264 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R100 Ref document number: 602013067743 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200408 |

|

| PLBM | Termination of opposition procedure: date of legal effect published |

Free format text: ORIGINAL CODE: 0009276 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201231 |

|

| 27C | Opposition proceedings terminated |

Effective date: 20220404 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230625 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20231221 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20231227 Year of fee payment: 11 |