EP2829681B1 - Vitrage isolant - Google Patents

Vitrage isolant Download PDFInfo

- Publication number

- EP2829681B1 EP2829681B1 EP13177634.6A EP13177634A EP2829681B1 EP 2829681 B1 EP2829681 B1 EP 2829681B1 EP 13177634 A EP13177634 A EP 13177634A EP 2829681 B1 EP2829681 B1 EP 2829681B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- glass

- spacer

- insulating glass

- spacers

- insulating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/66—Units comprising two or more parallel glass or like panes permanently secured together

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/66—Units comprising two or more parallel glass or like panes permanently secured together

- E06B3/663—Elements for spacing panes

- E06B3/66309—Section members positioned at the edges of the glazing unit

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/66—Units comprising two or more parallel glass or like panes permanently secured together

- E06B3/663—Elements for spacing panes

- E06B3/66309—Section members positioned at the edges of the glazing unit

- E06B2003/66385—Section members positioned at the edges of the glazing unit with special shapes

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/66—Units comprising two or more parallel glass or like panes permanently secured together

- E06B3/663—Elements for spacing panes

- E06B3/66309—Section members positioned at the edges of the glazing unit

- E06B3/66366—Section members positioned at the edges of the glazing unit specially adapted for units comprising more than two panes or for attaching intermediate sheets

Definitions

- the invention relates to an insulating glazing according to the preamble of claim 1 and to a method for producing such a glazing according to the preamble of claim 9.

- Such a glazing with a spacer for double or triple glazing can be seen.

- the spacer is arranged continuously in the outer periphery of the glazing and has, in order to connect the corner regions, in this area an elastic deformation body.

- insulating glazing In order to equip such large windows or door or facade surfaces with insulating glazing, it is necessary to provide spacers, which are usually arranged in the upper and lower and horizontally extending outer region of the insulating glazing.

- spacers which are usually arranged in the upper and lower and horizontally extending outer region of the insulating glazing.

- the strength of the insulating glazing is achieved by that the individual glasses are thermally pre-stressed, whereby higher deflections are possible.

- the spacers are designed according stiff and large area.

- thermally toughened insulating glazing also a certain thickness of the individual glass panes, which form the insulating glazing is provided.

- this thickening of the individual glass panes leads to an increase in the assembly costs, since such individual glass panes have an enormously high dead weight, which makes handling during assembly more difficult.

- the production costs increase as more raw materials are required for the production of the glass panes.

- the substructure is much more massive design.

- the respective glass pane facing adhesive surface of two of the four spacers in the vertical or horizontal longitudinal axis of the insulating glazing are designed higher in the manner of a dome or curvature, as in the corner of the glazing, characterized in that the two spacers parallel to the curved adhesive surface to each other and preferably extend in the vertical and in that the two outer glass panes are arched by the attachment to the plan designed adhesive surface of the two spacers, which are arched between the arched spacers outwards in the manner of a sandwich construction, creates a prestressed construction for a Insulating glazing, so that the thicknesses of the individual glass panes also correspond to those for smaller insulating glazing of 1.20 meters edge length, even for large-area insulating glazing with an edge length of twelve and more meters. As a result, the self-weight force of the large-sized insulating glass is reduced and the glass raw materials to be used are saved.

- an insulating glazing according to the invention expediently has the technical effect that force effects can be optimally absorbed by the bulges of the outer glass panes of the spacers, whereby the stability of the insulating glazing increases considerably.

- the glass panes in particular in the region of the vertical longitudinal axis of the insulating glazing, are spaced so far apart that no punctiform, linear or planar contact between two adjacent panes of glass occurs due to cold bridges or other damage.

- the two vertically extending spacers have an arcuately designed inner edge whose light width is dimensioned smaller in the region of the vertical longitudinal axis of the insulating glazing than in the corner regions.

- the support and adhesive surface of the respective spacer in the respective corner areas is increased and on the other creates an optical effect, because the thinner walled spacers in the vertical longitudinal axis of the glazing influence the transparency as a spacer with a constant light width over its entire length.

- the two outer glass sheets cold-formed to fix the spacers because by this cold deformation creates a prestressed construction.

- the outer dimension of the individual glass panes in the cold-forming process does not change in contrast to a thermoformed glass pane, which often has a distortion.

- the assembly work for the production of a cold-formed insulating glazing are less complex than the assembly steps for the thermoformed insulating glazings.

- the individual glass panes can be inserted, for example, in a preformed shell of polystyrene, to be subsequently connected to the corresponding spacers and the other external glass pane.

- the arched design of the two outer glass panes of the insulating glass is therefore achieved on the one hand by the shell and the self-weight of the glass pane, and on the other by the other opposite outer glass by the contours of the two lateral spacers with a curved Adhesive surface, so that a pre-stressed sandwich constellation is reached.

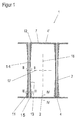

- an insulating glazing 1 refer to, which is formed of two outer glass sheets 2 and 3.

- the two glass sheets 2 and 3 are connected by means of four spacers 4 and 4 ', as explained in more detail below.

- a central glass pane 5 or a plurality of glass panes 5 provided between the two outer glass panes 2 and 3 may be present in order to provide a multiple insulating glazing 1.

- the spacer 4 consists of a drawn metallic profile, which is processed by means of milling, grinding and the like from the solid.

- the respective glass sheets 2 and 3 facing adhesive surfaces 11 are designed in the manner of a dome or curvature whose width is greater in the region of the horizontal longitudinal axis 17, as in the corner regions 15 of the insulating glazing 1. Consequently, the distance between the two outer glass sheets. 2 and 3 in the region of the horizontal longitudinal axis 17 substantially larger than in the Figures 2 . 3 and 11 shown as in the corner regions 15th

- a dehumidifying agent 10 is provided, through which the trapped air or a glass is dehumidified.

- FIGS. 2 and 3 can be seen that adjacent insulating glazing are immediately attached, so that without large gaps or distances between the two adjacent vertically extending spacer 4 insulating glazing 1 can be strung together.

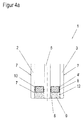

- FIG. 4a are the embodiments of the horizontal, ie in the upper and lower region of the insulating glazing 1, extending spacer 4 'shown.

- the spacers 4 ' have a plane configured adhesive surface 11, so that the distance between the two outer glass panes 2 and 3 along the spacer 4' is kept constant over the entire width of the insulating glazing. 1

- the spacers 4 ' are designed as a rectangular box, inside which the dehumidifying agent 10 is filled. If necessary, the middle glass pane 5 is arranged between two spacers 4 ', which are firmly connected together with the two outer glass panes 2 and 3 via the silicone adhesive 9.

- FIG. 4b it can be seen which deformations the insulating glazing 1 receives when lateral force.

- the curved configuration of the adhesive surface 11 of the vertically extending spacers 4 namely the two outer glass panes 2 and 3 in the horizontal longitudinal axis 17 of the insulating glazed 1 apart, so that a prestressed sandwich construction is formed by the corresponding lateral load forces optimally absorbed

- the load is caused for example by wind power on the outer glass pane 3 leads to an elastic deflection of the central glass pane 5 and an enlarged deflection of the glass pane 2, which faces a room inside.

- a shell 18 is made of polystyrene, in which a trough is incorporated.

- the first outer glass pane 2 is inserted. Due to the inner contour of the trough and the prevailing intrinsic weight force of the glass pane 2, this assumes the shape of the trough of the shell 18.

- FIGS. 7 and 8 it is shown how the outer glass pane 2, the central glass pane 5 and the mutually perpendicular spacers 4 and 4 'are fastened together. Since now the outwardly projecting and curved adhesive surface of the spacer 4 according to FIG. 9 are present, the other outer glass pane 3 can be placed on the spacers 4 and 4 '.

- the preassembled glazing 1 is formed in a prestressing sandwich construction whose two outer glass sheets 2 and 3 are cold-formed, and only with the help of the respective self-weight forces curved adhesive surfaces 11 of the spacer. 4

- FIG. 11 the spacer 4 is shown with the curved adhesive surfaces 11, which faces the glass pane 2 in the assembled state. Furthermore, from the FIGS. 1 and 11 can be seen that the perpendicular to the adhesive surface 11 extending inner edge 13 of the spacer 4 has a curved or curved outer contour. The spacer 4 is therefore dimensioned considerably larger in the corner regions 15 than in the region of the horizontal longitudinal axis 17 of the insulating glazing 1. By this constructive measure is achieved that a positive optical effect arises because the spacers 4 have in the horizontal longitudinal axis 17 of the double glazing 1 a smaller light width than in the corner regions 15th

- the support surface and the adhesive surface 11 are enlarged, so that the introduced forces are optimally supported in the corner regions 15 of the spacers 4 and in the spacer 4 'without the shearing forces acting on the spacers 4 or the adhesive bond between the glass panes 2 and 3 or the adhesive surfaces 11 of the spacers 4 and 4 'damage or even destroy.

Landscapes

- Engineering & Computer Science (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Securing Of Glass Panes Or The Like (AREA)

- Joining Of Glass To Other Materials (AREA)

Claims (9)

- Vitrage isolant (1) avec au moins deux vitres (2, 3) espacées l'une de l'autre et alignées parallèlement ou quasi parallèlement, et avec un écarteur (4, 4') s'étendant latéralement le long des bords extérieurs (7) formés par les vitres (2, 3) et qui est fixé directement sur les vitres (2, 3) à l'aide d'une surface collante (11, 12) prévue sur l'écarteur (4, 4') et qui les fixe ensemble afin de former le vitrage isolant (1), où, au niveau de l'axe longitudinal vertical ou horizontal (16 ou 17) du vitrage isolant (1), la surface collante (11) de deux sur quatre écarteurs (4) à la forme d'une coupole ou d'un bombement et donnant sur la vitre respective (2, 3) est plus élevée qu'aux coins du vitrage isolant (1), que les deux écarteurs (4) avec la surface collante bombée (11) s'étendent parallèlement l'une à l'autre et de préférence dans le plan vertical, et que, pour réaliser une pré-tension, les deux vitres extérieures (2, 3) sont voûtées vers l'extérieur en construction sandwich par la fixation sur la surface collante plane (12) des deux écarteurs (4') prévus entre les écarteurs voûtés (4),

caractérisé en ce que

l'écarteur monté (4) possède un flanc intérieur (13) sous la forme d'un arc ou convexe sur l'axe longitudinal vertical du vitrage isolant, de sorte qu'au centre (14) du vitrage isolant (1), l'écarteur (4) possède une portée libre inférieure à celle dans le coin du vitrage isolant (1),

et/ou

que dans l'écarteur (4, 4'), il est pratiqué au moins une gorge (6) dans laquelle il peut être inséré une vitre (5), l'écartement ou les écartements de la gorge (6) ou des gorges (6) des deux surfaces collantes extérieures (11, 12) de l'écarteur (4, 4') étant défini(s) par l'écartement des vitres intérieures (5) l'une de l'autre ou de la vitre extérieure respective (2, 3). - Vitrage isolant d'après la revendication 1,

caractérisé en ce que

l'écarteur (4, 4') est réalisé en matériau métallique étiré, de préférence en aluminium, et que les vitres individuelles (2, 3) du vitrage isolant (1) sont fixées par une ou par plusieurs colles (9) sur la surface collante respective (11, 12) de l'écarteur (4, 4'). - Vitrage isolant d'après une des revendications précédentes,

caractérisé en ce que

les deux faces extérieures du vitrage isolant (1) sont formées par une vitre (2, 3) formée à froid et que les deux vitres extérieures (2, 3) sont courbées ou voûtées respectivement vers l'extérieur autour de l'axe longitudinal vertical (16) du vitrage isolant (1) ou autour de l'axe longitudinal horizontal (17) du vitrage isolant (1). - Vitrage isolant d'après une des revendications précédentes,

caractérisé en ce que

dans l'écarteur (4), il est prévu un déshumidifiant (10) liant les particules d'humidité se trouvant dans l'air enfermé ou dans le verre monté. - Vitrage isolant d'après une des revendications précédentes,

caractérisé en ce que

le flanc intérieur courbé en arc (13) de l'écarteur (4) et les deux faces collantes (11) de l'écarteur (4) forment entre eux un angle droit. - Vitrage isolant d'après une des revendications précédentes,

caractérisé en ce que

dans le coin respectif (15), le flanc intérieur (13) de l'écarteur (4) est linéaire et qu'il se transforme, espacé du coin (15), en une structure en arc. - Vitrage isolant d'après une des revendications précédentes,

caractérisé en ce que

la face collante (11) et le flanc intérieur (13) de l'écarteur (4) sont fraisés dans la masse. - Vitrage isolant d'après une des revendications précédentes,

caractérisé en ce que

les vitres individuelles (2, 3, 5) sont également réalisées en verre feuilleté ou en verre de sécurité feuilleté. - Procédé de réalisation d'un vitrage isolant possédant les caractéristiques d'une des revendications 1 à 8, et réalisée d'après les phases de procédé suivantes :- Préparation d'une coupelle (18), de préférence en polystyrène,- Insertion dans la coupelle (18) d'une première vitre (2) formant la face extérieure du vitrage isolant (1),- Placement de deux écarteurs (4) réalisés d'après une des revendications 1 à 9,- Pose de la deuxième vitre extérieure (3) sur les deux écarteurs (4) et- Collage des deux vitres extérieures (2, 3) sur les surfaces collantes bombées (11) et sur les deux surfaces collantes planes (12) des écarteurs intermédiaires (4'),caractérisé en ce que

pour la réalisation d'un triple vitrage isolant (1), il est inséré une vitre centrale (5) dans une gorge (6) pratiquée dans l'écarteur respectif (4, 4'), avant qu'il soit fixé la deuxième vitre extérieure (3) sur les quatre écarteurs (4, 4').

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP13177634.6A EP2829681B1 (fr) | 2013-07-23 | 2013-07-23 | Vitrage isolant |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP13177634.6A EP2829681B1 (fr) | 2013-07-23 | 2013-07-23 | Vitrage isolant |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2829681A1 EP2829681A1 (fr) | 2015-01-28 |

| EP2829681B1 true EP2829681B1 (fr) | 2016-09-14 |

Family

ID=48875547

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP13177634.6A Not-in-force EP2829681B1 (fr) | 2013-07-23 | 2013-07-23 | Vitrage isolant |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP2829681B1 (fr) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9739085B2 (en) | 2013-06-14 | 2017-08-22 | Saint-Gobain Glass France | Spacer for triple-insulated glazing units |

| FR3046415A1 (fr) * | 2015-12-31 | 2017-07-07 | Saint Gobain | Procede et installation de fabrication d'un vitrage isolant |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE29711067U1 (de) * | 1997-06-25 | 1998-11-05 | Krischer Harry | Türblatt |

| AT406076B (de) * | 1997-12-02 | 2000-02-25 | Bug Alutechnic Aktiengesellsch | Profilleiste für abstandhalter für isolierglasscheiben und isolierglasscheibe |

| DE102004054484B4 (de) * | 2004-11-11 | 2010-11-04 | Eckelt Glas Gmbh | Isolier-Scheibenelement |

| DE102007005757B4 (de) * | 2007-02-06 | 2008-10-23 | Saint-Gobain Glass Deutschland Gmbh | Isolierscheibenelement mit einer gewölbten Scheibe |

| EP2172513A1 (fr) | 2008-10-02 | 2010-04-07 | Total Petrochemicals Research Feluy | Procédé pour l'addition de polymères dans des applications de rotomoulage |

-

2013

- 2013-07-23 EP EP13177634.6A patent/EP2829681B1/fr not_active Not-in-force

Also Published As

| Publication number | Publication date |

|---|---|

| EP2829681A1 (fr) | 2015-01-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3908983A1 (de) | Glasbauelement fuer eine ganzglasfassade | |

| EP2403716A1 (fr) | Toit en verre intégral pour un véhicule automobile | |

| DE202011106732U1 (de) | Fenster- oder Türenelement | |

| EP0301166B1 (fr) | Elément de façade vitré | |

| WO2016170079A1 (fr) | Procédé et dispositif de fabrication d'un triple vitrage isolant | |

| EP2666948A1 (fr) | Agencement de cadre pour un panneau de porte sectionnelle | |

| DE102009023883A1 (de) | Fassadenelement | |

| EP2829681B1 (fr) | Vitrage isolant | |

| DE102008021224B4 (de) | Schienenfahrzeug | |

| DE102008030944A1 (de) | Tragendes Bau-Konstruktionselement | |

| EP2803807B1 (fr) | Porte | |

| EP1458947B1 (fr) | Element de liaison pour structure montants-barres horizontales en verre | |

| EP2199511A2 (fr) | Porte coupe-feu | |

| EP3530860B1 (fr) | Élément de verre isolant pour façade en verre et façade en verre | |

| EP1843001B1 (fr) | Poteau en verre pour vitrage structurel | |

| EP1734217A2 (fr) | Elément de fenêtre, de porte ou de façade | |

| CH674541A5 (fr) | ||

| EP3464771B1 (fr) | Vitrage isolant a haute resistance a la rupture et profile de reception en forme de u | |

| EP3208402B1 (fr) | Système avec un élément de façade ou de toit sous forme d'un panneau isolant conçu en forme de sandwich et avec un élément de fenêtre | |

| DE202011109217U1 (de) | Isolierverglasung für Glasfassaden | |

| DE102010015612B4 (de) | Fenstereinheit mit einem Flügelrahmen | |

| EP3168406B1 (fr) | Élément de verre isolant et façade modulaire en verre | |

| EP1593492B1 (fr) | Matériau sandwich-verre | |

| DE102015120886A1 (de) | Vorrichtung zum statisch tragfähigen Verbinden eines als Stabtragwerk ausgeführten Paneels mit einem stoßstellenseitig angeordneten und als Flächentragwerk ausgeführten Paneel | |

| DE102021104503A1 (de) | Befestigungsvorrichtung für Fassadenelemente |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 17P | Request for examination filed |

Effective date: 20130723 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| R17P | Request for examination filed (corrected) |

Effective date: 20150508 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20160411 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 829210 Country of ref document: AT Kind code of ref document: T Effective date: 20161015 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502013004472 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20160914 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161214 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161215 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161214 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170116 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170114 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502013004472 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 |

|

| 26N | No opposition filed |

Effective date: 20170615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20170723 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20180330 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170723 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170723 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170731 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20170731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170723 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20180831 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20180719 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20181012 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20130723 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502013004472 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 829210 Country of ref document: AT Kind code of ref document: T Effective date: 20190723 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160914 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200201 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190723 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190731 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190731 |