EP2821618B1 - Turbocharger turbine rotor and manufacturing method thereof - Google Patents

Turbocharger turbine rotor and manufacturing method thereof Download PDFInfo

- Publication number

- EP2821618B1 EP2821618B1 EP13755039.8A EP13755039A EP2821618B1 EP 2821618 B1 EP2821618 B1 EP 2821618B1 EP 13755039 A EP13755039 A EP 13755039A EP 2821618 B1 EP2821618 B1 EP 2821618B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- turbine wheel

- turbine

- outer diameter

- back face

- filler metal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 8

- 238000005219 brazing Methods 0.000 claims description 66

- 229910052751 metal Inorganic materials 0.000 claims description 53

- 239000002184 metal Substances 0.000 claims description 53

- 239000000945 filler Substances 0.000 claims description 52

- 229910010038 TiAl Inorganic materials 0.000 claims description 26

- 229910000975 Carbon steel Inorganic materials 0.000 claims description 20

- 239000010962 carbon steel Substances 0.000 claims description 20

- 238000002844 melting Methods 0.000 claims description 18

- 230000008018 melting Effects 0.000 claims description 18

- 238000005304 joining Methods 0.000 claims description 4

- PXHVJJICTQNCMI-UHFFFAOYSA-N nickel Substances [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 39

- 230000007423 decrease Effects 0.000 description 28

- 239000000463 material Substances 0.000 description 12

- 230000000694 effects Effects 0.000 description 8

- 229910000831 Steel Inorganic materials 0.000 description 7

- 229910000746 Structural steel Inorganic materials 0.000 description 7

- 239000010959 steel Substances 0.000 description 7

- 229910045601 alloy Inorganic materials 0.000 description 5

- 239000000956 alloy Substances 0.000 description 5

- 238000010586 diagram Methods 0.000 description 4

- 238000009792 diffusion process Methods 0.000 description 4

- 239000012535 impurity Substances 0.000 description 4

- 229910052750 molybdenum Inorganic materials 0.000 description 4

- 229910000669 Chrome steel Inorganic materials 0.000 description 3

- 238000009826 distribution Methods 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 239000011733 molybdenum Substances 0.000 description 3

- 229910052759 nickel Inorganic materials 0.000 description 3

- 150000004767 nitrides Chemical class 0.000 description 3

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 description 2

- 239000000654 additive Substances 0.000 description 2

- 230000000996 additive effect Effects 0.000 description 2

- 238000004364 calculation method Methods 0.000 description 2

- 239000000470 constituent Substances 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 238000001513 hot isostatic pressing Methods 0.000 description 2

- 239000000314 lubricant Substances 0.000 description 2

- 229910052748 manganese Inorganic materials 0.000 description 2

- 239000011572 manganese Substances 0.000 description 2

- 229910000734 martensite Inorganic materials 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 229910000617 Mangalloy Inorganic materials 0.000 description 1

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 1

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 1

- OQPDWFJSZHWILH-UHFFFAOYSA-N [Al].[Al].[Al].[Ti] Chemical compound [Al].[Al].[Al].[Ti] OQPDWFJSZHWILH-UHFFFAOYSA-N 0.000 description 1

- 229910052796 boron Inorganic materials 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 229910052804 chromium Inorganic materials 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 230000006698 induction Effects 0.000 description 1

- 238000005495 investment casting Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 229910052758 niobium Inorganic materials 0.000 description 1

- 229910052763 palladium Inorganic materials 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 238000005245 sintering Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- -1 titan nitride Chemical class 0.000 description 1

- 229910021324 titanium aluminide Inorganic materials 0.000 description 1

- 229910052721 tungsten Inorganic materials 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/02—Blade-carrying members, e.g. rotors

- F01D5/08—Heating, heat-insulating or cooling means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K1/00—Soldering, e.g. brazing, or unsoldering

- B23K1/19—Soldering, e.g. brazing, or unsoldering taking account of the properties of the materials to be soldered

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K1/00—Soldering, e.g. brazing, or unsoldering

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K1/00—Soldering, e.g. brazing, or unsoldering

- B23K1/0008—Soldering, e.g. brazing, or unsoldering specially adapted for particular articles or work

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K1/00—Soldering, e.g. brazing, or unsoldering

- B23K1/0008—Soldering, e.g. brazing, or unsoldering specially adapted for particular articles or work

- B23K1/0018—Brazing of turbine parts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K35/00—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting

- B23K35/001—Interlayers, transition pieces for metallurgical bonding of workpieces

- B23K35/002—Interlayers, transition pieces for metallurgical bonding of workpieces at least one of the workpieces being of light metal

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K35/00—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting

- B23K35/001—Interlayers, transition pieces for metallurgical bonding of workpieces

- B23K35/004—Interlayers, transition pieces for metallurgical bonding of workpieces at least one of the workpieces being of a metal of the iron group

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K35/00—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting

- B23K35/02—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting characterised by mechanical features, e.g. shape

- B23K35/0222—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting characterised by mechanical features, e.g. shape for use in soldering, brazing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K35/00—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting

- B23K35/22—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting characterised by the composition or nature of the material

- B23K35/24—Selection of soldering or welding materials proper

- B23K35/26—Selection of soldering or welding materials proper with the principal constituent melting at less than 400 degrees C

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K35/00—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting

- B23K35/22—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting characterised by the composition or nature of the material

- B23K35/24—Selection of soldering or welding materials proper

- B23K35/30—Selection of soldering or welding materials proper with the principal constituent melting at less than 1550 degrees C

- B23K35/3033—Ni as the principal constituent

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C14/00—Alloys based on titanium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C19/00—Alloys based on nickel or cobalt

- C22C19/03—Alloys based on nickel or cobalt based on nickel

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/04—Ferrous alloys, e.g. steel alloys containing manganese

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/38—Ferrous alloys, e.g. steel alloys containing chromium with more than 1.5% by weight of manganese

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/02—Blade-carrying members, e.g. rotors

- F01D5/026—Shaft to shaft connections

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/12—Both compacting and sintering

- B22F3/14—Both compacting and sintering simultaneously

- B22F3/15—Hot isostatic pressing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2220/00—Application

- F05D2220/40—Application in turbochargers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/20—Manufacture essentially without removing material

- F05D2230/23—Manufacture essentially without removing material by permanently joining parts together

- F05D2230/232—Manufacture essentially without removing material by permanently joining parts together by welding

- F05D2230/237—Brazing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2300/00—Materials; Properties thereof

- F05D2300/10—Metals, alloys or intermetallic compounds

- F05D2300/17—Alloys

- F05D2300/171—Steel alloys

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2300/00—Materials; Properties thereof

- F05D2300/10—Metals, alloys or intermetallic compounds

- F05D2300/17—Alloys

- F05D2300/174—Titanium alloys, e.g. TiAl

Definitions

- This invention relates to a turbine rotor for a supercharger. More specifically, it relates to a turbine rotor for a supercharger including a TiAl turbine wheel and a steel shaft joined to each other by Ni brazing, and a manufacturing method thereof.

- a turbocharger for an automobile has been downsized for the purpose of improving fuel economy. Also, the exhaust gas temperature has been increased for the purpose of improving performance.

- Patent Document 1 JP2000-202683

- Patent Document 2 JPH10-193087

- Patent Document 3 JPH10-118764

- Patent Document 1 discloses a structure in which a turbine wheel of TiAl intermetallic-based alloy and a carbon steel shaft are joined to each other via an intermediate material.

- the turbine wheel is joined to the intermediate material so that the projection-like joint portion of the turbine wheel is fit into the recess-like joint portion of the intermediate material and a brazing filler metal is inserted therein.

- Patent Document 2 also discloses a structure in which a TiAl turbine wheel and a structural or martensite heat-resistant steel rotor shaft are joined to each other by inserting a brazing filler metal (silver brazing, nickel brazing, or copper brazing) between a projection of the TiAl turbine wheel and a recess of the shaft so as to fit the projection into the recess.

- Patent Document 3 discloses a structure in which a TiAl turbine wheel and a structural or martensite heat-resistant steel rotor shaft are joined to each other via a brazing filler metal.

- Patent document 4 relates to a turbocharger that may include a titanium-aluminide turbine and a shaft, which are connected by a single joint, wherein the joint may include an alloy comprising at least 80 atomic percent nickel and palladium and a method of producing said turbocharger.

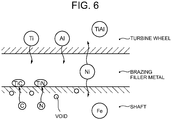

- the gasoline engine of a passenger vehicle may have an exhaust gas temperature that reaches approximately 1,000 °C. Exposing a TiAl turbine rotor to exhaust gas having such high temperature leads to progress of diffusion between the TiAl turbine wheel and the Ni brazing filler metal, or between the Ni brazing filler metal and the carbon steel shaft as shown in FIG. 6 .

- Diffusion herein is referred to as a phenomena in which the Ti component and the Al component of a turbine wheel transfer to a brazing filler metal, the Ni component of the Ni brazing filler metal transfers to a turbine wheel or a shaft, or the C component and the N component of the shaft transfer to the brazing filler metal, so as to average the composition distribution between the materials.

- the Ti having transferred from the turbine wheel then binds to the boundary part between the Ni brazing filler metal and the carbon steel shaft, thereby producing carbide, nitride or carbonitride such as TiC (titan carbide) and TiN (titan nitride).

- carbide, nitride or carbonitride such as TiC (titan carbide) and TiN (titan nitride).

- voids are generated in the place from which the C component and the N component have transferred and moved out.

- Patent Documents 1 to 3 disclose technologies for joining a TiAl turbine wheel to a carbon steel shaft via a brazing filler metal. However, they do not disclose preventing generation of Ti carbide, nitride, carbonitride or voids in the boundary part between the brazing filler metal and the carbon steel shaft to prevent decrease in the joint strength of the brazed part.

- downsizing is an essential component of the technology in view of the need for its mountability to a vehicle. If the brazing position is to be distanced from the turbine wheel for the purpose of preventing the decrease in the strength of the brazed part that could be caused by the thermal effect of the heat transferred to the brazed part from the turbine wheel or the thermal effect due to the exhaust gas leaking from the inlet side of the turbine wheel and flowing into the brazed part, it is necessary to increase the shaft length of the turbine rotor or the diameter of the turbine wheel, which leads to increased size of the turbocharger. Accordingly, downsizing contradicts preventing the decrease in the strength of the brazed part caused by thermal effect. Thus, how to approach the above issues is a significant problem.

- an object of the present invention is, for a turbine rotor where a TiAl turbine wheel and a carbon steel shaft are joined to each other via an Ni brazing filler metal, to dispose the brazing position distanced from the back face of the turbine wheel by a distance of the optimal range so as to retain the reduced size of a turbocharger while preventing the decrease in the strength of the brazed part caused by the exhaust gas temperature.

- a turbine rotor for a supercharger includes a TiAl turbine wheel and a carbon steel shaft joined to each other via an Ni brazing filler metal at a brazed part distanced from a back face of the turbine wheel so that a turbine-wheel outer diameter ratio calculated by "a distance from the back face of the turbine wheel to the brazed part" / "an outer diameter of the turbine wheel” is within a range of from 7 to 10%.

- the distance between the back face of the turbine wheel and the brazed part is set so that the turbine-wheel outer diameter ratio, which is calculated by the expression "a distance from the back face of the turbine wheel to the brazed part” / "an outer diameter of the turbine wheel", is in the range of from 7 to 10%.

- FIG. 3 is a characteristic graph of the temperature ratio relative to the axial positions of the shaft, where y-axis is the temperature ratio to the melting point of the brazing filler metal while x-axis is the ratio of the axial distance of the shaft to the outer diameter of the turbine wheel.

- the temperature decreases as the distance from the turbine wheel to the brazed part increases, thereby preventing the decrease in the joint strength.

- the rotor shaft becomes longer in accordance with the increased distance from the turbine wheel to the brazed part, there is a problem that it may increase the size of the turbocharger.

- the position of the joint part is set in the vicinity of the position just before exceeding the temperature of approximately 60% of the melting point of the brazing filler metal at which decrease in the strength becomes remarkable, i.e., at the position such that the maximum temperature of the position of the brazed part is within the temperature range of from 50 to 60% of the melting point of the Ni brazing filler metal, so that it is possible to prevent the decrease in the strength of the brazed part caused by the exhaust gas temperature while retaining the reduced size of the supercharger without increasing the length of the rotor shaft and changing the position of the bearing.

- the turbine-wheel outer diameter ratio corresponding to the temperature range of from 50 to 60% of the melting point of the Ni brazing filler metal is calculated by the expression "a distance from the back face of the turbine wheel to the brazed part" / "an outer diameter of the turbine wheel”.

- the turbine-wheel outer diameter ratio is optimal to set to substantially 8%, corresponding to the temperature range of from 55 to 60% that is just before exceeding 60% of the melting point of the Ni brazing filler metal.

- the temperature of the inlet side of the turbine wheel is substantially constant due to the exhaust gas temperature.

- the transferred heat that reaches the brazed part decreases in accordance with the size of the outer diameter of the turbine wheel if the outer diameter is large. Accordingly, the outer diameter of the turbine wheel is an important element in evaluating the joint strength of the brazed part.

- the joint position is set based on not only the distance from the back face of the turbine wheel to the brazed part, but on the turbine-wheel outer diameter ratio, which is calculated as a ratio of such distance to the outer diameter of the turbine wheel, thereby increasing reliability of the joint position to be set.

- a back plate may be disposed at a back face side of the turbine wheel along the back face with a gap between the back plate and the back face so as to prevent the exhaust gas that leaks from an inlet toward the back face of the turbine wheel from flowing into the joint part of the Ni brazing filler metal.

- a back plate i.e. a heat shield plate is disposed so as to prevent the leaking flow of the exhaust gas from directly affecting the joint part of brazing.

- a back plate i.e. a heat shield plate is disposed so as to prevent the leaking flow of the exhaust gas from directly affecting the joint part of brazing.

- the leaking flow of the exhaust gas that flows into the joint part is suppressed, which increases the accuracy of the position of the brazed part calculated based on the characteristic graph of FIG. 3 .

- a manufacturing method of manufacturing a turbine rotor for a supercharger where a TiAl turbine wheel and a carbon steel shaft are joined to each other via an Ni brazing filler metal includes the steps of:

- the outer diameter D of the turbine wheel is measured, and then using the measured value, a distance L from the back face of the turbine wheel to the brazed part is set so that the turbine-wheel outer diameter ratio H calculated by the expression "a distance L from the back face of the turbine wheel to the brazed part" / "an outer diameter D of the turbine wheel” is within the range of from 7 to 10%.

- Brazing is performed at the distance L using the Ni brazing filler metal.

- the brazed part based on the position at the distance L, it is possible to set the brazed part at the position such that the bearing span is expanded to the maximum, which makes it possible to prevent shaft vibration, as well as to prevent the supercharger from increasing in size while preventing the decrease in the strength of the brazed part caused by the exhaust gas temperature.

- the distance from the back face of the turbine wheel to the brazed part is set so that the turbine-wheel outer diameter ratio is in the range of from 7 to 10%.

- the outer diameter ratio is calculated by the expression "a distance from the back face of the turbine wheel to the brazed part" / "an outer diameter of the turbine wheel”.

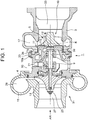

- FIG. 1 is a cross-sectional view of a supercharger 1 along its rotational axis center K.

- the supercharger 1 is for a gasoline engine of a passenger vehicle and includes a turbine housing 3 that houses a turbine wheel 5, a bearing housing 10 that includes a bearing 9 for rotatably supporting a rotor shaft (hereinafter, referred to as shaft) 7, and a compressor housing 15 that houses an impeller 13 of a compressor, arranged adjacent in the direction of the rotational axis center K.

- a scroll 17 is formed into a spiral shape on the outer circumferential part of the turbine housing 3.

- the turbine wheel 5 is disposed on the central part of the spiral shape.

- the turbine wheel 5 and an end of the shaft 7 are joined to each other via a brazing filler metal at the joint part B to be integrated with each other, thereby forming a turbine rotor 19.

- the bearing housing 10 includes a pair of right-and-left bearings 9, 9 that support the shaft 7 rotatably around the rotational axis center K.

- Lubricant oil is supplied to each of the bearings 9, 9 through lubricant oil passages 21.

- the bearing housing 10 and the turbine housing 3 are connected to each other by coupling the protruding flanges 10a, 3a respectively formed on their ends and then fitting a snap ring 23 of an annular shape having a substantially U-shaped cross-section onto the outer circumferences thereof.

- An outer flange part 11a of the outer circumferential part of a back plate 11 described below is interposed to be held in this connection part, so that the back plate 11 is fixed thereto.

- the back plate 11 has a substantially cylindrical shape with a closed bottom, including a bottom part 11b and a cylinder part 11c of a substantially cylindrical shape extending in one direction of the rotational axis center K from the outer circumferential rim of the bottom part. An end portion of the cylindrical part bends at a right angle with respect to the direction of the rotational axis center K so as to form the outer flange part 11a.

- the outer flange part 11a is interposed between the bearing housing 10 and the turbine housing 3 to be positioned and fixed thereto.

- the compressor housing 15 includes an air inlet passage 27, an air passage 29 of a spiral shape, and a diffuser, all of which constitute a centrifugal compressor 31.

- the exhaust gas from the engine enters the scroll 17, and then flows into the turbine blades of the turbine wheel 5 from the scroll 17 through the outer circumferential side of the turbine wheel 5, flowing in the radial direction toward the center. After having performed expansion work on the turbine wheel 5, the exhaust gas flows out in the axial direction to be guided to a gas outlet 33 and discharged outside.

- the turbine wheel 5 and the shaft 7 are joined to each other at the joint part B.

- a seal flange or a metal seal ring disposed on the shaft 7 is provided so as to prevent the exhaust gas from flowing into the bearing 9 side.

- the turbine rotor 19 includes the turbine wheel 5 and the rotor shaft (shaft) 7 as described above.

- the turbine wheel 5 and the shaft 7 are joined to each other by brazing.

- a projection-like joint portion 35 is formed on the rotation center of an end of the turbine wheel 5 while a recess-like joint portion 37 is formed on the shaft 7.

- the projection-like joint portion 35 and the recess-like joint portion 37 are in a fitting state, and the end face of the turbine wheel 5 and the end face of the shaft 7 are joined to each other via an Ni brazing filler metal 39.

- the turbine wheel 5 and the shaft 7 are joined to each other by, for instance, inserting the Ni brazing filler metal 39 between the turbine wheel 5 and the shaft 7, applying pressure in the axial direction to pressurize the Ni brazing filler metal 39, and then covering with a gas of inert atmosphere to heat it by, for instance, high-frequency induction heating.

- the Ni brazing filler metal 39 an Ni brazing filler metal of BNi-1, BNi-2, or the like specified in the JIS (Japanese Industrial Standards) is used.

- the turbine wheel 5 is composed of a TiAl-based alloy.

- the TiAl-based alloy contains Ti as the main constituent element and 28 to 35 wt% of Al, and it may further contain an additive element such as Nb, Cr, Mn, Si, W, C or B.

- HIP Hot-Isostatic-Pressing

- the shaft 7 is composed of a structural steel material.

- the structural steel material contains Fe as the main constituent element, 0.30 to 0.45 wt% of C, 0.85 to 1.25 wt% of Cr, 0.30 to 1.65 wt% of Mn, at most 0.030 wt% of P and at most 0.030 wt% of S.

- the structural steel material may further contain an additive element such as Ni or Mo, or N at a level of unavoidable impurities.

- An avoidable impurity means a substance contained in a slight amount in a structural steel material, because it is present in a raw material or it is unavoidably mixed in during production process.

- a level of unavoidable impurities means an amount in which an unavoidable impurity has little influence on properties of the structural steel material.

- a manganese steel, a manganese-chrome steel, a chrome steel, a chrome-molybdenum steel, a nickel-chrome steel, a nickel-chrome-molybdenum steel, or the like may be used as the structural steel material.

- SCM435 which is a chrome-molybdenum steel containing 0.33 wt% of C and 0.90 wt% of Cr, is used.

- the temperature decreases as the axial position shifts away from the reference position (the position of the back face of the turbine wheel 5) toward the minus side (the left side of FIG. 2 ).

- FIG. 4 illustrates the result of a test on the tensile strength for the brazed part after retaining high temperature for a long period of time, for instance, 800 hours in the turbine rotor 19.

- Y-axis is the brazing strength ratio where the strength at the room temperature (approximately 20°C) is defined as 100, which is the reference value, and x-axis is the temperature ratio to the melting point of the Ni brazing filler metal.

- the joint strength drops suddenly at the temperature ratio to the melting point of the brazing filler metal (also referred to as “melting point ratio”) of 60 to 65%, and then the strength decreases as the temperature increases.

- the joint strength of the brazed part remarkably decreases upon being exposed for a long period of time at a temperature whose melting point ratio is 60% or higher.

- the position of the brazed part is set by using not only the distance from the back face of the turbine wheel 5 as a parameter, but the turbine-wheel outer diameter ratio H, which is a ratio of such distance to the outer diameter D of the turbine wheel 5.

- the outer diameter of the turbine wheel is large, the amount of the leaking exhaust gas that reaches the brazed part decreases in accordance with the increased size of the outer diameter, which lowers the risk of exposing the brazed part to high temperature.

- the size of the outer diameter of the turbine wheel affects greatly the amount of the leaking exhaust gas that arrives at the brazed part.

- the temperature at the inlet side of the turbine wheel is substantially constant due to the exhaust gas temperature.

- the transferred heat reaching the brazed part decreases in accordance with the increased size of the outer diameter of the turbine wheel if the outer diameter is large.

- the outer diameter is an important element in evaluating the joint strength of the brazed part.

- the joint position is set using not only the distance from the back face of the turbine wheel to the brazed part, but the turbine-wheel outer diameter ratio H of the turbine wheel, which is a ratio of such distance to the outer diameter of the turbine wheel.

- the size of the outer diameter of the turbine wheel is reflected in the setting parameters.

- the outer diameter D of the turbine wheel 5 is measured and the distance L from the back face of the turbine wheel 5 to the brazed part is calculated so that the turbine-wheel outer diameter ratio H is in the range of from 7 to 10%, the ratio H being obtained by the expression "a distance L from the back face of the turbine wheel 5 to the brazed part" / "an outer diameter D of the turbine wheel”. Then, brazing work is performed on the TiAl turbine wheel and the carbon steel shaft at the position at the calculated distance L.

- the outer diameter D of the turbine wheel is measured, and using the measured value, the distance L from the back face of the turbine wheel to the brazed part is calculated so that the turbine-wheel outer diameter ratio H is in the range of from 7 to 10%, the ratio H being obtained by the expression "a distance L from the back face of the turbine wheel to the brazed part" / "an outer diameter D of the turbine wheel", and then brazing work is performed using the Ni brazing filler metal at the position of the distance L of the calculated value.

- the bearing span it is possible to be expanded to the maximum based on the position at the distance L to prevent axial vibration.

- FIG. 5B is an illustration of the case where the position of the joint part is unnecessarily distanced from the back face of the turbine wheel 5, while the bearing span S' is set short compared to the conventional bearing span S illustrated in FIG. 5A in order to maintain the reduced size of the supercharger 1.

- the length of the shaft 7 for the turbine rotor 19 is not changed, but the bearing span becomes short, which increases the risk of axial vibration of the shaft 7.

- FIG. 5C is an illustration of the case in which the position of the joint part is unnecessarily distanced from the back face of the turbine wheel 5, while the bearing span S needed for preventing the risk of axial vibration of the shaft 7 is set similarly to the conventional case. As a result, the entire length of the shaft 7 for the turbine rotor 19 becomes longer, which increases the size of the supercharger 1.

- the present invention for a turbine rotor where a TiAl turbine wheel and a carbon steel shaft are joined to each other via an Ni brazing filler metal, it is possible to retain a reduced size of a turbocharger while preventing decrease in the strength of the brazed part caused by the exhaust gas temperature by disposing the brazed part away from the back face of the turbine wheel by an optimum distance.

- the present invention is suitable for use in a turbocharger for an engine of an automobile, a ship, or a plane, or an engine used for a generator, or the like.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- General Engineering & Computer Science (AREA)

- Supercharger (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012044142A JP6021354B2 (ja) | 2012-02-29 | 2012-02-29 | エンジン用過給機 |

| PCT/JP2013/054990 WO2013129410A1 (ja) | 2012-02-29 | 2013-02-26 | 過給機のタービンロータおよびその製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2821618A1 EP2821618A1 (en) | 2015-01-07 |

| EP2821618A4 EP2821618A4 (en) | 2015-12-23 |

| EP2821618B1 true EP2821618B1 (en) | 2019-04-10 |

Family

ID=49082607

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP13755039.8A Active EP2821618B1 (en) | 2012-02-29 | 2013-02-26 | Turbocharger turbine rotor and manufacturing method thereof |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US9556738B2 (enExample) |

| EP (1) | EP2821618B1 (enExample) |

| JP (1) | JP6021354B2 (enExample) |

| CN (1) | CN104136738B (enExample) |

| WO (1) | WO2013129410A1 (enExample) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5916377B2 (ja) * | 2011-12-27 | 2016-05-11 | 三菱重工業株式会社 | 過給機用タービン及び過給機の組立方法 |

| DE102017207173B4 (de) * | 2017-04-28 | 2022-12-22 | Vitesco Technologies GmbH | Turbolader mit Sollbruchstelle für eine Brennkraftmaschine |

| CN107983950B (zh) * | 2017-12-04 | 2019-10-29 | 宁国市华成金研科技有限公司 | 一种高强度增压器涡轮叶轮注射成型的方法 |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0721876Y2 (ja) * | 1986-08-13 | 1995-05-17 | 日本特殊陶業株式会社 | セラミックスラジアルタービン翼車の翼車室 |

| JPH10118764A (ja) | 1996-10-18 | 1998-05-12 | Daido Steel Co Ltd | TiAl製タービン羽根車とローターシャフトとの接合 方法 |

| DE69724730T2 (de) * | 1996-10-18 | 2004-04-01 | Daido Steel Co. Ltd., Nagoya | Turbinenrotor aus Ti-Al und Verfahren zur Herstellung dieses Rotors |

| JPH10193087A (ja) | 1996-12-27 | 1998-07-28 | Daido Steel Co Ltd | TiAl製タービンローターの製造方法 |

| WO1998045081A1 (en) * | 1997-04-04 | 1998-10-15 | Nguyen Dinh Xuan | Friction welding interlayer and method for joining gamma titanium aluminide to steel, and turbocharger components thereof |

| JP3453302B2 (ja) | 1998-05-07 | 2003-10-06 | 三菱重工業株式会社 | TiAl合金部材と構造用鋼材との接合方法及び接合部品 |

| JP3534633B2 (ja) | 1999-01-05 | 2004-06-07 | 三菱重工業株式会社 | 接合部材およびタービン部材 |

| JP2004090130A (ja) | 2002-08-30 | 2004-03-25 | Mitsubishi Heavy Ind Ltd | TiAl基合金と鋼材の接合方法 |

| US7287960B2 (en) * | 2004-07-28 | 2007-10-30 | B{dot over (o)}rgWarner, Inc. | Titanium aluminide wheel and steel shaft connection thereto |

| US7631497B2 (en) * | 2005-04-21 | 2009-12-15 | Borgwarner Inc. | Turbine heat shield with ribs |

| US20070199977A1 (en) * | 2006-02-28 | 2007-08-30 | Michael Pollard | Turbocharger turbine and shaft assembly |

| JP4304190B2 (ja) * | 2006-03-03 | 2009-07-29 | 精密工業株式会社 | タービンホイールとロータシャフトの接合方法 |

| WO2008046556A2 (de) * | 2006-10-13 | 2008-04-24 | Borgwarner Inc. | Turbolader |

| JP2008202544A (ja) * | 2007-02-21 | 2008-09-04 | Mitsubishi Heavy Ind Ltd | ロータの製造方法及びこのロータをそなえた排気ターボ過給機 |

| JP2009203807A (ja) * | 2008-02-26 | 2009-09-10 | Mitsubishi Heavy Ind Ltd | タービンロータ及びロータの製造方法 |

| DE112009001230T5 (de) | 2008-06-19 | 2011-04-28 | Borgwarner Inc., Auburn Hills | Rotorwelle einer Turbomaschine und Verfahren zur Herstellung eines Rotors einer Turbomaschine |

-

2012

- 2012-02-29 JP JP2012044142A patent/JP6021354B2/ja active Active

-

2013

- 2013-02-26 WO PCT/JP2013/054990 patent/WO2013129410A1/ja not_active Ceased

- 2013-02-26 CN CN201380011158.2A patent/CN104136738B/zh active Active

- 2013-02-26 EP EP13755039.8A patent/EP2821618B1/en active Active

- 2013-02-26 US US14/380,952 patent/US9556738B2/en active Active

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| US20150037159A1 (en) | 2015-02-05 |

| JP6021354B2 (ja) | 2016-11-09 |

| EP2821618A1 (en) | 2015-01-07 |

| JP2013181415A (ja) | 2013-09-12 |

| EP2821618A4 (en) | 2015-12-23 |

| WO2013129410A1 (ja) | 2013-09-06 |

| US9556738B2 (en) | 2017-01-31 |

| CN104136738B (zh) | 2017-02-22 |

| CN104136738A (zh) | 2014-11-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9835165B2 (en) | Turbine housing assembly and manufacturing method of turbine housing assembly | |

| US8740561B2 (en) | Jacket impeller with functional graded material and method | |

| US9328738B2 (en) | Turbine scroll part structure | |

| EP2508731A1 (en) | Sheet metal turbine housing | |

| US9708932B2 (en) | Turbine housing assembly | |

| US8491271B2 (en) | Exhaust gas turbo-charger | |

| CN103827463B (zh) | 涡轮增压器以及用于该涡轮增压器的部件 | |

| CN102149837B (zh) | 涡轮增压器及其对应的叶片支承环 | |

| EP2818664A1 (en) | Turbo charger | |

| WO2015097872A1 (ja) | タービンハウジング | |

| US20160130979A1 (en) | Turbine housing for an exhaust gas turbocharger | |

| EP2821618B1 (en) | Turbocharger turbine rotor and manufacturing method thereof | |

| US9039365B2 (en) | Rotor, a steam turbine and a method for producing a rotor | |

| CN103534458A (zh) | 涡轮增压器以及用于该涡轮增压器的部件 | |

| JP2008202544A (ja) | ロータの製造方法及びこのロータをそなえた排気ターボ過給機 | |

| EP2479380A1 (en) | A welded rotor, a steam turbine having a welded rotor and a method for producing a welded rotor | |

| US8944761B2 (en) | Welded rotor, a steam turbine having a welded rotor and a method for producing a welded rotor | |

| EP2230037A1 (en) | Method of manufacture of a dual microstructure impeller | |

| EP2657453B1 (en) | Transition piece for a gas turbine engine | |

| EP2666962A2 (en) | A sectioned rotor, a steam turbine having a sectioned rotor and a method for producing a sectioned rotor | |

| US20130177431A1 (en) | Multi-material rotor, a steam turbine having a multi-material rotor and a method for producing a multi-material rotor | |

| US20130101431A1 (en) | Rotor, a steam turbine and a method for producing a rotor | |

| US9206704B2 (en) | Cast CrMoV steel alloys and the method of formation and use in turbines thereof | |

| EP2479378A1 (en) | A welded rotor, a steam turbine having a welded rotor and a method for producing a welded rotor |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20140821 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| RA4 | Supplementary search report drawn up and despatched (corrected) |

Effective date: 20151124 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F02B 39/00 20060101AFI20151118BHEP Ipc: B23K 1/00 20060101ALI20151118BHEP Ipc: B23K 1/19 20060101ALI20151118BHEP Ipc: C22C 38/38 20060101ALI20151118BHEP Ipc: F01D 5/04 20060101ALI20151118BHEP Ipc: F01D 25/00 20060101ALI20151118BHEP Ipc: B23K 103/24 20060101ALI20151118BHEP Ipc: C22C 14/00 20060101ALI20151118BHEP Ipc: C22C 38/00 20060101ALI20151118BHEP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 602013053718 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: F02B0039000000 Ipc: B22F0003150000 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: C22C 38/18 20060101ALI20180906BHEP Ipc: C22C 38/00 20060101ALI20180906BHEP Ipc: B23K 35/30 20060101ALI20180906BHEP Ipc: C22C 38/04 20060101ALI20180906BHEP Ipc: C22C 14/00 20060101ALI20180906BHEP Ipc: B23K 1/19 20060101ALI20180906BHEP Ipc: B23K 35/26 20060101ALI20180906BHEP Ipc: B23K 1/00 20060101ALI20180906BHEP Ipc: F01D 5/02 20060101ALI20180906BHEP Ipc: B23K 35/02 20060101ALI20180906BHEP Ipc: B23K 35/00 20060101ALI20180906BHEP Ipc: C22C 19/03 20060101ALI20180906BHEP Ipc: C22C 38/38 20060101ALI20180906BHEP Ipc: B22F 3/15 20060101AFI20180906BHEP Ipc: F01D 5/08 20060101ALI20180906BHEP |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: MITSUBISHI HEAVY INDUSTRIES ENGINE & TURBOCHARGER, |

|

| INTG | Intention to grant announced |

Effective date: 20180926 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 1118010 Country of ref document: AT Kind code of ref document: T Effective date: 20190415 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602013053718 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 1118010 Country of ref document: AT Kind code of ref document: T Effective date: 20190410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190710 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190910 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190711 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190710 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190810 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602013053718 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 |

|

| 26N | No opposition filed |

Effective date: 20200113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20200229 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200226 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200229 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200229 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200226 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200229 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20210113 Year of fee payment: 9 Ref country code: NL Payment date: 20210113 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20210217 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190410 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20220301 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20220226 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220301 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220226 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20241231 Year of fee payment: 13 |