EP2703587B1 - Ferrure destinée à être agencée de façon cachée dans la feuillure entre un battant et un cadre de fenêtre, de porte ou analogue - Google Patents

Ferrure destinée à être agencée de façon cachée dans la feuillure entre un battant et un cadre de fenêtre, de porte ou analogue Download PDFInfo

- Publication number

- EP2703587B1 EP2703587B1 EP13004118.9A EP13004118A EP2703587B1 EP 2703587 B1 EP2703587 B1 EP 2703587B1 EP 13004118 A EP13004118 A EP 13004118A EP 2703587 B1 EP2703587 B1 EP 2703587B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- wing

- bearing

- frame

- fitting according

- pivot

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000033001 locomotion Effects 0.000 claims description 14

- 230000004308 accommodation Effects 0.000 claims 1

- 230000015572 biosynthetic process Effects 0.000 claims 1

- 230000008878 coupling Effects 0.000 description 6

- 238000010168 coupling process Methods 0.000 description 6

- 238000005859 coupling reaction Methods 0.000 description 6

- 230000000712 assembly Effects 0.000 description 3

- 238000000429 assembly Methods 0.000 description 3

- 230000001747 exhibiting effect Effects 0.000 description 3

- 238000003780 insertion Methods 0.000 description 3

- 230000037431 insertion Effects 0.000 description 3

- 230000005540 biological transmission Effects 0.000 description 2

- 230000001154 acute effect Effects 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 230000008092 positive effect Effects 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05D—HINGES OR SUSPENSION DEVICES FOR DOORS, WINDOWS OR WINGS

- E05D7/00—Hinges or pivots of special construction

- E05D7/04—Hinges adjustable relative to the wing or the frame

- E05D7/0415—Hinges adjustable relative to the wing or the frame with adjusting drive means

- E05D7/0423—Screw-and-nut mechanisms

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05D—HINGES OR SUSPENSION DEVICES FOR DOORS, WINDOWS OR WINGS

- E05D15/00—Suspension arrangements for wings

- E05D15/28—Suspension arrangements for wings supported on arms movable in horizontal plane

- E05D15/30—Suspension arrangements for wings supported on arms movable in horizontal plane with pivoted arms and sliding guides

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2600/00—Mounting or coupling arrangements for elements provided for in this subclass

- E05Y2600/40—Mounting location; Visibility of the elements

- E05Y2600/41—Concealed

- E05Y2600/412—Concealed in the rabbet

Definitions

- the invention relates to a fitting for concealed arrangement in the fold between a wing and a frame of a window, a door or the like, with a frame side to be fastened bearing strip of a compassionecklagers, a wing side to be attached rempligelecklager and a wing pivot bearing, wherein a copetragarm is articulated on the bearing strip and wherein a coupled to the bearing strip and the rempligeltragarm Ausstell listening is provided by means of the wing pivot bearing is pivoted when pivoting the wing relative to the bearing strip.

- the present invention is directed to such concealed fittings in which the wing pivot bearing is exposed during pivoting of the wing, that is, pivoted away from the frame. This raising or Ausschwenkamba is usually required to allow pivoting of the wing relative to the frame at all.

- the EP 2 407 621 A2 discloses a concealed pivot fitting. This has a frame-side fitting part and a wing-side fitting part. Both fitting parts are connected to each other via two crossed and articulated joint levers. The articulated levers cause the rotational movement to be superimposed with a translational movement when the window is opened. As a result, the wing is swung out of the frame. However, opening angles significantly above 90 ° are not possible.

- the EP 2 444 578 A2 discloses a concealed fitting, which can also allow larger opening angle. To make this possible, however, a rather complicated belt or gear transmission is integrated into the fitting.

- a fitting for tilting, swing-wing windows and doors which is arranged concealed in the fold between the sash and the frame, wherein the fitting is designed as Ausstellschere with a support arm and a control arm.

- Ausstellschere By a toothing on the opposite ends of the wing of the support arm and the control arm an additional exhibition of the wing is effected when swinging.

- the mechanics of the Ausstellschere is relatively expensive and there are no much larger opening angle than 90 °.

- Object of the present invention is therefore to provide a fitting of the type mentioned, with which it is possible to swing the wing relative to the frame more than 90 ° and preferably up to 180 °, the fitting at the same time as simple as possible Mechanics has.

- the sprocket section makes it possible to act with a corresponding counter element on the sprocket section, which allows direct operation of the control lever.

- linkages of the control lever to other elements of the fitting which are necessary in conventional fittings for actuating the control lever omitted.

- pivoting of the wing ultimately leads to pivoting out of the wing pivot bearing.

- the gear is ultimately coupled to the wing pivot bearing and meshes with the rotation of the sprocket portion of the control lever.

- the control lever is set to the outside, which in turn leads to an adjustment of the viageltragarms.

- the wing pivot bearing is ultimately provided on the wing support arm, the swinging out of viageltragarms leads to swinging out of the wing pivot bearing. It is readily possible with appropriate design of the sprocket portion and thus meshing gear that pivoting of the wing relative to the bearing band over 90 °, preferably over 110 ° and in particular up to 180 ° is possible.

- the invention thus offers the same Advantages as with external fittings, so a maximum swinging of the wing up to 180 °, which at the same time the maximum swinging results in the positive effect that the fold of the wing is swung out of the opening area of the frame, so a complete view through the frame opening possible is.

- the fitting and in particular the Ausstell Tavern Marie is designed such that the pivot angle between the bearing strip and the wellgeltragarm when swiveling the wing over 90 ° beyond at least up to 135 ° remains unchanged or increases.

- the distance between the wing pivot bearing and the frame or the bearing strip when pivoting the wing beyond 90 ° is either increased to at least 135 ° or remains unchanged.

- the invention initially provides that the fitting according to the invention makes it possible to pivot the wing up to at least 135 °. It is the case that the wing pivot bearing is turned off by a certain amount from the frame when the wing is pivoted 90 °. If the wing is then swung further, for example, from 90 ° to 110 °, the distance between the pivot bearing and the bearing strip or frame remains the same or it increases. This condition occurs in any case until the wing is pivoted to 135 °. This angle when swinging the wing is referred to as a critical angle, since the distance of the rollover of the wing to the frame here is the lowest.

- the maximum swing angle or the distance of the wing pivot bearing to the frame should be selected at a pivoting position of the wing of 135 ° so that a minimal distance between the flap of the wing and the frame is created.

- the ratio of the pivoting angle during pivoting of the wing from 0 ° to 90 ° to the pivoting angle during pivoting of the wing from 91 ° to 180 ° from 2 to 4 to 0.5 to 1.5, preferably from 2 , 5 to 3.5 to 0.75 to 1.25 and in particular at least substantially 3 to 1.

- each individual ratio value is possible in principle. In exceptional cases, it is even possible that, as previously mentioned, for example, after reaching the 90 ° position, no further exhibiting the wing pivot bearing takes place.

- control lever and the gear are designed and / or arranged such that there is a reduction of the pivotal movement of the wing to the pivot angle between the bearing strip and the wellgeltragarm.

- the reduction means that, for example, when the wing swings up by 90 °, a pivoting angle between the bearing strip and the wing support arm between 15 ° and 25 °, preferably between 17 ° and 22 ° and preferably at least substantially 19 °. Alternatively it can be turned off on the distance of the wing pivot bearing to the central axis of the bearing strip.

- the reduction is also designed such that in a further pivoting from 90 ° to the 180 ° position, a pivot angle between 18 ° and 30 °, preferably 21 ° to 27 ° and in particular of at least substantially 24 ° is provided.

- a pivot angle between 18 ° and 30 °, preferably 21 ° to 27 ° and in particular of at least substantially 24 ° is provided.

- this is between 20 and 40 mm, preferably between 28 and 36 mm and in particular at least substantially at 32 mm.

- the gear is connected to the wing pivot bearing such that a pivoting of the wing acts directly on the gear, so complementary transmission elements are not provided.

- the gear in this embodiment will be directly part of the wing pivot bearing.

- control lever is hinged on the one hand on the bearing tape and slidably mounted in a backdrop on a sliding block and on the other hand articulated on copetragarm.

- the control lever could be stored on such a translational joint.

- recesses are provided on the wing support arm, on the bearing strip and / or on the control lever to form a free space for receiving a marginal rollover of the wing.

- the winged corner bearing is only connected to the wing support arm in the region of the wing pivot bearing. So there is only one connection point provided.

- the copegelecklager is pre-assembled on the wing, while the copegeltragarm is part of the assembly of the compassionecklagers, which is pre-assembled on the frame. Since only one connection point is provided, the insertion and removal of the wing can be realized very quickly and easily.

- adjustment means for height adjustment, side adjustment and / or Anyakver ein are provided on rempligelecklager and / or on compassionecklager.

- an adjusting screw for height adjustment provided on the lower rempligelecklagerabites be, which acts on a bearing bush of the wing pivot bearing.

- a Anyakver ein done when another set screw from the front or rear of the bearing bush acts and this moves with appropriate setting.

- an adjustment, in particular a lateral adjustment can be made via the bearing strip.

- an adjustable slide connected to the bearing pin of the rempligeltragarms can be provided on the bearing strip, the adjustment leads, for example via an adjusting screw to an adjustment of the bearing pin.

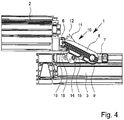

- Fig. 1 is a fitting 1 for concealed arrangement in the fold between a wing 2, in the Fig. 2 to 4 is shown only by an arrow, and shown a frame 3 of a window or a door.

- the fitting 1 has a frame corner bearing 4 and a winged corner bearing 5 as assemblies.

- the fitting has a wing pivot bearing 6, via which the wing 2 can be pivoted relative to the frame 3.

- a bearing strip 7 For mounting the compassionecklagers 4 on the frame is a bearing strip 7.

- the assembly of the compassionecklagers 4 next to the bearing strip 7 a copetragarm 8, which is connected via a hinge 9 with the bearing belt 7 pivotally or hingedly.

- the frame corner bearing 4 has a connected to the bearing strip 7 and the viageltragarm 8 Ausstellmati issued 16, by means of which the wing pivot bearing 6 and thus the wing 2 is pivoted during pivoting of the wing 2 relative to the bearing belt 7.

- the Ausstellattitician 10 has a control lever 11 with a swinging out when swinging the wing 2 arcuate sprocket section 12 and a gear 13 which is rotatably mounted on copegeltragarm 8 and meshes with the sprocket section 12.

- the gear 12 is positively connected to the wellgelecklager 5, so that the pivoting of the wing 2 leads to a rotation of the gear 12, which acts on the sprocket portion 12 on the control lever 11 so that it in turn acts on the copetragarm 8 and thus exhibiting the wing pivot bearing 6 results.

- a bearing strip 7 For mounting the compassionecklagers 4 on the frame 3 is a bearing strip 7.

- the assembly of the compassionecklagers 4 next to the bearing strip 7 a copetragarm 8, which is pivotally connected via a hinge 9 with the bearing strip 7.

- theticianecklager 4 has a coupled to the bearing tape 7 and the pogeltragarm 8 Ausstellrien heard 10, by means of which the wing pivot bearing 6 is swung when pivoting the wing 2 relative to the bearing belt 7.

- the fitting 1 is formed such that the pivot angle ⁇ between the bearing strip 7 and its longitudinal axis L and the diegeltragarm 8 and whose longitudinal axis M remains unchanged when swinging the wing 2 over 90 ° to a wing angle of at least 135 ° or increases.

- the pivot angle ⁇ corresponds to the distance a of the pivot axis of the wing pivot bearing 6, so that the distance a when pivoting the wing over 90 ° out to a wing angle of at least 135 ° either increased or unchanged.

- the Ausstell Tavern worn 10 is formed such that the ratio ⁇ 1 / ⁇ 2 of the pivot angle ⁇ 1 when swinging the wing 2 from 0 ° to 90 ° to the pivot angle ⁇ 2 when swinging the wing 2 of 91 ° to 180th ° is from 2 to 4 to 0.5 to 1.5, preferably from 2.5 to 3.5 to 0.75 to 1.25 and in particular at least substantially 3 to 1. It is understood that in principle every single ratio ⁇ 1 / ⁇ 2 within the specified limits is possible, so for example, a ratio ⁇ 1 / ⁇ 2 of 4 to 0.5 or from 2 to 1.5.

- the fitting 1 and the dispensing device 10 is formed such that a pivoting of the wing 2 relative to the bearing belt 7 to 180 ° is possible.

- the swinging to 180 ° is considered to be the end position very favorable.

- the gear 13 is connected to the wing pivot bearing 6 and the diegelecklager 5, that a pivoting of the wing 2 acts directly on the gear 13. This is produced in the result by the direct coupling or the positive connection of the winged corner bearing 5 with the gear 13.

- the control lever 11 itself is displaceably mounted, on the one hand, on the bearing band 7 via a joint 14 and, moreover, in a link 15 via a sliding block 16.

- the link 15 stands at an acute angle to the longitudinal axis L of the bearing strip 7 in order to ensure a certain predetermined oblique displacement track of the control lever 11.

- the angle of the link 15 to the longitudinal axis L is between 1 ° to 10 °.

- the control lever 11 is connected to the wellgeltragarm 8 via a hinge 17.

- Fig. 4 and 7 shows, 11 recesses for forming a clearance 18 for receiving a marginal rollover 19 of the wing 2 are provided on pogeltragarm 8, the bearing strip 7 and the control lever.

- the space 18 can constructively realize that in the maximum pivoted position, such as in Fig. 4 is shown, the necessary space for the rollover 19 is located and then a corresponding removal of material to the components provided there, namely the bearing belt 7 and / or the control lever 11 and / or the wellgeltragarm 8 is made.

- the optimum pivot angle ⁇ or distance a of the wing pivot bearing 6 to the frame 3 can be determined when the wing 2 is at a wing angle of 135 ° and the distance of the rollover 22 to the frame 2 is just such that the rollover 19 when swinging the wing 2 does not hit the frame 3.

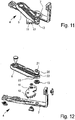

- the fitting 1 consists of the two assemblies of the strictlyecklagers 4 and the diegelecklagers 5.

- a coupling piece 20 which has an engagement opening 21 at its upper end.

- the coupling piece Towards the bottom, the coupling piece has a pin 22, with which the gear 13 is firmly connected.

- the coupling piece 20 is mounted in a joint receptacle 23 on the diegeltragarm 8 and forms together with the joint receptacle 23 the relevant part of the wing pivot bearing 6.

- In the engagement opening 21 engages a corresponding tongue 24 of the copegelecklagers 5 a. The joining of the two modules is thus carried out in the area of the wing pivot bearing 6 at only a single point.

- 5 adjusting means for height adjustment, lateral adjustment and / or Anyakver ein can basically be provided on the compassionecklager 4 and / or on the pogelecklager. Specifically, it is in the illustrated embodiment so that all adjustment options are integrated in the wellgelecklager 5.

- the pin 24 has a slot 26 through which a screw 27 engages and the pin 24 attached to the main body 25.

- the lateral adjustment via the screw 27, the lateral adjustment.

- the Anyakver ein via a set screw 28, which brings the tongue 24 to commute.

- the wing 2 is turned off the frame 3. This results in the pivoting of the wing 2 in the 90 ° position, a stronger parking, while the further pivoting of the wing 2 leads to the 180 ° position only to a lower exhibiting the wing pivot bearing 6.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Hinges (AREA)

- Harvester Elements (AREA)

Claims (12)

- Ferrure (1) destinée à être agencée de façon cachée dans la feuillure entre un battant (2) et un cadre (3) de fenêtre, de porte ou analogue, avec une bande de palier (7), à fixer côté cadre, d'un palier d'angle de cadre (4), un palier d'angle de battant (5) à fixer côté battant, et un palier pivotant de battant (6), un bras support de battant (8) étant supporté de façon articulée sur la bande de palier (7), et un équipement de commande de réglage (10) couplé à la bande de palier (7) et au bras support de battant (8) étant prévu, au moyen duquel le palier pivotant de battant (6) peut être basculé par pivotement lors du pivotement du battant (2) par rapport à la bande de palier (7),

caractérisée en ce que

l'équipement de commande de réglage (10) présente un levier de commande (11) avec un tronçon de couronne dentée (12), et une roue dentée (13), engrenant avec le tronçon de couronne dentée (12), qui est supportée de façon mobile en rotation sur le bras support de battant (8), le levier de commande (11) étant d'une part supporté de façon articulée sur la bande de palier (7) et de façon coulissante dans une coulisse (15) sur un coulisseau (16) et étant d'autre part supporté de façon articulée sur le bras support de battant (8), et la roue dentée (13) étant raccordée par liaison de forme au palier d'angle de battant (5) de telle sorte que, lors du pivotement du battant (2), la roue dentée (13) agit sur le levier de commande (11) par le biais du tronçon de couronne dentée (12) de telle sorte que ce levier agit à son tour sur le bras support de battant (8) et qu'il en résulte ainsi un réglage du palier pivotant de battant (6). - Ferrure selon la revendication 1, caractérisée en ce que le tronçon de couronne dentée (12) et la roue dentée (13) qui engrène avec lui sont constitués de telle sorte qu'un pivotement du battant (2) par rapport à la bande de palier (7) est possible jusqu'à 160°, de préférence jusqu'à 180°.

- Ferrure selon la revendication 1, caractérisée en ce que l'équipement de commande de réglage (10) est constitué de telle sorte que l'angle de pivotement (α) entre la bande de palier (7) et le bras support de battant (8) lors du pivotement du battant au-delà de 90° demeure inchangé jusqu'à au moins 135° ou augmente.

- Ferrure selon la revendication 1, caractérisée en ce que la géométrie de denture du tronçon de couronne dentée (12) d'une part et de la roue dentée (13) d'autre part est constituée de telle sorte que le rapport (α1/α2) de l'ange de pivotement (α1)n lors du pivotement du battant de 0° à 90°, à l'ange de pivotement (α2) de 91° à 180° est de 2 - 4 : 0,5 - 1,5, de préférence égal à 2,5 - 3,5 : 0,75 - 1,25, et en particulier au moins essentiellement de 3 : 1.

- Ferrure selon l'une des revendications précédentes, caractérisée en ce que le levier de commande (11) et la roue dentée (13) sont constitués et/ou agencés de telle sorte qu'il en résulte une démultiplication du mouvement de pivotement du battant (2) par rapport à l'angle de pivotement (α) entre la bande de palier (7) et le bras support de battant (8).

- Ferrure selon l'une des revendications précédentes, caractérisée en ce que la roue dentée (13) est raccordée au palier pivotant de battant (6) de telle sorte qu'un pivotement du battant (2) agit directement sur la roue dentée (13).

- Ferrure selon l'une des revendications précédentes, caractérisée en ce que, sur le bras support de battant (8), sur la bande de palier (7) et/ou sur le levier de commande (11), il est prévu des évidements pour la formation d'un espace libre (18) destiné à recevoir un recouvrement (19), côté bord, du battant (2).

- Ferrure selon l'une des revendications précédentes, caractérisée en ce que le palier d'angle de cadre (4) et le palier d'angle de battant (5) ne sont raccordés l'un à l'autre qu'à un emplacement de raccordement dans la zone du palier pivotant de battant (6).

- Ferrure selon l'une des revendications précédentes, caractérisée en ce que, sur le palier d'angle de cadre (4) et/ou le palier d'angle de battant (5), il est prévu des moyens d'ajustement pour le réglage en hauteur, le réglage latéral et/ou le réglage de pression.

- Ferrure selon l'une des revendications précédentes, caractérisée en ce que la ferrure (1) est constituée de telle sorte que le tronçon de couronne dentée (12) est basculé par pivotement lors du pivotement du battant (2).

- Ferrure selon l'une des revendications précédentes, caractérisée en ce que le palier d'angle de cadre (4) et le palier d'angle de battant (5) ne sont raccordés que par une languette (24) s'engageant dans une ouverture d'engagement (21).

- Ferrure selon la revendication 11 en liaison avec la revendication 9, caractérisée en ce que le réglage en hauteur, le réglage latéral et/ou le réglage de pression s'effectuent par le biais de la languette (24).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL13004118T PL2703587T3 (pl) | 2012-08-28 | 2013-08-20 | Okucie do krytego rozmieszczania we wręgu pomiędzy skrzydłem oraz ramą okna, drzwi lub tym podobnych |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102012017034.3A DE102012017034B3 (de) | 2012-08-28 | 2012-08-28 | Beschlag zur verdeckten Anordnung im Falz zwischen einem Flügel und einem Rahmen eines Fensters, einer Tür oder dergleichen |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2703587A2 EP2703587A2 (fr) | 2014-03-05 |

| EP2703587A3 EP2703587A3 (fr) | 2014-12-10 |

| EP2703587B1 true EP2703587B1 (fr) | 2017-06-21 |

Family

ID=49084715

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP13004118.9A Active EP2703587B1 (fr) | 2012-08-28 | 2013-08-20 | Ferrure destinée à être agencée de façon cachée dans la feuillure entre un battant et un cadre de fenêtre, de porte ou analogue |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP2703587B1 (fr) |

| DE (1) | DE102012017034B3 (fr) |

| ES (1) | ES2639946T3 (fr) |

| PL (1) | PL2703587T3 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4411095A1 (fr) | 2023-02-02 | 2024-08-07 | Gretsch-Unitas GmbH Baubeschläge | Ensemble ferrure et ensemble porte ou fenêtre pour un tel ensemble ferrure |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2016135579A1 (fr) * | 2015-02-24 | 2016-09-01 | Gsg International S.P.A. | Dispositif de fixation d'accessoires sur des portes ou des fenêtres |

| ITUB20152220A1 (it) | 2015-07-15 | 2017-01-15 | Fapim S P A | Cerniera a scomparsa |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE58905179D1 (de) * | 1989-09-20 | 1993-09-09 | Mila Beslag As | Verdeckt im falz angeordnete ausstellvorrichtung fuer kipp-schwenk-fluegel von fenstern oder tueren. |

| DE4129833C2 (de) * | 1991-09-05 | 2000-07-06 | Mila Hardware Ltd | Beschlag für Kipp- und Schwenkflügelfenster |

| DE202010010233U1 (de) * | 2010-07-14 | 2011-11-14 | MACO Vermögensverwaltung GmbH | Beschlagvorrichtung |

| DE202010014477U1 (de) * | 2010-10-19 | 2012-01-20 | Maco Technologie Gmbh | Beschlaganordnung |

-

2012

- 2012-08-28 DE DE102012017034.3A patent/DE102012017034B3/de not_active Expired - Fee Related

-

2013

- 2013-08-20 PL PL13004118T patent/PL2703587T3/pl unknown

- 2013-08-20 ES ES13004118.9T patent/ES2639946T3/es active Active

- 2013-08-20 EP EP13004118.9A patent/EP2703587B1/fr active Active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4411095A1 (fr) | 2023-02-02 | 2024-08-07 | Gretsch-Unitas GmbH Baubeschläge | Ensemble ferrure et ensemble porte ou fenêtre pour un tel ensemble ferrure |

Also Published As

| Publication number | Publication date |

|---|---|

| ES2639946T3 (es) | 2017-10-30 |

| PL2703587T3 (pl) | 2017-11-30 |

| EP2703587A2 (fr) | 2014-03-05 |

| DE102012017034B3 (de) | 2014-01-09 |

| EP2703587A3 (fr) | 2014-12-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102011000150B3 (de) | Türband für eine verdeckte Anordnung zwischen Türrahmen und Türflügel | |

| EP1836367B1 (fr) | Fenetre oscillobattante entrainee par un moteur electrique et dotee d'une chaine de poussee | |

| DE20023445U1 (de) | Verstecktes Scharnier | |

| EP2130997B1 (fr) | Porte avec charnière | |

| EP2703587B1 (fr) | Ferrure destinée à être agencée de façon cachée dans la feuillure entre un battant et un cadre de fenêtre, de porte ou analogue | |

| EP2754813B1 (fr) | Charnière, notamment pour portes et fenêtres en plastique | |

| EP2708692B1 (fr) | Ferrure destinée à être agencée de façon cachée dans la feuillure entre un battant et un cadre de fenêtre, de porte ou analogue | |

| EP1580381B1 (fr) | Ferrure de crémone | |

| DE202012008225U1 (de) | Beschlag zur verdeckten Anordnung im Falz zwischen einem Flügel und einem Rahmen eines Fensters, einer Tür oder dergleichen | |

| EP2136022A2 (fr) | Agencement d'entraînement pour un battant pivotant | |

| EP2009215A1 (fr) | Dispositif de détection pour un dispositiv d'entraînement des portes ou fenêtres | |

| EP0440937B1 (fr) | Dispositif pour l'ouverture et la fermeture motorisée de fenêtres, portes ou similaires | |

| DE102008028598B4 (de) | Insektenschutztür | |

| DE202007011982U1 (de) | Verstellbares Band | |

| EP2615232B1 (fr) | Ferrure de palier d'angle | |

| DE202005009745U1 (de) | Beschlaganordnung | |

| EP3516143B1 (fr) | Système de ferrure | |

| EP3279418B1 (fr) | Élément de ferrure d'une ferrure et procédé de montage d'un tel élément de ferrure | |

| DE102012017038B4 (de) | Beschlag zur verdeckten Anordnung im Falz zwischen einem Flügel und einem Rahmen eines Fensters, einer Tür oder dergleichen | |

| EP1780362B1 (fr) | Entraînement pour vantaux pivotants | |

| EP2802723A1 (fr) | Charnière pour arrangement caché entre battant et cadre | |

| DE3425810C2 (fr) | ||

| DE202012008227U1 (de) | Beschlag zur verdeckten Anordnung im Falz zwischen einem Flügel und einem Rahmen eines Fensters, einer Tür oder dergleichen | |

| DE102012017037B4 (de) | Beschlag zur verdeckten Anordnung im Falz zwischen einem Flügel und einem Rahmen eines Fensters, einer Tür oder dergleichen | |

| EP2374973A1 (fr) | Bande pour portes, fenêtres ou analogues |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E05D 15/30 20060101ALI20141106BHEP Ipc: E05D 7/04 20060101AFI20141106BHEP |

|

| 17P | Request for examination filed |

Effective date: 20150601 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| 17Q | First examination report despatched |

Effective date: 20160429 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20170220 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 903097 Country of ref document: AT Kind code of ref document: T Effective date: 20170715 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502013007525 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 5 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2639946 Country of ref document: ES Kind code of ref document: T3 Effective date: 20171030 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170922 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170921 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170921 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171021 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502013007525 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| 26N | No opposition filed |

Effective date: 20180322 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170820 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170820 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20130820 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20230821 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20230817 Year of fee payment: 11 Ref country code: IT Payment date: 20230825 Year of fee payment: 11 Ref country code: GB Payment date: 20230822 Year of fee payment: 11 Ref country code: CH Payment date: 20230902 Year of fee payment: 11 Ref country code: AT Payment date: 20230822 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20230814 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20231027 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240814 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20240821 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20240829 Year of fee payment: 12 |