EP2655840B1 - Piston pour moteur à combustion interne - Google Patents

Piston pour moteur à combustion interne Download PDFInfo

- Publication number

- EP2655840B1 EP2655840B1 EP11833595.9A EP11833595A EP2655840B1 EP 2655840 B1 EP2655840 B1 EP 2655840B1 EP 11833595 A EP11833595 A EP 11833595A EP 2655840 B1 EP2655840 B1 EP 2655840B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- piston

- piston component

- closing element

- component

- circumferential

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F3/00—Pistons

- F02F3/16—Pistons having cooling means

- F02F3/20—Pistons having cooling means the means being a fluid flowing through or along piston

- F02F3/22—Pistons having cooling means the means being a fluid flowing through or along piston the fluid being liquid

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F3/00—Pistons

- F02F3/0015—Multi-part pistons

- F02F3/003—Multi-part pistons the parts being connected by casting, brazing, welding or clamping

Definitions

- the present invention relates to a piston for an internal combustion engine having a first piston component and a second piston component, wherein the first piston component and the second piston component form an open to the second piston component, circumferential cooling channel, which is closed by means of a peripheral closure element.

- Pistons with such a cooling channel are known per se.

- the cooling channel of such a piston is closed by means of a circumferential, two-part sheet metal ring.

- the disadvantage of this arrangement is that two loosely additional components for the preparation of the cooling channel are required.

- WO 2007/093289 A1 discloses a piston for an internal combustion engine with a piston ring part, which forms an outer circumferential cooling channel with a piston main body and is welded or soldered thereto.

- the document DE 10 2004 057 624 A1 discloses a piston for an internal combustion engine, with a downwardly-opening circumferential cooling channel, which is closed by a separate, designed as a ring cooling channel cover.

- the object of the present invention is therefore to design a piston with such a cooling channel so that its production is simplified.

- the solution consists in that the closure element is integrally connected to the first piston component and extends radially in the direction of the second piston component, that the second piston component has a radially extending in the direction of the first piston component, integrally formed, circumferential support flange that the closure element below Pretension rests on the support flange or that the closure element with a circumferential lower edge supported on an end face of the support flange under bias, that the first piston member has a wall portion of a combustion bowl and the second piston member has a bottom portion of a combustion bowl, that the first piston member and the second piston member are connected to each other by means of a Reibsch rawvons, wherein a joining seam in the region of the combustion bowl is arranged.

- the closure element is designed as a one-piece structural element of the first piston component and the support flange as an integral structural element with the second piston component.

- the closure element is biased on the support flange to seal the cooling channel particularly reliable, so that a joining method for connecting the closure element and support flange is not necessary.

- the first and the second piston component according to the invention are connected to one another by means of a friction welding process.

- the resulting joint seam is arranged in the region of a combustion bowl. This makes it possible to provide a particular thermally reinforced piston crown or trough edge, depending on the material only of the first closure element. It follows that the first piston component has a wall region of the combustion bowl, while the second piston component has a bottom region of the combustion bowl.

- the radial width of the closure element and the support flange can be sized equal or different sizes.

- the radial width of the support flange can be greater than the radial width of the closure element.

- the end face of the support flange is arranged inclined in the direction of the closure element in order to optimize the sealing of the cooling channel.

- the closure element and the support flange can also be connected to each other by means of a joining process, for example. Welding or soldering.

- At least one coolant inlet opening and at least one coolant outlet opening are expediently provided in the closure element and / or in the support flange.

- the first piston component is a piston ring element which has at least a part of a piston crown, a circumferential crown land and a circumferential annular band provided with annular grooves.

- the closure element is connected to the first piston component in the region of a lower free end of the annular band.

- the second piston component is preferably designed as a piston main body, particularly preferably for a box piston, which has at least one piston shaft with piston hubs which are provided with hub bores.

- the piston skirt is thermally decoupled from the ring band.

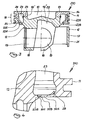

- FIG. 1 shows a first embodiment of a piston 10 according to the invention.

- the piston 10 consists of a first piston member 11 and a second piston member 12.

- the first piston member 11 is formed as a piston ring member and the second piston member 12 as a piston body for a box piston.

- Other divisions are also conceivable as long as the ring band 15 (see below) at least in the region of its free end 24 (see below) is formed by the first piston member 11. Both components can be made of any suitable metallic material.

- the first piston component 11 has a piston bottom 13 and a circumferential top land 14 and a circumferential annular band 15 with annular grooves for receiving piston rings (not shown).

- the first piston component 11 also forms a wall region 16 'of a combustion bowl 16.

- the second piston member 12 forms in the present embodiment, a thermally decoupled from the annular band 15 piston skirt 17, which is provided in a conventional manner with hubs 18 and hub bores 19 for receiving a piston pin (not shown).

- the hubs 18 are connected to each other via running surfaces 21.

- the second piston component 12 also forms a bottom region 16 "of the combustion bowl 16.

- the hubs 18 are connected via hub connections 22 on the underside of the combustion bowl 16.

- the first piston component 11 and the second piston component 12 are connected to one another via a joining seam 27, in the exemplary embodiment by means of friction welding.

- the annular band 15 has a closure element 25 at its free lower end 24.

- the closure element 25 extends radially in the direction of the second piston component 12 and, in the exemplary embodiment, is connected in one piece with the free end 24 of the annular band 15 of the first piston component 11.

- the second piston component 12 has, in the exemplary embodiment approximately at the level of the hub connections 22, a circumferential bearing flange 26, which is integral with the second piston component 12.

- the closure element 25 and the support flange 26 are dimensioned such that after the joining of the first piston component 11 and the second piston component 12, the closure element 25 rests on the support flange 26.

- the closure element 25 can in this case rest tension-free or under pretension on the support flange 26. In the latter case, a particularly reliable sealing of the cooling channel 23 is given.

- the closure element 25 and the support flange 26 may also be joined together by joining, for example. Welding or soldering.

- the radial width of the closure member 25 is sized larger than the radial width of the support flange 26 and extends in this particular case almost over the entire cross section of the cooling channel 23. Therefore, the openings 28 for the access and the flow of the coolant in the closure element 25th brought in.

- FIG. 2 shows a further embodiment of a piston 110 according to the invention.

- the piston 110 largely corresponds to the piston 10 according to FIG. 1 , so that the same reference numerals are provided for the same structural elements and in this regard to the description FIG. 1 is referenced.

- the main difference to that in FIG. 1 illustrated embodiment is that the radial width of the closure member 125 dimensioned smaller than the radial width of the support flange 126.

- the support flange 126 extends almost over the entire cross section of the cooling channel 23. Therefore, the openings 28 for the access or the Drain the coolant introduced in the support flange 126.

- FIG. 3 shows a further embodiment of a piston 210 according to the invention.

- the piston 210 largely corresponds to the piston 10 according to FIG. 1 , so that the same reference numerals are provided for the same structural elements and in this regard to the description FIG. 1 is referenced.

- the main difference to that in FIG. 1 illustrated embodiment is that the radial width of the closure element 225 in about the radial Width of the support flange 226 corresponds. Therefore, the openings 28 for the access and the discharge of the coolant are introduced both in the closure element 225 and in the support flange 226.

- FIG. 4 shows a detailed view of another embodiment of a piston 310 according to the invention.

- the piston 310 largely corresponds to the piston 10 according to FIG. 1 , so that the same reference numerals are provided for the same structural elements and in this regard to the description FIG. 1 is referenced.

- closure member 325 has a circumferential lower edge 329 and the support flange 326 has an end face 331.

- the end face 331 of the support flange 326 is arranged inclined in the direction of the closure element 325.

- the circumferential lower edge 329 of the closure element 325 is supported, possibly under prestress, on the end face 331 of the support flange 326.

- the openings 28 for the access or the discharge of the coolant are in this case introduced into the closure element 325.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Pistons, Piston Rings, And Cylinders (AREA)

Claims (9)

- Piston (10, 110, 210, 310) pour un moteur à combustion interne, comportant un premier composant de piston (11) et un deuxième composant de piston (12), dans lequel le premier composant de piston (11) et le deuxième composant de piston (12) forment un canal de refroidissement (23) circonférentiel, ouvert dans la direction du deuxième composant de piston (12), qui est obturé au moyen d'un moyen d'obturation circonférentiel, caractérisé en ce que l'élément d'obturation (25, 125, 225, 325) est relié en un seul tenant avec le premier composant de piston (11) et s'étend radialement dans la direction du deuxième composant de piston (12), en ce que le deuxième composant de piston (12) présente une bride d'ppaui (26, 126, 226, 326) circonférentielle, conçue en un seul tenant, s'étendant radialement dans la direction du premier composant de piston (11), en ce que l'élément d'obturation (25, 125, 225) vient reposer sous une précontrainte sur la bride d'appui (26, 126, 226) ou en ce que l'élément d'obturation (325) s'appuie par une précontrainte sur une arête inférieure circonférentielle (329) sur une surface frontale (331) de la bride d'appui (326), en ce que le premier composant de piston (11) présente une zone de paroi (16') d'un puits de chambre de combustion (16) et le deuxième composant de piston (12) présente une zone de base (16'') d'un puits de chambre de combustion (16), en ce que le premier composant de piston (11) et le deuxième composant de piston (12) sont reliés l'un à l'autre au moyen d'un procédé de soudage par friction, dans lequel un joint (27) est disposé au niveau du puits de chambre de combustion (16).

- Piston selon la revendication 1, caractérisé en ce que la largeur radiale de l'élément d'obturation (25, 125, 225, 325) et de la bride d'appui (26, 126, 226, 326) sont de dimensions identiques ou différentes.

- Piston selon la revendication 1, caractérisé en ce que la surface frontale (331) de la bride d'appui (326) est disposée en inclinaison dans la direction de l'élément d'obturation (325).

- Piston selon la revendication 1, caractérisé en ce que l'élément d'obturation (25, 125, 225, 325) et la bride d'appui (26, 126, 226, 326) sont reliés l'un à l'autre au moyen d'un procédé d'assemblage.

- Piston selon la revendication 1, caractérisé en ce que dans l'élément d'obturation (25, 125, 225, 325) et/ou dans la bride d'appui (26, 126, 226, 326) au moins une ouverture d'entrée de fluide de refroidissement (28) et au moins une ouverture de sortie de fluide de refroidissement (28) sont prévus.

- Piston selon la revendication 1, caractérisé en ce que le premier composant de piston (11) est un élément d'anneau de piston, qui présente au moins une partie d'une base de piston (13), un cordon de feu circonférentiel (14) ainsi qu'une bande annuaire (15) circonférentielle pourvue de rainures annulaires.

- Piston selon la revendication 1, caractérisé en ce que l'élément d'obturation (25, 125, 225, 325) est relié au niveau d'une extrémité libre inférieure de la bande annulaire (15) avec le premier composant de piston (11).

- Piston selon la revendication 1, caractérisé en ce que le deuxième composant de piston (12) est un corps de base de piston, qui présente au moins une tige de piston (17) avec des bossages de piston (18), qui sont pourvus d'alésages de bossage (19).

- Piston selon la revendication 1, caractérisé en ce que la tige de piston (17) est conçu comme étant découplé thermiquement de la bande annulaire (15).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102010056218A DE102010056218A1 (de) | 2010-12-24 | 2010-12-24 | Kolben für einen Verbrennungsmotor |

| PCT/DE2011/002129 WO2012083929A2 (fr) | 2010-12-24 | 2011-12-15 | Piston pour moteur à combustion interne |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2655840A2 EP2655840A2 (fr) | 2013-10-30 |

| EP2655840B1 true EP2655840B1 (fr) | 2015-06-03 |

Family

ID=45974186

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP11833595.9A Not-in-force EP2655840B1 (fr) | 2010-12-24 | 2011-12-15 | Piston pour moteur à combustion interne |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20120160203A1 (fr) |

| EP (1) | EP2655840B1 (fr) |

| CN (1) | CN203604062U (fr) |

| DE (1) | DE102010056218A1 (fr) |

| WO (1) | WO2012083929A2 (fr) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BR112015005723A2 (pt) * | 2012-09-27 | 2017-07-04 | Ks Kolbenschmidt Gmbh | pistão construído em duas peças de uma máquina de combustão interna |

| US20150260124A1 (en) * | 2012-10-08 | 2015-09-17 | Componenta Finland Oy | Piston for an internal combustion engine |

| DE102013009161A1 (de) * | 2013-05-31 | 2014-12-18 | Mahle International Gmbh | Kolben für einen Verbrennungsmotor |

| DE102013009164A1 (de) | 2013-05-31 | 2014-12-04 | Mahle International Gmbh | Kolben für einen Verbrennungsmotor |

| CN106662035B (zh) * | 2014-07-02 | 2019-07-23 | Ks科尔本施密特有限公司 | 在材料锁合地接合的冷却通道活塞中的间隙几何结构 |

| CN104747312A (zh) * | 2015-02-16 | 2015-07-01 | 山东滨州渤海活塞股份有限公司 | 带内冷油腔结构的内燃机活塞及内燃机 |

| CN204647277U (zh) * | 2015-03-17 | 2015-09-16 | 尹建 | 往复活塞链式连杆无死点发动机活塞连杆组 |

| EP3452712A1 (fr) | 2016-05-04 | 2019-03-13 | KS Kolbenschmidt GmbH | Piston |

| CN106979329A (zh) * | 2017-05-23 | 2017-07-25 | 湖南江滨机器(集团)有限责任公司 | 一种全钢活塞 |

| DE102019215486A1 (de) * | 2019-10-09 | 2021-04-15 | Mahle International Gmbh | Kolben für eine Brennkraftmaschine |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102008046115A1 (de) * | 2007-09-18 | 2009-03-19 | Art Metal Mfg. Co., Ltd., Ueda-shi | Verfahren zur Herstellung eines Kolbens für einen Verbrennungsmotor |

| DE102007061601A1 (de) * | 2007-12-20 | 2009-06-25 | Mahle International Gmbh | Kolben für einen Verbrennungsmotor sowie Verfahren zu seiner Herstellung |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BR9001859A (pt) * | 1990-04-17 | 1991-11-12 | Metal Leve Sa | Processo de fabricacao de embolo e embolo |

| DE60041153D1 (de) * | 1999-12-30 | 2009-01-29 | Federal Mogul Corp | Kolben mit entkoppeltem schaftteil |

| DE10040486C2 (de) * | 2000-08-18 | 2002-10-31 | Ks Kolbenschmidt Gmbh | Stahlkolben |

| DE10047258C2 (de) * | 2000-09-23 | 2003-02-06 | Ks Kolbenschmidt Gmbh | Kolben mit sich am Basisteil abstützenden und angeschweißtem Ringabschnitt |

| DE10132447A1 (de) * | 2001-07-04 | 2003-01-09 | Ks Kolbenschmidt Gmbh | Kolben mit angeschweißter Abdeckung des Kühlkanals |

| DE10244511A1 (de) * | 2002-09-25 | 2004-04-15 | Mahle Gmbh | Mehrteiliger gekühlter Kolben für einen Verbrennungsmotor |

| DE102004057624A1 (de) * | 2004-11-30 | 2006-06-01 | Mahle International Gmbh | Mehrteiliger, gekühlter Kolben für einen Verbrennungsmotor |

| PL1984613T3 (pl) * | 2006-02-17 | 2018-04-30 | Ks Kolbenschmidt Gmbh | Wieloczęściowy tłok stalowy do silnika spalinowego z kanałem chłodzącym |

| US20070283917A1 (en) * | 2006-06-12 | 2007-12-13 | Lapp Michael T | Piston for a combustion engine |

| DE102007031400A1 (de) * | 2007-07-05 | 2009-01-08 | Ks Kolbenschmidt Gmbh | Einteiliger Kühlkanalkolben mit zwei miteinander verschraubten Kolbenteilen |

| DE102007036236A1 (de) * | 2007-08-02 | 2009-02-05 | Mahle International Gmbh | Gebauter Kolben |

| DE102008038325A1 (de) * | 2007-12-20 | 2009-06-25 | Mahle International Gmbh | Verfahren zum Befestigen eines Ringelementes auf einem Kolben für einen Verbrennungsmotor |

| US8807109B2 (en) * | 2009-11-06 | 2014-08-19 | Federal-Mogul Corporation | Steel piston with cooling gallery and method of construction thereof |

-

2010

- 2010-12-24 DE DE102010056218A patent/DE102010056218A1/de not_active Withdrawn

-

2011

- 2011-04-18 US US13/066,552 patent/US20120160203A1/en not_active Abandoned

- 2011-12-15 CN CN201190000998.5U patent/CN203604062U/zh not_active Expired - Fee Related

- 2011-12-15 EP EP11833595.9A patent/EP2655840B1/fr not_active Not-in-force

- 2011-12-15 WO PCT/DE2011/002129 patent/WO2012083929A2/fr active Application Filing

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102008046115A1 (de) * | 2007-09-18 | 2009-03-19 | Art Metal Mfg. Co., Ltd., Ueda-shi | Verfahren zur Herstellung eines Kolbens für einen Verbrennungsmotor |

| DE102007061601A1 (de) * | 2007-12-20 | 2009-06-25 | Mahle International Gmbh | Kolben für einen Verbrennungsmotor sowie Verfahren zu seiner Herstellung |

Also Published As

| Publication number | Publication date |

|---|---|

| DE102010056218A1 (de) | 2012-06-28 |

| WO2012083929A2 (fr) | 2012-06-28 |

| US20120160203A1 (en) | 2012-06-28 |

| CN203604062U (zh) | 2014-05-21 |

| EP2655840A2 (fr) | 2013-10-30 |

| WO2012083929A3 (fr) | 2012-10-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2655840B1 (fr) | Piston pour moteur à combustion interne | |

| DE102010056220A1 (de) | Kolben für einen Verbrennungsmotor | |

| EP2681437B1 (fr) | Piston pour moteur à combustion interne et son procédé de production | |

| EP2184478A1 (fr) | Piston en plusieurs parties pour un moteur à combustion | |

| EP2681469B1 (fr) | Piston pour moteur a combustion | |

| EP2890884A1 (fr) | Piston pour un moteur à combustion interne | |

| EP1913250B1 (fr) | Piston pour un moteur a combustion interne et bague de fermeture pour le canal de refroidissement dudit piston | |

| EP3036419B1 (fr) | Ensemble constitué d'un piston et d'une buse de pulvérisation et destiné à un moteur à combustion interne | |

| DE102008055911A1 (de) | Mehrteiliger Kolben für einen Verbrennungsmotor sowie Verfahren zu seiner Herstellung | |

| DE102008055909A1 (de) | Mehrteiliger Kolben für einen Verbrennungsmotor | |

| EP2729689A1 (fr) | Piston pour un moteur à combustion interne | |

| EP2342441A1 (fr) | Piston avec canal de refroidissement pour un moteur à combustion interne, avec un élément de fermeture qui ferme le canal de refroidissement | |

| EP2321513B1 (fr) | Piston pour un moteur à combustion interne | |

| WO2012116688A1 (fr) | Piston pour moteur à combustion interne | |

| WO2012116687A1 (fr) | Piston pour moteur à combustion interne | |

| WO2014190962A1 (fr) | Piston pour moteur à combustion interne | |

| WO2013004218A1 (fr) | Piston pour un moteur à combustion interne | |

| WO2014012530A1 (fr) | Piston pour un moteur à combustion interne | |

| EP2893177B1 (fr) | Piston pour moteur à combustion interne | |

| WO2014190963A1 (fr) | Piston pour moteur à combustion interne | |

| WO2015104013A1 (fr) | Piston pour moteur à combustion interne et son procédé de fabrication | |

| DD243530A1 (de) | Eisenkolben fuer hubkolbenbrennkraftmaschinen | |

| EP1098082A2 (fr) | Piston |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20130712 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20141120 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 730063 Country of ref document: AT Kind code of ref document: T Effective date: 20150715 Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502011007017 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150903 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20150603 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150903 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150904 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151003 Ref country code: RO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150603 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151006 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502011007017 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 |

|

| 26N | No opposition filed |

Effective date: 20160304 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 Ref country code: LU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151215 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151231 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151231 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151215 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20111215 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 730063 Country of ref document: AT Kind code of ref document: T Effective date: 20161215 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161215 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150603 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20181221 Year of fee payment: 8 Ref country code: FR Payment date: 20181227 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20190228 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502011007017 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20191215 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200701 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191215 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191231 |