EP2616616B1 - Vehicle door handle comprising an inertial mass and a fuse - Google Patents

Vehicle door handle comprising an inertial mass and a fuse Download PDFInfo

- Publication number

- EP2616616B1 EP2616616B1 EP20110781736 EP11781736A EP2616616B1 EP 2616616 B1 EP2616616 B1 EP 2616616B1 EP 20110781736 EP20110781736 EP 20110781736 EP 11781736 A EP11781736 A EP 11781736A EP 2616616 B1 EP2616616 B1 EP 2616616B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- handle

- opening

- lever

- mass

- handle according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B77/00—Vehicle locks characterised by special functions or purposes

- E05B77/02—Vehicle locks characterised by special functions or purposes for accident situations

- E05B77/04—Preventing unwanted lock actuation, e.g. unlatching, at the moment of collision

- E05B77/06—Preventing unwanted lock actuation, e.g. unlatching, at the moment of collision by means of inertial forces

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B85/00—Details of vehicle locks not provided for in groups E05B77/00 - E05B83/00

- E05B85/10—Handles

- E05B85/14—Handles pivoted about an axis parallel to the wing

- E05B85/16—Handles pivoted about an axis parallel to the wing a longitudinal grip part being pivoted at one end about an axis perpendicular to the longitudinal axis of the grip part

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B77/00—Vehicle locks characterised by special functions or purposes

- E05B77/02—Vehicle locks characterised by special functions or purposes for accident situations

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T292/00—Closure fasteners

- Y10T292/57—Operators with knobs or handles

Definitions

- the invention relates to the vehicle opening handles.

- Sash handles are known that are equipped with an inertial system capable, in the event of a side impact and under the effect of the acceleration variation, of taking a locking position which inhibits the mechanism of the handle to prevent any inadvertent opening. of the opening, especially if the inertia of the shock tends to actuate a control member of the handle.

- DE102009016898 describes a handle equipped with a system according to the prior art.

- Inertial systems of the reversible type and inertial systems of the irreversible type are known in particular.

- a reversible system returns to the rest position at the end of the shock. It has the advantage of allowing the opening of the opening by means of the handle after the shock. However, it has the disadvantage of being generally very sensitive to lateral accelerations in both directions, as well as rebounds. Thus, if there are variations in the direction of the acceleration during the impact, the system may return to its rest position and activate again the mechanism of the handle that was initially inhibited. This can cause the handle to move under the impact and open the opening.

- An irreversible inertial system remains in the locked position for the duration of the shock and after the shock. It has the advantage of not being sensitive to variations in acceleration during the shock, or rebounds. It is therefore certain that the handle mechanism is properly inhibited throughout the duration of the shock, so that the opening does not open. This system however has the disadvantage that the handle mechanism remains inhibited after the shock and therefore makes it impossible to open the opening manually by operating the handle.

- An object of the invention is to combine the advantages of the two types of system without their disadvantages.

- the opening can be a front door, a rear door or a rag. It is in this case an external handle for the operation of the opening for unlocking and opening from outside the vehicle.

- the invention is nevertheless also applicable to an internal handle for opening the opening.

- the orthogonal coordinate system XYZ is used in the following, in which the horizontal directions X and Y are respectively parallel and perpendicular to the direction of travel of the vehicle and the direction Z is vertical.

- the handle 2 includes a support or frame 4 rigidly fixed to the structure of the opening. It comprises an external gripping portion 6 intended to be actuated manually by a user wishing to open the opening from outside the vehicle.

- This part 6 is in this case articulated to the support 4 about a vertical axis 8 and this by means known in themselves which are not detailed here.

- the gripping portion 6 extends inside the handle and the opening by an extension 10 extending in the direction Y.

- the handle 2 comprises a lever 12 mounted to rotate relative to the support 4 about a vertical axis 14.

- This lever comprises in particular an arm 16 extending in the path of an end edge of the extension 10 of so that when a user maneuvers the gripping portion 6 outward in the direction Y, the extension 10 carries the arm 16, which rotates the lever 12.

- the lever is connected, in a manner not shown and which will not be described here, to other parts of the handle mechanism, including a traction cable. This mechanism serves to unlock the opening relative to the vehicle body.

- the handle 2 also comprises an inertial system comprising a part 18 forming a mass mounted to rotate relative to the support 4 about a vertical axis 20.

- This part comprises two profiled parts 22 and 24 giving the part as seen in section on the Figures 2 to 4 a general shape in "V".

- the mass 18 can occupy different positions around its axis 20.

- the locking portion 22 extends out of the path of the lever 12, so that it allows its rotation and allows to control the opening of the opening by maneuvering the gripping portion 6.

- the locking portion 22 extends in the path of the lever 12 so that it prevents rotation, so that it inhibits the handle mechanism.

- the compression portion 24 of the mass 18 can indeed bear against a stop 26 rigidly secured to the support 4. It thereby holds the gripping portion 6 in position and prevents the opening of the opening.

- a return spring 19 of the mass to its rest position is supported on the one hand on the mass and on the other hand on the support 4.

- the compression portion 24 has a mass greater than that of the locking portion 22 , so that if the mass undergoes an acceleration in the Y direction towards the outside of the vehicle, it pivots in the counter-clockwise direction to move from the rest position to the locking position.

- the free end of the locking portion 24 carries an elastic tongue 27 a proximal portion extends in the extension of the face of the locking portion 24 facing outwards, and a distal portion is folded parallel to the Y direction when the mass 18 is at rest.

- the two parts of the tongue are parallel to the Z direction.

- the frame 4 further comprises a stop 29 having a ramp face 31 and a stop face 33, both parallel to the Z direction.

- the ramp face is inclined with respect to the direction X and extends opposite the tongue 27 when the mass is in the rest position.

- the stop face 33 is perpendicular to the Y direction and oriented in the opposite direction to the tongue in the rest position of the mass.

- the tongue 27 cooperates with the stop 29 to form a non-return device. Indeed, when the mass passes from the rest position to the locking position, the tongue 27 bears against the ramp 31 which has the effect of bending the tongue to allow it to pass the stop 29. When the tongue reaches the level of the face 33, it unfolds elastically. The face 33 then forms an obstacle for the tongue 27 preventing the return of the mass 18 in the rest position.

- the face 33 is in fact oriented in a plane perpendicular to that of the average fiber of the distal portion of the tongue 27.

- the stops 26 and 29 are rigid and therefore have negligible elasticity.

- the lever 12 comprises an arm or plate 35 by means of which it is adapted to come into direct contact with the locking portion 22.

- the arm 35 has a substantially planar shape parallel to the axis 14 but not radial to the latter.

- the arm 35 has a constant thickness, with the exception of a thinned zone forming a rupture primer.

- This zone 37 has a "U" shape when the arm 35 is observed at rest in a plane in the Y direction.

- the lever 12 comprises two disks 39 and 41 of axis 14 to which the arms 16 and 35 are rigidly fixed.

- "U" branches are parallel to the disks and extend along them respectively.

- the base of the "U” is parallel to the axis 14.

- the free ends of the branches extend at the free edge of the arm.

- the thinned zone thus delimits a free end zone 43 of the arm capable of breaking.

- the lever and more generally the handle, is configured so that the rupture of the free end 43 only occurs if a user exerts on the member 6 a bias having an intensity exceeding a predetermined threshold. For example, it can be set at 500 newtons.

- the handle according to the invention operates as follows.

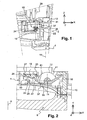

- the figure 1 illustrates the handle in the rest position of all parts.

- the locking portion 22 extends out of the path of the lever and its compression portion 24 extends away from the stop 26. If a user wishes to open the opening, it actuates the gripping portion 6 which drives with the extension 10 the lever 12 in rotation about its axis to cause the unlocking of the opening.

- the return spring 19 keeps the mass 18 out of the path of the lever 12 so that the extension 10 can freely drive the latter.

- the handle according to the invention thus has both the advantage of providing an irreversible inertial system which remains in the locking position during the entire shock and at the end of the latter, and to allow the voluntary opening of the opening on command of a user after the shock.

- the fuse piece is not able to break but to deform, provided that it suffices to allow the opening of the opening when the mass occupies the blocking position.

- the threshold value of 500 newtons is given only as an example. It can be expected to increase or reduce this threshold. It is a question of determining a threshold which avoids an inadvertent opening of the sash under the effect of the inertial displacement of the gripping member but allows a deliberate opening of the sash by the manipulation of this member.

Landscapes

- Lock And Its Accessories (AREA)

Description

L'invention concerne les poignées d'ouvrant de véhicule.The invention relates to the vehicle opening handles.

On connaît des poignées d'ouvrant équipées d'un système inertiel apte, en cas de choc latéral et sous l'effet de la variation d'accélération, à prendre une position de blocage qui inhibe le mécanisme de la poignée pour interdire toute ouverture intempestive de l'ouvrant, notamment si l'inertie du choc tend à actionner un organe de commande de la poignée.Sash handles are known that are equipped with an inertial system capable, in the event of a side impact and under the effect of the acceleration variation, of taking a locking position which inhibits the mechanism of the handle to prevent any inadvertent opening. of the opening, especially if the inertia of the shock tends to actuate a control member of the handle.

On connait en particulier des systèmes inertiels de type réversible et des systèmes inertiels de type irréversible.Inertial systems of the reversible type and inertial systems of the irreversible type are known in particular.

Un système réversible revient en position de repos à l'issue du choc. Il a pour avantage de permettre l'ouverture de l'ouvrant au moyen de la poignée après le choc. Il a toutefois pour inconvénient d'être en général très sensible aux accélérations latérales dans les deux sens, ainsi qu'aux rebonds. Ainsi, s'il se produit des variations de direction de l'accélération lors du choc, il se peut que te système revienne à sa position de repos et rende à nouveau actif le mécanisme de la poignée qui se trouvait initialement inhibé. Cela peut entraîner le déplacement de la poignée sous l'effet du choc et l'ouverture de l'ouvrant.A reversible system returns to the rest position at the end of the shock. It has the advantage of allowing the opening of the opening by means of the handle after the shock. However, it has the disadvantage of being generally very sensitive to lateral accelerations in both directions, as well as rebounds. Thus, if there are variations in the direction of the acceleration during the impact, the system may return to its rest position and activate again the mechanism of the handle that was initially inhibited. This can cause the handle to move under the impact and open the opening.

Un système inertiel irréversible demeure en position de blocage pendant toute la durée du choc et après ce dernier. Il a pour avantage de ne pas être sensible aux variations d'accélération durant le choc, ni aux rebonds. On est donc sûr que le mécanisme de poignée est convenablement inhibé pendant toute la durée du choc, de sorte que l'ouvrant ne s'ouvre pas. Ce système a toutefois pour inconvénient que le mécanisme de poignée demeure inhibé après le choc et rend donc impossible l'ouverture volontaire de l'ouvrant par la manoeuvre de la poignée.An irreversible inertial system remains in the locked position for the duration of the shock and after the shock. It has the advantage of not being sensitive to variations in acceleration during the shock, or rebounds. It is therefore certain that the handle mechanism is properly inhibited throughout the duration of the shock, so that the opening does not open. This system however has the disadvantage that the handle mechanism remains inhibited after the shock and therefore makes it impossible to open the opening manually by operating the handle.

Un but de l'invention est de combiner les avantages des deux types de système sans leurs inconvénients.An object of the invention is to combine the advantages of the two types of system without their disadvantages.

A cet effet, on prévoit une poignée d'ouvrant de véhicule selon la revendication 1.For this purpose, there is provided a handle of a vehicle opening according to claim 1.

choc, et bien que le mécanisme demeure a priori inhibé, il est possible de forcer l'ouverture de l'ouvrant en sollicitant l'organe de commande de façon à rompre ou à déformer le levier qui forme ainsi un fusible mécanique. L'ouvrant peut donc être ouvert pour permettre la sortie d'un occupant du véhicule. Cette poignée combine les avantages des systèmes des deux types précités tout en palliant leurs inconvénients.shock, and although the mechanism remains a priori inhibited, it is possible to force the opening of the opening by soliciting the control member so as to break or deform the lever which thus forms a mechanical fuse. The opening can be opened to allow the exit of an occupant of the vehicle. This handle combines the advantages of the systems of the two aforementioned types while overcoming their disadvantages.

La poignée pourra avantageusement présenter en outre au moins l'une quelconque des caractéristiques suivantes:

- le levier est agencé pour transmettre un mouvement de l'organe de commande à un mécanisme d'ouverture de la poignée ;

- le seuil vaut 500 newtons ;

- le levier présente une zone de rupture préférentielle amincie ;

- la zone amincie est ménagée dans une partie plane du levier ;

- la zone amincie présente une forme de « U » ;

- la poignée comprend un bâti formant une butée pour la masse lors de la rupture ou de la déformation du levier ; et

- la poignée est agencée pour interdire à la masse inertielle de passer de la position de blocage à une position de repos autorisant l'ouverture.

- the lever is arranged to transmit a movement of the control member to an opening mechanism of the handle;

- the threshold is 500 newtons;

- the lever has a thinned preferential rupture zone;

- the thinned zone is formed in a flat part of the lever;

- the thinned zone has a shape of "U";

- the handle comprises a frame forming a stop for the mass during the breaking or deformation of the lever; and

- the handle is arranged to prevent the inertial mass from moving from the locking position to a rest position allowing opening.

D'autres caractéristiques et avantages de l'invention definie par les revendications annexées apparaîtront encore dans la description suivante d'un mode de réalisation donné à titre d'exemple non limitatif en référence aux dessins annexés sur lesquels :

- la

figure 1 est une vue partielle en perspective d'un mécanisme d'une poignée selon un mode de réalisation de l'invention ; et - les

figures 2 à 4 illustrent trois étapes respectives du fonctionnement de ce mécanisme.

- the

figure 1 is a partial perspective view of a mechanism of a handle according to one embodiment of the invention; and - the

Figures 2 to 4 illustrate three different stages in the operation of this mechanism.

Nous allons décrire ci-après un mode de réalisation d'une poignée d'ouvrant de véhicule automobile selon l'invention. L'ouvrant peut être une portière avant, une portière arrière ou encore un haillon. Il s'agit en l'espèce d'une poignée externe permettant la manoeuvre de l'ouvrant pour son déverrouillage et son ouverture depuis l'extérieur du véhicule. L'invention est néanmoins également applicable à une poignée interne pour l'ouverture de l'ouvrant.We will describe below an embodiment of a motor vehicle opening handle according to the invention. The opening can be a front door, a rear door or a rag. It is in this case an external handle for the operation of the opening for unlocking and opening from outside the vehicle. The invention is nevertheless also applicable to an internal handle for opening the opening.

On utilise dans la suite le repère orthogonal XYZ dans lequel les directions horizontales X et Y sont respectivement parallèle et perpendiculaire à la direction de marche du véhicule et la direction Z est verticale.The orthogonal coordinate system XYZ is used in the following, in which the horizontal directions X and Y are respectively parallel and perpendicular to the direction of travel of the vehicle and the direction Z is vertical.

En référence tout d'abord aux

La poignée 2 comprend un levier 12 monté mobile à rotation par rapport au support 4 autour d'un axe vertical 14. Ce levier comprend notamment un bras 16 s'étendant dans le trajet d'un rebord d'extrémité de l'extension 10 de sorte que, lorsqu'un utilisateur manoeuvre la partie de préhension 6 vers l'extérieur suivant la direction Y, l'extension 10 emporte le bras 16, ce qui fait tourner le levier 12.The

Le levier est relié, d'une façon non illustrée et qui ne sera pas décrite ici, à d'autres pièces du mécanisme de poignée, notamment à un câble de traction. Ce mécanisme sert à déverrouiller l'ouvrant par rapport à la caisse du véhicule.The lever is connected, in a manner not shown and which will not be described here, to other parts of the handle mechanism, including a traction cable. This mechanism serves to unlock the opening relative to the vehicle body.

La poignée 2 comprend aussi un système inertiel comportant une pièce 18 formant une masse montée mobile à rotation par rapport au support 4 autour d'un axe vertical 20. Cette pièce comprend deux parties profilées 22 et 24 donnant à la pièce telle que vue en coupe sur les

La masse 18 peut occuper différentes positions autour de son axe 20.The

Dans la position de repos illustrée à la

Dans la position de blocage illustrée à la

Un ressort de rappel 19 de la masse vers sa position de repos prend appui d'une part sur la masse et d'autre part sur le support 4. La partie de compression 24 a une masse plus grande que celle de la partie de blocage 22, de sorte que si la masse subit une accélération suivant la direction Y vers l'extérieur du véhicule, elle pivote dans le sens anti-horaire pour passer de la position de repos à la positon de blocage.A

L'extrémité libre de la partie de blocage 24 porte une languette élastique 27 dont une partie proximale s'étend dans le prolongement de la face de la partie de blocage 24 tournée vers l'extérieur, et dont une partie distale est repliée parallèlement à la direction Y lorsque la masse 18 est au repos. Les deux parties de la languette sont parallèles à la direction Z.The free end of the

Le bâti 4 comprend en outre une butée 29 présentant une face de rampe 31 et une face d'arrêt 33, toutes deux parallèles à la direction Z. La face de rampe est inclinée par rapport à la direction X et s'étend en regard de la languette 27 lorsque la masse est en position de repos. La face d'arrêt 33 est perpendiculaire à la direction Y et orientée en direction opposée à la languette en position de repos de la masse.The

La languette 27 coopère avec la butée 29 pour former un dispositif anti-retour. En effet, lorsque la masse passe de la position de repos à la position de blocage, la languette 27 vient en appui contre la rampe 31 qui a pour effet de fléchir la languette pour lui permettre de passer la butée 29. Lorsque la languette arrive au niveau de la face 33, elle se déplie élastiquement. La face 33 forme alors un obstacle pour la languette 27 empêchant le retour de la masse 18 en position de repos. La face 33 est en effet orientée dans un plan perpendiculaire à celui de la fibre moyenne de la partie distale de la languette 27.The

D'autres aménagements de retenue de la masse inertielle en position de blocage sont envisageables, tels qu'une roue à cliquets solidaire de la masse inertielle ou encore une lame métallique élastique en flexion, dissociée de la masse inertielle mais venant recevoir dans un orifice adapté un ergot de la masse inertielle lorsque cette dernière est en position de blocage.Other arrangements for retaining the inertial mass in the locking position are conceivable, such as a ratchet wheel integral with the inertial mass or an elastic metal plate flexion, dissociated from the inertial mass but receiving in a suitable orifice a lug of the inertial mass when the latter is in the locking position.

Les butées 26 et 29 sont rigides et présentent donc une élasticité négligeable.The stops 26 and 29 are rigid and therefore have negligible elasticity.

Le levier 12 comprend un bras ou plaquette 35 au moyen duquel il est apte à venir en contact direct avec la partie de blocage 22. Le bras 35 a une forme essentiellement plane parallèle à l'axe 14 mais non radiale à ce dernier. Le bras 35 présente une épaisseur constante, à l'exception d'une zone amincie formant une amorce de rupture. Cette zone 37 a une forme en « U » lorsque le bras 35 est observé au repos en plan suivant la direction Y. Le levier 12 comprend deux disques 39 et 41 d'axe 14 auxquels sont rigidement fixés les bras 16 et 35. Les deux branches du « U » sont parallèles aux disques et s'étendent le long de ceux-ci respectivement. La base du « U » est parallèle à l'axe 14. Les extrémités libres des branches s'étendent au niveau du bord libre du bras. La zone amincie délimite ainsi une zone d'extrémité libre 43 du bras apte à se rompre. Le levier, et plus généralement la poignée, est configuré de sorte que la rupture de l'extrémité libre 43 n'intervient que si un utilisateur exerce sur l'organe 6 une sollicitation ayant une intensité dépassant un seuil prédéterminé. On peut par exemple fixer ce dernier à 500 newtons.The

La poignée selon l'invention fonctionne de la façon suivante.The handle according to the invention operates as follows.

La

En référence à la

On suppose à la

La poignée selon l'invention a donc tout à la fois pour avantage de procurer un système inertiel irréversible qui reste donc en position de blocage pendant tout le choc et à l'issue de ce dernier, et de permettre l'ouverture volontaire de l'ouvrant sur commande d'un utilisateur après le choc.The handle according to the invention thus has both the advantage of providing an irreversible inertial system which remains in the locking position during the entire shock and at the end of the latter, and to allow the voluntary opening of the opening on command of a user after the shock.

Bien entendu, on pourra apporter à l'invention définie par les revendications annexées de nombreuses modifications sans sortir du cadre de celle-ci.Of course, we can bring to the invention defined by the appended claims many changes without departing from the scope thereof.

On pourrait prévoir que la languette 27 est portée par le bâti et que la butée 29 est portée par la masse 18.One could provide that the

On peut également prévoir que la pièce fusible est apte non pas à se rompre mais à se déformer, pourvu que cela suffise à permettre l'ouverture de l'ouvrant lorsque la masse occupe la position de blocage.It is also possible that the fuse piece is not able to break but to deform, provided that it suffices to allow the opening of the opening when the mass occupies the blocking position.

La valeur de seuil de 500 newtons est donnée seulement à titre d'exemple. On peut prévoir d'augmenter ou de réduire ce seuil. Il s'agit de déterminer un seuil qui évite une ouverture intempestive de l'ouvrant sous l'effet du déplacement inertiel de l'organe de préhension mais permette une ouverture volontaire de l'ouvrant par la manipulation de cet organe.The threshold value of 500 newtons is given only as an example. It can be expected to increase or reduce this threshold. It is a question of determining a threshold which avoids an inadvertent opening of the sash under the effect of the inertial displacement of the gripping member but allows a deliberate opening of the sash by the manipulation of this member.

Claims (8)

- A handle for a movable panel of a vehicle, including:- an inertial mass (18) capable of assuming a position of blocking opening of the handle, and- a lever (12) adapted to break or to be deformed because of the effect of applying a force to an operating member (6) of the handle having an intensity exceeding a predetermined threshold to allow opening when the mass is in the blocking position, characterized in that the lever (12) is arranged to be in direct contact with the mass (18).

- Handle according to the preceding claim in which the lever (12) is adapted to transmit a movement of the operating member (6) to an opening mechanism of the handle.

- Handle according to at least either one of the preceding claims wherein the threshold has a value of 500 newtons.

- Handle according to at least any one of the preceding claims in which the lever (12) has a thinner preferential rupture area (37).

- Handle according to the preceding claim wherein the thinner area (37) is provided in a plane portion (35) of the lever (12).

- Handle according to at least either one of claims 4 and 5 in which the thinner area (37) is U-shaped.

- Handle according to at least any one of the preceding claims which includes a frame (4) forming an abutment (26) for the mass (18) on rupture or deformation of the lever (12).

- Handle according to at least any one of the preceding claims which is adapted to prevent the inertial mass moving from the blocking position to a rest position allowing opening.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ITMI20101664 ITMI20101664A1 (en) | 2010-09-13 | 2010-09-13 | VEHICLE LEAF HANDLE INCLUDING AN INERTIAL MASS AND A FUSE |

| PCT/EP2011/004500 WO2012034665A1 (en) | 2010-09-13 | 2011-09-07 | Handle for a movable panel of a vehicle including an inertial body and a fuse |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2616616A1 EP2616616A1 (en) | 2013-07-24 |

| EP2616616B1 true EP2616616B1 (en) | 2015-04-29 |

Family

ID=43738892

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20110781736 Active EP2616616B1 (en) | 2010-09-13 | 2011-09-07 | Vehicle door handle comprising an inertial mass and a fuse |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US20130234455A1 (en) |

| EP (1) | EP2616616B1 (en) |

| JP (1) | JP2013539828A (en) |

| CN (1) | CN103348076B (en) |

| BR (1) | BR112013005769B1 (en) |

| IT (1) | ITMI20101664A1 (en) |

| WO (1) | WO2012034665A1 (en) |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITMI20112367A1 (en) * | 2011-12-22 | 2013-06-23 | Valeo Spa | SAFETY DEVICE FOR A VEHICLE DOOR HANDLE. |

| EP2735676B1 (en) * | 2012-11-20 | 2017-02-15 | U-Shin Italia S.p.A. | Vehicle panel handle assembly |

| US9062477B2 (en) * | 2012-11-28 | 2015-06-23 | Huf North America Automotive Parts Mfg. Corp. | Vehicular door handle assembly with inertial secondary catch position |

| DE102013006826A1 (en) | 2013-04-22 | 2014-10-23 | Illinois Tool Works Inc. | Door handle arrangement for an automobile |

| JP5934159B2 (en) * | 2013-09-02 | 2016-06-15 | 本田技研工業株式会社 | Door outer handle |

| KR101459964B1 (en) * | 2013-11-06 | 2014-11-10 | 현대자동차주식회사 | Device for preventing from opening the of vehicle |

| KR101575424B1 (en) * | 2013-12-17 | 2015-12-07 | 현대자동차주식회사 | Door latch apparatus for vehicle |

| DE102014004550A1 (en) * | 2014-03-31 | 2015-10-01 | Kiekert Aktiengesellschaft | Actuation device for a motor vehicle lock |

| JP6549357B2 (en) * | 2014-07-02 | 2019-07-24 | 株式会社アルファ | Vehicle steering wheel |

| EP3141680B1 (en) * | 2015-09-09 | 2018-01-31 | U-Shin Italia S.p.A. | Electronic handle for a vehicle door |

| DE102016212215A1 (en) * | 2016-07-05 | 2018-01-11 | Volkswagen Aktiengesellschaft | Arrangement for preventing an automatic opening of a vehicle door or flap and vehicle with such an arrangement |

| DE102016125167A1 (en) * | 2016-12-21 | 2018-06-21 | Kiekert Ag | Locking device for a motor vehicle |

| WO2018213391A1 (en) | 2017-05-17 | 2018-11-22 | Adac Plastics, Inc. | Resettable inertia lock assembly |

| DE102017216920A1 (en) * | 2017-09-25 | 2019-03-28 | Volkswagen Aktiengesellschaft | Door handle device for a door of a motor vehicle, door, motor vehicle |

| EP3832057B1 (en) * | 2019-12-04 | 2023-01-25 | U-Shin Italia S.p.A. | Door leaf handle for a motor vehicle |

| EP4198228A1 (en) * | 2021-12-16 | 2023-06-21 | U-Shin Italia S.p.A. | Electronic handle for a vehicle door |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19952798C1 (en) * | 1999-11-03 | 2001-05-31 | Huf Huelsbeck & Fuerst Gmbh | Operating device for automobile door catch has operation of maunal handle trasferred to operating rod for door catch dependent on position of catch locking device |

| JP2002013333A (en) * | 2000-06-30 | 2002-01-18 | Tokai Rika Co Ltd | Locking device for lid member |

| GB0214817D0 (en) * | 2002-06-27 | 2002-08-07 | Arvinmeritor Light Vehicle Sys | Door latch mechanism |

| FR2869937B1 (en) * | 2004-05-05 | 2007-12-21 | Peugeot Citroen Automobiles Sa | DEVICE FOR OPENING AN OPENING OF A MOTOR VEHICLE WITH SAFETY REINFORCED IN THE EVENT OF SHOCK, AND METHOD OF MOUNTING THE DEVICE ON THE OPENING |

| ITRM20040337A1 (en) * | 2004-07-07 | 2004-10-07 | Valeo Sicurezza Abitacolo Spa | DOOR HANDLE, IN PARTICULAR OF THE VEHICLE, WITH INERTIAL SAFETY SYSTEM. |

| KR100792931B1 (en) * | 2006-12-12 | 2008-01-08 | 기아자동차주식회사 | Door opening prevention device in case of side collision of door out side handle |

| ITMI20071748A1 (en) * | 2007-09-11 | 2009-03-12 | Valeo Sicurezza Abitacolo Spa | SAFETY HANDLE FOR VEHICLES |

| JP2010024802A (en) * | 2008-07-24 | 2010-02-04 | Aisin Seiki Co Ltd | Door handle for car and door handle device for car |

| JP5039015B2 (en) * | 2008-12-12 | 2012-10-03 | 株式会社アルファ | Vehicle door handle device |

| DE102008062214B4 (en) * | 2008-12-13 | 2023-07-20 | Dr. Ing. H.C. F. Porsche Aktiengesellschaft | door handle device |

| IT1392678B1 (en) * | 2009-01-19 | 2012-03-16 | Valeo Spa | SAFETY DEVICE FOR VEHICLE HANDLES AND VEHICLE HANDLE INCLUDING THIS SAFETY DEVICE |

| DE102009016898A1 (en) * | 2009-03-04 | 2010-09-09 | Huf Hülsbeck & Fürst Gmbh & Co. Kg | Outside door handle for motor vehicle, has blocking element and mass element movable and cooperated during crash such that stop and counter-stop are locked together by permanent connection |

| DE102009013324A1 (en) * | 2009-03-18 | 2010-09-23 | Huf Hülsbeck & Fürst Gmbh & Co. Kg | Grip assembly for vehicle door, has safety unit cooperating with bearing frame such that inert-mass remains irreversibly in active position during initial blocking of transmission element when grip is not accelerated |

| US8833812B2 (en) * | 2009-07-31 | 2014-09-16 | Toyota Shatai Kabushiki Kaisha | Door lock release mechanism for automobile door |

| CN201531171U (en) * | 2009-10-16 | 2010-07-21 | 镇江美驰轻型车系统(第二)有限公司 | Emergency locking device for a door lock in automobile collision |

-

2010

- 2010-09-13 IT ITMI20101664 patent/ITMI20101664A1/en unknown

-

2011

- 2011-09-07 JP JP2013527494A patent/JP2013539828A/en active Pending

- 2011-09-07 US US13/822,827 patent/US20130234455A1/en not_active Abandoned

- 2011-09-07 BR BR112013005769-6A patent/BR112013005769B1/en active IP Right Grant

- 2011-09-07 WO PCT/EP2011/004500 patent/WO2012034665A1/en active Application Filing

- 2011-09-07 CN CN201180054517.3A patent/CN103348076B/en active Active

- 2011-09-07 EP EP20110781736 patent/EP2616616B1/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN103348076B (en) | 2016-02-03 |

| EP2616616A1 (en) | 2013-07-24 |

| US20130234455A1 (en) | 2013-09-12 |

| ITMI20101664A1 (en) | 2012-03-14 |

| CN103348076A (en) | 2013-10-09 |

| BR112013005769A2 (en) | 2016-05-03 |

| WO2012034665A1 (en) | 2012-03-22 |

| JP2013539828A (en) | 2013-10-28 |

| BR112013005769B1 (en) | 2020-05-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2616616B1 (en) | Vehicle door handle comprising an inertial mass and a fuse | |

| EP2611978B1 (en) | Vehicle door handle comprising an inertial mass | |

| EP2432954B1 (en) | Handle for a door leaf of an automobile | |

| EP2663705B1 (en) | Handle of an opening element of a vehicle, comprising a grip part | |

| EP2563999B1 (en) | Handle for an openable body section of a vehicle, including a safety device | |

| EP3456579A1 (en) | Guide for vehicle seat and vehicle seat comprising such a guide | |

| EP4219871B1 (en) | Opening control device with reversible and irreversible inertial safety lock | |

| EP1593802B1 (en) | Opening device for a vehicle door with enhanced safety in case of impact, and method for mounting the device on the door | |

| WO2019038194A1 (en) | Locking system equipped with a handle and with a remotely situated inertial system | |

| FR2940813A1 (en) | Handle for side door leaf of motor vehicle, has inertial mass anti-return unit to anti-return inertial mass in blocking position, and inhibition unit to inhibit anti-return unit before assembling handle | |

| EP3034723B1 (en) | Lock for a door of a motor vehicle | |

| FR2880308A1 (en) | HEAD SUPPORT FOR A MOTOR VEHICLE SEAT | |

| EP3149262B1 (en) | Lock for a motor vehicle | |

| EP2440728B1 (en) | Handle of an openable body section of an automobile | |

| FR2883521A1 (en) | DEPLACABLE VEHICLE SEAT IN FRONT, COMPRISING A FRONT-FOLDING SUPPORT AND BACKREST | |

| EP3063035B1 (en) | Retractable seat for a vehicle | |

| EP3032010B1 (en) | Lock for a door of a motor vehicle | |

| FR3100262A1 (en) | Motor vehicle opening handle fitted with an inertial safety system | |

| EP2640915B1 (en) | Automobile handle having a blocking inertial body actuated by a counterweight | |

| EP2503082B1 (en) | Motorisiertes Schloss für Kraftfahrzeug | |

| FR3077836A1 (en) | PREVENTION SYSTEM AGAINST UNINTENDED OPENING OF A STORAGE DEVICE IN THE EVENT OF SHOCK. | |

| FR2853293A1 (en) | Mechanical parking brake control handle for use in vehicle, has latch of lever blocking mechanism movable between active and inactive blocking positions of lever by application force by parking brake on lever | |

| FR2659919A1 (en) | BUCKLE FOR A VEHICLE SEAT BELT. | |

| EP1844974A1 (en) | Guide mechanism of a seat and corresponding motor vehicle | |

| FR2876636A1 (en) | Seat e.g. middle seat, guiding mechanism for e.g. minivan, has elastic cable to actuate slide, to be fixed to seat, by tractive force towards rear position of seat, when slide is located between front and rear positions of seat |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20130326 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: U-SHIN ITALIA S.P.A. |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20140721 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E05B 85/16 20140101ALI20140715BHEP Ipc: E05B 77/06 20140101AFI20140715BHEP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 602011016146 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: E05B0065120000 Ipc: E05B0077060000 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20141121 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E05B 77/02 20140101ALN20141112BHEP Ipc: E05B 85/16 20140101ALI20141112BHEP Ipc: E05B 77/06 20140101AFI20141112BHEP |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 724544 Country of ref document: AT Kind code of ref document: T Effective date: 20150515 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602011016146 Country of ref document: DE Effective date: 20150611 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20150429 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 724544 Country of ref document: AT Kind code of ref document: T Effective date: 20150429 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150831 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150730 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150829 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602011016146 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 Ref country code: RO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150429 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20160201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 Ref country code: LU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150907 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20150907 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150930 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150930 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150907 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150907 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20110907 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150930 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150429 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240912 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20240925 Year of fee payment: 14 |