EP2604801B1 - Stator blade ring and method of making the ring - Google Patents

Stator blade ring and method of making the ring Download PDFInfo

- Publication number

- EP2604801B1 EP2604801B1 EP12195193.3A EP12195193A EP2604801B1 EP 2604801 B1 EP2604801 B1 EP 2604801B1 EP 12195193 A EP12195193 A EP 12195193A EP 2604801 B1 EP2604801 B1 EP 2604801B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- blade

- steam turbine

- passageway

- stator

- ring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 10

- 238000005219 brazing Methods 0.000 claims description 19

- 238000011144 upstream manufacturing Methods 0.000 claims description 4

- 238000000034 method Methods 0.000 claims description 3

- 239000002184 metal Substances 0.000 claims description 2

- 239000012530 fluid Substances 0.000 claims 1

- 239000007788 liquid Substances 0.000 description 4

- 230000008439 repair process Effects 0.000 description 3

- 230000000694 effects Effects 0.000 description 2

- 238000003754 machining Methods 0.000 description 2

- 230000003014 reinforcing effect Effects 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 238000004891 communication Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000005553 drilling Methods 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 239000007791 liquid phase Substances 0.000 description 1

- 238000003801 milling Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 230000002250 progressing effect Effects 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 230000002787 reinforcement Effects 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D9/00—Stators

- F01D9/02—Nozzles; Nozzle boxes; Stator blades; Guide conduits, e.g. individual nozzles

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D25/00—Component parts, details, or accessories, not provided for in, or of interest apart from, other groups

- F01D25/32—Collecting of condensation water; Drainage ; Removing solid particles

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/14—Form or construction

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/30—Fixing blades to rotors; Blade roots ; Blade spacers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D9/00—Stators

- F01D9/02—Nozzles; Nozzle boxes; Stator blades; Guide conduits, e.g. individual nozzles

- F01D9/04—Nozzles; Nozzle boxes; Stator blades; Guide conduits, e.g. individual nozzles forming ring or sector

- F01D9/041—Nozzles; Nozzle boxes; Stator blades; Guide conduits, e.g. individual nozzles forming ring or sector using blades

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D9/00—Stators

- F01D9/02—Nozzles; Nozzle boxes; Stator blades; Guide conduits, e.g. individual nozzles

- F01D9/04—Nozzles; Nozzle boxes; Stator blades; Guide conduits, e.g. individual nozzles forming ring or sector

- F01D9/042—Nozzles; Nozzle boxes; Stator blades; Guide conduits, e.g. individual nozzles forming ring or sector fixing blades to stators

- F01D9/044—Nozzles; Nozzle boxes; Stator blades; Guide conduits, e.g. individual nozzles forming ring or sector fixing blades to stators permanently, e.g. by welding, brazing, casting or the like

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D9/00—Stators

- F01D9/02—Nozzles; Nozzle boxes; Stator blades; Guide conduits, e.g. individual nozzles

- F01D9/04—Nozzles; Nozzle boxes; Stator blades; Guide conduits, e.g. individual nozzles forming ring or sector

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2220/00—Application

- F05D2220/30—Application in turbines

- F05D2220/31—Application in turbines in steam turbines

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2230/00—Manufacture

- F05D2230/20—Manufacture essentially without removing material

- F05D2230/23—Manufacture essentially without removing material by permanently joining parts together

- F05D2230/232—Manufacture essentially without removing material by permanently joining parts together by welding

- F05D2230/237—Brazing

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49316—Impeller making

- Y10T29/4932—Turbomachine making

- Y10T29/49323—Assembling fluid flow directing devices, e.g., stators, diaphragms, nozzles

Definitions

- the present invention relates generally to steam turbines and, more specifically, to a stator blade ring for a steam turbine and a method of making a stator blade ring.

- a steam turbine is a turbo machine which converts thermal and pressure energy of steam into rotary motion which may be used to perform work. Steam turbines may be used, for example, to drive electrical generators or compressors.

- Each stage typically includes a stator blade diaphragm and a bearing mounted rotor assembly including at least one impeller.

- US 3 881 842 discloses a diaphragm for the ultimate stage of a steam turbine comprising welded hollow blades. Each hollow blade has a slot for liquid phase removal with each slot communicating with an interior of the guide blade. The interior of the guide blade is communicated only with an annular channel of the rim and with an annular channel of the body. The rim is provided with openings adapted to establish communication between the channel and a condenser.

- stator blade diaphragms In modem steam turbines, the manufacture of stator blade diaphragms represents a significant cost, particularly in multi stage steam turbines having three or more stages each of which may include one or more separate stator blade diaphragms.

- stator blade diaphragm If a stator blade diaphragm is damaged, the steam turbine may need to be shut down and the damaged stator diaphragm removed for servicing. If on site repair is not possible, the entire diaphragm may need to be sent for repair or alternatively, an entire new stator diaphragm must be installed. Worse yet, if a replacement is available, a new stator blade diaphragm must be fabricated. Thus, in addition to the cost of the stator diaphragm, costs associated with the extended downtime of the steam turbine are also incurred. Accordingly, what is needed is a replacement for the conventional stator blade diaphragm, which is easily serviced and/or replaced, which is capable of successful operation in the presence of wet steam, and which provides a simple design which is easier manufactured.

- the present invention relates to a stator blade ring for a steam turbine according to claim 1 including a plurality of stator blade modules defining an annular chamber, each stator blade module including an elongated blade portion including a first blade shell portion and a second blade shell portion brazed to the first blade shell portion.

- the elongated blade portion further includes a longitudinal passageway and at least one opening extending through one of the first blade shell portion and the second blade shell portion to the longitudinal passageway.

- An inner portion brazed to a first longitudinal end of the blade portion, the inner portion including a through hole forming a portion of the annular chamber, the inner portion further including an inner passageway extending from the through hole to the longitudinal passageway.

- An outer portion brazed to a second longitudinal end of the blade portion and engaged to the steam turbine, the outer portion including an outer passageway open to a surface of the steam turbine and the longitudinal passageway.

- a turbo machine includes a rotor assembly including at least one impeller, a bearing connected to, and for rotatably supporting, the rotor assembly, and a stator blade ring having a plurality of stator blade modules defining an annular chamber.

- Each blade module includes at least one elongated blade portion including a first blade shell portion and a second blade shell portion brazed to the first blade shell portion, an inner portion brazed to a first longitudinal end of the at least one blade portion, the inner portion including a through hole forming a portion of the annular chamber, and an outer portion brazed to a second longitudinal end of the at least one blade portion and engaged to a surface of the steam turbine.

- At least one of the blade modules includes a longitudinal passageway and at least one opening in the at least one blade portion for liquid to enter the longitudinal passageway and an inner passageway in the inner portion extending from the through hole to the longitudinal passageway for allowing the liquid to flow between the annular chamber and the longitudinal passageway.

- At least one of the blade modules includes a longitudinal passageway in the at least one blade portion, an inner passageway in the inner portion extending from the through hole to the longitudinal passageway for allowing the liquid to flow between the annular chamber and the longitudinal passageway and an outer passageway in the outer portion extending from the longitudinal passageway and opening to the surface of the turbo machine for allowing the liquid to flow out of the stator blade ring.

- the invention relates to a method of making a blade module for a stator blade ring according to claim 11 including the steps of brazing first and second edges of a first blade shell portion to first and second edges of a second blade shell portion to provide an elongated blade portion having a longitudinal passageway, forming a through hole in the inner portion, forming an inner passageway in the inner portion extending from a surface of the inner portion to the through hole, brazing a first longitudinal end of the blade portion to the surface of the inner portion such that the longitudinal passageway is open to the inner passageway, forming an outer passageway in the outer portion extending from a first surface to a second surface of the outer portion, and, brazing a second longitudinal end of the blade portion to the first surface of the outer portion such that the longitudinal passageway is open to the outer passageway.

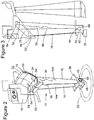

- FIG. 1 schematically illustrates a turbo machine in the form of a multistage steam turbine 400.

- the steam turbine 400 includes a housing (stator) 420 within which a number of stator blade diaphragms 430 are disposed along with a rotor shaft 450 provided with a plurality of impeller rotors 440.

- the shaft 450 is supported radially and axially through bearings 480.

- the steam turbine takes a steam input from an inlet 460 through various stages of expansion, to an outlet 470 leading to a condensor.

- steam is directed by a stator diaphragm 430 onto an impeller rotor 440 thereby converting the temperature and pressure energy of the steam into rotating energy available for work at the rotor shaft 450.

- FIG. 2 shows a portion of a stator blade ring 12 according to an exemplary embodiment of the present invention.

- Stator blade ring 12 includes a plurality of individual stator blade modules 14 extending around rotor 28 ( Fig. 3 ) in steam turbine 10.

- Figure 2 shows two such blade modules 14a and 14b.

- Each stator blade module 14a, 14b includes an elongated blade portion 16, as shown in Figs. 2 and 3 .

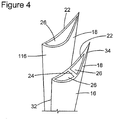

- Fig. 4 shows a cross-sectional view of an elongated blade portion 16 having a longitudinal reinforcing rib 24 and longitudinal passageways 26.

- a blade portion 116 may also be provided without reinforcing rib 24 and may thus have a single longitudinal passageway 26.

- each blade portion 16 is made by brazing a first blade shell portion 18 to a second blade shell portion 22 along the upstream edge 32 and the downstream edge 34 thereof.

- each blade portion 16 includes a plurality of openings 36 in at least one of blade shell portion 22 and blade shell portion 24.

- each opening 36 is a slot formed by electric discharge machining.

- openings 36 may be formed by other machining processes such as drilling or milling, or, openings 36 may be formed during the initial manufacture of blade shell portion 22 and blade shell portion 24, for example, by a mold insert.

- Each blade module 14 includes an inner portion 38 connected to a first longitudinal end of at least one blade portion 16, as shown in Fig. 2 .

- inner portion 38 is brazed to blade portion 16, as will be discussed further below.

- Each inner portion 38 includes a through hole 42 extending transversely to the longitudinal axis 46 ( Fig. 3 ) of blade portion 16.

- Through hole 42 forms a part of an annular chamber 20 in stator blade ring 12 when each of the blade modules are installed into the steam turbine 10.

- at least one end of each through hole 42 may be provided with a groove 48 configured to receive a sealing gasket.

- groove 48 is configured to receive an O-ring.

- Each inner portion 38 also includes at least one inner passageway 44, as shown in Fig. 3 , extending from through hole 42 to each longitudinal passageway 26.

- a single inner passageway 44 may be open to both longitudinal passageways 26.

- Each stator blade module 14 also includes an outer portion 52 connected to a second longitudinal end of at least one blade portion 16, as shown in Figs. 2 and 3 .

- Each outer portion 52 includes at least one outer passageway 54 which is open to each longitudinal passageway 26 and to an interior surface of steam turbine 10, as shown in Figs. 2 , 9 and 10 .

- each outer portion may include a groove 74 on at least one side thereof. Groove 74 may be configured to receive a gasket for sealing adjacent outer portions 52 to each other and/or for providing a dampening effect to stator blade ring 12.

- Stator blade ring 12 may be used in one of the latter stages of the steam turbine 10, as shown in Fig. 2 .

- condensate from the wet steam impinging against each blade portion 14 may enter the longitudinal passageway 26 of a blade portion 16 through one of the openings 36.

- Multiple paths are available for the condensate to travel within the blade modules 14 before exiting outside stator blade ring 12 at a location where the condensate may be less likely to cause damage to the components of steam turbine 10.

- the condensate may travel downwardly through each longitudinal passageway 26 and inner passageway 44 into through hole 42.

- the open through holes 42 in adjacent blade modules 14 that form the annular chamber 20 extending around stator blade ring 12 allow the condensate to continue flowing downwardly with gravity.

- the condensate may exit the annular chamber 20 and continue on a downward path through an inner passageway 44 of a blade module 14 below the rotor shaft of steam turbine 10. Finally, the condensate may flow through an outer passageway 54 to a surface of steam turbine outside of blade ring 12.

- condensate may enter a longitudinal passageway 26 of a blade portion 16 below the rotor shaft of steam turbine 10 and flow out through outer passageway 54 without first travelling through the annular chamber 20 formed by through holes 42.

- stator blade ring 12 allows for the collection of condensate which may include residual heat for use in other processes.

- Some blade modules for example, blade modules above the rotor shaft of steam turbine 10, may be provided without an outer passageway 54, for example, to reduce manufacturing costs, since the downward flow of condensate may obviate the need for outer passageways 54 in blade modules 14 above the rotor shaft.

- some blade modules 14 may be provided with blade portions 16 without slots, for example, to further reduce manufacturing costs.

- each of the blade modules 14 may be identical to one another. This feature provides a number of benefits. For example, the manufacturing process is rendered more uniform. Also, servicing of steam turbine 10 is also more convenient in that, during repair or replacement of a single blade module 14 which is made possible by the exemplary embodiment, only a single part number is necessary since all blade modules 14 are identical within the stator blade ring 12.

- blade modules 14 provide a simple one piece design which is easier to install and/or replace than conventional stator blade diaphragm rings.

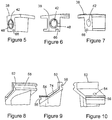

- the outer portion 52 of each stator blade module 14 is engaged directly to steam turbine 10.

- each outer portion 52 includes an upstream groove 56 and a downstream groove 58.

- Steam turbine 10 includes an upstream ridge 62 engaging groove 56 and a downstream ridge 64 engaging groove 58.

- Groove 56 is offset closer to inner portion 38 than groove 58.

- each stator blade module may be used to better conform to the desired flow path of the steam through steam turbine 10, and may also prevent a technician from inadvertently installing a blade module 14 in an improper orientation during construction or servicing of stator blade ring 12.

- outer passageway 54 opens to a surface of steam turbine 10 between ridge 62 and ridge 64.

- a chamber 76 is formed between the outer surface of blade ring 12 and the surface of steam turbine 10. Chamber 76 may facilitate convenient collection of condensate which flows out of outer passageways 54.

- a groove 66 in each inner portion 38 forms a continuous circumferential groove facing a center of stator blade ring 12, as shown in Figs. 2, 3 , and 5-7 . As shown in Fig. 3 , each groove 66 is engaged by a metal ring 68 which locks the stator blade modules 14 together.

- each stator blade module 14 defines an inner brazing platform 72 surrounding the first longitudinal end of each blade portion 16.

- the outer portion 52 of each stator blade module defines an outer brazing platform 74 surrounding the second longitudinal end of each blade portion 16.

- Brazing platform 72 and brazing platform 74 provide a convenient surface for brazing the longitudinal ends of each blade portion 16 as well as defining a portion of a stage and/or steam flow path within steam turbine 10. Note from Figs. 2 and 3 that the brazing platform 74 of each outer portion 52 transitions evenly to the surrounding surfaces of steam turbine 10.

- blade shell portion 18 may be vacuum brazed to blade shell portion 22.

- the first and second longitudinal ends of the resulting blade portion 16 may then be vacuum brazed to the inner portion 38 and outer portion 52 of each stator blade module 14.

- the vacuum brazing equipment used to perform the vacuum brazing of diaphragm 14 can be standard vacuum brazing equipment as, for example, disclosed in U.S. Patent Nos. 4,874,918 and 4,401,254 .

- a method (1000) of making a blade module for a stator blade ring can include the steps of brazing (1002) first and second edges of a first blade shell portion to first and second edges of a second blade shell portion to form a longitudinal passageway in the elongated blade portion, forming (1004) a through hole in the inner portion, forming (1006) an inner passageway in the inner portion extending from a surface of the inner portion to the through hole, brazing (1008) a first longitudinal end of the blade portion to the surface of the inner portion such that the longitudinal passageway is open to the inner passageway, forming (1010) an outer passageway in the outer portion extending from a first surface to a second surface of the outer portion, and, brazing (1012) a second longitudinal end of the blade portion to the first surface of the outer portion such that the longitudinal passageway is open to the outer passageway.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

Description

- The present invention relates generally to steam turbines and, more specifically, to a stator blade ring for a steam turbine and a method of making a stator blade ring.

- A steam turbine is a turbo machine which converts thermal and pressure energy of steam into rotary motion which may be used to perform work. Steam turbines may be used, for example, to drive electrical generators or compressors.

- To enhance steam turbine efficiency, steam is often expanded through a number of stages. Each stage typically includes a stator blade diaphragm and a bearing mounted rotor assembly including at least one impeller.

-

US 3 881 842 discloses a diaphragm for the ultimate stage of a steam turbine comprising welded hollow blades. Each hollow blade has a slot for liquid phase removal with each slot communicating with an interior of the guide blade. The interior of the guide blade is communicated only with an annular channel of the rim and with an annular channel of the body. The rim is provided with openings adapted to establish communication between the channel and a condenser. - As steam progresses through the latter stages of the steam turbine, sufficient energy may be absorbed from the steam to cause portions of the steam to condense, and thus, to become so called, wet steam. In addition to having a potential corrosive effect, when wet steam impinges against the stator blade diaphragm, the condensate tends to violently impact the stator blades and other parts of the diaphragm. As a result, the stator blades and other portions of each stator blade diaphragm in the latter stages of the steam turbine may be damaged, for example, during prolonged exposure to wet steam having a high proportion of condensate.

- In modem steam turbines, the manufacture of stator blade diaphragms represents a significant cost, particularly in multi stage steam turbines having three or more stages each of which may include one or more separate stator blade diaphragms.

- If a stator blade diaphragm is damaged, the steam turbine may need to be shut down and the damaged stator diaphragm removed for servicing. If on site repair is not possible, the entire diaphragm may need to be sent for repair or alternatively, an entire new stator diaphragm must be installed. Worse yet, if a replacement is available, a new stator blade diaphragm must be fabricated. Thus, in addition to the cost of the stator diaphragm, costs associated with the extended downtime of the steam turbine are also incurred. Accordingly, what is needed is a replacement for the conventional stator blade diaphragm, which is easily serviced and/or replaced, which is capable of successful operation in the presence of wet steam, and which provides a simple design which is easier manufactured.

- The present invention relates to a stator blade ring for a steam turbine according to claim 1 including a plurality of stator blade modules defining an annular chamber, each stator blade module including an elongated blade portion including a first blade shell portion and a second blade shell portion brazed to the first blade shell portion. The elongated blade portion further includes a longitudinal passageway and at least one opening extending through one of the first blade shell portion and the second blade shell portion to the longitudinal passageway. An inner portion brazed to a first longitudinal end of the blade portion, the inner portion including a through hole forming a portion of the annular chamber, the inner portion further including an inner passageway extending from the through hole to the longitudinal passageway. An outer portion brazed to a second longitudinal end of the blade portion and engaged to the steam turbine, the outer portion including an outer passageway open to a surface of the steam turbine and the longitudinal passageway.

- According to another exemplary embodiment, a turbo machine includes a rotor assembly including at least one impeller, a bearing connected to, and for rotatably supporting, the rotor assembly, and a stator blade ring having a plurality of stator blade modules defining an annular chamber. Each blade module includes at least one elongated blade portion including a first blade shell portion and a second blade shell portion brazed to the first blade shell portion, an inner portion brazed to a first longitudinal end of the at least one blade portion, the inner portion including a through hole forming a portion of the annular chamber, and an outer portion brazed to a second longitudinal end of the at least one blade portion and engaged to a surface of the steam turbine. At least one of the blade modules includes a longitudinal passageway and at least one opening in the at least one blade portion for liquid to enter the longitudinal passageway and an inner passageway in the inner portion extending from the through hole to the longitudinal passageway for allowing the liquid to flow between the annular chamber and the longitudinal passageway. At least one of the blade modules includes a longitudinal passageway in the at least one blade portion, an inner passageway in the inner portion extending from the through hole to the longitudinal passageway for allowing the liquid to flow between the annular chamber and the longitudinal passageway and an outer passageway in the outer portion extending from the longitudinal passageway and opening to the surface of the turbo machine for allowing the liquid to flow out of the stator blade ring. Furthermore the invention relates to a method of making a blade module for a stator blade ring according to claim 11 including the steps of brazing first and second edges of a first blade shell portion to first and second edges of a second blade shell portion to provide an elongated blade portion having a longitudinal passageway, forming a through hole in the inner portion, forming an inner passageway in the inner portion extending from a surface of the inner portion to the through hole, brazing a first longitudinal end of the blade portion to the surface of the inner portion such that the longitudinal passageway is open to the inner passageway, forming an outer passageway in the outer portion extending from a first surface to a second surface of the outer portion, and, brazing a second longitudinal end of the blade portion to the first surface of the outer portion such that the longitudinal passageway is open to the outer passageway.

- The accompanying drawings, which are incorporated in and constitute a part of the specification, illustrate one or more embodiments and, together with the description, explain these embodiments. In the drawings:

-

Figure 1 depicts a steam turbine. -

Figure 2 shows a perspective view of an exemplary embodiment. -

Figure 3 shows a side view of the exemplary embodiment ofFigure 2 . -

Figure 4 shows a cross-sectional view of the exemplary embodiment shown inFigure 2 . -

Figures 5 to 7 show an inner portion of the exemplary embodiment shown inFig. 2 . -

Figures 8 to 10 show an outer portion of the exemplary embodiment shown inFig. 2 . -

Figure 11 is a flowchart illustrating a method of making a blade module for a stator blade ring according to an exemplary embodiment. - The following description of the exemplary embodiments refers to the accompanying drawings. The same reference numbers in different drawings identify the same or similar elements. The following detailed description does not limit the invention. Instead, the scope of the invention is defined by the appended claims. The following embodiments are discussed, for simplicity, with regard to the terminology and structure of a turbo machine that has a stator and a rotor. However, the embodiments to be discussed next are not limited to these exemplary systems, but may be applied to other systems.

- Reference throughout the specification to "one embodiment" or "an embodiment" means that a particular feature, structure, or characteristic described in connection with an embodiment is included in at least one embodiment of the subject matter disclosed. Thus, the appearance of the phrases "in one embodiment" or "in an embodiment" in various places throughout the specification is not necessarily referring to the same embodiment. Further, the particular features, structures or characteristics may be combined in any suitable manner in one or more embodiments.

- To provide some context for the subsequent discussion relating to stator blades according to these exemplary embodiments,

Figure 1 schematically illustrates a turbo machine in the form of amultistage steam turbine 400. Therein, thesteam turbine 400 includes a housing (stator) 420 within which a number ofstator blade diaphragms 430 are disposed along with arotor shaft 450 provided with a plurality ofimpeller rotors 440. Theshaft 450 is supported radially and axially throughbearings 480. - During operation, the steam turbine takes a steam input from an

inlet 460 through various stages of expansion, to anoutlet 470 leading to a condensor. At each turbine stage, steam is directed by astator diaphragm 430 onto animpeller rotor 440 thereby converting the temperature and pressure energy of the steam into rotating energy available for work at therotor shaft 450. -

Figure 2 shows a portion of astator blade ring 12 according to an exemplary embodiment of the present invention.Stator blade ring 12 includes a plurality of individual stator blade modules 14 extending around rotor 28 (Fig. 3 ) insteam turbine 10.Figure 2 shows twosuch blade modules - Each

stator blade module elongated blade portion 16, as shown inFigs. 2 and 3 .Fig. 4 shows a cross-sectional view of anelongated blade portion 16 having a longitudinal reinforcingrib 24 andlongitudinal passageways 26. As is further shown inFig. 4 , ablade portion 116 may also be provided without reinforcingrib 24 and may thus have a singlelongitudinal passageway 26. As will be discussed in further detail below, eachblade portion 16 is made by brazing a firstblade shell portion 18 to a secondblade shell portion 22 along theupstream edge 32 and thedownstream edge 34 thereof. - As further shown in

Figs. 2 to 4 , eachblade portion 16 includes a plurality ofopenings 36 in at least one ofblade shell portion 22 andblade shell portion 24. In the embodiment ofFigs. 2 to 4 , eachopening 36 is a slot formed by electric discharge machining. Alternatively,openings 36 may be formed by other machining processes such as drilling or milling, or,openings 36 may be formed during the initial manufacture ofblade shell portion 22 andblade shell portion 24, for example, by a mold insert. - Each blade module 14 includes an

inner portion 38 connected to a first longitudinal end of at least oneblade portion 16, as shown inFig. 2 . In the embodiment shown inFigs. 2 to 4 ,inner portion 38 is brazed toblade portion 16, as will be discussed further below. Eachinner portion 38 includes a throughhole 42 extending transversely to the longitudinal axis 46 (Fig. 3 ) ofblade portion 16. Throughhole 42 forms a part of anannular chamber 20 instator blade ring 12 when each of the blade modules are installed into thesteam turbine 10. In order to enhance the seal between throughholes 42 in adjacent blade modules 14, at least one end of each throughhole 42 may be provided with agroove 48 configured to receive a sealing gasket. In the embodiment ofFigs. 2 to 4 , groove 48 is configured to receive an O-ring. - Each

inner portion 38 also includes at least oneinner passageway 44, as shown inFig. 3 , extending from throughhole 42 to eachlongitudinal passageway 26. Alternatively, ifreinforcement rib 24 is terminated prior to the longitudinal end ofblade portion 16, then a singleinner passageway 44 may be open to bothlongitudinal passageways 26. - Each stator blade module 14 also includes an

outer portion 52 connected to a second longitudinal end of at least oneblade portion 16, as shown inFigs. 2 and 3 . Eachouter portion 52 includes at least oneouter passageway 54 which is open to eachlongitudinal passageway 26 and to an interior surface ofsteam turbine 10, as shown inFigs. 2 ,9 and 10 . Further, in the embodiment ofFigs. 2 to 4 and8-10 , each outer portion may include agroove 74 on at least one side thereof.Groove 74 may be configured to receive a gasket for sealing adjacentouter portions 52 to each other and/or for providing a dampening effect tostator blade ring 12.Stator blade ring 12 may be used in one of the latter stages of thesteam turbine 10, as shown inFig. 2 . During operation, condensate from the wet steam impinging against each blade portion 14 may enter thelongitudinal passageway 26 of ablade portion 16 through one of theopenings 36. Multiple paths are available for the condensate to travel within the blade modules 14 before exiting outsidestator blade ring 12 at a location where the condensate may be less likely to cause damage to the components ofsteam turbine 10. In one path, which may include stator blade modules 14 above the rotor shaft, the condensate may travel downwardly through eachlongitudinal passageway 26 andinner passageway 44 into throughhole 42. The open throughholes 42 in adjacent blade modules 14 that form theannular chamber 20 extending aroundstator blade ring 12 allow the condensate to continue flowing downwardly with gravity. The condensate may exit theannular chamber 20 and continue on a downward path through aninner passageway 44 of a blade module 14 below the rotor shaft ofsteam turbine 10. Finally, the condensate may flow through anouter passageway 54 to a surface of steam turbine outside ofblade ring 12. - In another path, condensate may enter a

longitudinal passageway 26 of ablade portion 16 below the rotor shaft ofsteam turbine 10 and flow out throughouter passageway 54 without first travelling through theannular chamber 20 formed by throughholes 42. - The removal of condensate from the wet steam progressing through the latter stages of

steam turbine 10 may prevent damage to thestator blade ring 12 as well as to theturbine blades 16 and other downstream components ofsteam turbine 10. Moreover,stator blade ring 12 allows for the collection of condensate which may include residual heat for use in other processes. - Some blade modules, for example, blade modules above the rotor shaft of

steam turbine 10, may be provided without anouter passageway 54, for example, to reduce manufacturing costs, since the downward flow of condensate may obviate the need forouter passageways 54 in blade modules 14 above the rotor shaft. Further, some blade modules 14 may be provided withblade portions 16 without slots, for example, to further reduce manufacturing costs. Alternatively, and as shown in the embodiment ofFigs. 2-3 and5-10 , each of the blade modules 14 may be identical to one another. This feature provides a number of benefits. For example, the manufacturing process is rendered more uniform. Also, servicing ofsteam turbine 10 is also more convenient in that, during repair or replacement of a single blade module 14 which is made possible by the exemplary embodiment, only a single part number is necessary since all blade modules 14 are identical within thestator blade ring 12. - In addition to providing cost savings over stator blade diaphragms which may need to be serviced or replaced as a unit, blade modules 14 provide a simple one piece design which is easier to install and/or replace than conventional stator blade diaphragm rings. As shown in

Figs. 2, 3 and8 to 10 , theouter portion 52 of each stator blade module 14 is engaged directly tosteam turbine 10. Specifically, eachouter portion 52 includes anupstream groove 56 and adownstream groove 58.Steam turbine 10 includes anupstream ridge 62 engaginggroove 56 and adownstream ridge 64 engaginggroove 58.Groove 56 is offset closer toinner portion 38 thangroove 58. The offset betweengrooves steam turbine 10, and may also prevent a technician from inadvertently installing a blade module 14 in an improper orientation during construction or servicing ofstator blade ring 12. - As shown in

Figs. 2 and 3 ,outer passageway 54 opens to a surface ofsteam turbine 10 betweenridge 62 andridge 64. Note that achamber 76 is formed between the outer surface ofblade ring 12 and the surface ofsteam turbine 10.Chamber 76 may facilitate convenient collection of condensate which flows out ofouter passageways 54. - A

groove 66 in eachinner portion 38 forms a continuous circumferential groove facing a center ofstator blade ring 12, as shown inFigs. 2, 3 , and5-7 . As shown inFig. 3 , eachgroove 66 is engaged by ametal ring 68 which locks the stator blade modules 14 together. - As further shown in

Figs. 2, 3 and5 to 7 , theinner portion 38 of each stator blade module 14 defines an inner brazing platform 72 surrounding the first longitudinal end of eachblade portion 16. Also, as shown inFigs. 2, 3 and8 to 10 , theouter portion 52 of each stator blade module defines anouter brazing platform 74 surrounding the second longitudinal end of eachblade portion 16. - Brazing platform 72 and

brazing platform 74 provide a convenient surface for brazing the longitudinal ends of eachblade portion 16 as well as defining a portion of a stage and/or steam flow path withinsteam turbine 10. Note fromFigs. 2 and 3 that thebrazing platform 74 of eachouter portion 52 transitions evenly to the surrounding surfaces ofsteam turbine 10. - In the embodiment of

Figs. 2 to 4 ,blade shell portion 18 may be vacuum brazed toblade shell portion 22. The first and second longitudinal ends of the resultingblade portion 16 may then be vacuum brazed to theinner portion 38 andouter portion 52 of each stator blade module 14. The vacuum brazing equipment used to perform the vacuum brazing of diaphragm 14 can be standard vacuum brazing equipment as, for example, disclosed inU.S. Patent Nos. 4,874,918 and4,401,254 . - Thus, according to an exemplary embodiment shown in

Fig. 11 , a method (1000) of making a blade module for a stator blade ring, the blade module including an elongated blade portion, an inner portion, and an outer portion, can include the steps of brazing (1002) first and second edges of a first blade shell portion to first and second edges of a second blade shell portion to form a longitudinal passageway in the elongated blade portion, forming (1004) a through hole in the inner portion, forming (1006) an inner passageway in the inner portion extending from a surface of the inner portion to the through hole, brazing (1008) a first longitudinal end of the blade portion to the surface of the inner portion such that the longitudinal passageway is open to the inner passageway, forming (1010) an outer passageway in the outer portion extending from a first surface to a second surface of the outer portion, and, brazing (1012) a second longitudinal end of the blade portion to the first surface of the outer portion such that the longitudinal passageway is open to the outer passageway. - The above-described exemplary embodiments are intended to be illustrative in all respects, rather than restrictive, of the present invention. Thus the present invention is capable of many variations in detailed implementation that can be derived from the description contained herein by a person skilled in the art. All such variations and modifications are considered to be within the scope of the present invention as defined by the following claims.

Claims (11)

- A stator blade ring (12) for a steam turbine, said stator blade ring comprising:a plurality of stator blade modules (14) defining an annular chamber, each stator blade module comprising,an elongated blade portion (16) including a first blade shell portion (18) and a second blade shell portion (22) brazed to said first blade shell portion, said elongated blade portion (16) further including a longitudinal passageway (26) and at least one opening (36) extending through at least one of said first blade shell portion (18) and said second blade shell portion (22) to said longitudinal passageway (26);an inner portion (38) brazed to a first longitudinal end of said blade portion (16), said inner portion (38) including a through hole (42) forming a portion of said annular chamber (20), said inner portion (38) further including an inner passageway (44) extending from said through hole (42) to said longitudinal passageway (26); andan outer portion (52) brazed to a second longitudinal end of said blade portion (16) and engaged to said steam turbine, said outer portion (52) including an outer passageway (54) open to a surface of said steam turbine and said longitudinal passageway (26).

- The stator blade ring of claim 1, wherein said outer portion (52) includes a first groove (56) configured to engage a first ridge in said surface of said steam turbine and a second groove (58) configured to engage a second ridge in said surface of said steam turbine.

- The stator blade ring of claim 1 or claim 2, wherein said first groove (56) and said second groove (58) are offset relative to said inner portion (38).

- The stator blade ring of any preceding claim, wherein a groove (66) in said inner portion (38) of each said blade module (14) forms a circumferential groove in said stator blade ring and said circumferential groove is engaged by a metal ring (68) for locking said plurality of blade modules (14) together.

- The stator blade ring of claim 4, wherein said circumferential groove faces inwardly towards a center of said stator blade ring.

- A steam turbine comprising:a rotor assembly including at least one impeller;a bearing connected to, and for rotatably supporting the rotor assembly anda stator blade ring according to any one of the preceding claims.

- A multi-stage steam turbine comprising:a rotor assembly including at least one impeller ;a bearing connected to, and for rotatably supporting, the rotor assembly;a stator blade ring according to any one of claims 1 to 5 for the last stage of the steam turbine.

- The steam turbine of claim 7, wherein a first groove (56) in said outer portion of each said blade module is engaged by a first ridge on said surface of said steam turbine.

- The steam turbine of claim 7 or claim 8, wherein a second groove (58) in said outer portion of each said blade module is engaged by a second ridge on said surface of said steam turbine.

- The steam turbine of any of claims 7 to 9, wherein said first groove faces upstream and said second groove faces downstream of a flow of working fluid within said turbo machine.

- A method of making a blade module for a stator blade ring in the last stage of a steam turbine, the blade module including an elongated blade portion, an inner portion, and an outer portion, said method comprising:brazing first and second edges of a first blade shell portion to first and second edges of a second blade shell portion to form a longitudinal passageway in said elongated blade portion (1002);forming a through hole in said inner portion (1004);forming an inner passageway in said inner portion extending from a surface of said inner portion to said through hole (1006);brazing a first longitudinal end of said blade portion to said surface of said inner portion such that said longitudinal passageway is open to said inner passageway (1008);forming an outer passageway in said outer portion extending from a first surface to a second surface of said outer portion (1010); andbrazing a second longitudinal end of said blade portion to said first surface of said outer portion such that said longitudinal passageway is open to said outer passageway (1012).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL12195193T PL2604801T3 (en) | 2011-12-12 | 2012-12-03 | Stator blade ring and method of making the ring |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT000060A ITCO20110060A1 (en) | 2011-12-12 | 2011-12-12 | STEAM TURBINE, PALLET AND METHOD |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2604801A1 EP2604801A1 (en) | 2013-06-19 |

| EP2604801B1 true EP2604801B1 (en) | 2018-03-14 |

Family

ID=45571626

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12195193.3A Not-in-force EP2604801B1 (en) | 2011-12-12 | 2012-12-03 | Stator blade ring and method of making the ring |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US20130149106A1 (en) |

| EP (1) | EP2604801B1 (en) |

| JP (1) | JP6163299B2 (en) |

| KR (1) | KR102016170B1 (en) |

| CN (1) | CN103161512A (en) |

| CA (1) | CA2797235C (en) |

| IN (1) | IN2012DE03364A (en) |

| IT (1) | ITCO20110060A1 (en) |

| PL (1) | PL2604801T3 (en) |

| RU (1) | RU2631852C2 (en) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITCO20130051A1 (en) * | 2013-10-23 | 2015-04-24 | Nuovo Pignone Srl | METHOD FOR THE PRODUCTION OF A STAGE OF A STEAM TURBINE |

| PL3215715T3 (en) * | 2014-11-03 | 2021-03-08 | Nuovo Pignone S.R.L. | Sector for the assembly of a stage of a turbine and corresponding manufacturing method |

| CN105772244B (en) * | 2016-04-29 | 2018-08-10 | 泉州市宏恩新能源汽车科技有限公司 | A kind of aerodynamics nozzle |

| CN106754169A (en) * | 2016-11-18 | 2017-05-31 | 贵州省仁怀市茅台镇君丰酒业有限公司 | The brewage process of white wine |

| CN110945212B (en) * | 2017-09-05 | 2022-07-08 | 三菱重工业株式会社 | Steam turbine blade, steam turbine, and method for manufacturing steam turbine blade |

| JP7369301B2 (en) * | 2020-08-13 | 2023-10-25 | 三菱重工業株式会社 | Stator blade segment and steam turbine equipped with the same |

| CN113007126A (en) * | 2021-02-26 | 2021-06-22 | 英飞同仁风机股份有限公司 | Multi-stage centrifugal blower partition plate, preparation method thereof and multi-stage centrifugal blower |

Family Cites Families (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB760734A (en) * | 1954-03-12 | 1956-11-07 | English Electric Co Ltd | Improvements in and relating to steam turbines |

| DE2038047A1 (en) * | 1970-07-31 | 1972-02-03 | Maschf Augsburg Nuernberg Ag | Drainage of the surfaces of the guide vanes and the flow space of steam turbines, especially saturated and wet steam turbines |

| US3724967A (en) * | 1971-10-28 | 1973-04-03 | Westinghouse Electric Corp | Moisture removal device for a steam turbine |

| JPS503844Y1 (en) * | 1973-01-22 | 1975-02-01 | ||

| GB1411057A (en) * | 1973-04-06 | 1975-10-22 | Kosyak J F | Steam turbines |

| US3881842A (en) * | 1973-04-10 | 1975-05-06 | Jury Fedorovich Kosyak | Diaphragm for steam turbine stage |

| US4401254A (en) | 1980-09-29 | 1983-08-30 | Stewart-Warner Corporation | Vacuum brazing process with improved gettering |

| US4701102A (en) * | 1985-07-30 | 1987-10-20 | Westinghouse Electric Corp. | Stationary blade assembly for a steam turbine |

| SU1386719A1 (en) * | 1986-10-15 | 1988-04-07 | Харьковский политехнический институт им.В.И.Ленина | Stator vanes of axial-flow turbine |

| US4874918A (en) | 1987-02-14 | 1989-10-17 | Nihon Sinku Gijutsu Kabusiki Kaisha | Vacuum brazing apparatus |

| JPS63263204A (en) * | 1987-04-21 | 1988-10-31 | Toshiba Corp | Erosion prevention device for turbine blade |

| JPS6445904A (en) * | 1987-08-13 | 1989-02-20 | Toshiba Corp | Steam turbine nozzle |

| JPH0326802A (en) * | 1989-06-23 | 1991-02-05 | Hitachi Ltd | Stationary blade apparatus of steam turbine |

| JP2760621B2 (en) * | 1990-02-09 | 1998-06-04 | 株式会社東芝 | Steam turbine nozzle |

| JP2723334B2 (en) * | 1990-04-12 | 1998-03-09 | 株式会社東芝 | Steam turbine nozzle water droplet removal equipment |

| JP3630740B2 (en) * | 1994-12-08 | 2005-03-23 | 株式会社東芝 | Drain discharge device for steam turbine |

| JPH1122410A (en) * | 1997-06-30 | 1999-01-26 | Toshiba Corp | Moisture content separation device of steam turbine and its manufacture |

| EP0894558A1 (en) * | 1997-07-29 | 1999-02-03 | Siemens Aktiengesellschaft | Turbine blade and method of fabrication of a turbine blade |

| DE10005250B4 (en) * | 1999-02-09 | 2004-10-28 | Mtu Aero Engines Gmbh | Process for the production of fiber-reinforced metallic components |

| FR2829176B1 (en) * | 2001-08-30 | 2005-06-24 | Snecma Moteurs | STATOR CASING OF TURBOMACHINE |

| JP2004124751A (en) * | 2002-09-30 | 2004-04-22 | Toshiba Corp | Moisture separation device for steam turbine |

| JP4269763B2 (en) * | 2003-04-28 | 2009-05-27 | 株式会社Ihi | Turbine nozzle segment |

| FR2885310B1 (en) * | 2005-05-09 | 2008-12-26 | Snecma Services Sa | METHOD FOR MANUFACTURING A HOLLOW DAWN COMPRISING A TUB SHAPED TOP, A METHOD FOR REPAIRING SUCH A BLADE AND DAWN OBTAINED BY ONE OF THESE PROCESSES |

| JP2007023895A (en) * | 2005-07-15 | 2007-02-01 | Toshiba Corp | Steam turbine, turbine nozzle diaphragm, nozzle blade used for same and method for manufacturing same |

| US7780407B2 (en) * | 2006-01-04 | 2010-08-24 | General Electric Company | Rotary machines and methods of assembling |

| JP4908137B2 (en) * | 2006-10-04 | 2012-04-04 | 株式会社東芝 | Turbine rotor and steam turbine |

| US7713024B2 (en) * | 2007-02-09 | 2010-05-11 | General Electric Company | Bling nozzle/carrier interface design for a steam turbine |

| US20110200430A1 (en) * | 2010-02-16 | 2011-08-18 | General Electric Company | Steam turbine nozzle segment having arcuate interface |

| FR2981602B1 (en) * | 2011-10-25 | 2017-02-17 | Snecma Propulsion Solide | PROCESS FOR MANUFACTURING TURBINE DISPENSER SECTOR OR COMPRESSOR RECTIFIER OF COMPOSITE MATERIAL FOR TURBOMACHINE AND TURBINE OR COMPRESSOR INCORPORATING A DISPENSER OR RECTIFIER FORMED OF SUCH SECTORS |

-

2011

- 2011-12-12 IT IT000060A patent/ITCO20110060A1/en unknown

-

2012

- 2012-11-01 IN IN3364DE2012 patent/IN2012DE03364A/en unknown

- 2012-11-29 CA CA2797235A patent/CA2797235C/en not_active Expired - Fee Related

- 2012-12-03 PL PL12195193T patent/PL2604801T3/en unknown

- 2012-12-03 EP EP12195193.3A patent/EP2604801B1/en not_active Not-in-force

- 2012-12-07 JP JP2012267849A patent/JP6163299B2/en not_active Expired - Fee Related

- 2012-12-11 RU RU2012153181A patent/RU2631852C2/en not_active IP Right Cessation

- 2012-12-11 KR KR1020120143748A patent/KR102016170B1/en active IP Right Grant

- 2012-12-12 CN CN2012105334531A patent/CN103161512A/en active Pending

- 2012-12-12 US US13/712,258 patent/US20130149106A1/en not_active Abandoned

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| PL2604801T3 (en) | 2018-06-29 |

| RU2012153181A (en) | 2014-06-20 |

| ITCO20110060A1 (en) | 2013-06-13 |

| KR20130066537A (en) | 2013-06-20 |

| CA2797235C (en) | 2019-09-24 |

| EP2604801A1 (en) | 2013-06-19 |

| JP2013122246A (en) | 2013-06-20 |

| CA2797235A1 (en) | 2013-06-12 |

| US20130149106A1 (en) | 2013-06-13 |

| IN2012DE03364A (en) | 2015-07-24 |

| KR102016170B1 (en) | 2019-08-29 |

| RU2631852C2 (en) | 2017-09-26 |

| JP6163299B2 (en) | 2017-07-12 |

| CN103161512A (en) | 2013-06-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2604801B1 (en) | Stator blade ring and method of making the ring | |

| EP2597263B1 (en) | Bucket assembly for turbine system | |

| EP3060758B1 (en) | Method for manufacturing a stage of a steam turbine | |

| US20120134845A1 (en) | Blade for a gas turbine, method for manufacturing a turbine blade, and gas turbine with a blade | |

| EP3163025B1 (en) | Turbine bucket having outlet path in shroud | |

| JP2010156204A (en) | Radial flow fluid machine | |

| CN104251232B (en) | Axial flow turbo-machine compressor drum with blades double fixed form | |

| CN104364474B (en) | Stator vane diaphragm rings, turbine and method | |

| EP2226471B1 (en) | Working fluid extraction in an axial turbine | |

| EP2672062A2 (en) | Nozzle diaphragm inducer | |

| EP2597262B1 (en) | Bucket assembly for turbine system | |

| CN109252903B (en) | Condensed water discharge structure of steam turbine and method for reforming same | |

| US8545170B2 (en) | Turbo machine efficiency equalizer system | |

| US20080050226A1 (en) | Methods and apparatus for fabricating a rotor for a steam turbine | |

| RU2567524C2 (en) | System and method of work fluid extraction from internal volume of turbine machine, and turbine machine with such system | |

| EP3282089B1 (en) | Steam turbine with stationary blades and method of assembling same | |

| WO2014022629A1 (en) | Turbomachine exhaust diffuser | |

| CN109844265A (en) | It is suitable for the multiatage axial flow turbine run under low vapor (steam) temperature | |

| US10697329B2 (en) | Turbine diaphragm drain | |

| EP3426894B1 (en) | Turbine last stage rotor blade with forced driven cooling air |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| 17P | Request for examination filed |

Effective date: 20131219 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20180103 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 979087 Country of ref document: AT Kind code of ref document: T Effective date: 20180315 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602012043933 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20180314 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180614 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 979087 Country of ref document: AT Kind code of ref document: T Effective date: 20180314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180615 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180614 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602012043933 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180716 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 |

|

| 26N | No opposition filed |

Effective date: 20181217 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181203 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20181231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181203 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181231 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181203 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CZ Payment date: 20191125 Year of fee payment: 8 Ref country code: DE Payment date: 20191119 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20191120 Year of fee payment: 8 Ref country code: PL Payment date: 20191121 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20191121 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20121203 Ref country code: MK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180714 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602012043933 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201203 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20201203 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210701 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201203 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201203 |