EP2589909A2 - Dispositif de chauffage ou de séchage de matériaux allongés - Google Patents

Dispositif de chauffage ou de séchage de matériaux allongés Download PDFInfo

- Publication number

- EP2589909A2 EP2589909A2 EP12007469.5A EP12007469A EP2589909A2 EP 2589909 A2 EP2589909 A2 EP 2589909A2 EP 12007469 A EP12007469 A EP 12007469A EP 2589909 A2 EP2589909 A2 EP 2589909A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- elongated

- section

- cavity

- radiant heater

- hollow body

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000001035 drying Methods 0.000 title claims abstract description 26

- 239000000463 material Substances 0.000 title claims abstract description 26

- 238000010438 heat treatment Methods 0.000 title claims description 33

- 238000007599 discharging Methods 0.000 claims abstract description 7

- 230000005855 radiation Effects 0.000 abstract description 9

- 229910052782 aluminium Inorganic materials 0.000 abstract description 3

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 abstract description 3

- 229910052751 metal Inorganic materials 0.000 abstract description 3

- 239000002184 metal Substances 0.000 abstract description 3

- 238000010792 warming Methods 0.000 abstract 1

- 238000001816 cooling Methods 0.000 description 10

- 238000000034 method Methods 0.000 description 6

- 238000005265 energy consumption Methods 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000000758 substrate Substances 0.000 description 2

- 206010013786 Dry skin Diseases 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000010924 continuous production Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 239000003344 environmental pollutant Substances 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 231100000719 pollutant Toxicity 0.000 description 1

- 230000001629 suppression Effects 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F26—DRYING

- F26B—DRYING SOLID MATERIALS OR OBJECTS BY REMOVING LIQUID THEREFROM

- F26B13/00—Machines and apparatus for drying fabrics, fibres, yarns, or other materials in long lengths, with progressive movement

- F26B13/001—Drying and oxidising yarns, ribbons or the like

-

- D—TEXTILES; PAPER

- D02—YARNS; MECHANICAL FINISHING OF YARNS OR ROPES; WARPING OR BEAMING

- D02J—FINISHING OR DRESSING OF FILAMENTS, YARNS, THREADS, CORDS, ROPES OR THE LIKE

- D02J13/00—Heating or cooling the yarn, thread, cord, rope, or the like, not specific to any one of the processes provided for in this subclass

- D02J13/001—Heating or cooling the yarn, thread, cord, rope, or the like, not specific to any one of the processes provided for in this subclass in a tube or vessel

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F26—DRYING

- F26B—DRYING SOLID MATERIALS OR OBJECTS BY REMOVING LIQUID THEREFROM

- F26B3/00—Drying solid materials or objects by processes involving the application of heat

- F26B3/28—Drying solid materials or objects by processes involving the application of heat by radiation, e.g. from the sun

- F26B3/30—Drying solid materials or objects by processes involving the application of heat by radiation, e.g. from the sun from infrared-emitting elements

Definitions

- the invention relates to a device for heating or drying of elongated materials, in particular for yarns or threads.

- Devices for heating or drying of different materials are used in various manufacturing processes.

- devices In the textile, plastics, wire and converting industry, devices are used to heat and dry yarns or filaments after application of a liquid medium during the manufacturing process.

- the known devices are based on the fact that the wetted with a liquid yarn or threads of air flow or infrared radiation are exposed. In general, uniform drying results are achieved with simultaneously high process speeds.

- the infrared radiators used for heating or drying have proven themselves in practice.

- the disadvantage, however, is that conventional infrared emitters have a relatively high power loss.

- the invention is based, on the one hand to improve the heating or drying process of elongated materials, in particular of yarns or threads, on the one hand, and on the other hand to reduce the energy consumption associated with the heating and drying on the object.

- the inventive device for heating or drying of elongated materials in particular yarns or threads, but also wires, has at least one open at the end faces, extending along an axis hollow body with at least one elongated cavity for receiving the elongated materials, which the hollow body in can go through a continuous process.

- a radiant heater extending in the longitudinal direction of the cavity for heating or drying the elongated materials is arranged.

- the device according to the invention is characterized in that the radiation heating extends only over a partial section of the elongated cavity extending along one axis or several different sections of the elongated cavity, wherein a device for supplying and removing a gaseous medium is provided is formed such that the gaseous medium is supplied to the portion of the elongated cavity in which the radiant heater is disposed, and the gaseous medium from the portion in which the radiant heater is not disposed, is removed.

- the gaseous medium thus flows through both the section in which the elongated materials are heated and dried with the radiant heater and the section in which the elongate materials are not heated by the radiant heater.

- the radiant heating extends over several different sections of the elongated cavity, which may be arranged in any sequence, but the device again has one or more sections in which the radiant heater is not arranged.

- Elongated materials are also understood to mean axially symmetrical substrates which may be round or angular. Depending on the diameter, the cavity can also pass through a plurality of elongate materials.

- the gaseous medium may be air or a gas.

- the gaseous medium flowing through the section of the elongate hollow body with the radiant heating serves, on the one hand, to cool the radiant heating.

- the gaseous medium takes up the loss line of the heater as heat energy, whereby the gaseous medium is heated.

- the gaseous medium flows through the subsection without radiation heating, the gaseous medium gives off the heat energy again to the elongate materials, which pass through both subsections.

- the elongated materials are heated and dried in a second process stage.

- the heating or drying process is divided into two sub-processes, wherein in the one sub-process, the heating or drying with a convective heat radiation and in the other sub-process takes place in a previously heated by the radiant heating air flow, this results in not only an improved drying result , but also lower energy consumption.

- Another decisive factor is the relatively small drying space, which the hollow-shaped body encloses, compared to the known dryers.

- a preferred embodiment of the invention provides for the supply and removal of the gaseous medium, a device having at least one inflow channel, which leads into the portion of the elongated cavity in which the radiant heater is disposed, and at least one outflow channel, which of the Subsection of the elongated cavity goes off, on which the radiant heater is not arranged.

- the inflow and outflow can be designed differently.

- the supply of supply air and the discharge of the exhaust air takes place on the side of the elongated hollow body.

- the supply or exhaust air is guided in a closed system, since it may be contaminated with pollutants. In principle, however, it is also possible to supply the air at the one open end side of the elongate hollow body and remove it at the other open end side.

- the device for supplying and removing a gaseous medium preferably has means for conveying the gaseous medium into the inflow channel and Means for conveying the gaseous medium from the outflow on.

- the air is supplied with overpressure and discharged with suppression.

- the device may have arranged in the supply air duct and / or exhaust duct fan or fans.

- the elongated hollow body can be subdivided into a different number of subsections in which a radiant heater is arranged or a radiant heater is not arranged.

- a particularly preferred embodiment provides that the elongated hollow body has only two subsections, wherein in the first subsection the radiant heating is arranged and in the second subsection the radiant heating is not arranged.

- This embodiment allows convection drying in one section and drying with hot air in the other section.

- the hollow body can be traversed by the elongated materials in one or the other direction. Consequently, it is possible to use the device according to the invention as a function of the passage direction of the elongated materials for pre- or post-drying.

- the first section of the elongated hollow body with radiant heating has substantially the same length as the second section without radiant heating.

- An alternative embodiment provides that the first section with radiant heating has a greater length than the second section without radiant heating. In principle, however, it is also possible that the first section is shorter than the second section. Depending on the length of the sections and / or the direction of passage and / or the process speed, different results can be achieved for the materials to be heated or dried. It is also possible for the different sections to be arranged one after the other in an arbitrary sequence.

- the radiant heater may include a plurality of elongated radiator elements distributed around the circumference of the cavity. But it is basically sufficient if the radiant heater has only one elongated radiator element, which is arranged on only one side of the wall of the elongated hollow body.

- a reflector device is preferably provided in the section in which the radiation heating is arranged.

- the hollow body may be formed differently.

- the cavity does not need a circular, but may also have a non-circular, in particular elliptical, parabolic or polygonal cross-section.

- the hollow body is preferably formed as a tubular body, which preferably consists of metal, in particular aluminum.

- the tubular body can form a modular unit that can be combined with other modular units to form a universally applicable drying system.

- the device for heating or drying may be formed as a system consisting of a plurality of hollow bodies, wherein the hollow bodies are arranged one above the other and / or next to one another and / or behind one another. This results in a very compact construction.

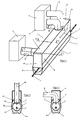

- Fig. 1 shows a simplified representation of the essential components of the device for heating and drying of elongated materials, in particular yarns or threads.

- the inventive device 1 is designed as a continuous dryer, which is traversed by a thread 2.

- the direction of passage of the thread is in Fig. 1 marked with an arrow.

- the device according to the invention has a tubular hollow body 3, which consists of a lower portion 3A and an upper portion 3B, which enclose an elongated cavity 4.

- the hollow body 3 may be a metal body, for example an aluminum body.

- the hollow body 3 is open, so that the thread can enter at one end face 5 and exit at the other end face 6.

- the thread 1 passes through the region of the cavity in the lower portion 3A of the hollow body 3.

- the hollow body 3 is divided into a front section 7 in the direction of yarn advancement and a rear section 8 in the direction of yarn travel.

- the front section 7 can have the same length as the rear section 8 or the front portion may be longer than the rear portion.

- the radiator element 9A is an infrared radiator which extends along the wall of the upper portion 3B of the hollow body 3. Instead of an infrared radiator, however, it is also possible to provide a UV radiator or another radiation source.

- the length of the tubular body may for example be between 250 mm and 6000 mm.

- the diameter of the cavity may, for example, be between 50 mm and 500 mm.

- an elongated cover 11 which can accommodate various components of the device, for example.

- a power supply 12 and the electrical lines 13 ( Fig. 4 ).

- the device according to the invention has a device 14 for supplying air or a gas into the tubular body 3 and for discharging the air or gas from the tubular body 3.

- the device 14 has an aggregate 15 for supplying cooling air, eg. a fan or a fan, and an aggregate 16 for discharging the cooling air, for example, a blower or a fan.

- the one unit 15 generates an overpressure, with which the cooling air is supplied, and the other unit 16 generates a negative pressure, with which the cooling air is discharged.

- two inflow channels 15A, 15B are connected, each extending through the cover 11 to a supply air opening 15C at the top of the upper portion 3B of the hollow body 3 ( Fig. 2 ).

- the supply air openings are located in the front portion 7A of the front portion 7 of the elongated cavity 3, so that the cooling air flows along the elongated heating element 9 through the front portion 7 in the rear portion 8 of the cavity 4.

- the upper section 3B of the hollow body 3 has an outlet opening 17, to which a discharge channel 18 is connected, which leads to the unit 16 for sucking off the cooling air.

- the infrared radiator 9A With the cooling air flowing into the front section 7 of the cavity 4, the infrared radiator 9A is cooled, whereby the cooling air is heated.

- the thread 2 is then in the rear section 8 further heated by the air heated in the front section and dried.

- the cavity 4 of the hollow body 3 can thus be divided into a convective heating zone in which the heat is given by convection to the thread 2, and a zone in which the trough is discharged by hot air to the thread.

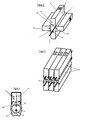

- Fig. 5 shows an alternative embodiment of the device according to the invention, which differs from that with reference to the Fig. 1 to 4 described embodiment differs only by the radiant heater. For the corresponding parts, therefore, the same reference numerals are used.

- the radiant heater 9 has four elongated radiator elements 9A, 9B, 9C, 9D, which may again be infrared radiators.

- the infrared radiators 9A, 9B, 9C, 9D are arranged distributed circumferentially along the cavity 4 of the hollow body 3.

- the adjacent infrared emitters each enclose an angle of 90 °.

- Each infra-red beam is assigned an inflow and an outflow channel. This results in a total of eight air inlets and four air outlets.

- the supply and exhaust air ducts, as well as the means for supplying or discharging air are in Fig. 5 not shown.

- Fig. 6 shows a system for heating and drying elongated materials comprising a plurality of modules 3.

- Each module consists of the referring to the Fig. 1 to 4

- the individual modules are arranged side by side and one above the other in the manner of a matrix, which can be extended in the longitudinal direction by the inclusion of other units. This makes it possible to construct a modular system with the device according to the invention, with which a large number of elongated materials can be heated and dried in a small space with low energy loss.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Life Sciences & Earth Sciences (AREA)

- Microbiology (AREA)

- Drying Of Solid Materials (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102011117604A DE102011117604A1 (de) | 2011-11-04 | 2011-11-04 | Vorrichtung zur Erwärmung oder Trocknung von langgestreckten Materialien |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2589909A2 true EP2589909A2 (fr) | 2013-05-08 |

| EP2589909A3 EP2589909A3 (fr) | 2015-08-26 |

Family

ID=47225880

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12007469.5A Withdrawn EP2589909A3 (fr) | 2011-11-04 | 2012-11-02 | Dispositif de chauffage ou de séchage de matériaux allongés |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP2589909A3 (fr) |

| DE (1) | DE102011117604A1 (fr) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2017005691A1 (fr) * | 2015-07-07 | 2017-01-12 | Oerlikon Textile Gmbh & Co. Kg | Dispositif chauffant |

| CN111519264A (zh) * | 2020-04-24 | 2020-08-11 | 江苏奥神新材料股份有限公司 | 一种纤维加热系统 |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1254631A (en) * | 1968-05-15 | 1971-11-24 | Goodyear Tire & Rubber | Dryer and heater |

| DE8817120U1 (de) * | 1988-04-07 | 1993-02-04 | Vits Maschinenbau Gmbh, 4018 Langenfeld | Vorrichtung zur Wärmebehandlung und/oder Trocknung einer Materialbahn |

-

2011

- 2011-11-04 DE DE102011117604A patent/DE102011117604A1/de not_active Withdrawn

-

2012

- 2012-11-02 EP EP12007469.5A patent/EP2589909A3/fr not_active Withdrawn

Non-Patent Citations (1)

| Title |

|---|

| None |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2017005691A1 (fr) * | 2015-07-07 | 2017-01-12 | Oerlikon Textile Gmbh & Co. Kg | Dispositif chauffant |

| CN111519264A (zh) * | 2020-04-24 | 2020-08-11 | 江苏奥神新材料股份有限公司 | 一种纤维加热系统 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2589909A3 (fr) | 2015-08-26 |

| DE102011117604A1 (de) | 2013-05-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3811620C2 (fr) | ||

| DE4223779C1 (de) | Solaranlage mit einem Lufterhitzer und Luftrückführung | |

| EP3720716B1 (fr) | Procédé pour le séchage d'un substrat, module de séchage pour la mise en oeuvre du procédé ainsi que système de séchage | |

| EP2225044B2 (fr) | Dispositif de refroidissement et procédé de refroidissement d'objets sortant d'un dispositif d'application de revêtement | |

| DE4436713B4 (de) | Vorrichtung zur Trocknung der Oberflächen eines Gegenstandes | |

| EP2589909A2 (fr) | Dispositif de chauffage ou de séchage de matériaux allongés | |

| EP2063206B1 (fr) | Dispositif destiné au traitement d'une bande de substrat | |

| DE20104205U1 (de) | Heißlufttrockner für eine Beschichtungsanlage | |

| AT521541B1 (de) | Verfahren zum Erhitzen eines Mediums | |

| DE19538364C5 (de) | Vorrichtung zur Schnellerwärmung von Metall-Preßbolzen | |

| CH656696A5 (de) | Verfahren und vorrichtung zum intensiven waerme- und/oder stoffaustausch, insbesondere in oefen. | |

| DE102004059903A1 (de) | Verfahren und Anlage zum Beschichten eines Matallbands mit einer lösemittelhaltigen Beschichtung und zum Trocknen und/oder Vernetzen derselben | |

| EP2192366B1 (fr) | Dispositif de rayonnement d'un substrat | |

| EP0937955A1 (fr) | Système de séchage à chauffage par rayonnement | |

| WO2015039732A1 (fr) | Dispositif à flux de gaz pour une installation destinée au traitement par irradiation de substrats | |

| DE2422906C2 (de) | Vakuumfilter zum Abscheiden von Feststoffen aus Dämpfen oder dergleichen | |

| DE10258262A1 (de) | Heizvorrichtung und Verfahren zum Erwärmen eines Fadens | |

| DE2854911C2 (fr) | ||

| EP3765806B1 (fr) | Boîte à buses pour un dispositif de séchage servant à sécher des matériaux en forme de panneau | |

| EP3291651B1 (fr) | Dispositif et procédé de production d'un plasma atmosphérique | |

| DE102007025760A1 (de) | Trockner mit Infrarotheizung | |

| DD263427A3 (de) | Vorrichtung zum trocknen spezifischer teilabschnitte an einer geschlossenen oberflaeche | |

| DE102010000509B4 (de) | Einrichtung zur Wärmerückgewinnung in einer Abluftanlage einer Wärmebehandlungsmaschine | |

| DE1497431C3 (de) | Kühleinrichtung für den Belichtungszylinder eines Photokopiergeräts | |

| DE102022113076A1 (de) | Behandlungsanlage zum Behandeln von Werkstücken und ein Verfahren zum Behandeln von Werkstücken |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F26B 3/30 20060101AFI20150717BHEP Ipc: F26B 13/00 20060101ALI20150717BHEP |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Effective date: 20150925 |