EP2500115B1 - Procédé de mise en forme de tôles mécano soudées de forte épaisseur et structure obtenue par ce procédé - Google Patents

Procédé de mise en forme de tôles mécano soudées de forte épaisseur et structure obtenue par ce procédé Download PDFInfo

- Publication number

- EP2500115B1 EP2500115B1 EP12156603.8A EP12156603A EP2500115B1 EP 2500115 B1 EP2500115 B1 EP 2500115B1 EP 12156603 A EP12156603 A EP 12156603A EP 2500115 B1 EP2500115 B1 EP 2500115B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- sheet

- groove

- folded

- key

- forming process

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 title claims description 18

- 238000007493 shaping process Methods 0.000 title description 3

- 239000011324 bead Substances 0.000 claims description 6

- 239000000463 material Substances 0.000 description 5

- 238000005452 bending Methods 0.000 description 3

- 238000003754 machining Methods 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 238000010276 construction Methods 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D11/00—Bending not restricted to forms of material mentioned in only one of groups B21D5/00, B21D7/00, B21D9/00; Bending not provided for in groups B21D5/00 - B21D9/00; Twisting

- B21D11/08—Bending by altering the thickness of part of the cross-section of the work

Definitions

- the technical field of the invention is that of folding processes of thick sheets and in particular the folding of sheets intended to form part of a mechanically welded structure of a shielded vehicle.

- the patent GB2197810 proposes a method of shaping sheets to produce housings or technical cabinets according to the preamble of claim 1.

- This patent teaches to machine at least one groove in the sheet perpendicular to the direction of bending.

- the groove thus made causes a reduction in the thickness of the sheet which allows easier folding.

- This solution is well suited for the realization of technical cabinets for which the thickness of the sheet is reduced and the problem of ballistic resistance does not arise.

- This solution is however not transferable to the field of folding of thick sheets, particularly for sheets for the realization of vehicle structures and for which the ballistic continuity of the structure is essential. Indeed, if the thickness of the sheet is less in the corners, it will be all the easier to perforate by a projectile.

- the structure in general is weakened at the level of the fold.

- the invention proposes to solve this problem by practicing a groove of a particular type which has a recess in its bottom.

- the planes defining the groove can be brought into contact during bending or the groove can accommodate a key corresponding to the plans of the groove.

- the thickness of material at the corner thus created will be at least equal to the thickness of the sheet.

- the particular shape of the recess will make it possible to distribute the stresses generated by the folding.

- the invention has the main advantage of providing a method for obtaining acceptable ballistic continuity.

- the invention also has the advantage of allowing reduced radii of curvature to be obtained.

- the invention also has the advantage of precisely positioning the folding operation while simplifying the implementation of this operation.

- the invention makes it possible to obtain a geometrical precision of the folded part which avoids post-bending machining.

- the invention also has the advantage of distributing the folding stresses.

- the subject of the invention is a process for forming a sheet of high thickness, comprising at least one folding step along a fold line according to claim 1.

- the recess comprises a bulge at the bottom of the groove.

- the groove is delimited by two intersecting planes (V-groove).

- the sheet is folded so that the planes delimiting the groove bear against one another and then the outer edges of the groove are secured by at least one weld bead.

- a key having surfaces intended to come into contact after folding with the planes delimiting the groove is positioned at the level of the groove, then the sheet is folded to bring the planes delimiting the groove resting on the corresponding surfaces of the key, and finally the outer edges of the groove are secured with the key by at least one weld bead.

- the sheet may be folded such that the groove and the key are within the projecting angle formed by the folded sheet.

- the sheet may be folded so that the groove and the key are outside the projecting angle formed by the folded sheet.

- the key may include two lateral flanges covering the sheet.

- the groove after folding may be delimited by two parallel planes.

- the invention also relates to a mechanically welded structure, in particular for a body of a vehicle, characterized in that it comprises at least one sheet shaped by the method according to one of the preceding claims.

- a thickly shielded sheet metal 1 has a groove 2 delimited by two secant lateral planes 2a and 2b forming a V open towards the outside of the groove 2.

- This recess 3 comprises lobes 3a and 3b.

- Each of the lobes 3a and 3b is placed partly below the respective planes 2a and 2b.

- the lobes 3a and 3b are separated from each other by a bulge of material 3c with a thickness h greater than one millimeter relative to the bottom of the lobes 3a and 3b.

- the planes 2a and 2b extend in a direction perpendicular to the plane of the figure 1 over the entire length of the sheet 1 to be folded. It is the same recesses 3a and 3b and 3c bulge.

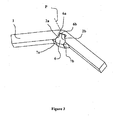

- sheet 1 which was represented flat at the figure 1 , has undergone a folding operation at 90 ° around a fold line P. This folding brought the planes 2a and 2b in abutment against each other.

- a weld bead 4 secures the outer edges of the planes 2a and 2b over the entire length of the sheet.

- the thickness of material contained in the total thickness M of the corner thus formed is large and close to the thickness E of the sheet.

- the distribution of folding stresses is made at the two areas of thinned sheet 8a and 8b which are separated by the bulge 3c. This is due to the lesser thickness of material that is left by the machining of the recess 3 at the bottom of the lobes 3a and 3b.

- the mutual support of the planes 2a and 2b provides the corner 5 thus formed with increased strength.

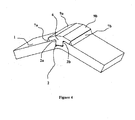

- sheet 1 has the same machining and shapes as at the figure 1 and it is folded on the side of the groove 2 (the sheet is folded so that the groove is inside the projecting angle formed by the folded sheet).

- a metal key 6 of the same material as that of the sheet is placed in the groove 2 over the entire length of the latter.

- This key 6 comprises two surfaces 6a and 6b corresponding with the planes 2a and 2b delimiting the groove 2.

- the outer edges of the planes 2a and 2b are secured to the key 6 by weld seams 7a and 7b.

- the key 6 has a thickness such that it bears against the bottom of the groove 2 at the bulge 3c. This embodiment makes it possible to produce a folded sheet at an angle greater than 90 °.

- the key 6 thus placed provides a solid structural support to the planes 2a and 2b, which reinforces the structure formed by the folding of the sheet 1.

- the massive character of the key 6 and its thickness covering the entire depth of the groove 2 brings a ballistic continuity to the folded sheet 1.

- the sheet 1 is folded in the opposite direction of the folding made at the figure 3 .

- the sheet 1 is folded on the opposite side to the groove 2 (the groove 2 is thus outside the projecting angle formed by the folded sheet).

- a key 6 occupies the open space at the groove 2.

- the edges of the key 6 are secured to the sheet 1 by means of weld beads 7a and 7b.

- the key 6 covers the entire length and the depth of the groove 2 and the side surfaces 6a and 6b of the key are supported on the planes 2a and 2b delimiting the groove 2. In this way the ballistic continuity is ensured as well as the strength of the structure.

- Key 6 of the figure 4 has flanges 9a, 9b covering the sheet 1 which further improves the ballistic protection.

- the groove 2 can be initially machined on the flat sheet 1 with a shape of V whose opening is towards the inside of the groove 2. In this way the sheet 1 can be folded until the planes 2a and 2b of the groove 2 are parallel.

- the method according to the invention can be used to produce a complex mechano-welded structure comprising several thick plates folded in several places. It will thus be possible to make a complete box of an armored vehicle whose ballistic protection will not be reduced by the folds.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Butt Welding And Welding Of Specific Article (AREA)

- Laser Beam Processing (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL12156603T PL2500115T3 (pl) | 2011-03-14 | 2012-02-22 | Proces formowania mechanicznie spawanych bardzo grubych arkuszy oraz konstrukcja otrzymywana wspomnianym procesem |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR1100766A FR2972653B1 (fr) | 2011-03-14 | 2011-03-14 | Procede de mise en forme de toles mecano soudees de forte epaisseur et structure obtenue par ce procede |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2500115A1 EP2500115A1 (fr) | 2012-09-19 |

| EP2500115B1 true EP2500115B1 (fr) | 2013-10-02 |

Family

ID=45607671

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12156603.8A Active EP2500115B1 (fr) | 2011-03-14 | 2012-02-22 | Procédé de mise en forme de tôles mécano soudées de forte épaisseur et structure obtenue par ce procédé |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP2500115B1 (pl) |

| DK (1) | DK2500115T3 (pl) |

| FR (1) | FR2972653B1 (pl) |

| PL (1) | PL2500115T3 (pl) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104439975A (zh) * | 2014-11-28 | 2015-03-25 | 吴中区光福华宇钣金厂 | 一种支架加工工艺 |

| US20230398734A1 (en) * | 2020-07-15 | 2023-12-14 | Spirit Aerosystems, Inc. | Method of manufacturing folded structure with additive features |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102933059B (zh) * | 2012-11-08 | 2016-01-27 | 昆山万禾精密电子有限公司 | 显示器支撑架及其制备方法 |

| CN102933060A (zh) * | 2012-11-13 | 2013-02-13 | 昆山万禾精密电子有限公司 | 一种电子设备显示模组的支撑装置及制备方法 |

| CN113458727A (zh) * | 2021-06-29 | 2021-10-01 | 江苏铁锚玻璃股份有限公司 | 控制铝框煨弯焊接变形的工艺方法及煨弯成型铝框 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2197810B (en) * | 1986-09-22 | 1990-10-03 | Jackson Paul Adrian Southon | Sheet metal articles |

| WO2006133704A1 (en) * | 2005-06-13 | 2006-12-21 | Isic A/S | Process for creating an angle connection in a plane member |

| DE102005044423A1 (de) * | 2005-09-16 | 2007-03-22 | Blanco Gmbh + Co Kg | Verfahren zum Erzeugen einer Abkantung an einem Blechelement |

| DE102009056324A1 (de) * | 2009-12-01 | 2010-07-01 | Dreistern Gmbh & Co. Kg | Verfahren und Vorrichtung zum Längsumformen eines Metallbands mit entlang seiner Längsachse variierender Materialstärke |

-

2011

- 2011-03-14 FR FR1100766A patent/FR2972653B1/fr not_active Expired - Fee Related

-

2012

- 2012-02-22 DK DK12156603.8T patent/DK2500115T3/da active

- 2012-02-22 EP EP12156603.8A patent/EP2500115B1/fr active Active

- 2012-02-22 PL PL12156603T patent/PL2500115T3/pl unknown

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104439975A (zh) * | 2014-11-28 | 2015-03-25 | 吴中区光福华宇钣金厂 | 一种支架加工工艺 |

| US20230398734A1 (en) * | 2020-07-15 | 2023-12-14 | Spirit Aerosystems, Inc. | Method of manufacturing folded structure with additive features |

Also Published As

| Publication number | Publication date |

|---|---|

| PL2500115T3 (pl) | 2014-03-31 |

| EP2500115A1 (fr) | 2012-09-19 |

| FR2972653B1 (fr) | 2013-03-15 |

| FR2972653A1 (fr) | 2012-09-21 |

| DK2500115T3 (da) | 2013-12-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2500115B1 (fr) | Procédé de mise en forme de tôles mécano soudées de forte épaisseur et structure obtenue par ce procédé | |

| EP3057851B1 (fr) | Structure de bavolet de véhicule automobile | |

| EP2137049B1 (fr) | Véhicule comprenant une prolonge avec appui perfectionné | |

| EP3177507B1 (fr) | Structure de véhicule avec renfort entre longeron aluminium et pied avant | |

| WO2016016138A1 (fr) | Procédé de fabrication additive à base de poudre d'une pièce, notamment d'une lamelle de garniture pour moule de pneumatiques, et d'un élément de renfort associé | |

| FR2942418A1 (fr) | Procede de fabrication d'un composant de vehicule automobile sous forme d'un profile de torsion | |

| FR3010921A1 (fr) | Outil d'emboutissage pour reprendre une piece emboutie ayant un bord tombe | |

| EP0989917B1 (fr) | Procede pour la liaison de deux pieces tubulaires l'une a l'autre et ensemble mecanique comportant deux pieces tubulaires | |

| EP2355953B1 (fr) | Procédé d'assemblage de deux toles par soudure laser, notamment pour assembler la tôle d'encadrement d'une porte de véhicule automobile à la doublure de cette porte | |

| EP3145795B1 (fr) | Pavillon de toit de véhicule automobile soudo-brasé aux côtés de caisse | |

| EP1854707A1 (fr) | Elément de liaison pour réaliser un longeron pour véhicule automobile et longeron comportant un tel élément | |

| EP2890541B1 (fr) | Dispositif et procédé pour la réalisation de préformes | |

| EP1320427B1 (fr) | Procede et installation de fabrication d'une piece comportant au moins une section tubulaire | |

| EP4158111A1 (fr) | Element d'armatures pour paroi moulee muni d'un porte-joint d'etancheite | |

| EP1435309B1 (fr) | Caisse pour un véhicule industriel, procédé de fabrication d'une telle caisse et véhicule industriel comportant une telle caisse | |

| EP3020533A1 (fr) | Ensemble comprenant un boîtier et un capot, et procédé de fixation du capot sur le boîtier | |

| WO2022002805A1 (fr) | Procédé de fabrication d'une poutre à section fermée | |

| EP3851615B1 (fr) | Ensemble d'attente pour reprise de bétonnage | |

| EP3264940B1 (fr) | Glissière pour des systèmes de réglage coulissants | |

| EP3950460B1 (fr) | Bas de caisse de véhicule, véhicule et procédé d'assemblage associés | |

| FR2926524A1 (fr) | Traverse centrale de pavillon d'un vehicule automobile | |

| FR3013285A1 (fr) | Structure de pare-chocs de vehicule et vehicule correspondant | |

| EP1160025A1 (fr) | Procédé de pliage de tôle forte, et coffre-fort en tôle forte pliée | |

| EP2505731B1 (fr) | Procédé de fabrication d'une tôle à nervures ouvertes destinée à former une armature pour un plancher collaborant | |

| WO2018115656A1 (fr) | Dispositif de pliage pour former une ondulation dans une tole metallique et procede d'utilisation dudit dispositif |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| 17P | Request for examination filed |

Effective date: 20130318 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B21D 11/08 20060101AFI20130404BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20130425 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 634335 Country of ref document: AT Kind code of ref document: T Effective date: 20131015 Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602012000346 Country of ref document: DE Effective date: 20131128 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 Effective date: 20131213 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 634335 Country of ref document: AT Kind code of ref document: T Effective date: 20131002 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20131002 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140202 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140102 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140203 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602012000346 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 |

|

| BERE | Be: lapsed |

Owner name: NEXTER SYSTEMS Effective date: 20140228 |

|

| 26N | No opposition filed |

Effective date: 20140703 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140222 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602012000346 Country of ref document: DE Effective date: 20140703 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140222 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150228 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150228 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150228 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140101 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140103 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140228 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20120222 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 6 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131002 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250122 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20250121 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20250121 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20250121 Year of fee payment: 14 Ref country code: PL Payment date: 20250122 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20250121 Year of fee payment: 14 Ref country code: GB Payment date: 20250123 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20250129 Year of fee payment: 14 |