EP2398606B1 - Verfahren zur herstellung eines pressgehärteten metallbauteils - Google Patents

Verfahren zur herstellung eines pressgehärteten metallbauteils Download PDFInfo

- Publication number

- EP2398606B1 EP2398606B1 EP10701860.8A EP10701860A EP2398606B1 EP 2398606 B1 EP2398606 B1 EP 2398606B1 EP 10701860 A EP10701860 A EP 10701860A EP 2398606 B1 EP2398606 B1 EP 2398606B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- press

- hardened

- metal component

- wall thickness

- stampings

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 239000002184 metal Substances 0.000 title claims description 78

- 238000004519 manufacturing process Methods 0.000 title description 17

- 239000011265 semifinished product Substances 0.000 claims description 28

- 238000000034 method Methods 0.000 claims description 24

- 238000004049 embossing Methods 0.000 claims description 15

- 229910000831 Steel Inorganic materials 0.000 claims description 13

- 239000010959 steel Substances 0.000 claims description 13

- 239000002131 composite material Substances 0.000 claims description 12

- 229910000851 Alloy steel Inorganic materials 0.000 claims description 9

- 229910000712 Boron steel Inorganic materials 0.000 claims description 3

- PALQHNLJJQMCIQ-UHFFFAOYSA-N boron;manganese Chemical compound [Mn]#B PALQHNLJJQMCIQ-UHFFFAOYSA-N 0.000 claims description 3

- 239000000463 material Substances 0.000 description 16

- 230000008569 process Effects 0.000 description 10

- 238000001816 cooling Methods 0.000 description 6

- 229910000734 martensite Inorganic materials 0.000 description 5

- 230000008901 benefit Effects 0.000 description 3

- 230000009467 reduction Effects 0.000 description 3

- 230000006978 adaptation Effects 0.000 description 2

- 238000005304 joining Methods 0.000 description 2

- 239000007858 starting material Substances 0.000 description 2

- 230000007704 transition Effects 0.000 description 2

- 238000005452 bending Methods 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 239000000109 continuous material Substances 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 239000000047 product Substances 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 238000010583 slow cooling Methods 0.000 description 1

- 239000002436 steel type Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/62—Quenching devices

- C21D1/673—Quenching devices for die quenching

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D22/00—Shaping without cutting, by stamping, spinning, or deep-drawing

- B21D22/02—Stamping using rigid devices or tools

- B21D22/022—Stamping using rigid devices or tools by heating the blank or stamping associated with heat treatment

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2221/00—Treating localised areas of an article

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/12—All metal or with adjacent metals

- Y10T428/12389—All metal or with adjacent metals having variation in thickness

Definitions

- the invention relates to a method for producing a press-hardened metal component made of steel or a steel alloy, in which a printed circuit board or a semifinished product is press-hardened in a forming tool.

- the invention also relates to a press-hardened metal component made of steel or a steel alloy, in particular for a motor vehicle, which is not press-hardened in at least one partial area.

- components of high hardness are usually required.

- a very high strength and a very high hardness can be achieved by the process of press hardening.

- a board or a semi-finished product is hot-worked in a tool at temperatures above the austenitizing temperature and then cooled abruptly in the same tool.

- the austenitic structure of the component during hot forming is converted into a martensitic structure of high strength and hardness by the rapid cooling process.

- WO 2006/038868 A1 For the production of such components is from the, WO 2006/038868 A1 a method is known in which the die used for the press hardening in the areas in which the component to be produced is to have a lower hardness has recesses on the surface. This ensures that the board does not bear against the die during press hardening in the region of the recesses, but an air gap between the die and the board is formed. In this way, the board is cooled more slowly in this area, so that the hardness and thus the strength after the press-hardening of the component in this area is lower.

- the method described has the disadvantage that the provided with the recesses dies are expensive to manufacture. Furthermore, it is for the production in principle of similar components, which should have only other areas with reduced hardness, it is necessary to have a separate die for each component. As a result, the cost of producing such components are greatly increased.

- the recesses in the tool can also lead to deformations in the component, so that an accurate shaping of the component with this method is difficult and sometimes even impossible.

- the EP 2 108 467 A2 describes a method for producing highly dimensional half shells by drawing, in which a previously introduced into the sheet material reserve in the form of bulges to improve the forming behavior.

- the finished product accordingly has a uniform material thickness.

- the present invention seeks to provide a simple and inexpensive method for producing a press-hardened metal component and a press-hardened metal component made of steel or a steel alloy, in which the disadvantages of the prior art are avoided.

- the printed circuit board or the semi-finished product has partial regions with a reduced wall thickness, the partial regions having a reduced wall thickness not being press-hardened.

- the board or the semifinished product in the corresponding subregions does not lie directly against the wall of the tool used for reshaping, so that air gaps form between this subarea of the board or semifinished product and the wall of the tool.

- the heat transfer from the blank or semi-finished product to the tool is reduced through the air gaps, so that slower cooling rates occur.

- the component is thus not press-hardened in these areas. This has in particular the consequence that only a small or even no martensitic microstructure can form in these subregions and the hardness in these areas is thus lower and the elongation at break value greater.

- the advantage of this method lies in the fact that it is possible in this way with a regular press-hardening tool to produce a component having portions with a lower hardness or a higher elongation at break value. It is therefore not necessary in particular to design the tool in the non-press-hardened sub-areas. In this way, the cost of production is significantly reduced.

- the subregions are provided with reduced wall thickness by embossing the blank or semifinished product prior to press hardening.

- embossing the depressions can be produced in a particularly simple manner.

- an embossing punch or an embossing roll which is particularly advantageous in the embossing of large areas, can be used.

- a "tailored blank" is press-hardened.

- “Tailored blanks” are individual blanks that are welded together using a joining technique to form a single board. As a result, for example, blanks with the same materials, but different sheet thicknesses or different materials with the same or different sheet thickness can be welded to form a board.

- tailored blanks in the process is advantageous because in this way components with complex shapes and variable material properties can be produced. Furthermore, the reductions in the wall thicknesses in the subregions can be achieved in a very simple and flexible manner.

- the tailored blank preferably has at least one board without embossing and at least one board with embossing.

- the tailored blank has at least two embossed boards of different thickness.

- a material is rolled to different thickness over its length using a flexible rolling process. This allows a reduction in thickness in the workpieces with a continuous material transition, so that hardness edges are avoided in the transition to the non-press-hardened portions of the component.

- a tailored rolled blank is press-hardened from previously embossed starting material.

- the press-hardened metal component according to the invention made of steel or a steel alloy, in particular for a motor vehicle, at least one non-press-hardened partial region has a reduced wall thickness compared with the press-hardened partial regions.

- the metal component is preferably produced by a method according to the invention.

- metal components can be used advantageously, for example, for motor vehicle bodies or housing, since they meet the variable material properties required there and are also inexpensive to manufacture.

- a flexible adaptation of the metal components to the load requirements is achieved according to a further embodiment in that the non-press-hardened portions of the metal component are arranged load. Since in this case only the subregions with a reduced wall thickness have to be arranged correspondingly, without an adaptation of the tool required for the manufacture being required, the production of such a component can be carried out simply and inexpensively.

- the non-press-hardened portions of the metal component are preferably arranged in areas in which the metal component should have an increased elongation at break.

- a particularly high hardness or strength of the metal component is achieved in a further embodiment in that the metal component consists of a manganese-boron steel, preferably of a steel type 22MnB5.

- the subareas of the press-hardened metal component with reduced wall thickness are formed by embossing.

- the portions of reduced wall thickness are particularly easy to manufacture and flexible to arrange.

- the press-hardened metal component is given by the fact that the embossments are formed strip-shaped. This is particularly advantageous, for example, if the metal component is to have edges of lesser hardness, for example predetermined bending edges.

- stampings are formed point or rectangular.

- a punctiform embossment is understood, for example, a circular embossing, but also generally a stamp with a small aspect ratio.

- the stampings are of a similar design and / or uniformly distributed in the non-press-hardened partial areas. In this way, areas with a uniform average hardness can be achieved.

- the training uniform or evenly distributed Stamping is also easier and less expensive.

- the embossing of the semifinished product for the production of the metal component can take place before the press hardening, for example with the aid of an embossing roller.

- stampings By not identically designed or not uniformly distributed stampings, however, can be achieved very flexible average hardness properties of the metal component. In this way, for example, a medium hardness gradient can be formed.

- a press-hardened metal component with a total average hardness between a press-hardened and a non-press-hardened component can be achieved in a further preferred embodiment by virtue of the metal component having embossings substantially over its entire surface.

- a further embodiment of the press-hardened component is given by the fact that the metal component is produced from a composite sheet which has at least two sinkers and one of the sinkers has deformations in order to provide partial regions of reduced wall thickness. This is advantageous because the board with the recesses and / or stampings can be produced separately. Furthermore, a large influence on the material properties of the metal component is possible by the choice of different materials for the boards.

- a particularly flexible and cost-effective production is especially in complex press-hardened metal components possible in that the metal component is made of a tailored blank, a tailored strip or a tailored rolled blank.

- the metal component is made of a tailored blank, a tailored strip or a tailored rolled blank.

- a tailored blank or a tailored strip blanks of different steels in particular can be used.

- the metal component was produced from a tailored blank made from at least two embossed blanks of different sheet thickness or that the metal component was produced from a tailored blank or a tailored strip made from joined blanks of different sheet thickness.

- the metal component has been produced from a tailored rolled blank of previously embossed starting material.

- FIGS. 1a to 1c an embodiment of a method according to the invention is shown.

- Fig. 1a shows a board 2, which has a reduced wall thickness in partial areas 4. The reduction of the wall thickness was achieved in the board 2 by stampings 6 on the upper side 8 of the board 2. As a result, the board 2 on its upper side 8 elevations 10.

- the board 2 consists of a steel or a steel alloy, preferably of a manganese-boron steel, in particular of a steel 22MnB5 type.

- the stampings 6 may have been introduced into the board 2, for example by means of an embossing roll.

- Fig. 1b shows a tool 12 for press hardening with an upper tool 14 and a lower tool 16.

- the inner surface 18 of the upper tool 14 and the inner surface 20 of the lower tool 16 are adapted to the contour of the component to be produced.

- the upper tool 14 and the lower tool 16 are moved apart.

- the board 2 is then positioned between the upper tool 14 and the lower tool 16, and the upper tool 14 and the lower tool 16 then go back together.

- the board 2 is hot-worked at temperatures which are preferably above the austenitizing temperature.

- the elevations 10 are applied directly to the inner surface 18 of the upper tool 14, while the board 2 are spaced in the partial regions 4 with reduced wall thickness by the Vergargisme 6 of the inner surface 18 of the upper tool 14.

- an air gap 24 is formed in each case between the plate 2 and the inner surface 18 of the upper tool 14 in the region of the stampings 6.

- it is quenched in the tool 12. Due to the direct contact of the elevation 10 with the inner surface 18 of the upper tool 14, the cooling of the board 2 in this area is very fast, so that there is a martensite of the material. In the partial regions 4 with reduced wall thickness, the cooling takes place more slowly due to the air gap 24, so that only little or no martensite occurs in these regions.

- the upper tool 14 and the lower tool 16 are moved apart again and removed from the board 2 and press-hardened component 22 removed.

- the finished component 22 is in Fig. 1c displayed.

- inventive Semifinished product 30 consists of a board 32, have been applied to the patches 34.

- the patches 34 are connected to the board 32 preferably cohesively.

- the wall thickness of the semifinished product 30 is locally increased by the patches 34, so that partial areas 36 with a smaller wall thickness relative to the areas with the patches 34 result between the patches.

- the patches 34 are applied directly to the tool, while an air gap is formed in the partial regions 36.

- the advantage of using patches 34 is that the change in wall thickness of the semifinished product 30 can be achieved in a very simple and flexible manner.

- a semifinished product 40 according to the invention is shown, which is designed as a composite sheet. It has a first circuit board 42 and a second circuit board 44, which is arranged above it and is connected to the first circuit board 42, preferably in a materially bonded manner.

- the second board 44 has embossments 46, so that the wall thickness of the semifinished product 40 is reduced in these areas.

- the stampings 46 may be inserted into the second board 44, for example, before the second board 44 is connected to the first board. In this way, it is possible, for example, to produce the second circuit board 44 in advance and emboss and apply it as needed on first boards 42, which should not have press-hardened portions. Furthermore, by using different materials for the first board 42 and the second board 44, it is possible to flexibly influence the material properties of the resulting semi-finished product 40.

- This in Fig. 2c shown semifinished product 50 is also made as a composite sheet of a first board 52 and a second board 54.

- the second board 54 of the semifinished product 50 has no stampings, but continuous recesses 56.

- the recesses 56 may be in the form of bores, for example.

- the recesses 56 may be provided by punching the second board 54.

- a conventional perforated plate made of steel or a steel alloy can be used as the second circuit board 54, since this is particularly cost-effective and thus the wall thickness-reduced areas of the semifinished product 50 can be provided in a simple and favorable manner.

- the semi-finished products or blanks are not limited to provide the portions of reduced wall thickness by one-sided provision of recesses or stampings. This is how the in Fig. 2d Semifinished product 60 shown on a board 62, in which stampings 64 have been introduced from both sides. In this way, the hot-formed semi-finished product 60 has an air gap to the upper or lower tool on both sides in the thickness-reduced subregions. This is particularly advantageous when both the upper and the lower tool are actively cooled during press hardening. As a result, a particularly slow cooling process is possible in these subareas, so that the material has essentially no martensite in this area.

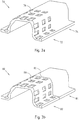

- FIGS. 3a and 3b two embodiments of the press-hardened metal component are shown.

- This in Fig. 3a shown metal component 70 was made of a locally stamped Board made.

- the metal component 70 thus has a first region 72 and a second region 74. Rectangular depressions 76 were introduced into the first region 72 before the press-hardening.

- the second region 74 has no such depressions.

- the metal component 70 was made of a board, for example the one in FIG Fig. 1a shown board 2, first in the in Fig. 3a hot-formed form and then quenched in the tool.

- the metal component 70 in the second region 74 was in direct contact with the tool surfaces over the entire surface, the first region 72 had air gaps on the rectangular stampings 76, so that the component 70 was not press-hardened at these locations.

- the second region 74 of the component 70 is thus completely press-hardened and accordingly has a high hardness, while the first region 72 of the component 70 has a lower hardness due to the non-press-hardened partial regions in the depressions 76 on average.

- Such areas with lower average hardness are preferably arranged according to load.

- the arrangement is particularly advantageous in those places where high elongation at break values are required.

- Metal component 80 shown differs from metal component 70 Fig. 3a in that the metal component 80 is designed as a composite metal sheet.

- the first region 82 and the second region 84 of the metal component 80 were each press-hardened separately and then joined together at the seam 86 by a joining process.

- the stampings 76, 88 of the components 70, 80 are not limited to a rectangular shape, but can also in any other shapes, such as circular, be designed as a polygon or strip-shaped.

- Fig. 4a a further embodiment of a press-hardened metal component 90, which was produced from a locally stamped board.

- the component 90 has a first region 92 with Vergargungen 94 and a second region 96 without stampings. Accordingly, the component 90 is not press-hardened in the region of the stampings 94, which in this case are strip-shaped, so that the first region 92 has a lower average hardness than the second region 96 Fig. 4b

- the metal component 100 shown differs from the metal component 90 Fig. 4a in that it has been produced from tailored blanks or tailored strips with different sheet thicknesses.

- a tailored blank 102 and two tailored strips 104, 106 with the same thickness and two tailored strips 108, 110 with a smaller thickness were added to a semifinished product and then press-hardened.

- an air gap was arranged between the semifinished product and the tool in the area of the tailored strips 108, 110 with a smaller wall thickness.

- the metal component 100 is not press-hardened in the area of the tailored strips 108, 110 with a smaller thickness.

- Fig. 5a and Fig. 5b show a further embodiment of a press-hardened metal component.

- the metal component 111 shown here consists of a lower metal component 112 and an upper metal component 114.

- the lower metal component 112 and the upper metal component 114 are identical in construction and independent of each other in one Press hardening process produced.

- the two metal components 112, 114 each have honeycomb-shaped recesses on one side, in the region of which there was no direct contact with the tool during the press-hardening.

- the metal components 112, 114 are therefore not press-hardened in these areas.

- the metal components 112, 114 with sides having depressions are joined together, preferably welded.

- the resulting composite sheet 111 has on average by the stampings of the metal components 112, 114 lower hardness than a fully press-hardened composite sheet.

- the composite metal sheet 111 advantageously has smooth outer surfaces 118, 120.

- the metal components 112, 114 are first joined together with the recesses having sides, and then press-hardened, optionally also a corresponding shape can be provided. Also in this example, the force gap between the sheets causes an average reduced hardness as a fully press-hardened composite sheet.

- the invention is not limited to the described embodiments, but that in particular all combinations of the embodiments are possible.

- the properties of the press-hardened metal components can be generally improved by the fact that the blanks, semi-finished or finished metal components by one or more typical metallic or non-metallic coating concepts are coated.

- the blanks, semi-finished or finished metal components by one or more typical metallic or non-metallic coating concepts are coated.

- tailored blanks and tailored strips it is basically possible and may be advantageous to use different steel materials.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Mechanical Engineering (AREA)

- Crystallography & Structural Chemistry (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Shaping Metal By Deep-Drawing, Or The Like (AREA)

- Forging (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL10701860T PL2398606T3 (pl) | 2009-02-19 | 2010-01-27 | Sposób wytwarzania części metalowej hartowanej podczas tłoczenia |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102009003508A DE102009003508B4 (de) | 2009-02-19 | 2009-02-19 | Verfahren zur Herstellung eines pressgehärteten Metallbauteils |

| PCT/EP2010/050931 WO2010094538A1 (de) | 2009-02-19 | 2010-01-27 | Verfahren zur herstellung eines pressgehärteten metallbauteils |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2398606A1 EP2398606A1 (de) | 2011-12-28 |

| EP2398606B1 true EP2398606B1 (de) | 2017-08-09 |

Family

ID=41815606

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP10701860.8A Not-in-force EP2398606B1 (de) | 2009-02-19 | 2010-01-27 | Verfahren zur herstellung eines pressgehärteten metallbauteils |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US20120040205A1 (enExample) |

| EP (1) | EP2398606B1 (enExample) |

| JP (1) | JP2012517901A (enExample) |

| KR (1) | KR20110122679A (enExample) |

| CN (1) | CN102317001B (enExample) |

| CA (1) | CA2752855C (enExample) |

| DE (1) | DE102009003508B4 (enExample) |

| ES (1) | ES2646314T3 (enExample) |

| PL (1) | PL2398606T3 (enExample) |

| WO (1) | WO2010094538A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102022114057A1 (de) | 2022-06-03 | 2023-12-14 | Bayerische Motoren Werke Aktiengesellschaft | Unterschiedliche Blechdicken und Festigkeiten aufweisendes pressgehärtetes Blechformteil |

Families Citing this family (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102011007937B4 (de) * | 2011-01-03 | 2015-09-10 | Benteler Automobiltechnik Gmbh | Verfahren zum Herstellen eines Strukturbauteils einer Kraftfahrzeugkarosserie |

| DE102011009891A1 (de) * | 2011-01-31 | 2012-08-02 | Benteler Automobiltechnik Gmbh | Verfahren zum Herstellen von Blechbauteilen sowie Vorrichtung zur Durchführung des Verfahrens |

| DE102011051728A1 (de) * | 2011-07-11 | 2013-01-17 | Thyssenkrupp Lasertechnik Gmbh | Verfahren und Vorrichtung zum Herstellen von maßgeschneiderten Blechbändern |

| DE102011052291B4 (de) * | 2011-07-29 | 2016-03-10 | Benteler Automobiltechnik Gmbh | Kraftfahrzeugbauteil sowie Verfahren zur Herstellung eines Kraftfahrzeugbauteils |

| DE102011116715A1 (de) * | 2011-10-22 | 2013-04-25 | Volkswagen Aktiengesellschaft | Vorrichtung und Verfahren zum Warmformen/Presshärten und Schneiden eines Blechmaterials in einem Werkzeug mit automatisierter Entnahme des Blechabfalls |

| JP2013233548A (ja) * | 2012-05-02 | 2013-11-21 | Unipres Corp | 熱間プレス成形装置 |

| DE102012015431A1 (de) * | 2012-08-03 | 2014-02-06 | Voestalpine Stahl Gmbh | Bauteil mit Sandwich-Struktur und Verfahren zu dessen Herstellung |

| DE102012110138B3 (de) * | 2012-10-24 | 2014-02-27 | Manuela Braun | Vorrichtung und Verfahren zum Presshärten von Blechzuschnitten und/oder Blechformteilen aus Stahl mit unterschiedlicher Materialdicke |

| CN104232871B (zh) * | 2013-06-06 | 2017-06-16 | 天龙科技炉业(无锡)有限公司 | 火车轮整体淬火工艺 |

| DE102013214250A1 (de) | 2013-07-22 | 2015-01-22 | Bayerische Motoren Werke Aktiengesellschaft | Pressgehärtetes Blechbauteil mit Lochung und Verfahren zu dessen Herstellung |

| US20150314363A1 (en) * | 2014-04-30 | 2015-11-05 | GM Global Technology Operations LLC | Method of forming a vehicle body structure from a pre-welded blank assembly |

| DE102015203644A1 (de) | 2015-03-02 | 2016-09-08 | Bayerische Motoren Werke Aktiengesellschaft | Pressgehärtetes Blechformteil mit unterschiedlichen Blechdicken und Festigkeiten |

| DE102015220347B4 (de) * | 2015-10-20 | 2018-06-21 | Thyssenkrupp Ag | Verfahren zum Herstellen eines Bauteils für ein Fahrzeug |

| DE102016201036A1 (de) * | 2016-01-26 | 2017-07-27 | Zf Friedrichshafen Ag | Verfahren zur Herstellung eines Bauteils und nach diesem Verfahren hergestelltes Bauteil |

| JP6724452B2 (ja) * | 2016-03-18 | 2020-07-15 | 日本製鉄株式会社 | 焼入れ鋼管部材及び焼入れ鋼管部材の製造方法 |

| BR112018073277A2 (pt) * | 2016-05-18 | 2019-02-19 | Nippon Steel & Sumitomo Metal Corporation | método de produção de produto moldado em prensa e linha de produção de produto moldado em prensa |

| TWI622491B (zh) * | 2016-12-16 | 2018-05-01 | 財團法人金屬工業研究發展中心 | Hot stamping forming low heat transfer heating mold and hot stamping part forming method |

| DE102016124931A1 (de) * | 2016-12-20 | 2018-06-21 | Bayerische Motoren Werke Aktiengesellschaft | Verfahren zum Herstellen eines einteiligen Verstärkungselements für einen Seitenrahmen eines Fahrzeugs, Verstärkungselement für einen Seitenrahmen eines Fahrzeugs sowie Fahrzeug |

| WO2019090109A1 (en) | 2017-11-02 | 2019-05-09 | Ak Steel Properties, Inc. | Press hardened steel with tailored properties |

| DE102017127158A1 (de) * | 2017-11-17 | 2019-05-23 | HoDforming GmbH | Verfahren zum Umformen eines Blechrohlings, z. B. einer Platine oder eines Hohlkörperrohlings als Werkstück in einem Umformwerkzeug |

| JP7155986B2 (ja) * | 2018-12-13 | 2022-10-19 | トヨタ自動車株式会社 | 鋼板部材及びその製造方法 |

| CN118989087A (zh) * | 2019-02-13 | 2024-11-22 | 麦格纳国际公司 | 热冲压方法和热冲压系统 |

| CN109909379B (zh) * | 2019-03-29 | 2020-05-12 | 重庆大学 | 热冲压成形模具镶块结构及其加工方法 |

| CN112207219B (zh) * | 2019-07-12 | 2023-09-22 | 余姚市佳福车业有限公司 | 一种热锻打金属件内孔的生产制造方法 |

| DE102019219651A1 (de) * | 2019-12-16 | 2021-06-17 | Thyssenkrupp Steel Europe Ag | Metallblech mit einer deterministischen Oberflächenstruktur und Verfahren zur Herstellung eines umgeformten und lackierten Blechbauteils |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2006038868A1 (en) * | 2004-10-04 | 2006-04-13 | Gestamp Hardtech Ab | A method of hot stamping and hardening a metal sheet |

| DE102005025026B3 (de) * | 2005-05-30 | 2006-10-19 | Thyssenkrupp Steel Ag | Verfahren zum Herstellen eines Metallbauteils mit aneinander angrenzenden Abschnitten unterschiedlicher Materialeigenschaften |

| WO2008024042A1 (en) * | 2006-08-25 | 2008-02-28 | Gestamp Hardtech Ab | A method of hot-shaping and hardening an object from a metal sheet, and a b-pillar for a vehicle |

| WO2010133526A1 (de) * | 2009-05-18 | 2010-11-25 | Thyssenkrupp Steel Europe Ag | Verfahren zur herstellung eines metallbauteils aus einem warmverprägten ausgangsmaterial |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19742818A1 (de) * | 1997-09-27 | 1999-04-01 | Volkswagen Ag | Platine für ein Strukturbauteil, Strukturbauteil und Verfahren zur Herstellung eines Strukturbauteiles für Kraftfahrzeuge |

| DE19743093C1 (de) * | 1997-09-30 | 1998-12-17 | Thyssenkrupp Stahl Ag | Verfahren und Vorrichtung zum Herstellen eines Metallbandes mit über seine Breite verschieden dicken Bereichen |

| JP4497736B2 (ja) * | 2001-03-02 | 2010-07-07 | 本田技研工業株式会社 | 2枚重ね製品の成形用ブランク材 |

| JP4316842B2 (ja) * | 2002-07-26 | 2009-08-19 | アイシン高丘株式会社 | テーラードブランクプレス成形品の製造方法 |

| JP2004154853A (ja) * | 2002-11-08 | 2004-06-03 | Futaba Industrial Co Ltd | 塑性加工品の製造方法 |

| DE10333165A1 (de) * | 2003-07-22 | 2005-02-24 | Daimlerchrysler Ag | Pressgehärtetes Bauteil und Verfahren zur Herstellung eines pressgehärteten Bauteils |

| JP3863874B2 (ja) * | 2003-10-02 | 2006-12-27 | 新日本製鐵株式会社 | 金属板材の熱間プレス成形装置及び熱間プレス成形方法 |

| DE102004053917B3 (de) * | 2004-11-05 | 2006-04-13 | Benteler Automobiltechnik Gmbh | Seitenwand eines Kraftfahrzeugs |

| DE102007063629B4 (de) * | 2007-08-14 | 2016-07-07 | Benteler Automobiltechnik Gmbh | Verfahren zur Herstellung einer Stoßfängeranordnung eines Kraftfahrzeugs |

| EP2025771A1 (en) * | 2007-08-15 | 2009-02-18 | Corus Staal BV | Method for producing a coated steel strip for producing taylored blanks suitable for thermomechanical shaping, strip thus produced, and use of such a coated strip |

| DE102007050907A1 (de) * | 2007-10-23 | 2009-04-30 | Benteler Automobiltechnik Gmbh | Verfahren zur Herstellung eines gehärteten Blechprofils |

| DE102008018656B9 (de) * | 2008-04-11 | 2009-07-09 | Thyssenkrupp Steel Ag | Verfahren zur Herstellung von hochmaßhaltigen Halbschalen |

| US20110151271A1 (en) * | 2008-07-10 | 2011-06-23 | Shiloh Industries, Inc. | Metal forming process and welded coil assembly |

| DE102008053878B4 (de) * | 2008-10-30 | 2011-04-21 | Benteler Automobiltechnik Gmbh | Warmformbauteil und Verfahren zur Herstellung eines Warmformbauteils |

| SE533825C2 (sv) * | 2009-06-15 | 2011-01-25 | Gestamp Hardtech Ab | Sätt att forma och härda ett ämne av stålplåt |

| DE102010004081C5 (de) * | 2010-01-06 | 2016-11-03 | Benteler Automobiltechnik Gmbh | Verfahren zum Warmformen und Härten einer Platine |

-

2009

- 2009-02-19 DE DE102009003508A patent/DE102009003508B4/de not_active Expired - Fee Related

-

2010

- 2010-01-27 JP JP2011550500A patent/JP2012517901A/ja active Pending

- 2010-01-27 ES ES10701860.8T patent/ES2646314T3/es active Active

- 2010-01-27 US US13/202,385 patent/US20120040205A1/en not_active Abandoned

- 2010-01-27 WO PCT/EP2010/050931 patent/WO2010094538A1/de not_active Ceased

- 2010-01-27 EP EP10701860.8A patent/EP2398606B1/de not_active Not-in-force

- 2010-01-27 CA CA2752855A patent/CA2752855C/en not_active Expired - Fee Related

- 2010-01-27 KR KR1020117019234A patent/KR20110122679A/ko not_active Ceased

- 2010-01-27 CN CN201080008202.0A patent/CN102317001B/zh not_active Expired - Fee Related

- 2010-01-27 PL PL10701860T patent/PL2398606T3/pl unknown

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2006038868A1 (en) * | 2004-10-04 | 2006-04-13 | Gestamp Hardtech Ab | A method of hot stamping and hardening a metal sheet |

| DE102005025026B3 (de) * | 2005-05-30 | 2006-10-19 | Thyssenkrupp Steel Ag | Verfahren zum Herstellen eines Metallbauteils mit aneinander angrenzenden Abschnitten unterschiedlicher Materialeigenschaften |

| WO2008024042A1 (en) * | 2006-08-25 | 2008-02-28 | Gestamp Hardtech Ab | A method of hot-shaping and hardening an object from a metal sheet, and a b-pillar for a vehicle |

| WO2010133526A1 (de) * | 2009-05-18 | 2010-11-25 | Thyssenkrupp Steel Europe Ag | Verfahren zur herstellung eines metallbauteils aus einem warmverprägten ausgangsmaterial |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102022114057A1 (de) | 2022-06-03 | 2023-12-14 | Bayerische Motoren Werke Aktiengesellschaft | Unterschiedliche Blechdicken und Festigkeiten aufweisendes pressgehärtetes Blechformteil |

Also Published As

| Publication number | Publication date |

|---|---|

| US20120040205A1 (en) | 2012-02-16 |

| DE102009003508A1 (de) | 2010-09-02 |

| CN102317001A (zh) | 2012-01-11 |

| JP2012517901A (ja) | 2012-08-09 |

| CN102317001B (zh) | 2016-02-24 |

| CA2752855C (en) | 2016-10-18 |

| ES2646314T3 (es) | 2017-12-13 |

| DE102009003508B4 (de) | 2013-01-24 |

| CA2752855A1 (en) | 2010-08-26 |

| KR20110122679A (ko) | 2011-11-10 |

| WO2010094538A1 (de) | 2010-08-26 |

| PL2398606T3 (pl) | 2018-01-31 |

| EP2398606A1 (de) | 2011-12-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2398606B1 (de) | Verfahren zur herstellung eines pressgehärteten metallbauteils | |

| DE102009025821B4 (de) | Verfahren zur Herstellung eines Metallbauteils | |

| DE102008044523B4 (de) | Warmumformprofile | |

| EP2155917B1 (de) | Verfahren zur herstellung eines lokal gehärteten profilbauteils | |

| EP0946311B1 (de) | Verfahren zum herstellen eines blechformteiles durch umformen | |

| DE102013114245B3 (de) | Verfahren und Vorrichtung zur Herstellung warmumgeformter Radschüsseln | |

| EP3160667B1 (de) | Verfahren und umformwerkzeug zum warmumformen sowie entsprechendes werkstück | |

| DE102008020473A1 (de) | Verfahren zur Herstellung von in der Dicke variierenden Blechplatinen | |

| EP3138708B1 (de) | Drehstab-stabilisator und verfahren zu dessen herstellung | |

| DE102014112755B4 (de) | Verfahren zum Umformen eines Werkstücks, insbesondere einer Platine, aus Stahlblech | |

| DE102015203644A1 (de) | Pressgehärtetes Blechformteil mit unterschiedlichen Blechdicken und Festigkeiten | |

| DE102014111501B4 (de) | Warmumformvorrichtung und Verfahren zum Herstellen von pressgehärteten Formbauteilen aus Stahlblech | |

| EP2094415B1 (de) | Zahnstange | |

| EP3177416B1 (de) | Verfahren zur herstellung von warmumgeformten bauteilen | |

| WO2013072055A1 (de) | Strukturbauteile für fahrzeugsitze sowie verfahren zu deren herstellung | |

| DE102011054866A1 (de) | Verfahren zur Herstellung eines warmumgeformten und pressgehärteten Kraftfahrzeugkarosseriebauteils sowie Kraftfahrzeugkarosseriebauteil | |

| EP2169084B1 (de) | Verfahren zur Herstellung eines Formbauteils mit Bereichen unterschiedlicher Festigkeit aus Kaltband | |

| DE102009053534B4 (de) | Vorrichtung und Verfahren zum Umformen und/oder Vergüten von Blechbauteilen sowie damit hergestelltes Blechformteil | |

| WO2005075279A1 (de) | Bautell mit einem verbindungsbereich, sowie verfahren und werkzeug zu seiner herstellung | |

| DE102005041741B4 (de) | Verfahren zum Herstellen eines pressgehärteten Bauteils | |

| WO2019048025A1 (de) | Verfahren zur herstellung eines bauteils und werkzeug dafür | |

| EP2586881B1 (de) | Verfahren zur Herstellung eines Formteiles aus hochfestem oder höchstfestem Stahl | |

| DE102008016224B4 (de) | Profilteil für Kraftfahrzeugkarosserie mit variabler Profilbreite | |

| EP2314397B1 (de) | Verfahren zum Herstellen eines Teiles aus einem Blech | |

| DE102006062242A1 (de) | Formteil |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20110728 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20141212 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20170309 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: SIKORA, SASCHA Inventor name: ULRICHS, ANDREAS Inventor name: PATBERG, LOTHAR Inventor name: LENZE, FRANZ-JOSEF |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 916261 Country of ref document: AT Kind code of ref document: T Effective date: 20170815 Ref country code: CH Ref legal event code: EP |

|

| RIN2 | Information on inventor provided after grant (corrected) |

Inventor name: SIKORA, SASCHA Inventor name: ULRICHS, ANDREAS Inventor name: LENZE, FRANZ-JOSEF Inventor name: PATBERG, LOTHAR |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502010013968 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20170809 Ref country code: ES Ref legal event code: FG2A Ref document number: 2646314 Country of ref document: ES Kind code of ref document: T3 Effective date: 20171213 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170809 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170809 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170809 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170809 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171110 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170809 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171209 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170809 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170809 |

|

| REG | Reference to a national code |

Ref country code: SK Ref legal event code: T3 Ref document number: E 26382 Country of ref document: SK |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502010013968 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170809 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170809 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20180511 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170809 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170809 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180127 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20180131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180131 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180131 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170809 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20191227 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20200122 Year of fee payment: 11 Ref country code: DE Payment date: 20200121 Year of fee payment: 11 Ref country code: GB Payment date: 20200124 Year of fee payment: 11 Ref country code: ES Payment date: 20200221 Year of fee payment: 11 Ref country code: IT Payment date: 20200131 Year of fee payment: 11 Ref country code: SE Payment date: 20200121 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20100127 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170809 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CZ Payment date: 20200123 Year of fee payment: 11 Ref country code: SK Payment date: 20200123 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170809 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170809 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20200124 Year of fee payment: 11 Ref country code: FR Payment date: 20200121 Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502010013968 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 916261 Country of ref document: AT Kind code of ref document: T Effective date: 20210127 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20210127 |

|

| REG | Reference to a national code |

Ref country code: SK Ref legal event code: MM4A Ref document number: E 26382 Country of ref document: SK Effective date: 20210127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210127 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210131 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210128 Ref country code: SK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210127 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210127 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210803 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210127 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20220429 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210128 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210127 |