EP2369580B1 - Wirbel für ein Saiteninstrument - Google Patents

Wirbel für ein Saiteninstrument Download PDFInfo

- Publication number

- EP2369580B1 EP2369580B1 EP10157648.6A EP10157648A EP2369580B1 EP 2369580 B1 EP2369580 B1 EP 2369580B1 EP 10157648 A EP10157648 A EP 10157648A EP 2369580 B1 EP2369580 B1 EP 2369580B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- string

- section

- machine head

- collar

- vortex

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 238000004804 winding Methods 0.000 claims description 17

- 230000008901 benefit Effects 0.000 description 3

- 230000002093 peripheral effect Effects 0.000 description 3

- 238000005336 cracking Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000036651 mood Effects 0.000 description 1

- 230000002040 relaxant effect Effects 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G10—MUSICAL INSTRUMENTS; ACOUSTICS

- G10D—STRINGED MUSICAL INSTRUMENTS; WIND MUSICAL INSTRUMENTS; ACCORDIONS OR CONCERTINAS; PERCUSSION MUSICAL INSTRUMENTS; AEOLIAN HARPS; SINGING-FLAME MUSICAL INSTRUMENTS; MUSICAL INSTRUMENTS NOT OTHERWISE PROVIDED FOR

- G10D3/00—Details of, or accessories for, stringed musical instruments, e.g. slide-bars

- G10D3/14—Tuning devices, e.g. pegs, pins, friction discs or worm gears

-

- G—PHYSICS

- G10—MUSICAL INSTRUMENTS; ACOUSTICS

- G10D—STRINGED MUSICAL INSTRUMENTS; WIND MUSICAL INSTRUMENTS; ACCORDIONS OR CONCERTINAS; PERCUSSION MUSICAL INSTRUMENTS; AEOLIAN HARPS; SINGING-FLAME MUSICAL INSTRUMENTS; MUSICAL INSTRUMENTS NOT OTHERWISE PROVIDED FOR

- G10D3/00—Details of, or accessories for, stringed musical instruments, e.g. slide-bars

-

- G—PHYSICS

- G10—MUSICAL INSTRUMENTS; ACOUSTICS

- G10G—REPRESENTATION OF MUSIC; RECORDING MUSIC IN NOTATION FORM; ACCESSORIES FOR MUSIC OR MUSICAL INSTRUMENTS NOT OTHERWISE PROVIDED FOR, e.g. SUPPORTS

- G10G7/00—Other auxiliary devices or accessories, e.g. conductors' batons or separate holders for resin or strings

Definitions

- the present invention relates to a vortex for a stringed instrument having the features of the preamble of claim 1. It further relates to a provided with such a vortex string instrument itself.

- the whirling wooden pegs or metal pegs on which the string ends are rolled up are called vertebrae.

- the tension of the strings can be changed and the instrument can be tuned with it.

- the vertebrae are adjustable by means of appropriate handling gear stages, to be able to cause a fine tuning.

- whirls are waves on which a string end can be wound up for a tightening and thus higher mood, or for relaxing and thus for deeper voices.

- a string to a vertebra typically has, in a winding section, a through hole or slot through which the string end is guided and subsequently fixed by knotting or entangling.

- This type of fixing a string end to the vortex is complicated to perform and there is - especially in non-professional execution - the risk of loosening or yielding of the end of the string and, consequently, a detuning of the instrument.

- a node attached here for fixing the end of the string or a similar twisted construct occupies a considerable space, so that the space required for vertebrae is comparatively large.

- the above-mentioned disadvantages also have an effect, in particular, on such vertebrae which, as part of automated tuning systems, adjust the tension of the strings by motor-driven means.

- it depends on a high strength of the specified end of the string for a reproducible tuning of the instrument.

- for a motor-driven adjustment as uniform as possible winding the string end on the vertebrae of advantage which is difficult for a one-sided arranged on a vertebra node or a similar loop, since there the string always on the through the node or the Loop formed increase accumulates.

- a vortex for a stringed instrument which can be used according to the invention in particular for a guitar, but also for other stringed instruments, has a winding section on which the string runs, and a fastening device for fixing a free end of the string.

- the fastening device comprises a clamping element, an abutment section on the vortex and a holding section on the vortex.

- the holding section and the clamping element are set up such that the clamping element can be axially displaced along the holding section onto the vortex and locked in a clamping position.

- the clamping member and the abutment portion are arranged to interpose one another Clamp longitudinal section of the free end of the string and can hold.

- a longitudinal section of the free end of the string is to be understood as an elongate section which has a clear longitudinal extent and differs in this respect from a piece of the string to be clamped only at certain points.

- the end of a string to be defined therein and to be adjusted with respect to its tension and tuning can not simply be fixed by arranging a corresponding longitudinal section of the free end of the string on the abutment section and by means of the holding section clamped on the vertebra clamping element is clamped there.

- the jamming of the string end can be carried out in a particularly high positional and stable, so that not as in the traditional method a yielding of a node or a release from the attachment to be feared and thus no induced thereby detuning the specified there string.

- a circumferential collar is provided according to the invention.

- This circumferential collar extends around the axis of the vortex and serves as a support for a portion of the string end, which there guided around a considerable peripheral part (up to almost 360 °) about the axis of the vortex and then clamped with this entire length portion by means of the clamping element can be.

- Such a circumferential collar thus offers the possibility in compact space to clamp the string end over a considerable longitudinal extent and thus to distribute the clamping forces over a wide portion of the string. This results in addition to the already mentioned reduction of Spitzenentlasten also improved support, as over a longer and larger portion of the string end the clamping and thus the backing due to the clamping and frictional forces takes place.

- the circumferential collar of the vortex according to the invention is further partially along the circumference around the vertebra is interrupted, has one or more cuts on is called.

- Such a cut can e.g. can be used to measure the end of the string from one side of the collar, on e.g. the winding section may (see claim 2) to the opposite side, on which the collar has the abutment surface and on the e.g.

- the holding section can lie (see claim 2) to lead, without having to form here a particularly sharp-edged kink of the string on the collar edge.

- the string end can be performed in comparatively gently curved radii, which in turn benefits the durability of the string, in which sharp-angled deflections always represent a point of weakness, especially then if there is still friction due to the vibrating string.

- the holding portion may be a provided with an external thread portion of the vortex and the clamping element is a screw with a corresponding to the external thread internal thread.

- the externally threaded portion is arranged at a free end of the vortex in such a manner that the screw is completely detachable from the vortex screwed onto the externally threaded holding portion.

- This type of design allows in particular easy replacement and care of the parts.

- the screw is provided for better handling of the same in an advantageous manner with a handle portion, which may in particular be toothed, knurled or structured in any other way as a peripheral portion.

- a handle portion which may in particular be toothed, knurled or structured in any other way as a peripheral portion.

- a vortex according to the invention is shown, which is here a vortex for a guitar, in particular an electric guitar.

- the figures shown are purely schematic and do not represent complete design drawings. They are merely illustrative and description of an embodiment for further illustrating the invention.

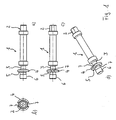

- FIGS. 1a to 1d is shown in four different views, an inventive vortex shown without the fastening device for fixing the end of a string of the musical instrument also belonging clamping element.

- the vortex 1 is an elongated part, technically a wave. At its one longitudinal end, it has a connecting portion 2 for connection to an actuating mechanism, for example a hand-wheel drive for rotational adjustment of the vortex 1.

- the vertebra 1 further has a winding section 3, on which a string of the musical instrument wound or from which they are unwound can be used to increase or decrease the tension of the strings to adjust the tuning of the string.

- a winding section 3 On the opposite side of the connecting portion 2 of the winding section 3 is limited by a circumferential collar 4, on the one hand forms a lateral stop for the string and thus a limitation of the winding section 3, but on the other hand also on the winding section 3 opposite side forms an abutment surface 5, whose function will be explained below.

- On the side opposite the winding section 3 side of the collar 4 further includes a holding portion 6, which forms the connecting portion 2 opposite free end of the vortex 1.

- the holding portion 6 has a not-shown here external thread, which cooperates in a manner to be described later with the internal thread of a clamping element.

- incisions 7 are also provided at radially opposite positions, in which the collar 4 is cut to the diameter of the winding section. These cuts 7 are used to carry out a string or a string end of the winding section 3 on the opposite side of the collar 4 to the abutment surface. 5

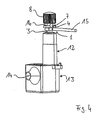

- Fig. 2 is shown as a clamping element, a clamping screw 8.

- This clamping screw is formed substantially cylindrical and has on its peripheral surface, which forms the grip portion of the clamping screw 8, a knurling 9.

- This knurling 9 improves the grip and allows easy operation of the clamping screw 8 with two fingers of one hand.

- the clamping screw 8 on its inside a there not graphically illustrated, but provided with the reference numeral 10 internal thread.

- This internal thread is formed corresponding to the formed on the holding portion 6 of the vertebra 1 external thread and can be brought into engagement with this for screwing the clamping screw 8 on the free end of the vertebra 1 with the holding portion 6.

- the clamping screw 8 in axial Direction of the vortex 1 are screwed up and down, in particular with a clamping surface 17 against the abutment surface 5 are pressed.

- FIG. 3 an assembly of the vortex 1 with the clamping screw 8 is shown in an exploded view, and further a drive housing, in which the vortex 1 is used.

- the drive housing consists of a guide member 11 with molded thereon housing cover and a housing part 13 in which the drive units are arranged.

- the guide member 11 is provided with a guide sleeve 12 in which the swivel 1 is rotatably mounted.

- an opening 14 is arranged through which a drive axle, for example with a hand screw for manual adjustment of the rotational angular position of the vortex 1 can be passed.

- the structure shown here is set up in particular for a motor drive of the vortex 1, for which a motor, possibly with a gear unit, can be arranged in the housing part 13.

- Fig. 4 is finally the assembly of in Fig. 3 shown in exploded view parts, and it is shown how a string 1 5 runs onto the winding portion 3 and is fixed with a free end 16 in accordance with the invention by means of the fastening device.

- the string 15 runs, as already mentioned, on the winding section 3, its free end is passed through the incision 7 in the collar 4 and placed in a circle around almost 360 ° on the abutment surface of the collar 4.

- the clamping screw 8 is screwed onto the holding portion of the vertebra 1 and presses with its clamping surface on the free end 16 of the string 15 and thus jammed this free end 16 against the abutment surface of the collar. 4

- the free end 16 of the string 15 can be set as easy and fast on the vortex 1.

- the clamping takes place over a considerable longitudinal portion of the free end 16 of the string 15, so that the forces distributed over a longer range of the string 15 are applied to this and not, as known in the art, selectively. This reduces clearly the risk of cracking or breaking the string.

Landscapes

- Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Acoustics & Sound (AREA)

- Multimedia (AREA)

- Stringed Musical Instruments (AREA)

- Surgical Instruments (AREA)

Priority Applications (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP10157648.6A EP2369580B1 (de) | 2010-03-24 | 2010-03-24 | Wirbel für ein Saiteninstrument |

| JP2013500516A JP2013522685A (ja) | 2010-03-24 | 2011-03-24 | 弦楽器用糸巻き |

| US13/636,788 US8710339B2 (en) | 2010-03-24 | 2011-03-24 | Tuning peg for a stringed instrument |

| CN201180015264.9A CN103026403B (zh) | 2010-03-24 | 2011-03-24 | 弦乐器用的弦轴 |

| CA2794224A CA2794224A1 (en) | 2010-03-24 | 2011-03-24 | Tuning peg for a stringed instrument |

| PCT/EP2011/054570 WO2011117367A1 (de) | 2010-03-24 | 2011-03-24 | Wirbel für ein saiteninstrument |

| KR1020127026754A KR20130054251A (ko) | 2010-03-24 | 2011-03-24 | 현악기용 튜닝 페그 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP10157648.6A EP2369580B1 (de) | 2010-03-24 | 2010-03-24 | Wirbel für ein Saiteninstrument |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2369580A1 EP2369580A1 (de) | 2011-09-28 |

| EP2369580B1 true EP2369580B1 (de) | 2014-04-02 |

Family

ID=42797421

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP10157648.6A Not-in-force EP2369580B1 (de) | 2010-03-24 | 2010-03-24 | Wirbel für ein Saiteninstrument |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US8710339B2 (enExample) |

| EP (1) | EP2369580B1 (enExample) |

| JP (1) | JP2013522685A (enExample) |

| KR (1) | KR20130054251A (enExample) |

| CN (1) | CN103026403B (enExample) |

| CA (1) | CA2794224A1 (enExample) |

| WO (1) | WO2011117367A1 (enExample) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AU2015100011B4 (en) * | 2014-01-13 | 2015-07-16 | Apple Inc. | Temperature compensating transparent force sensor |

| CN106463102A (zh) | 2014-03-12 | 2017-02-22 | 希欧多尔·巴克斯霍顿·柯伦 | 用于更换乐器弦的装置 |

| JP2016081020A (ja) * | 2014-10-09 | 2016-05-16 | 満 倉知 | 糸巻きノブを取り外し可能にしたギター用ペグ(糸巻き) |

| KR101762387B1 (ko) * | 2015-07-24 | 2017-07-28 | 주식회사 하이딥 | 터치 압력 감도 보정 방법 및 컴퓨터 판독 가능한 기록 매체 |

| TWM556912U (zh) * | 2017-06-05 | 2018-03-11 | 子恩 譚 | 用於弦樂器的固音器 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US532053A (en) * | 1895-01-08 | String-clamp for musical instruments | ||

| US4748889A (en) * | 1987-04-07 | 1988-06-07 | Schaller Rene K F | Machine head |

| US5103708A (en) * | 1991-01-16 | 1992-04-14 | Steinberger Sound Corporation | Gearless tuner |

| JPWO2002056291A1 (ja) * | 2001-01-12 | 2004-05-20 | 後藤ガット有限会社 | 弦楽器用糸巻装置およびその製造方法 |

| US6580022B2 (en) * | 2001-04-12 | 2003-06-17 | Han-Soo Kang | Machine head for guitar |

| DE102005014625A1 (de) * | 2005-03-23 | 2006-10-05 | Rudolf Wittner Gmbh & Co. Kg | Wirbelelement und Saiten-Musikinstrument |

| CN201170946Y (zh) * | 2008-02-26 | 2008-12-24 | 宾玮兴业股份有限公司 | 弦线紧度调整结构 |

-

2010

- 2010-03-24 EP EP10157648.6A patent/EP2369580B1/de not_active Not-in-force

-

2011

- 2011-03-24 WO PCT/EP2011/054570 patent/WO2011117367A1/de not_active Ceased

- 2011-03-24 CN CN201180015264.9A patent/CN103026403B/zh not_active Expired - Fee Related

- 2011-03-24 KR KR1020127026754A patent/KR20130054251A/ko not_active Withdrawn

- 2011-03-24 CA CA2794224A patent/CA2794224A1/en not_active Abandoned

- 2011-03-24 US US13/636,788 patent/US8710339B2/en not_active Expired - Fee Related

- 2011-03-24 JP JP2013500516A patent/JP2013522685A/ja not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| CN103026403B (zh) | 2015-06-03 |

| CA2794224A1 (en) | 2011-09-29 |

| JP2013522685A (ja) | 2013-06-13 |

| KR20130054251A (ko) | 2013-05-24 |

| CN103026403A (zh) | 2013-04-03 |

| US20130008297A1 (en) | 2013-01-10 |

| WO2011117367A1 (de) | 2011-09-29 |

| EP2369580A1 (de) | 2011-09-28 |

| US8710339B2 (en) | 2014-04-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3212828C2 (de) | Chirurgische Klammer und Vorrichtung zum Entfernen von chirurgischen Klammern | |

| DE3903354C1 (enExample) | ||

| EP0391384B1 (de) | Lithotriptor | |

| EP0868128B1 (de) | Stockgriff | |

| EP2369580B1 (de) | Wirbel für ein Saiteninstrument | |

| DE29805908U1 (de) | Vorrichtung zur Handhabung eines einen Knochenkanal abdeckenden Implantats | |

| DE3100426A1 (de) | Federzange | |

| DE3804749C2 (enExample) | ||

| WO2018184708A1 (de) | Justierbarer faserkollimator | |

| EP0440682B1 (de) | Verfahren zur bespannung von schlägern für ballspiele sowie vorrichtung zur durchführung des verfahrens | |

| DE3522728C2 (enExample) | ||

| EP2730232A1 (de) | Chirurgische Fadenspannvorrichtung | |

| DE4200858B4 (de) | Vorrichtung zum Stimmen der Saiten eines Musikinstrumentes | |

| EP2944267B1 (de) | Chirurgische Fadenzugvorrichtung | |

| EP0273372B1 (de) | Halsstab für Saiteninstrumente | |

| DE1961980B2 (de) | Nabenbefestigung | |

| DE3490386C2 (enExample) | ||

| DE3914591C2 (enExample) | ||

| DE102006057954B4 (de) | Zahnseidenhalter | |

| DE4408696C1 (de) | Befestigungs- und Stimmechanik für eine Saite eines Chordophons | |

| DE3808238A1 (de) | Schraubwerkzeug mit drehmomentbegrenzung | |

| DE2933845A1 (de) | Kupplungseinrichtung zur loesbaren verbindung eines tragbandes mit einem zu tragenden gegenstand. | |

| WO2007104303A1 (de) | Halter für rolleneinheiten, aufnahmemodul für einen rollenhalter und angelrute mit einem derartigen halter oder aufnahmemodul | |

| CH233978A (de) | Nadel für chirurgische Nähinstrumente. | |

| DE8716673U1 (de) | Akupunkturnadel |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA ME RS |

|

| 17P | Request for examination filed |

Effective date: 20120328 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20131011 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 660532 Country of ref document: AT Kind code of ref document: T Effective date: 20140415 Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502010006521 Country of ref document: DE Effective date: 20140522 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20140402 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140702 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140702 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140703 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140804 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502010006521 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20150106 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502010006521 Country of ref document: DE Effective date: 20150106 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 Ref country code: LU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150324 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20150922 Year of fee payment: 6 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20150324 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20151130 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150324 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150331 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150331 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150324 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150331 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 660532 Country of ref document: AT Kind code of ref document: T Effective date: 20150324 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150324 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502010006521 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20100324 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140402 |