EP2175702B2 - Nozzle for a fluid-cooled plasma torch, nozzle cap for same and plasma torch head with same - Google Patents

Nozzle for a fluid-cooled plasma torch, nozzle cap for same and plasma torch head with same Download PDFInfo

- Publication number

- EP2175702B2 EP2175702B2 EP09011322.6A EP09011322A EP2175702B2 EP 2175702 B2 EP2175702 B2 EP 2175702B2 EP 09011322 A EP09011322 A EP 09011322A EP 2175702 B2 EP2175702 B2 EP 2175702B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- nozzle

- liquid supply

- section

- case

- groove

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000110 cooling liquid Substances 0.000 claims description 87

- 239000007788 liquid Substances 0.000 claims description 76

- 239000002826 coolant Substances 0.000 description 57

- 239000007789 gas Substances 0.000 description 23

- 238000001816 cooling Methods 0.000 description 13

- 238000005520 cutting process Methods 0.000 description 11

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 11

- 230000007704 transition Effects 0.000 description 8

- 239000012530 fluid Substances 0.000 description 6

- 239000000463 material Substances 0.000 description 5

- 240000006829 Ficus sundaica Species 0.000 description 4

- 238000013021 overheating Methods 0.000 description 4

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 3

- 239000003570 air Substances 0.000 description 3

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 3

- 239000004020 conductor Substances 0.000 description 3

- 229910052802 copper Inorganic materials 0.000 description 3

- 239000010949 copper Substances 0.000 description 3

- 238000002845 discoloration Methods 0.000 description 3

- 239000001301 oxygen Substances 0.000 description 3

- 229910052760 oxygen Inorganic materials 0.000 description 3

- 238000003466 welding Methods 0.000 description 3

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- 229910001369 Brass Inorganic materials 0.000 description 2

- 239000010951 brass Substances 0.000 description 2

- 230000007797 corrosion Effects 0.000 description 2

- 238000005260 corrosion Methods 0.000 description 2

- 239000001257 hydrogen Substances 0.000 description 2

- 229910052739 hydrogen Inorganic materials 0.000 description 2

- 230000001590 oxidative effect Effects 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 230000008646 thermal stress Effects 0.000 description 2

- 230000001154 acute effect Effects 0.000 description 1

- 230000002528 anti-freeze Effects 0.000 description 1

- 229910052786 argon Inorganic materials 0.000 description 1

- 125000004429 atom Chemical group 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 229910052735 hafnium Inorganic materials 0.000 description 1

- VBJZVLUMGGDVMO-UHFFFAOYSA-N hafnium atom Chemical compound [Hf] VBJZVLUMGGDVMO-UHFFFAOYSA-N 0.000 description 1

- 125000004435 hydrogen atom Chemical class [H]* 0.000 description 1

- 238000011835 investigation Methods 0.000 description 1

- 150000002500 ions Chemical class 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 230000007935 neutral effect Effects 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 239000012811 non-conductive material Substances 0.000 description 1

- 238000007750 plasma spraying Methods 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 1

- 229910052721 tungsten Inorganic materials 0.000 description 1

- 239000010937 tungsten Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05H—PLASMA TECHNIQUE; PRODUCTION OF ACCELERATED ELECTRICALLY-CHARGED PARTICLES OR OF NEUTRONS; PRODUCTION OR ACCELERATION OF NEUTRAL MOLECULAR OR ATOMIC BEAMS

- H05H1/00—Generating plasma; Handling plasma

- H05H1/24—Generating plasma

- H05H1/26—Plasma torches

- H05H1/28—Cooling arrangements

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05H—PLASMA TECHNIQUE; PRODUCTION OF ACCELERATED ELECTRICALLY-CHARGED PARTICLES OR OF NEUTRONS; PRODUCTION OR ACCELERATION OF NEUTRAL MOLECULAR OR ATOMIC BEAMS

- H05H1/00—Generating plasma; Handling plasma

- H05H1/24—Generating plasma

- H05H1/26—Plasma torches

- H05H1/32—Plasma torches using an arc

- H05H1/34—Details, e.g. electrodes, nozzles

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05H—PLASMA TECHNIQUE; PRODUCTION OF ACCELERATED ELECTRICALLY-CHARGED PARTICLES OR OF NEUTRONS; PRODUCTION OR ACCELERATION OF NEUTRAL MOLECULAR OR ATOMIC BEAMS

- H05H1/00—Generating plasma; Handling plasma

- H05H1/24—Generating plasma

- H05H1/26—Plasma torches

- H05H1/32—Plasma torches using an arc

- H05H1/34—Details, e.g. electrodes, nozzles

- H05H1/3457—Nozzle protection devices

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05H—PLASMA TECHNIQUE; PRODUCTION OF ACCELERATED ELECTRICALLY-CHARGED PARTICLES OR OF NEUTRONS; PRODUCTION OR ACCELERATION OF NEUTRAL MOLECULAR OR ATOMIC BEAMS

- H05H1/00—Generating plasma; Handling plasma

- H05H1/24—Generating plasma

- H05H1/26—Plasma torches

- H05H1/32—Plasma torches using an arc

- H05H1/34—Details, e.g. electrodes, nozzles

- H05H1/3478—Geometrical details

Definitions

- the present invention relates to a nozzle for a liquid-cooled plasma torch and to a plasma torch head having the same.

- Plasma is a thermally highly heated electrically conductive gas, which consists of positive and negative ions, electrons and excited and neutral atoms and molecules.

- the plasma gas used is a variety of gases, for example the monatomic argon and / or the diatomic gases hydrogen, nitrogen, oxygen or air. These gases ionize and dissociate through the energy of an arc.

- the plasma jet can be greatly influenced in its parameters by the design of the nozzle and electrode. These parameters of the plasma jet are, for example, the beam diameter, the temperature, the energy density and the flow velocity of the gas.

- the plasma is constricted through a nozzle, which may be gas or water cooled.

- a nozzle which may be gas or water cooled.

- energy densities up to 2x10 6 W / cm 2 can be achieved.

- Temperatures of up to 30,000 ° C are generated in the plasma jet, which, in combination with the high flow velocity of the gas, produce very high cutting speeds on materials.

- Plasma torches can be operated directly or indirectly.

- the current from the power source flows through the electrode of the plasma torch, the arc generated by the arc and constricted by the nozzle directly back to the power source via the workpiece.

- electrically conductive materials can be cut.

- the current flows from the power source through the electrode of the plasma torch, the plasma jet generated by the arc and constricted by the nozzle and the nozzle back to the power source.

- the nozzle is even more heavily loaded than with direct plasma cutting, because it not only constricts the plasma jet, but also realizes the starting point of the arc.

- both electrically conductive and non-conductive materials can be cut.

- the nozzle is then inserted into a plasma torch whose main components are a plasma torch head, a nozzle cap, a plasma gas guide member, a nozzle, a nozzle holder, an electrode holder, an electrode holder with electrode insert and in modern plasma torches a nozzle cap holder and a nozzle cap.

- the electrode holder fixes a tungsten tip insert which is suitable for the use of non-oxidizing gases as plasma gas, for example an argon-hydrogen mixture.

- a so-called flat electrode whose electrode insert consists for example of hafnium is also suitable for the use of oxidizing gases as plasma gas, for example air or oxygen.

- oxidizing gases for example air or oxygen.

- the nozzle In order to achieve a long service life for the nozzle, it is cooled here with a liquid, for example water.

- the coolant is directed towards the nozzle via a water feed and a water return from the nozzle and flows through a coolant space which is delimited by the nozzle and the nozzle cap.

- a nozzle In DD 36014 B1 a nozzle is described. This consists of a highly conductive material, for example copper, and has a geometric shape associated with the respective plasma torch type, for example a conical discharge space with a cylindrical nozzle exit.

- the outer shape of the nozzle is formed as a cone, wherein an approximately equal wall thickness is achieved, which is dimensioned so that a good stability of the nozzle and a good heat conduction to the coolant is ensured.

- the nozzle sits in a nozzle holder.

- the nozzle holder is made of corrosion-resistant material, such as brass, and has inside a centering for the nozzle and a groove for a rubber seal, which seals the discharge space against the coolant.

- nozzle holder for the coolant supply and return.

- the nozzle cap also made of corrosion-resistant material, such as brass, is formed at an acute angle and has a useful for the dissipation of radiant heat to the coolant wall thickness.

- the smallest inner diameter is provided with a round ring.

- the easiest way to cool water is to use water. This arrangement is intended to allow easy production of the nozzles with economical use of material and rapid replacement of these and by the acute-angled design pivoting of the plasma torch relative to the workpiece and thus bevel cuts.

- a plasma torch preferably for plasma cutting of materials and for welding edge preparation is described.

- the slender shape of the burner head is achieved by the use of a particularly acute-angled cutting nozzle whose inner and outer angles are equal to each other and equal to the inner and outer angles of the nozzle cap.

- a coolant space is formed, in which the nozzle cap is provided with a collar, which seals with the metal cutting nozzle, thereby forming a uniform annular gap as the coolant space.

- the supply and discharge of the coolant generally water, is carried out by two 180 ° offset from each other arranged slots in the nozzle holder.

- a plasma arc torch in particular for cutting or welding, is described, in which the electrode holder and the nozzle body form an exchangeable structural unit.

- the outer coolant supply is essentially formed by a comprehensive the nozzle body cap.

- the coolant flows via channels into an annular space, which is formed by the nozzle body and the cap.

- DE 692 33 071 T2 relates to an arc plasma cutting device. Described herein is an embodiment of a plasma arc cutting nozzle nozzle formed from a conductive material and having a plasma jet jet exit and a hollow body portion configured to have a generally conical thin-walled configuration in the direction is inclined to the outlet opening and has an enlarged head portion which is formed integrally with the body portion, wherein the head portion is solid except for a central channel, which is aligned with the outlet opening and having a generally conical outer surface, which is also in the direction of the outlet opening is inclined and has a diameter adjacent to that of the adjacent body portion exceeding the diameter of the body portion to form a recessed recess.

- the arc plasma cutter has a secondary gas cap.

- a water-cooled cap is disposed between the nozzle and the secondary gas cap to form a water-cooled chamber for the outer surface of the nozzle for high-efficiency cooling.

- the nozzle is characterized by a large head surrounding an exit port for the plasma jet and a sharp undercut or recess to a conical body. This nozzle design favors the cooling of the nozzle.

- the coolant is led back to the nozzle via a water feed channel and away from the nozzle via a water return channel.

- These channels are usually offset by 180 ° to each other and the coolant should flow around the nozzle as evenly as possible on the way from the flow to the return. Nevertheless, overheating in the vicinity of the nozzle channel are repeatedly found.

- FIG. 1 Another coolant guide for a burner, preferably plasma torches, in particular for plasma welding, plasma cutting, plasma melting and plasma spraying, which withstands high thermal stresses on the nozzle and the cathode is disclosed in US Pat DD 83890 B1 described.

- the nozzle in the nozzle holding part easily deployable and removabledemedienleitring arranged to limit the cooling media on a thin layer of a maximum thickness of 3 mm along the outer nozzle wall has a circumferential Formnut, in the more than one, preferably two to four, and star-shaped to this radially and symmetrically to the nozzle axis and star connected to this at an angle between 0 and 90 ° mounted cooling lines so that it is adjacent by two cooling media outlets and each cooling medium outflow of two cooling medium inflows.

- the invention is therefore based on the object to avoid overheating in the vicinity of the nozzle channel or the nozzle bore in a simple manner.

- substantially cylindrical is intended to mean that the outer surface is, at least when thinking away of the grooves, such as liquid inlet and - Weglaufnuten, by and large cylindrical.

- substantially conically tapered means that the outer surface, at least when the grooves are thought out, such as liquid inlet and return grooves, is conically tapered by and large.

- the nozzle has one or twodestattkeitszulaufnut (s), and the nozzle cap on its inner surface at least two, in particular exactly three, recesses whose openings facing the nozzle each extend over an arc length (b 2 ), wherein the arc length of the circumferentially adjacent to thedefactkeitszulaufnut (s) adjacent to the ordefactkeitszulaufnut (s) outwardly projecting portions of the nozzle is greater than the arc length (d4, e4).

- a shunt from the coolant inlet to the coolant return is particularly elegant avoided.

- the two bores each extend substantially parallel to the longitudinal axis of the plasma burner head. This ensures that coolant lines can be connected to save space on the plasma burner head.

- the bores for the cooling liquid inlet to the Küh gutkeits Weglauf can be arranged offset by 180 °.

- the radian dimension of the section between the recesses of the nozzle cap is at most half the size of the minimum radian measure of the coolant return groove or the minimum radian measure of the coolant inlet groove (s) of the nozzle.

- the liquid return groove (s) may also extend over a portion of the first portion in the outer surface of the nozzle.

- At least two fluid inlet grooves are provided in case a) and at least two fluid pressure grooves are provided in case b).

- the center of the liquid inlet groove and the center of the copestechniks Weglaüfnut are arranged offset by 180 ° to each other over the circumference of the nozzle.

- the liquid inlet groove and the liquid return groove face each other.

- the width of the liquid return groove and in case b) the width of the liquid inlet groove in the direction of contact in the range of 90 ° to 270 °.

- the liquid inlet groove extends in the circumferential direction of the first portion of the nozzle over the entire circumference.

- liquid inlet groove in the circumferential direction of the first portion of the nozzle over an angle of 60 ° to 300 ° and in case b) the liquid return groove in the circumferential direction of the first portion of the nozzle over an angle in the range of 60 ° to 300 °.

- this may be provided that in the case of a) this diesstechnikszulaufnut in the circumferential direction of the first portion of the nozzle over an angle in the range of 90 ° to 270 ° and in case b) the liquid return groove in the circumferential direction of the first portion of the nozzle over an angle in Range extends from 90 ° to 270 °.

- the two liquid feed grooves may be arranged circumferentially of the nozzle symmetrical to a straight line extending from the center of the liquid return groove at right angles through the longitudinal axis of the nozzle and in case b) the two liquid return grooves symmetrical about the circumference of the nozzle are arranged to a straight line extending from the center of the diesstechnikszulaufnut at right angles through the longitudinal axis of the nozzle.

- the width of the liquid return groove and in case b) the width of the liquid inlet groove in the circumferential direction is in the range of 120 ° to 270 °.

- the liquid inlet groove in case a) via one or both of the fluid inlet grooves and in case b) the fluid return groove beyond one or both of the fluid return grooves.

- the liquid inlet groove extends in the circumferential direction of the first portion of the nozzle over the entire circumference.

- the two holes could each extend substantially parallel to the longitudinal axis of the plasma burner head.

- the holes for the coolant inlet and the coolant return are arranged offset by 180 °.

- the invention is based on the surprising finding that by supplying and / or removing the cooling liquid at right angles to the longitudinal axis of the plasma burner head instead of - as in the prior art - parallel to the longitudinal axis of the plasma burner head, a better cooling of the nozzle by significantly longer contact of the cooling liquid the nozzle is achieved.

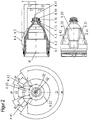

- the in the FIG. 1 shown plasma burner head 1 takes with an electrode holder 6, an electrode 7 in the present case via a thread (not shown).

- the electrode is designed as a flat electrode.

- air or oxygen can be used as the plasma gas (PG).

- a nozzle 4 is received by a substantially cylindrical nozzle holder 5.

- a nozzle cap 2 which is attached via a thread (not shown) to the plasma burner head 1, fixed the nozzle 4 and forms with this a cooling liquid space 10.

- the cooling liquid space 10 is realized by a realized with a circular ring seal 4.16, which in a groove 4.15 of Nozzle 4 is sealed between the nozzle 4 and the nozzle cap 2.

- a cooling liquid eg. As water or antifreeze added water flows through the coolant chamber 10 from a bore of the coolant flow WV to a bore of the coolant return WR, wherein the holes are arranged offset by 180 ° to each other.

- the nozzle bore 4.10 of the nozzle 4 is insufficiently cooled because the cooling liquid insufficiently flows through the part 10.20 of the cooling liquid space 10 closest to the nozzle bore and / or even on the side facing the coolant liquid return not reached.

- the cooling liquid is aptly directed into the cooling liquid space 10 almost perpendicular to the longitudinal axis of the plasma burner head 1 from the nozzle holder 5 to the nozzle 4.

- a deflection space 10.10 of the cooling liquid space 10 the cooling liquid from the direction parallel to the longitudinal axis in the bore of the cooling liquid flow WV of the plasma burner in Direction first nozzle section 4.1 (s. Fig. 2 ) is deflected almost perpendicular to the longitudinal axis of the plasma burner head 1.

- the cooling liquid flows through the coolant flowing from adestattkeitsvorlaufnut 4.20 (s. Fig. 1a .

- the plasma burner head 1 is equipped with a nozzle protection cap holder 8 and a nozzle protection cap 9. Through this area flows the secondary gas SG, in the plasma jet surrounds.

- the secondary gas SG flows through a secondary gas guide 9.1 and can be rotated by this.

- Fig. 1a shows a sectional view along the line AA of the plasma torch FIG. 1 , This shows how the formed by thedefactkeitszulaufnut 4.20 of the nozzle 4 and the nozzle cap 2 space 10.11 by sections 4.41 and 4.42 of protruding portions 4.31 and 4.32 of the nozzle 4 in combination with the inner surface 2.5 of the nozzle cap 2 prevent a shunt between the cooling liquid flow and coolant return , So that in each position of the nozzle 4 to the nozzle cap 2 to each other, the shunt of the cooling liquid is prevented, the sheet dimensions d4 and e4 of sections 4.41 and 4.42 of the protruding areas 4.31 and 4.32 of the nozzle 4 must be at least as large as the radians b2 to the nozzle facing recesses 2.6 of the nozzle cap 2 (s. Fig. 14 to 16 ).

- an effective cooling of the nozzle 4 is achieved in the region of the nozzle tip and prevents thermal overload. It is ensured that as much coolant as possible reaches the space 10.20 of the coolant chamber 10. There was no discoloration of the nozzle in the area of the nozzle bore 4.10 in experiments. Also leaks between the nozzle 4 and the nozzle cap 2 did not occur and the circular ring 4.16 was not overheated.

- FIG. 1b includes a sectional view taken along the line B of the plasma burner head FIG. 1 , which shows the plane of the deflection 10.10.

- Fig. 2 shows the nozzle 4 of the plasma burner head FIG. 1 , It has a nozzle bore 4.10 for the exit of a plasma jet at a nozzle tip 4.11, a first section 4.1, the outer surface 4.4 is substantially cylindrical, and adjoining the nozzle tip 4.11 second section 4.2, the outer surface of the 4.5 to the nozzle tip 4.11 out in essentially conically tapered.

- Thedestattkeitszulaufnut 4.20 extends over a portion of the first section 4.1 and the second section 4.2 in the outer surface 4.5 of the nozzle 4 to the nozzle tip 4.11 and ends in front of the cylindrical outer surface 4.3.

- Thedestattkeits Weglaufnut 4.22 extends over the second section 4.2 of the nozzle 4.

- the center of thedeckenkeitszulaufnut 4.20 and the center of thedefactkeitsschreiblaufnut (4.22) are arranged offset by 180 ° to each other over the circumference of the nozzle (4).

- the width alpha 4 of thedefactkeitsschreiblaufnut 4.22 in the circumferential direction is about 250 °.

- Between thedeckenkeitsvorlaufnut 4.20 and thedeckenkeitsschreiblaufnut 4.22 are the outwardly projecting areas 4.31 and 4.32 with the corresponding sections 4.41 and 4.42.

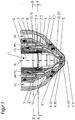

- FIG. 3 shows a plasma burner similar FIG. 1 ,

- the nozzle 4 has twodestattkeitszulaufnuten 4.20 and 4.21.

- the cooling liquid is directed almost perpendicular to the longitudinal axis of the plasma burner head 1 of the nozzle holder 5 on the nozzle 4 in the cooling liquid space 10.

- the cooling liquid is deflected from the direction parallel to the longitudinal axis in the bore of the cooling liquid flow WV of the plasma burner in the direction of the first nozzle section 4.1 almost perpendicular to the longitudinal axis of the plasma burner head 1.

- the cooling liquid flows through a groove 5.1 of the nozzle holder 5 in the two formed by thedeckenkeitszulaufnuten 4.20 and 4.21 of the nozzle 4 and the nozzle cap 2 spaces 10.11 and 10.12 to the nozzle bore 4.10 surrounding area 10.20 of the cooling liquid space 10 and flows around the nozzle 4 there , Thereafter, the cooling liquid flows back through the space 10.15 formed by the cooling liquid return groove 4.22 of the nozzle 4 and the nozzle cap 2 to the coolant return WR, the transition taking place substantially parallel to the longitudinal axis of the plasma burner head.

- Fig. 3a includes a sectional view taken along the line AA of the plasma torch FIG. 3 and shows how the spaces 10.11 and 10.12 formed by the cooling liquid supply grooves 4.20 and 4.21 of the nozzle 4 and the nozzle cap 2 form a shunt between the portions 4.41 and 4.42 of the protruding portions 4.31 and 4.32 of the nozzle 4 in combination with the inner surface 2.5 of the nozzle cap 2 Prevent the coolant flow and coolant return. At the same time, a shunt between the spaces 10.11 and 10.12 is prevented by the section 4.43 of the protruding area 4.33.

- the sheet dimensions d4 and e4 of sections 4.41 and 4.42 of the nozzle 4 must be at least as large as the radians b2 to the nozzle facing recesses 2.6 of the nozzle cap 2 (s , Fig. 14 to 16 ).

- FIG. 3b is a sectional view taken along the line BB of the plasma torch FIG. 3 that the plane of the deflection 10.10 and the connection with both coolant outlets 4.20 and 4.21 through the groove 5.1 in the nozzle holder 5 shows.

- Fig. 4 shows the nozzle 4 of the plasma burner head FIG. 3 , It has a nozzle bore 4.10 for the exit of a plasma jet at a nozzle tip 4.11, a first section 4.1, the outer surface 4.4 is substantially cylindrical, and adjoining the nozzle tip 4.11 second section 4.2, the outer surface of the 4.5 to the nozzle tip 4.11 out in essentially conically tapered.

- Thedestattkeitszulaufnuten 4.20 and 4.21 extend over a portion of the first section 4.1 and the second section 4.2 in the outer surface of the nozzle 4 4.5 to the nozzle tip 4.11 and end in front of the cylindrical outer surface 4.3.

- Thedestattkeits Weglaufnut 4.22 extends over the second section 4.2 of the nozzle 4.

- the width alpha 4 of thede crampkeitsschreiblaufnut 4.22 in the circumferential direction is about 190 °.

- Between thedeckenkeitszulaufnuten 4.20; 4.21 and thedeckenkeitsschreiblaufnut 4.22 are the outwardly projecting areas 4.31; 4.32 and 4.33 with the corresponding sections 4.41; 4.42 and 4.43.

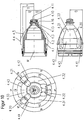

- FIG. 5 shows a plasma burner similar FIG. 3 but according to a particular embodiment of the invention.

- the nozzle 4 has twodestattkeitszulaufnuten 4.20 and 4.21 (s. Fig. 5a ).

- the cooling liquid is directed almost perpendicular to the longitudinal axis of the plasma burner head 1 of the nozzle holder 5 on the nozzle 4 in the cooling liquid space 10.

- the cooling liquid is deflected from the direction parallel to the longitudinal axis in the bore of the cooling liquid flow WV of the plasma burner in the direction of the first nozzle section 4.1 almost perpendicular to the longitudinal axis of the plasma burner head 1.

- the cooling liquid flows through a remplisstechnikszulaufnut 4.6 of the nozzle 4 in the two formed by thedefactkeitsvorlaufnuten 4.20 and 4.21 of the nozzle 4 and the nozzle cap 2 spaces 10.11 and 10.12 to the nozzle bore 4.10 surrounding area 10.20 of the cooling liquid chamber 10 and flows around the nozzle 4 there , Thereafter, the cooling liquid flows back through the space 10.15 formed by the cooling liquid return groove 4.22 of the nozzle 4 and the nozzle cap 2 to the coolant return WR, the transition taking place substantially parallel to the longitudinal axis of the plasma burner head.

- Fig. 5a is the sectional view taken along the line AA of the plasma torch FIG. 5 showing how the spaces 10.11 and 10.12 formed by the cooling liquid supply grooves 4.20 and 4.21 of the nozzle 4 and the nozzle cap 2 form a shunt through the sections 4.41 and 4.42 of the protruding areas 4.31 and 4.32 of the nozzle 4 in combination with the inner surface 2.5 of the nozzle cap 2 between the coolant flow and coolant return. At the same time, a shunt between the spaces 10.11 and 10.12 is prevented by the section 4.43 of the protruding area 4.33.

- the sheet dimensions d4 and e4 of sections 4.41 and 4.42 of the nozzle 4 must be at least as large as the radians b2 to the nozzle facing recesses 2.6 of the nozzle cap. 2

- FIG. 5b is a sectional view taken along the line BB of the plasma torch FIG. 5 showing the plane of the deflection space 10.10 and the connection with both coolant liquid feeds through the liquid inlet groove 4.6 in the nozzle 4.

- Fig. 6 shows the nozzle 4 of the plasma burner head FIG. 5 , It has a nozzle bore 4.10 for the exit of a plasma jet at a nozzle tip 4.11, a first section 4.1, the outer surface 4.4 is substantially cylindrical, and adjoining the nozzle tip 4.11 second section 4.2, the outer surface of the 4.5 to the nozzle tip 4.11 out in essentially conically tapered.

- Thedestattkeitszulaufnuten 4.20 and 4.21 extend over a portion of the first section 4.1 and the second section 4.2 in the outer surface of the nozzle 4 4.5 to the nozzle tip 4.11 and end in front of the cylindrical outer surface 4.3.

- Thedestattkeits Weglaufnut 4.22 extends over the second section 4.2 of the nozzle 4.

- the width alpha 4 of thede crampkeitsschreiblaufnut 4.22 in the circumferential direction is about 190 °.

- the cooling liquid grooves 4.20; 4.21 and thedeckenkeitsschreiblaufnut 4.22 are the outwardly projecting areas 4.31; 4.32 and 4.33 with the corresponding sections 4.41; 4.42 and 4.43.

- Thedestattkeitszulaufnuten 4.20 and 4.21 are interconnected by the groove 4.6 of the nozzle.

- FIG. 7 illustrates a plasma burner head according to another specific embodiment, the embodiment not belonging to the invention.

- the cooling liquid is directed almost perpendicular to the longitudinal axis of the plasma burner head 1 of a nozzle holder 5 on the nozzle 4 in a cooling liquid space 10.

- the cooling liquid is deflected from the direction parallel to the longitudinal axis in the bore of the cooling liquid flow WV of the plasma burner in the direction of the first nozzle section 4.1 almost perpendicular to the longitudinal axis of the plasma burner head 1.

- the cooling liquid flows through a space 10.11 formed by a cooling liquid supply groove 4.20 of the nozzle 4 and the nozzle cap 2 (see FIG. Fig.

- Fig. 7a is a sectional view taken along the line AA of the plasma torch FIG. 7 showing how the space 10.11 formed by the coolant inlet groove 4.20 of the nozzle 4 and the nozzle cap 2 passes through the portions 4.41 and 4.42 of the protruding areas 4.31 and 4.32 of the nozzle 4 in combination with the inner surface of the nozzle cap 2 to prevent a shunt between the cooling liquid flow and coolant return.

- FIG. 7b is a sectional view taken along the line BB of the plasma burner head FIG. 7 showing the plane of the deflection spaces 10.10.

- Fig. 8 shows the nozzle 4 of the plasma burner head FIG. 7 , It has a nozzle bore 4.10 for the exit of a plasma jet at a nozzle tip 4.11, a first section 4.1, the outer surface 4.4 is substantially cylindrical, and adjoining the nozzle tip 4.11 second section 4.2, the outer surface of the 4.5 to the nozzle tip 4.11 out in essentially conically tapered.

- Thedefactkeitszulaufnut 4.20 and thedeckenkeitsschreibonnenut 4.22 extend over a portion of the first section 4.1 and the second section 4.2 in the outer surface 4.5 of the nozzle 4 to the nozzle tip 4.11 and end in front of the cylindrical outer surface 4.3.

- the center of thedeckenkeitszulaufnut 4.20 and the center of thedeckensschreiblaufnut 4.22 are offset by 180 ° to each other over the circumference of the nozzle 4 and the same size. Between thedeckenkeitsvorlaufnut 4.20 and thedeckensschreiblaufnut 4.22 are the outwardly projecting areas 4.31 and 4.32 with the corresponding sections 4.41 and 4.42.

- FIG. 9 shows a plasma burner head, the embodiment does not belong to the invention.

- the nozzle 4 has twodestattkeitsvorlaufnuten 4.20 and 4.21.

- the cooling liquid is directed almost perpendicular to the longitudinal axis of the plasma burner head 1 of the nozzle holder 5 on the nozzle 4 in the cooling liquid space 10.

- the cooling liquid is deflected from the direction parallel to the longitudinal axis in the bore of the cooling liquid flow WV of the plasma torch in the direction of the first nozzle section 4.1 almost perpendicular to the longitudinal axis of the plasma burner head 1.

- the cooling liquid flows through a groove 5.1 of the nozzle holder 5 in the two formed by thedeckenkeitszulaufnuten 4.20 and 4.21 of the nozzle 4 and the nozzle cap 2 spaces 10.11 and 10.12 to the nozzle bore 4.10 surrounding area 10.20 of the cooling liquid space 10 and flows around the nozzle 4 there , Thereafter, the cooling liquid flows back through the space formed by thedestattkeitsschreiblaufnut 4.22 of the nozzle 4 and the nozzle cap 2 10.15 back to the coolant return WR, the transition here is almost perpendicular to the longitudinal axis of the plasma burner head, by a deflection 10.10.

- Fig. 9a is a sectional view taken along the line AA of the plasma torch FIG. 9 showing how the spaces 10.11 and 10.12 formed by the cooling liquid inlet grooves 4.20 and 4.21 of the nozzle 4 and the nozzle cap 2 pass through the sections 4.41 and 4.42 of the protruding areas 4.31 and 4.32 of the nozzle 4 in combination with the inner surface of the nozzle cap 2 Prevent the coolant flow and coolant return. At the same time, a shunt between the spaces 10.11 and 10.12 is prevented by the section 4.43 of the protruding area 4.33.

- FIG. 9b is a sectional view taken along the line BB of the plasma burner head FIG. 9 showing the plane of the deflection spaces 10.10 and shows the connection with bothdestattkeitsvor conceptn 4.20 and 4.21 through the groove 5.1 in the nozzle holder 5.

- FIG. 10 shows the nozzle 4 of the plasma burner head FIG. 9 , It has a nozzle bore 4.10 for the exit of a plasma jet at a nozzle tip 4.11, a first section 4.1, the outer surface 4.4 is substantially cylindrical, and adjoining the nozzle tip 4.11 second section 4.2, the outer surface of the 4.5 to the nozzle tip 4.11 out in essentially conically tapered.

- Thedestattkeitszulaufnuten 4.20 and 4.21 extend over a portion of the first section 4.1 and the second section 4.2 in the outer surface of the nozzle 4 4.5 to the nozzle tip 4.11 back and end in front of the cylindrical outer surface 4.3.

- Thedeckenkeitsschreiblaufnut 4.22 extends over the second section 4.2 and the first section 4.1 in the outer surface 4.5 of the nozzle 4. Between thedeckenkeitsvorlaufnuten 4.20; 4.21 and thedeckensschreiblaufnut 4.22 are the outwardly projecting areas 4.31; 4.32 and 4.33 with the corresponding sections 4.41; 4.42 and 4.43.

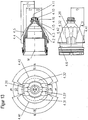

- FIG. 11 shows a plasma burner head similar FIG. 5 but according to another particular embodiment of the invention.

- the bores of the coolant flow WV and the coolant return are arranged at an angle of 90 °.

- the nozzle 4 has twodestattkeitszulaufnuten 4.20 and 4.21 and in the circumferential direction of the first section 4.1 over the entire circumference horrrekkende and thedefactkeitszulaufnuten connecting groove 4.6.

- the cooling liquid is directed approximately perpendicular to the longitudinal axis of the plasma burner head 1 of the nozzle holder 5 on the nozzle 4 aptly into the cooling liquid space 10.

- the cooling liquid is deflected from the direction parallel to the longitudinal axis in the bore of the cooling liquid flow WV of the plasma burner in the direction of the first nozzle section 4.1 almost perpendicular to the longitudinal axis of the plasma burner head 1.

- the cooling liquid flows through the sosstechnikszulaufnut 4.6, which extends in the circumferential direction of the first section 4.1 of the nozzle 4 on a partial circumference between the grooves 4.20 and 4.21, ie over about 300 °, in the two by thedefactkeitsvorlaufnuten 4.20 and 4.21 of Nozzle 4 and the nozzle cap 2 formed spaces 10.11 and 10.12 to the nozzle bore 4.10 surrounding area 10.20 of the cooling liquid space 10 and flows around the nozzle 4 there. Thereafter, the cooling liquid flows back through the space 10.15 formed by the cooling liquid return groove 4.22 of the nozzle 4 and the nozzle cap 2 to the coolant return WR, the transition taking place substantially parallel to the longitudinal axis of the plasma burner head.

- Fig. 11a is a sectional view taken along the line AA of the plasma torch FIG. 11 showing how the spaces 10.11 and 10.12 formed by the cooling liquid inlet grooves 4.20 and 4.21 of the nozzle 4 and the nozzle cap 2 form a shunt through the sections 4.41 and 4.42 of the protruding areas 4.31 and 4.32 of the nozzle 4 in combination with the inside surface 2.5 of the nozzle cap 2 between the coolant flow and coolant return. At the same time, a shunt between the spaces 10.11 and 10.12 is prevented by the section 4.43 of the protruding area 4.33.

- the sheet dimensions d4 and e4 of sections 4.41 and 4.42 of the nozzle 4 must be at least as large as the radians b2 to the nozzle facing recesses 2.6 of the nozzle cap. 2

- FIG. 11b is a sectional view taken along the line BB of the plasma torch FIG. 11 , which shows the plane of the deflection space 10.10 and the connection with both cooling liquid flows through the over approximately 300 ° circumferential liquid inlet groove 4.6 in the nozzle 4 and offset by 90 ° arranged holes for the coolant flow WV and the coolant return WR.

- FIG. 12 shows the nozzle 4 of the plasma burner head FIG. 11 , It has a nozzle bore 4.10 for the exit of a plasma jet at a nozzle tip 4.11, a first section 4.1, the outer surface 4.4 is substantially cylindrical, and adjoining the nozzle tip 4.11 second section 4.2, the outer surface of the 4.5 to the nozzle tip 4.11 out in essentially conically tapered.

- Thedestattkeitszulaufnuten 4.20 and 4.21 extend over a portion of the first section 4.1 and the second section 4.2 in the outer surface of the nozzle 4 4.5 to the nozzle tip 4.11 back and end in front of the cylindrical outer surface 4.3.

- Thedestattkeits Weglaufnut 4.22 extends over the second section 4.2 of the nozzle 4.

- Thedeckenkeitszulaufnuten 4.20; 4.21 and thedeckenkeitsschreiblaufnut 4.22 are the outwardly projecting areas 4.31; 4.32 and 4.33 with the corresponding sections 4.41; 4.42 and 4.43.

- Thedeckenkeitszulaufnuten 4.20 and 4.21 are connected by a circumferential direction of the first section 4.1 of the nozzle 4 on a partial circumference between the grooves 4.20 and 4.21, ie over about 300 ° extending liquid inlet groove 4.6 of the nozzle. This is particularly advantageous for the cooling of the transition between the nozzle holder 5 and the nozzle 4.

- FIG. 13 shows a nozzle according to another specific embodiment of the invention, which in the plasma burner head after FIG. 8 can be used.

- Thedestattkeitszulaufnut 4.20 is connected to a remplisstechnikszulaufnut 4.6 which extends in the circumferential direction over the entire circumference.

- This has the advantage that the bore for the cooling liquid flow WV and the coolant return WR in the plasma burner head need not be arranged offset by exactly 180 °, but also as for example in FIG. 11 can be arranged offset by 90 °.

- this is advantageous for the cooling of the transition between the nozzle holder 5 and the nozzle 4.

- the same can of course be used for achenkeits Weglaufnut 4.22.

- FIG. 14 shows a nozzle cap 2, wherein the embodiment does not belong to the invention.

- the nozzle cap 2 has an essentially conically tapering inner surface 2.2, which in this case has recesses 2.6 in a radial plane.

- the recesses 2.6 are arranged equidistantly over the inner circumference and semicircular in the radial section.

- FIGS. 15 and 16 shown nozzle caps differ from the in Fig. 14 shown embodiment in the shape of the recesses 2.6.

- the recesses 2.6 in Fig. 15 are in the view shown there to the nozzle tip out frustoconical, with in Fig. 16 the frustoconical shape is slightly rounded.

Landscapes

- Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Plasma & Fusion (AREA)

- Spectroscopy & Molecular Physics (AREA)

- Geometry (AREA)

- Arc Welding In General (AREA)

- Plasma Technology (AREA)

Description

Die vorliegende Erfindung betrifft eine Düse für einen flüssigkeitsgekühlten Plasmabrenner, sowie einen Plasmabrennerkopf mit derselben.The present invention relates to a nozzle for a liquid-cooled plasma torch and to a plasma torch head having the same.

Als Plasma wird ein thermisch hoch aufgeheiztes elektrisch leitfähiges Gas bezeichnet, das aus positiven und negativen Ionen, Elektronen sowie angeregten und neutralen Atomen und Molekülen besteht.Plasma is a thermally highly heated electrically conductive gas, which consists of positive and negative ions, electrons and excited and neutral atoms and molecules.

Als Plasmagas werden unterschiedliche Gase, zum Beispiel das einatomige Argon und/oder die zweiatomigen Gase Wasserstoff, Stickstoff, Sauerstoff oder Luft eingesetzt. Diese Gase ionisieren und dissoziieren durch die Energie eines Lichtbogens.The plasma gas used is a variety of gases, for example the monatomic argon and / or the diatomic gases hydrogen, nitrogen, oxygen or air. These gases ionize and dissociate through the energy of an arc.

Der Plasmastrahl kann in seinen Parametern durch die Gestaltung der Düse und Elektrode stark beeinflusst werden. Diese Parameter des Plasmastrahls sind zum Beispiel der Strahldurchmesser, die Temperatur, Energiedichte und die Strömungsgeschwindigkeit des Gases.The plasma jet can be greatly influenced in its parameters by the design of the nozzle and electrode. These parameters of the plasma jet are, for example, the beam diameter, the temperature, the energy density and the flow velocity of the gas.

Beim Plasmaschneiden beispielsweise wird das Plasma durch eine Düse, die gas- oder wassergekühlt sein kann, eingeschnürt. Dadurch können Energiedichten bis 2x106 W/cm2 erreicht werden. Im Plasmastrahl entstehen Temperaturen bis 30.000 °C, die in Verbindung mit der hohen Strömungsgeschwindigkeit des Gases sehr hohe Schneidgeschwindigkeiten an Werkstoffen realisieren.In plasma cutting, for example, the plasma is constricted through a nozzle, which may be gas or water cooled. As a result, energy densities up to 2x10 6 W / cm 2 can be achieved. Temperatures of up to 30,000 ° C are generated in the plasma jet, which, in combination with the high flow velocity of the gas, produce very high cutting speeds on materials.

Plasmabrenner können direkt oder indirekt betrieben werden. Bei der direkten Betriebsweise fließt der Strom von der Stromquelle über die Elektrode des Plasmabrenners, den mittels Lichtbogen erzeugten und durch die Düse eingeschnürten Plasmastrahl direkt über das Werkstück zur Stromquelle zurück. Mit der direkten Betriebsweise können elektrisch leitfähige Materialien geschnitten werden.Plasma torches can be operated directly or indirectly. In the direct mode of operation, the current from the power source flows through the electrode of the plasma torch, the arc generated by the arc and constricted by the nozzle directly back to the power source via the workpiece. With the direct mode of operation, electrically conductive materials can be cut.

Bei der indirekten Betriebsweise fließt der Strom von der Stromquelle über die Elektrode des Plasmabrenners, den mittels Lichtbogen erzeugten und durch die Düse eingeschnürten Plasmastrahl und die Düse zurück zur Stromquelle. Dabei wird die Düse noch stärker belastet als bei direktem Plasmaschneiden, da sie nicht nur den Plasmastrahl einschnürt, sondern auch den Ansatzpunkt des Lichtbogens realisiert. Mit der indirekten Betriebsweise können sowohl elektrisch leitende als auch nicht leitende Materialien geschnitten werden.In the indirect mode, the current flows from the power source through the electrode of the plasma torch, the plasma jet generated by the arc and constricted by the nozzle and the nozzle back to the power source. The nozzle is even more heavily loaded than with direct plasma cutting, because it not only constricts the plasma jet, but also realizes the starting point of the arc. With the indirect mode of operation, both electrically conductive and non-conductive materials can be cut.

Wegen der hohen thermischen Belastung der Düse wird diese in der Regel aus einem metallischen Werkstoff, vorzugsweise wegen seiner hohen elektrischen Leitfähigkeit und Wärmeleitfähigkeit aus Kupfer, hergestellt. Gleiches gilt für den Elektrodenhalter, der aber auch aus Silber hergestellt sein kann. Die Düse wird dann in einem Plasmabrenner, dessen Hauptbestandteile ein Plasmabrennerkopf, eine Düsenkappe, ein Plasmagasführungsteil, eine Düse, eine Düsenhalterung, eine Elektrodenaufnahme, ein Elektrodenhalter mit Elektrodeneinsatz und bei modernen Plasmabrennern eine Düsenschutzkappenhalterung und eine Düsenschutzkappe sind, eingesetzt. Der Elektrodenhalter fixiert einen spitzen Elektrodeneinsatz aus Wolfram, der für den Einsatz nicht oxidierender Gase als Plasmagas, zum Beispiel ein Argon-Wasserstoff-Gemisch geeignet ist. Eine sogenannte Flachelektrode, deren Elektrodeneinsatz beispielsweise aus Hafnium besteht, ist auch für den Einsatz oxidierender Gase als Plasmagas, zum Beispiel Luft oder Sauerstoff, geeignet. Um eine hohe Lebensdauer für die Düse zu erreichen, wird diese hier mit einer Flüssigkeit, zum Beispiel Wasser, gekühlt. Das Kühlmittel wird über einen Wasservorlauf zur Düse hin- und einen Wasserrücklauf von der Düse weggeführt und durchströmt dabei einen Kühlmittelraum, der durch die Düse und die Düsenkappe begrenzt wird.Because of the high thermal load of the nozzle, this is usually made of a metallic material, preferably because of its high electrical conductivity and thermal conductivity of copper. The same applies to the electrode holder, which can also be made of silver. The nozzle is then inserted into a plasma torch whose main components are a plasma torch head, a nozzle cap, a plasma gas guide member, a nozzle, a nozzle holder, an electrode holder, an electrode holder with electrode insert and in modern plasma torches a nozzle cap holder and a nozzle cap. The electrode holder fixes a tungsten tip insert which is suitable for the use of non-oxidizing gases as plasma gas, for example an argon-hydrogen mixture. A so-called flat electrode whose electrode insert consists for example of hafnium is also suitable for the use of oxidizing gases as plasma gas, for example air or oxygen. In order to achieve a long service life for the nozzle, it is cooled here with a liquid, for example water. The coolant is directed towards the nozzle via a water feed and a water return from the nozzle and flows through a coolant space which is delimited by the nozzle and the nozzle cap.

In

In

In

Bei den vorangehend beschriebenen Plasmabrennern wird das Kühlmittel über einen Wasservorlaufkanal zur Düse hin- und über einen Wasserrücklaufkanal von der Düse weggeführt. Diese Kanäle sind meist um 180° zueinander versetzt und das Kühlmittel soll auf dem Weg vom Vor- zum Rücklauf die Düse möglichst gleichmäßig umspülen. Dennoch werden immer wieder Überhitzungen in der Nähe des Düsenkanals festgestellt.In the plasma torches described above, the coolant is led back to the nozzle via a water feed channel and away from the nozzle via a water return channel. These channels are usually offset by 180 ° to each other and the coolant should flow around the nozzle as evenly as possible on the way from the flow to the return. Nevertheless, overheating in the vicinity of the nozzle channel are repeatedly found.

Eine andere Kühlmittelführung für einen Brenner, vorzugsweise Plasmabrenner, insbesondere für Plasmaschweiß-, Plasmaschneid-, Plasmaschmelz- und Plasmaspritzzwecke, die hohen thermischen Beanspruchungen der Düse und der Katode standhält, ist in

Diese Anordnung hat wiederum den Nachteil, dass ein höherer Aufwand für die Kühlung durch die Verwendung eines zusätzlichen Bauteils, den Kühlmedienleitring, notwendig ist. Außerdem vergrößert sich dadurch die gesamte Anordnung.This arrangement in turn has the disadvantage that a higher outlay for the cooling by the use of an additional component, the Kühlmedienleitring, is necessary. In addition, this increases the entire arrangement.

Der Erfindung liegt somit die Aufgabe zugrunde, auf einfache Weise eine Überhitzung in der Nähe des Düsenkanals bzw. der Düsenbohrung zu vermeiden.The invention is therefore based on the object to avoid overheating in the vicinity of the nozzle channel or the nozzle bore in a simple manner.

Erfindungsgemäß wird diese Aufgabe gelöst durch einen Plasmabrennerkopf gemäß Anspruch 13.According to the invention this object is achieved by a plasma burner head according to claim 13.

Weiterhin liefert die vorliegende Erfindung eine Düse gemäß Anspruch. Mit im wesentlich zylindrisch soll gemeint sein, dass die Außenfläche zumindest bei Wegdenken der Nuten, wie Flüssigkeitszulauf- und -rücklaufnuten, im Großen und Ganzen zylindrisch ist. In analoger Weise soll "im wesentlichen kegelig verjüngt" bedeuten, dass die Außenfläche zumindest bei Wegdenken der Nuten, wie Flüssigkeitszulauf- und -rücklaufnuten, im Großen und Ganzen kegelig verjüngt ist.Furthermore, the present invention provides a nozzle according to claim. By substantially cylindrical is intended to mean that the outer surface is, at least when thinking away of the grooves, such as liquid inlet and -rücklaufnuten, by and large cylindrical. In an analogous manner, "substantially conically tapered" means that the outer surface, at least when the grooves are thought out, such as liquid inlet and return grooves, is conically tapered by and large.

Gemäß einer besonderen Ausführungsform des Plasmabrennerkopfes weist die Düse ein oder zwei Kühlflüssigkeitszulaufnut(en) auf, und weist die Düsenkappe auf ihrer Innenfläche mindestens zwei, insbesondere genau drei, Ausnehmungen, deren zur Düse gewandten Öffnungen sich jeweils über eine Bogenlänge (b2) erstrecken, auf, wobei die Bogenlänge der in Umfangsrichtung an die Kühlflüssigkeitszulaufnut(en) angrenzenden, gegenüber der bzw. den Kühlflüssigkeitszulaufnut(en) nach außen hervorstehenden Bereiche der Düse jeweils größer als die Bogenlänge (d4, e4) ist. Auf diese Weise wird ein Nebenschluss vom Kühlmittelzulauf zum Kühlmittelrücklauf besonders elegant vermieden.According to a particular embodiment of the plasma burner head, the nozzle has one or two Kühlflüssigkeitszulaufnut (s), and the nozzle cap on its inner surface at least two, in particular exactly three, recesses whose openings facing the nozzle each extend over an arc length (b 2 ), wherein the arc length of the circumferentially adjacent to the Kühlflüssigkeitszulaufnut (s) adjacent to the or Kühlflüssigkeitszulaufnut (s) outwardly projecting portions of the nozzle is greater than the arc length (d4, e4). In this way, a shunt from the coolant inlet to the coolant return is particularly elegant avoided.

Weiterhin kann bei dem Plasmabrennerkopf vorgesehen sein, dass sich die beiden Bohrungen jeweils im wesentlichen parallel zur Längsachse des Plasmabrennerkopfes erstrecken. Dadurch wird erreicht, dass Kühlflüssigkeitsleitungen platzsparend an den Plasmabrennerkopf angeschlossen werden können.Furthermore, it can be provided in the plasma burner head, that the two bores each extend substantially parallel to the longitudinal axis of the plasma burner head. This ensures that coolant lines can be connected to save space on the plasma burner head.

Insbesondere können die Bohrungen für die Kühlflüssigkeitszulauf an den Kühflüssigkeitsrücklauf um 180° versetzt angeordnet sein.In particular, the bores for the cooling liquid inlet to the Kühflüssigkeitsrücklauf can be arranged offset by 180 °.

Vorteilhafterweise ist das Bogenmaß des Abschnitts zwischen den Ausnehmungen der Düsenkappe maximal halb so groß wie das minimale Bogenmaß der Kühlflüssigkeitsrücklaufnut oder das minimale Bogenmaß der Kühlflüssigkeitszulaufnut(en) der Düse.Advantageously, the radian dimension of the section between the recesses of the nozzle cap is at most half the size of the minimum radian measure of the coolant return groove or the minimum radian measure of the coolant inlet groove (s) of the nozzle.

Günstigerweise kann sich bei der Düse die Flüssigkeitsrücklaufnut(en) auch über einen Teil des ersten Abschnitts in der Außenfläche der Düse erstrecken.Conveniently, at the nozzle, the liquid return groove (s) may also extend over a portion of the first portion in the outer surface of the nozzle.

In einer besonderen Ausführungsform der Düse sind im Fall a) mindestens zwei Flüssigkeitszulaufnuten und im Fall b) mindestens zwei Flüssigkeitsrucklaufnuten vorgesehen.In a particular embodiment of the nozzle, at least two fluid inlet grooves are provided in case a) and at least two fluid pressure grooves are provided in case b).

Vorteilhafterweise sind der Mittelpunkt der Flüssigkeitszulaufnut und der Mittelpunkt der Flüssigkeitsrücklaüfnut um 180° versetzt zueinander über den Umfang der Düse angeordnet. Mit anderen Worten liegen die Flüssigkeitszulaufnut und die Flüssigkeitsrücklaufnut einander gegenüber.Advantageously, the center of the liquid inlet groove and the center of the Flüssigkeitsrücklaüfnut are arranged offset by 180 ° to each other over the circumference of the nozzle. In other words, the liquid inlet groove and the liquid return groove face each other.

Vorteilhafterweise liegt im Fall a) die Breite der Flüssigkeitsrücklaufnut und im Fall b) die Breite der Flüssigkeitszulaufnut in Umgangsrichtung im Bereich von 90° bis 270°. Durch eine derartige besonders breite Flüssigkeitsrück- bzw. -zulaufnut lässt sich eine besonders gute Kühlung der Düse erreichen.Advantageously, in case a) the width of the liquid return groove and in case b) the width of the liquid inlet groove in the direction of contact in the range of 90 ° to 270 °. By means of such a particularly wide fluid return or inlet groove, a particularly good cooling of the nozzle can be achieved.

Es kann vorgesehen sein, dass sich im Fall a) die Flüssigkeitszulaufnut in Umfangsrichtung des ersten Abschnitts der Düse über den gesamten Umfang erstreckt.It may be provided that in case a) the liquid inlet groove extends in the circumferential direction of the first portion of the nozzle over the entire circumference.

Insbesondere kann dabei vorgesehen sein, dass sich im Fall a) die Flüssigkeitszulaufnut in Umfangsrichtung des ersten Abschnitts der Düse über einen Winkel von 60° bis 300° und im Fall b) die Flüssigkeitsrücklaufnut in Umfangsrichtung des ersten Abschnitts der Düse über einen Winkel im Bereich von 60 ° bis 300 ° erstreckt.In particular, it may be provided that in case a) the liquid inlet groove in the circumferential direction of the first portion of the nozzle over an angle of 60 ° to 300 ° and in case b) the liquid return groove in the circumferential direction of the first portion of the nozzle over an angle in the range of 60 ° to 300 °.

Insbesondere kann dabei vorgesehen sein, dass sich im Fall a) diese Flüssigkeitszulaufnut in Umfangsrichtung des ersten Abschnitts der Düse über einen Winkel im Bereich von 90° bis 270° und im Fall b) die Flüssigkeitsrücklaufnut in Umfangrichtung des ersten Abschnitts der Düse über einen Winkel im Bereich von 90 ° bis 270 ° erstreckt.In particular, it may be provided that in the case of a) this Flüssigkeitszulaufnut in the circumferential direction of the first portion of the nozzle over an angle in the range of 90 ° to 270 ° and in case b) the liquid return groove in the circumferential direction of the first portion of the nozzle over an angle in Range extends from 90 ° to 270 °.

Bei einer weiteren Ausfiihrungsform der Düse sind im Fall a) genau zwei Flüssigkeitszulaufnuten und im Fall b) genau zwei Flüssigkeitsrücklaufnuten vorgesehen.In a further embodiment of the nozzle, exactly two liquid feed grooves are provided in case a) and exactly two liquid return grooves are provided in case b).

Insbesondere können im Fall a) die beiden Flüssigkeitszulaufnuten über den Umfang der Düse symmetrisch zu einer Geraden angeordnet sein, die sich vom Mittelpunkt der Flüssigkeitsrücklaufnut im rechten Winkel durch die Längsachse der Düse erstreckt und im Fall b) die beiden Flüssigkeitsrücklaufnuten über den Umfang der Düse symmetrisch zu einer Geraden angeordnet sind, die sich vom Mittelpunkt der Flüssigkeitszulaufnut im rechten Winkel durch die Längsachse der Düse erstreckt.In particular, in case a), the two liquid feed grooves may be arranged circumferentially of the nozzle symmetrical to a straight line extending from the center of the liquid return groove at right angles through the longitudinal axis of the nozzle and in case b) the two liquid return grooves symmetrical about the circumference of the nozzle are arranged to a straight line extending from the center of the Flüssigkeitszulaufnut at right angles through the longitudinal axis of the nozzle.

Vorteilhafterweise sind im Fall a) die Mittelpunkte der beiden Flüssigkeitszulaufnuten und im Fall b) die Mittelpunkte der beiden Flüssigkeitsrücklaufnuten um einen Winkel versetzt zueinander über den Umfang der Düse angeordnet, der im Bereich von 30° bis 180° liegt.Advantageously, in case a) the centers of the two liquid inlet grooves and in the case b) the centers of the two liquid return grooves offset by an angle to each other over the circumference of the nozzle, which is in the range of 30 ° to 180 °.

Vorteilhafterweise liegt im Fall a) die Breite der Flüssigkeitsrücklaufnut und im Fall b) die Breite der Flüssigkeitszulaufnut in Umfangsrichtung im Bereich von 120° bis 270°.Advantageously, in case a) the width of the liquid return groove and in case b) the width of the liquid inlet groove in the circumferential direction is in the range of 120 ° to 270 °.

Zweckmäßigerweise geht die Flüssigkeitszulaufnut im Fall a) über eine der oder beide Flüssigkeitszulaufnuten und im Fall b) die Flüssigkeitsrücklaufnut über eine der oder beide Flüssigkeitsrücklaufnuten hinaus.Appropriately, the liquid inlet groove in case a) via one or both of the fluid inlet grooves and in case b) the fluid return groove beyond one or both of the fluid return grooves.

Es kann vorgesehen sein, dass sich im Fall a) die Flüssigkeitszulaufnut in Umfangsrichtung des ersten Abschnitts der Düse über den gesamten Umfang erstreckt.It may be provided that in case a) the liquid inlet groove extends in the circumferential direction of the first portion of the nozzle over the entire circumference.

Insbesondere kann dabei vorgesehen sein, dass sich die Flüssigkeitszulaufnut in Umfangsrichtung des ersten Abschnitts der Düse über einen Winkel im Bereich von 60° bis 300° erstreckt.In particular, it can be provided that extends the liquid inlet groove in the circumferential direction of the first portion of the nozzle over an angle in the range of 60 ° to 300 °.

Insbesondere kann dabei vorgesehen sein, dass sich die Flüssigkeitszulaufnut in Umfangsrichtung des ersten Abschnitts der Düse über einen Winkel im Bereich von 90° bis 270° erstreckt.In particular, it can be provided that extends the liquid inlet groove in the circumferential direction of the first portion of the nozzle over an angle in the range of 90 ° to 270 °.

In einer besonderen Ausführungsform des Plasmabrennerkopfes könne sich die beiden Bohrungen jeweils im wesentlichen parallel zur Längsachse des Plasmabrennerkopfes erstrecken.In a particular embodiment of the plasma burner head, the two holes could each extend substantially parallel to the longitudinal axis of the plasma burner head.

Vorteilhafterweise sind die Bohrungen für den Kühlflüssigkeitszulauf und den Kühlflüssigkeitsrücklauf um 180° versetzt angeordnet.Advantageously, the holes for the coolant inlet and the coolant return are arranged offset by 180 °.

Der Erfindung liegt die überraschende Erkenntnis zugrunde, dass durch Zuführen und/oder Abführen der Kühlflüssigkeit im rechten Winkel zur Längsachse des Plasmabrennerkopfes statt - wie im Stand der Technik - parallel zur Längsachse des Plasmabrennerkopfes, eine bessere Kühlung der Düse durch deutlich längeren Kontakt der Kühlflüssigkeit mit der Düse erzielt wird.The invention is based on the surprising finding that by supplying and / or removing the cooling liquid at right angles to the longitudinal axis of the plasma burner head instead of - as in the prior art - parallel to the longitudinal axis of the plasma burner head, a better cooling of the nozzle by significantly longer contact of the cooling liquid the nozzle is achieved.

Wenn mehr als eine Kühlflüssigkeitszulaufnut vorgesehen sind, so lässt sich damit im Bereich der Düsenspitze eine besonders gute Verwirbelung der Kühlflüssigkeit durch das Aufeinandertreffen der Kühlflüssigkeitsströme erzielen, die üblicherweise auch mit einer besseren Kühlung der Düse einhergeht.If more than one Kühlflüssigkeitszulaufnut are provided, it can thus be achieved in the nozzle tip a particularly good turbulence of the cooling liquid by the meeting of the cooling liquid flows, which is usually accompanied by a better cooling of the nozzle.

Weitere Merkmale und Vorteile der Erfindung ergeben sich aus den beigefügten Ansprüchen und der nachstehenden Beschreibung, in der mehrere Ausführungsbeispiele anhand der schematischen Zeichnungen im einzelnen erläutert sind. Dabei zeigt:

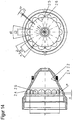

- Fig. 1

- eine Längsschnittansicht durch einen Plasmabrennerkopf mit Plasma- und Sekundärgaszuführung mit einer Düse und einer Düsenkappe, wobei die Ausführungsform nicht zur Erfindung gehört;

- Fig. 1a

- eine Schnittdarstellung entlang der Linie A-A von

Fig. 1 ; - Fig. 1b

- eine Schnittdarstellung entlang der Linie B-B von

Fig. 1 ; - Fig. 2

- Einzeldarstellungen (links oben: Draufsicht von vorne; rechts oben: Längsschnittansicht; rechts unten: Seitenansicht) der Düse von

Fig. 1 ; - Fig. 3

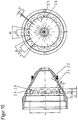

- eine Längsschnittansicht durch einen Plasmabrennerkopf mit Plasma- und Sekundärgaszufiihrung mit einer Düse und einer Düsenkappe, wobei die Ausführungsform nicht zur Erfindung gehört;

- Fig. 3a

- eine Schnittdarstellung entlang der Linie A-A von

Fig. 3 ; - Fig. 3b

- eine Schnittdarstellung entlang der Linie B-B von

Fig. 3 - Fig. 4

- Einzeldarstellungen (links oben: Draufsicht von vorne; rechts oben: Längsschnittansicht; rechts unten: Seitenansicht) der Düse von

Fig. 3 ; - Fig. 5

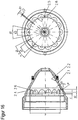

- eine Längsschnittansicht durch einen Plasmabrennerkopf mit Plasma- und Sekundärgaszuführung mit einer Düse und einer Düsenkappe gemäß einer besonderen Ausführungsform der vorliegenden Erfindung

- Fig. 5a

- eine Schnittdarstellung entlang der Linie A-A von

Fig. 5 ; - Fig. 5b

- eine Schnittdarstellung entlang der Linie B-B von

Fig. 5 ; - Fig. 6

- Einzeldarstellungen (links oben: Draufsicht von vorne; rechts oben: Längsschnittansicht; rechts unten: Seitenansicht) der Düse von

Fig. 5 ; - Fig. 7

- eine Längsschnittansicht durch einen Plasmabrennerkopf mit Plasma- und Sekundärgaszuführung mit einer Düse, wobei die Ausführungsform nicht zur Erfindung gehört;

- Fig. 7a

- eine Schnittdarstellung entlang der Linie A-A von

Fig. 7 ; - Fig. 7b

- eine Schnittdarstellung entlang der Linie B-B von

Fig. 7 ; - Fig. 8

- Einzeldarstellungen (links oben: Draufsicht von vorne; rechts oben: Längsschnittansicht; rechts unten: Seitenansicht) der Düse von

Fig. 7 ; - Fig. 9

- eine Längsschnittansicht durch einen Plasmabrennerkopf mit Plasma- und Sekundärgaszufiihrung mit einer Düse, wobei die Ausführungsform nicht zur Erfindung gehört;

- Fig. 9a

- eine Schnittdarstellung entlang der Linie A-A von

Fig. 9 ; - Fig. 9b

- eine Schnittdarstellung entlang der Linie B-B von

Fig. 9 ; - Fig. 10

- Einzeldarstellungen (links oben: Draufsicht von vorne; rechts oben: Längsschnittansicht; rechts unten: Seitenansicht) der Düse von

Fig. 9 ; - Fig. 11

- eine Längsschnittansicht durch einen Plasmabrennerkopf mit Plasma- und Sekundärgaszuführung mit einer Düse gemäß einer weiteren besonderen Ausführungsform der vorliegenden Erfindung;

- Fig, 11a

- eine Schnittdarstellung entlang der Linie A-A von

Fig. 11 ; - Fig. 11b

- eine Schnittdarstellung entlang der Linie B-B von

Fig. 11 ; - Fig. 12

- Einzeldarstellungen (links oben: Draufsicht von vorne; rechts oben: Längsschnittansicht; rechts unten: Seitenansicht) der Düse von

Fig. 11 ; - Fig. 13

- Einzeldarstellungen (links oben: Draufsicht von vorne; rechts oben: Längsschnittansicht; rechts unten: Seitenansicht) Düse gemäß einer weiteren besonderen Ausführungsform der Erfindung;

- Fig. 14

- Einzeldarstellungen (links: Längsschnittansicht; rechts: Draufsicht von vorne) der Düsenkappe von

Fig. 1 ,Fig. 3 undFig. 5 sowieFig. 11 ; - Fig. 15

- Einzeldarstellungen (links: Längsschnittansicht; rechts: Draufsicht von vorne) einer Düsenkappe gemäß einer besonderen Ausführungsform, wobei die Ausführungsform nicht zur Erfindung gehört;

- Fig. 16

- Einzeldarstellungen (links: Längsschnittansicht; rechts: Draufsicht von vorne) einer Düsenkappe gemäß einer weiteren speziellen Ausführungsform, wobei die Ausführungsform nicht zur Erfindung gehört;

- Fig. 1

- a longitudinal sectional view through a plasma burner head with plasma and secondary gas supply with a nozzle and a nozzle cap, the embodiment does not belong to the invention;

- Fig. 1a

- a sectional view taken along the line AA of

Fig. 1 ; - Fig. 1b

- a sectional view taken along the line BB of

Fig. 1 ; - Fig. 2

- Individual representations (top left: top view from the front, top right: longitudinal section view, bottom right: side view) of the nozzle of

Fig. 1 ; - Fig. 3

- a longitudinal sectional view through a plasma burner head with plasma and Sekundärgaszufiihrung with a nozzle and a nozzle cap, the embodiment does not belong to the invention;

- Fig. 3a

- a sectional view taken along the line AA of

Fig. 3 ; - Fig. 3b

- a sectional view taken along the line BB of

Fig. 3 - Fig. 4

- Individual representations (top left: top view from the front, top right: longitudinal section view, bottom right: side view) of the nozzle of

Fig. 3 ; - Fig. 5

- a longitudinal sectional view through a plasma burner head with plasma and secondary gas supply with a nozzle and a nozzle cap according to a particular embodiment of the present invention

- Fig. 5a

- a sectional view taken along the line AA of

Fig. 5 ; - Fig. 5b

- a sectional view taken along the line BB of

Fig. 5 ; - Fig. 6

- Individual representations (top left: top view from the front, top right: longitudinal section view, bottom right: side view) of the nozzle of

Fig. 5 ; - Fig. 7

- a longitudinal sectional view through a plasma burner head with plasma and secondary gas supply with a nozzle, the embodiment does not belong to the invention;

- Fig. 7a

- a sectional view taken along the line AA of

Fig. 7 ; - Fig. 7b

- a sectional view taken along the line BB of

Fig. 7 ; - Fig. 8

- Individual representations (top left: top view from the front, top right: longitudinal section view, bottom right: side view) of the nozzle of

Fig. 7 ; - Fig. 9

- a longitudinal sectional view through a plasma burner head with plasma and Sekundärgaszufiihrung with a nozzle, the embodiment does not belong to the invention;

- Fig. 9a

- a sectional view taken along the line AA of

Fig. 9 ; - Fig. 9b

- a sectional view taken along the line BB of

Fig. 9 ; - Fig. 10

- Individual representations (top left: top view from the front, top right: longitudinal section view, bottom right: side view) of the nozzle of

Fig. 9 ; - Fig. 11

- a longitudinal sectional view through a plasma burner head with plasma and secondary gas supply with a nozzle according to another particular embodiment of the present invention;

- Fig. 11a

- a sectional view taken along the line AA of

Fig. 11 ; - Fig. 11b

- a sectional view taken along the line BB of

Fig. 11 ; - Fig. 12

- Individual representations (top left: top view from the front, top right: longitudinal section view, bottom right: side view) of the nozzle of

Fig. 11 ; - Fig. 13

- Individual representations (top left: top view from the front, top right: longitudinal section view, bottom right: side view) nozzle according to a further particular embodiment of the invention;

- Fig. 14

- Individual illustrations (left: longitudinal section view, right: top view from the front) of the nozzle cap of

Fig. 1 .Fig. 3 andFig. 5 such asFig. 11 ; - Fig. 15

- Individual representations (left: longitudinal sectional view, right: plan view from the front) of a nozzle cap according to a particular embodiment, wherein the embodiment does not belong to the invention;

- Fig. 16

- Individual representations (left: longitudinal sectional view, right: plan view from the front) of a nozzle cap according to a further specific embodiment, wherein the embodiment does not belong to the invention;

In der nachfolgenden Beschreibung werden Ausführungsformen gezeigt, die mindestens eine Flüssigkeitslaufnut, hier als Kühlflüssigkeitszulaufnut bezeichnet und genau eine Flüssigkeitsrücklaufnut, hier als Kühlflüssigkeitsrücklaufnut bezeichnet, aufweisen. Die Erfindung ist darauf jedoch nicht beschränkt. Genauso gut können die Anzahl an Flüssigkeitszulaufnuten und Flüssigkeitsrückaufnuten vertauscht werden bzw. umgekehrt sein.In the following description, embodiments are shown which have at least one Flüssigkeitslaufnut, here referred to as Kühlflüssigkeitszulaufnut and exactly one liquid return groove, here referred to as Kühlflüssigkeitsrücklaufnut. However, the invention is not limited thereto. Just as well, the number of liquid inlet grooves and Flüssigkeitsrückaufnuten can be reversed or vice versa.

Der in den

Ein Kühlflüssigkeit, z. B. Wasser oder mit Gefrierschutzmittel versetztes Wasser durchströmt den Kühlflüssigkeitsraum 10 von einer Bohrung des Kühlflüssigkeitsvorlaufs WV zu einer Bohrung des Kühlflüssigkeitsrücklaufs WR, wobei die Bohrungen um 180° zueinander versetzt angeordnet sind.A cooling liquid, eg. As water or antifreeze added water flows through the

Bei Plasmabrennern im Stand der Technik kommt es immer wieder zur Überhitzung der Düse 4 im Bereich der Düsenbohrung 4.10. Es kann aber auch zu Überhitzungen zwischen dem zylindrischen Abschnitt der Düse 4 und der Düsenhalterung 5 kommen. Dies trifft insbesondere auf Plasmabrenner, die mit hohem Pilotstrom oder indirekt betrieben werden, zu. Dies zeigt sich durch Verfärbung des Kupfers nach kurzer Betriebszeit. Hier treten schon bei Strömen von 40A Verfärbungen nach kurzer Zeit (z.B. 5 Minuten) auf. Ebenso wird die Dichtstelle zwischen Düse 4 und Düsenkappe 2 überlastet, was zur Beschädigung des Rundrings 4.16 und damit zur Undichtigkeit und Kühlflüssigkeitsaustritt führt. Untersuchungen haben ergeben, dass dieser Effekt besonders auf der dem Kühlflüssigkeitsrücklauf zugewandten Seite der Düse 4 auftritt. Es wird angenommen, das der thermisch am höchsten beanspruchte Bereich, die Düsenbohrung 4.10 der Düse 4 unzureichend gekühlt wird, weil die Kühlflüssigkeit den der Düsenbohrung am nächsten liegenden Teil 10.20 des Kühlflüssigkeitsraumes 10 unzureichend durchströmt und/oder diesen insbesondere auf der dem Kühlflüssigkeitsrücklauf zugewandten Seite gar nicht erreicht.In plasma torches in the prior art, overheating of the

Im vorliegenden Plasmabrenner nach

Weiterhin ist der Plasmabrennerkopf 1 mit einer Düsenschutzkappenhalterung 8 und einer Düsenschutzkappe 9 ausgestattet. Durch diesen Bereich strömt das Sekundärgas SG, in den Plasmastrahl umgibt. Das Sekundärgas SG durchströmt eine Sekundärgasführung 9.1 und kann durch diese in Rotation versetzt werden.Furthermore, the

So wird eine wirksame Kühlung der Düse 4 im Bereich der Düsenspitze erreicht und eine thermische Überlastung verhindert. Es wird sichergestellt, dass möglichst viel Kühlflüssigkeit den Raum 10.20 des Kühlmittelraums 10 erreicht. Es kam bei Versuchen zu keiner Verfärbung der Düse im Bereich der Düsenbohrung 4.10 mehr. Auch traten Undichtigkeiten zwischen der Düse 4 und der Düsenkappe 2 nicht mehr auf und der Rundring 4.16 wurde nicht überhitzt.Thus, an effective cooling of the

Die

Die in den

Claims (15)

- Nozzle (4) for a liquid-cooled plasma torch, comprising a nozzle bore (4.10) for the exit of a plasma gas jet at a nozzle tip (4.11), a first section (4.1) of which the outer surface (4.4) is substantially cylindrical, and, adjoining the nozzle tip (4.11), a second section (4.2) of which the outer surface (4.5) tapers substantially conically towards the nozzle tip (4.11), wherein a) at least one liquid supply groove (4.20; 4.21) is provided and extends over the second section (4.2) in the outer surface (4.5) of the nozzle (4) towards the nozzle tip (4.11), and exactly one liquid return groove (4.22), which is separate from the liquid supply groove(s) (4.20; 4.21), is provided and extends over the second section (4.2), or b) exactly one liquid supply groove (4.20 or 4.21) is provided and extends over the second section (4.2) in the outer surface (4.5) of the nozzle (4) towards the nozzle tip (4.11), and at least one liquid return groove (4.22), which is separate from the liquid supply groove (4.20 or 4.21), is provided and extends over the second section (4.2), wherein the liquid supply groove (4.20; 4.21) also extends over a part of the first section (4.1), characterized in that, in case a), a liquid supply groove (4.6) that communicates there with the liquid supply groove (4.20), and extends in the circumferential direction of the first section (4.1), is located in the first section (4.1) of the nozzle (4), and, in case b), a liquid supply groove that communicates there with the liquid return groove (4.22), and extends in the circumferential direction of the first section (4.1), is located in the first section (4.1) of the nozzle (4).

- Nozzle according to Claim 1, characterized in that the liquid return groove(s) (4.22) also extend(s) over a part of the first section (4.1) in the outer surface of the nozzle (4).

- Nozzle according to Claim 1 or 2, characterized in that, in case a), at least two liquid supply grooves (4.20; 4.21) are provided, and, in case b), at least two liquid return grooves (4.22) are provided.

- Nozzle according to Claim 3, characterized in that the centre point of the liquid supply groove (4.20) and the centre point of the liquid return groove (4.22) are arranged, offset by 180° to each other, around the circumference of the nozzle (4).

- Nozzle according to one of Claims 1 to 4, characterized in that, in case a), the width of the liquid return groove in the circumferential direction, and, in case b), the width of the liquid supply groove in the circumferential direction, lies in the range from 90° to 270°.

- Nozzle according to one of the preceding claims, characterized in that, in case a), the liquid supply groove (4.6) extends in the circumferential direction of the first section (4.1) of the nozzle (4) around the entire circumference, or in that, in case a), the liquid supply groove (4.6) extends in the circumferential direction of the first section (4.1) of the nozzle (4) by an angle in the range from 60° to 300°, and in that, in case b), the liquid supply groove extends in the circumferential direction of the first section (4.1) of the nozzle (4) by an angle in the range from 60° to 300°, or in that, in case a), the liquid supply groove (4.6) extends in the circumferential direction of the first section (4.1) of the nozzle (4) by an angle in the range from 90° to 270°, and in that, in case b), the liquid supply groove extends in the circumferential direction of the first section (4.1) of the nozzle (4) by an angle in the range from 90° to 270°.

- Nozzle according to one of the preceding claims, characterized in that, in case a), exactly two liquid supply grooves (4.20; 4.21) are provided, and, in case b), exactly two liquid return grooves (4.22) are provided.

- Nozzle according to Claim 7, characterized in that, in case a), the two liquid supply grooves (4.20; 4.21) are arranged around the circumference of the nozzle symmetrically with respect to a straight line extending from the centre point of the liquid return groove (4.22) at a right angle through the longitudinal axis of the nozzle (4), and, in case b), the two liquid return grooves are arranged around the circumference of the nozzle symmetrically with respect to a straight line extending from the centre point of the liquid supply groove at a right angle through the longitudinal axis of the nozzle (4).

- Nozzle according to Claim 7 or 8, characterized in that, in case a), the centre points of the two liquid supply grooves (4.20; 4.21), and, in case b), the centre points of the two liquid return grooves, are arranged around the circumference of the nozzle (4) in a manner offset relative to each other by an angle lying in the range from 30° to 180°.

- Nozzle according to one of Claims 7 to 9, characterized in that, in case a), the width of the liquid return groove (4.22) in the circumferential direction, and, in case b), the width of the liquid supply groove in the circumferential direction, lies in the range from 120° to 270°.

- Nozzle according to one of Claims 7 to 10, characterized in that, in case a), the two liquid supply grooves (4.20; 4.21) are connected to each other in the first section (4.1) of the nozzle (4), and in that, in case b), the two liquid return grooves are connected to each other in the first section (4.1) of the nozzle (4).