EP2157397B1 - Front window for an armoured vehicle - Google Patents

Front window for an armoured vehicle Download PDFInfo

- Publication number

- EP2157397B1 EP2157397B1 EP09167766.6A EP09167766A EP2157397B1 EP 2157397 B1 EP2157397 B1 EP 2157397B1 EP 09167766 A EP09167766 A EP 09167766A EP 2157397 B1 EP2157397 B1 EP 2157397B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pillar

- vehicle

- window frame

- windscreen frame

- vehicle according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F41—WEAPONS

- F41H—ARMOUR; ARMOURED TURRETS; ARMOURED OR ARMED VEHICLES; MEANS OF ATTACK OR DEFENCE, e.g. CAMOUFLAGE, IN GENERAL

- F41H5/00—Armour; Armour plates

- F41H5/26—Peepholes; Windows; Loopholes

- F41H5/263—Mounting of transparent armoured panels, e.g. bulletproof windows on vehicles

Definitions

- a basic idea of the invention lies in the fact that the window frame is arranged on the vehicle such that it is supported against a frontal area of the A-pillar. As a result, from the driver's point of view, the window frame is behind the A-pillar and the viewing area is increased.

- At least one armor element such as an armor plate, is fastened to the window frame at the front of the vehicle.

- the attachment can be done by means of one or more arranged on the window frame fasteners.

- the A-pillar can still be relieved by the fact that the window frame rests loosely on the A-pillar.

- the attachment of the window frame can thus take place only on the horizontally extending elements of the window frame.

- the invention can provide the advantage that the construction of the A-pillar can be simplified, in particular narrowed, so that the field of view is only slightly limited.

- the window frame is in view of the eye point of the vehicle in the visual shadow of the A-pillar.

- an eyepoint in this case a point is assumed, in which the driver's eyes are assumed to be combined and which is located on a vertical at 700 mm above the unloaded, located in its center position driver's seat, the vertical at 130 mm from the front edge of the backrest on to build the centerline of the seat. Due to the position in the visual shadow of the A-pillar, there is no visual impairment due to the window frame.

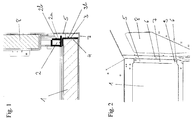

- FIGS. 1 to 4 show a possible arrangement of the windshield 1 with a window frame 3 in the region of the A-pillar 2 of a vehicle, not shown, which also has a side window 8, wherein the A-pillar 2 is arranged between the hood and vehicle roof.

- the windscreen 1 made of bulletproof glass, which is a composite safety glass that can withstand impact, bombardment and blasting effects, is encompassed and fixed by a circumferential potting frame 3 via a flexible potting compound 4.

- Of the Window frame 3 is supported against the A-pillar 2, namely against a frontal surface 2a of the A-pillar 2.

- the frontal surface 2a of the A-pillar 2 is thus the surface of the A-pillar, which is in the vehicle direction of travel.

- an armor element 5 in the region of the A-pillar 2 is arranged.

- the armor element 5 is fastened on a lateral surface 3b of the window frame 3 via screw connections as fastening means 6, wherein it covers the connection point between the window frame 3 and the A-pillar 2.

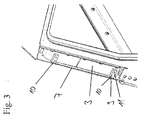

- the Fig. 3 shows the vehicle with removed side armor element 5.

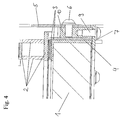

- the frontal and lateral threaded holes have as fastening elements 11, in which, as in Fig. 4 represented, the fastening means 6 and 9 are screwed.

- the window frame 3 is located in the region of the A-pillar 2 only loosely on the A-pillar surface 2a.

- the window frame 3 is connected only in a manner not shown on the horizontally extending edges with the vehicle, z. B. bolted or welded.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Body Structure For Vehicles (AREA)

- Window Of Vehicle (AREA)

Description

Die Erfindung betrifft ein gepanzertes Fahrzeug mit einer A-Säule und einer Frontscheibe, die insbesondere aus einem Panzerungsmaterial wie Panzerglas hergestellt ist. Bei solchen Fahrzeugen ist die Frontscheibe zumindest teilweise von einem Scheibenrahmen umfasst, über den die Scheibe am Fahrzeug befestigt werden kann.The invention relates to an armored vehicle with an A-pillar and a windscreen, which is made in particular of an armor material such as bulletproof glass. In such vehicles, the windshield is at least partially enclosed by a window frame, via which the window can be fastened to the vehicle.

Bei bekannten Fahrzeugen (siehe z.B.

Nachteilig an der bekannten Ausgestaltung ist, dass, aufgrund der entsprechenden Konstruktion der A-Säule sowie der daran angepassten Ausgestaltung der Scheibe sowie des Scheibenrahmens, der Sichtbereich für den Fahrer eingeschränkt wird.A disadvantage of the known configuration that, due to the corresponding construction of the A-pillar and the adapted thereto design of the disc and the window frame, the field of view for the driver is restricted.

Die Erfindung hat die Aufgabe, ein gepanzertes Fahrzeug mit einem verbesserten Sichtbereich bereitzustellen.The invention has the object to provide an armored vehicle with an improved field of view.

Die Erfindung löst die Aufgabe mit den Merkmalen aus dem kennzeichnenden Teil des Patentanspruchs 1. Vorteilhafte Ausgestaltungen sind Bestandteil der abhängigen Ansprüche.The invention solves the problem with the features of the characterizing part of claim 1. Advantageous embodiments are part of the dependent claims.

Ein Grundgedanke der Erfindung liegt darin, dass der Scheibenrahmen derart am Fahrzeug angeordnet wird, dass er sich gegen eine frontale Fläche der A-Säule abstützt. Dadurch liegt der Scheibenrahmen aus Sicht des Fahrers hinter der A-Säule und der Sichtbereich wird vergrößert.A basic idea of the invention lies in the fact that the window frame is arranged on the vehicle such that it is supported against a frontal area of the A-pillar. As a result, from the driver's point of view, the window frame is behind the A-pillar and the viewing area is increased.

Zudem kann seitlich am Fahrzeug zumindest ein Panzerungselement wie eine Panzerplatte an einer vorzugsweise seitlichen Fläche des Scheibenrahmens befestigt sein. Die Befestigung kann mittels einer oder mehrerer am Scheibenrahmen angeordneter Befestigungsvorrichtungen erfolgen. Somit wird der Vorteil erreicht, dass das seitliche Panzerungselement auf Grund der Befestigung am Scheibenrahmen nicht mehr an der A-Säule befestigt werden muss, so dass die A-Säule entlastet wird. Hierdurch kann ihre Bauweise kompakt gehalten werden, so dass weiterhin der Sichtbereich für den Fahrer vergrößert wird. Insbesondere kann das seitliche Panzerungselement zudem den Scheibenrahmen und die A-Säule überdecken, bevorzugt mindestens aber die Fuge zwischen Scheibenrahmen und A-Säule, so dass eine ballistisch vorteilhafte Ausgestaltung entsteht.In addition, at least one armor element such as an armor plate can be fastened on the side of the vehicle to a preferably lateral surface of the window frame. The attachment can be done by means of one or more arranged on the window frame fasteners. Thus, the advantage is achieved that the side armor element due to the attachment to the window frame no longer needs to be attached to the A-pillar, so that the A-pillar is relieved. As a result, their design can be kept compact, so that the range of vision for the driver is further increased. In particular, the lateral armor element can also cover the window frame and the A-pillar, but preferably at least the joint between the window frame and the A-pillar, so that a ballistically advantageous embodiment is created.

Bei einer bevorzugten Ausgestaltung ist frontal am Fahrzeug zumindest ein Panzerungselement wie eine Panzerplatte am Scheibenrahmen befestigt. Die Befestigung kann mittels eines oder mehrerer am Scheibenrahmen angeordneter Befestigungsvorrichtungen erfolgen. Hierdurch wird wiederum die A-Säule entlastet, wodurch eine Verbesserung hinsichtlich des Sichtbereiches erreicht werden kann.In a preferred embodiment, at least one armor element, such as an armor plate, is fastened to the window frame at the front of the vehicle. The attachment can be done by means of one or more arranged on the window frame fasteners. As a result, in turn, the A-pillar is relieved, whereby an improvement in the field of view can be achieved.

Eine seitliche Fläche des Scheibenrahmens und eine seitliche Fläche der A-Säule können bei einer vorteilhaften Ausgestaltung im Wesentlichen in einer gemeinsamen Ebene liegen. Durch die sich ergebende ebene Fläche kann das seitliche Panzerungselement einen konstanten Abstand zur A-Säule und zur seitlichen Fläche des Scheibenrahmens aufweisen, so dass eine ballistisch vorteilhafte Ausgestaltung entsteht.A lateral surface of the disc frame and a lateral surface of the A-pillar can lie in an advantageous embodiment substantially in a common plane. Due to the resulting flat surface, the side armor element may have a constant distance from the A-pillar and the lateral surface of the window frame, so that a ballistically advantageous embodiment.

Die A-Säule kann weiterhin dadurch entlastet werden, dass der Scheibenrahmen lose an der A-Säule anliegt. Die Befestigung des Scheibenrahmens kann somit lediglich an den horizontal verlaufenden Elementen des Scheibenrahmens erfolgen.The A-pillar can still be relieved by the fact that the window frame rests loosely on the A-pillar. The attachment of the window frame can thus take place only on the horizontally extending elements of the window frame.

Die Erfindung kann den Vorteil bieten, dass die Konstruktion der A-Säule vereinfacht, insbesondere verschmälert werden kann, so dass der Sichtbereich nur geringfügig eingeschränkt wird.The invention can provide the advantage that the construction of the A-pillar can be simplified, in particular narrowed, so that the field of view is only slightly limited.

Bevorzugt liegt der Scheibenrahmen hinsichtlich des Augpunktes des Fahrzeugs im Sichtschatten der A-Säule. Als Augpunkt wird hierbei ein Punkt angenommen, in dem die Augen des Fahrers vereinigt angenommen liegen und welcher auf einer senkrechten in 700 mm Höhe über dem unbelasteten, in seiner Mittelstellung befindlichen Führersitz liegt, wobei die Senkrechte in 130 mm Abstand von der Vorderkante der Rückenlehne auf der Mittellinie des Sitzes zu errichten ist. Durch die Lage im Sichtschatten der A-Säule kommt es zu keiner Sichtbeeinträchtigung durch den Scheibenrahmen.Preferably, the window frame is in view of the eye point of the vehicle in the visual shadow of the A-pillar. As an eyepoint in this case a point is assumed, in which the driver's eyes are assumed to be combined and which is located on a vertical at 700 mm above the unloaded, located in its center position driver's seat, the vertical at 130 mm from the front edge of the backrest on to build the centerline of the seat. Due to the position in the visual shadow of the A-pillar, there is no visual impairment due to the window frame.

Ein vorteilhaftes Ausführungsbeispiel der Erfindung wird anhand der

- Fig. 1

- einen horizontalen Schnitt durch eine an einem Fahrzeug angeordnete Frontscheibe im Bereich der A-Säule;

- Fig. 2

- den Ausschnitt des Fahrzeugs gemäß

Fig. 1 in einer perspektivischen Darstellung; - Fig. 3

- das Fahrzeug nach

Fig. 2 mit abgenommenem seitlichem Panzerungselement; - Fig. 4

- einen Schnitt gemäß

Fig. 1 an einer anderen Stelle der A-Säule.

- Fig. 1

- a horizontal section through a arranged on a vehicle windshield in the area of the A-pillar;

- Fig. 2

- the section of the vehicle according to

Fig. 1 in a perspective view; - Fig. 3

- the vehicle after

Fig. 2 with removed side armor element; - Fig. 4

- a section according to

Fig. 1 at another point of the A-pillar.

Die

Seitlich am Fahrzeug ist ein Panzerungselement 5 im Bereich der A-Säule 2 angeordnet. Das Panzerungselement 5 ist an einer seitlichen Fläche 3b des Scheibenrahmens 3 über Schraubverbindungen als Befestigungsmittel 6 befestigt, wobei es die Verbindungsstelle zwischen dem Scheibenrahmen 3 und der A-Säule 2 überdeckt.Laterally on the vehicle, an

Am Fahrzeug ist zudem frontal ein Panzerungselement 7 im Bereich der A-Säule 2 angeordnet, welches am Scheibenrahmen 3 über Schrauben als Befestigungsmittel 9 befestigt ist. Die

Der Scheibenrahmen 3 liegt im Bereich der A-Säule 2 nur lose an der A-Säule-Fläche 2a an. Der Scheibenrahmen 3 ist lediglich in nicht dargestellter Weise an den horizontal verlaufenden Rändern mit dem Fahrzeug verbunden, z. B. verschraubt oder verschweißt.The

- 11

- Frontscheibewindscreen

- 22

- A-SäuleA column

- 2a2a

- frontale Fläche der A-Säulefrontal area of the A-pillar

- 2b2 B

- seitliche Fläche der A-Säulelateral surface of the A-pillar

- 33

- Scheibenrahmenwindow frame

- 3b3b

- seitliche Fläche des Scheibenrahmenslateral surface of the window frame

- 44

- Vergussmassepotting compound

- 55

- Seitliches PanzerungselementLateral armor element

- 66

- Befestigungsmittelfastener

- 77

- Frontales PanzerungselementFrontal armor element

- 88th

- Seitenscheibeside window

- 99

- Befestigungsmittelfastener

- 1010

- Befestigungsvorrichtungfastening device

- 1111

- Befestigungselementfastener

Claims (7)

- Armoured vehicle having an A pillar (2) and a front windscreen (1), in particular made of an armour material, which is surrounded at least partially by a windscreen frame (3) supported against a front surface (2a) of the A pillar (2), characterized in that at least one armour element (5, 7) is fastened to the windscreen frame (3) on the side and/or on the front of the vehicle.

- Vehicle according to Claim 1, characterized in that at least one armour element (5) is fastened to a lateral surface (3b) of the windscreen frame (3) on the side of the vehicle.

- Vehicle according to Claim 2, characterized in that the armour element (5) at least partially covers the windscreen frame (3) and the A pillar (2).

- Vehicle according to one of the preceding claims, characterized in that a lateral surface (3b) of the windscreen frame (3) and a lateral surface (2b) of the A pillar (2) lie substantially in a common plane.

- Vehicle according to one of the preceding claims, characterized in that the windscreen frame (3) bears loosely against the A pillar (2).

- Vehicle according to one of the preceding claims, characterized in that at least one fastening device (10) is arranged on the windscreen frame (3) and has fastening elements (11), in particular in the form of front and/or lateral bores, for fastening armour elements (5, 7).

- Vehicle according to one of the preceding claims, characterized in that the windscreen frame (3) lies in the shadow of the A pillar (2) with respect to the viewpoint from the vehicle.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE200810038604 DE102008038604B4 (en) | 2008-08-21 | 2008-08-21 | Armored vehicle with an A-pillar and a windshield |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2157397A2 EP2157397A2 (en) | 2010-02-24 |

| EP2157397A3 EP2157397A3 (en) | 2012-07-25 |

| EP2157397B1 true EP2157397B1 (en) | 2016-07-20 |

Family

ID=41057644

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09167766.6A Active EP2157397B1 (en) | 2008-08-21 | 2009-08-13 | Front window for an armoured vehicle |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP2157397B1 (en) |

| DE (1) | DE102008038604B4 (en) |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202004007765U1 (en) * | 2004-05-13 | 2005-09-22 | Ah Worldwide Lp, Edinburgh | Double armour plating for fighting vehicle or vehicle carrying civilians threatened by explosion or gunfire |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2226833A (en) * | 1939-11-15 | 1940-12-31 | Perfection Windshield Company | Bulletproof glass mounting unit |

| US4352316A (en) * | 1978-06-30 | 1982-10-05 | Medlin Richard C | Lightweight armored vehicle and method of making same using woven polyester glass protective sheets |

| DE4314092A1 (en) * | 1992-07-11 | 1994-01-13 | Wendler Karosseriebau Gmbh | Armoured vehicle for transporting currency - has armoured glass windscreen with frame in cross-section formed by angle |

| DE19733034C2 (en) * | 1997-07-31 | 2003-03-20 | Daimler Chrysler Ag | Emergency exit for motor vehicles |

| GB0200524D0 (en) * | 2002-01-11 | 2002-02-27 | Bending Light | Improvements in and relating to optical systems |

| JP2004009966A (en) * | 2002-06-10 | 2004-01-15 | Honda Motor Co Ltd | Vehicle windshield mounting structure |

| JP3805722B2 (en) * | 2002-06-10 | 2006-08-09 | 本田技研工業株式会社 | Vehicle windshield |

| DE102007005706A1 (en) * | 2006-02-04 | 2007-08-09 | Acs Armoured Car Systems Gmbh | Bulletproof glass windscreen has auxiliary safety glass or plastic windscreen mounted in front of it |

| DE102007013956A1 (en) * | 2006-06-27 | 2008-01-24 | Hino Motors, Ltd., Hino | Front structure of a vehicle |

-

2008

- 2008-08-21 DE DE200810038604 patent/DE102008038604B4/en active Active

-

2009

- 2009-08-13 EP EP09167766.6A patent/EP2157397B1/en active Active

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202004007765U1 (en) * | 2004-05-13 | 2005-09-22 | Ah Worldwide Lp, Edinburgh | Double armour plating for fighting vehicle or vehicle carrying civilians threatened by explosion or gunfire |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2157397A3 (en) | 2012-07-25 |

| DE102008038604A1 (en) | 2010-02-25 |

| EP2157397A2 (en) | 2010-02-24 |

| DE102008038604B4 (en) | 2013-04-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2681504B1 (en) | Vehicle, especially military vehicle | |

| DE10134394B4 (en) | Mine protection floor for an armored vehicle | |

| EP3012571B1 (en) | Vehicle floor pan comprising additional armouring | |

| DE102008020304B4 (en) | Vehicle body of a motor vehicle with a front-end module | |

| DE102012024429A1 (en) | vehicle seat | |

| EP1449747A2 (en) | Reinforcement means in the region of the C-pillar of a vehicle body | |

| EP2275773A2 (en) | Mine protection | |

| EP2157397B1 (en) | Front window for an armoured vehicle | |

| DE102022118861A1 (en) | Device for attaching a container to a vehicle | |

| EP1916496A1 (en) | Motor vehicle, in particular military, protected against external explosions | |

| EP3279063A1 (en) | Cross member and cockpit module | |

| DE102016200358B4 (en) | Holding element for arranging a separate design element of a vehicle and arrangement of a design element on a holding element | |

| DE10236976B4 (en) | Roof load carrier for a vehicle roof with a front and a rear cross member | |

| DE10359514B4 (en) | Roof attachment for a cab of a commercial vehicle | |

| EP2585790B1 (en) | Military vehicle housing | |

| EP3798081B1 (en) | A-column and railway vehicle with a-columns | |

| DE202020105426U1 (en) | Safety paneling for a driver's cab of a vehicle | |

| DE202020102987U1 (en) | Vehicle with replaceable safety cladding for a driver's cab of the vehicle | |

| DE202020102985U1 (en) | Armored safety cladding for a driver's cab of a vehicle | |

| DE2547424A1 (en) | TWO-PIECE HANDRAIL FOR RAILING, ESPECIALLY BRIDGE RAILING | |

| DE102021129638A1 (en) | Engine mounting arrangement for a vehicle | |

| DE2101742A1 (en) | Cab with an internal protective frame | |

| DE102016102966B4 (en) | Arrangement of an air intake grille in a body cover of a motor vehicle | |

| DE102022100259A1 (en) | Working vehicle, in particular a wheel loader, with a front protective cover for protecting a driver's cab | |

| DE202004012982U1 (en) | Front end construction for vehicle has the bonnet lock cross member in front of the top edge of the radiator providing a crush zone between the top of the cross member and the front of the bonnet |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Free format text: PREVIOUS MAIN CLASS: F41H0007040000 Ipc: F41H0005260000 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F41H 5/26 20060101AFI20120618BHEP Ipc: F41H 7/04 20060101ALI20120618BHEP |

|

| 17P | Request for examination filed |

Effective date: 20130124 |

|

| 17Q | First examination report despatched |

Effective date: 20130409 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20160126 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE BG CH CY CZ DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R108 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 814457 Country of ref document: AT Kind code of ref document: T Effective date: 20160815 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20160720 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161120 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161020 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161121 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161021 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161020 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| 26N | No opposition filed |

Effective date: 20170421 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160813 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160813 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20090813 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160720 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230517 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: HC Ref document number: 814457 Country of ref document: AT Kind code of ref document: T Owner name: KNDS DEUTSCHLAND GMBH & CO. KG, DE Effective date: 20250203 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20250829 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20250822 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20250819 Year of fee payment: 17 Ref country code: FR Payment date: 20250821 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20250901 Year of fee payment: 17 |