EP2124231A2 - Fentes pour un dispositif d'imagerie - Google Patents

Fentes pour un dispositif d'imagerie Download PDFInfo

- Publication number

- EP2124231A2 EP2124231A2 EP09160478A EP09160478A EP2124231A2 EP 2124231 A2 EP2124231 A2 EP 2124231A2 EP 09160478 A EP09160478 A EP 09160478A EP 09160478 A EP09160478 A EP 09160478A EP 2124231 A2 EP2124231 A2 EP 2124231A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- radiation

- axis

- additional

- aperture

- gap

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- G—PHYSICS

- G21—NUCLEAR PHYSICS; NUCLEAR ENGINEERING

- G21K—TECHNIQUES FOR HANDLING PARTICLES OR IONISING RADIATION NOT OTHERWISE PROVIDED FOR; IRRADIATION DEVICES; GAMMA RAY OR X-RAY MICROSCOPES

- G21K1/00—Arrangements for handling particles or ionising radiation, e.g. focusing or moderating

- G21K1/02—Arrangements for handling particles or ionising radiation, e.g. focusing or moderating using diaphragms, collimators

-

- G—PHYSICS

- G21—NUCLEAR PHYSICS; NUCLEAR ENGINEERING

- G21K—TECHNIQUES FOR HANDLING PARTICLES OR IONISING RADIATION NOT OTHERWISE PROVIDED FOR; IRRADIATION DEVICES; GAMMA RAY OR X-RAY MICROSCOPES

- G21K2207/00—Particular details of imaging devices or methods using ionizing electromagnetic radiation such as X-rays or gamma rays

Definitions

- the invention relates to a diaphragm, in particular for an imaging device, according to the preamble of claim 1.

- the radiation source can be, for example, the effective focal spot on the anode of an x-ray tube or surface-distributed radiating material.

- the latter can be radioactive waste distributed over a room in a collecting bin, whereby alleged discrepancies between declaration and actual content must be clarified.

- Further examples of radiation sources whose shape one wishes to image are deposits with uranium-containing ores or nuclear facilities, in which it is often not only of importance to determine the nature of the radiation, but also to determine the spatial structure of the radiation sources.

- the sources mentioned, which generate the high-energy radiation directly are also those that generate them by X-ray or Gammaschenstreuung.

- the thickness of the material for the pinhole diaphragm must be large, that is to say in relation to the half-value thickness of the intensity of the radiation used for imaging. Therefore, the achievable image quality is essentially determined by aperture diameter and material thickness and density. Often, therefore, one obtains at best a shadow image of the actual pinhole, wherein the pinhole, which is to serve for imaging, due to the wall thickness becomes a collimator, which can pass only a straight-line beam. Therefore, the aperture in the hole cameras is often trumpet-shaped with the narrow spot to the radiation source designed so as not to lose the imaging properties completely.

- the DE 690 01 117 discloses a device for detecting radiation sources in real time.

- the device comprises a collimator which is delimited by a wall in the form of a double cone, the double cone being formed from two cones of the same opening angle, which are set opposite each other at the vertex.

- the vertex forms the pinhole of the resulting camera.

- DD 240 091 a rotating diaphragm system, which consists of several concentrically arranged around the optical axis hollow cones.

- Each hollow cone consists of half of the respective radiation strongly or weakly absorbing material, the hollow halves are inserted into each other so that always hollow cone halves of different materials adjoin one another.

- Another mechanically moving solution is from the DE 40 00 507 known, in which a slit aperture acts like the opening of a pinhole camera.

- the relative movement of the slit diaphragm to the detector exposes the radiation scattered from various points of the test object to the detector. Due to the relative position of the slit, it is predetermined from which depth of the test object secondary radiation is detected by a detector.

- a solution for expanding the field of view in a pinhole camera is from the DE 196 03 212 in which the core of the camera has a cylindrical borehole crystal which is terminated by a pinhole collimator, which is conically arched in the region of the borehole. In the center of the collimator is an aperture. Depending on the shape of the collimator, the field of view has an opening angle of up to approximately 120 °.

- the diaphragm is not based on a mechanically moving solution and can be realized with almost any material thickness, without losing its imaging properties.

- the diaphragm is suitable for limiting radiation originating from a radiation source, in particular high-energy radiation, and for directing it to an imaging region along an optical axis x according to the hole-camera principle.

- the diaphragm comprises the radiation at least partially absorbing regions, and in the diaphragm there is a gap or at least one radiation absorbing portion which has at least a first non-planar surface and a second non-planar surface which separates it from the radiation delimit at least partially absorbent areas.

- the imaging quality, the image size and the radiation yield are subject to restrictions.

- the imaging quality can be increased; However, this is simultaneously the pictured Restricted range in y- direction and reduced the beam yield.

- the slit width By increasing the slit width, the imaged area in the y- direction is expanded and the beam yield is increased, but at the same time the imaging quality is lowered.

- the object of the invention is therefore to provide a diaphragm for a pinhole camera, which has the advantages of the published patent application DE 10 2005 029 674 A1 disclosed aperture, but achieves a better imaging quality and / or a larger imaging range and / or a higher beam efficiency.

- Another object of the invention is to provide a diaphragm with better imaging quality and / or larger imaging range and / or higher beam efficiency, which after a comparison with that in the German patent application with the file reference 10 2007 057 261.3 disclosed methods of making the disclosed in the publication DE 10 2005 029 674 A1 disclosed aperture can be produced only slightly modified method.

- the description of the surface contours is based on a three-dimensional Cartesian coordinate system whose origin lies on the first non-planar surface without restriction of generality (cf. FIG. 2 ).

- the mode of operation of the diaphragm can be explained by considering a beam with a directional vector (1, y s , z s ), ie a beam which propagates in the direction of the positive optical axis x.

- a direction vector (1,0, tan ⁇ ) cf. FIG.

- the gap already described or the region which absorbs little radiation is referred to here as the first gap or the radiation having a low absorption, since the diaphragm according to the invention has at least one additional gap or at least one additional region which absorbs the radiation to a small extent.

- the low radiation absorbing regions may be filled with a suitable material which absorbs the relevant radiation less than the radiation at least partially absorbing regions, the material being in the form of a separate insert or a coating applied to at least one of the non-planar surfaces can.

- a gap is also to be understood as meaning a region which absorbs the radiation to a low degree and which is filled with material.

- non-planar surfaces is meant any surface that is not flat, such as curved and curved surfaces.

- affine mapping refers to an image of the three-dimensional space on itself, which maps each straight line to a straight line. Such a map can be vectored with respect to a given affine, ie, rectilinear, coordinate system by a mapping rule of the form x ⁇ A x + b describe, where x the vector describing the point to be imaged, A any regular 3x3 matrix and b is an arbitrary three-vector.

- isometry refers to an isometric mapping of the three-dimensional space to itself, ie a rigid body movement that leaves distances and angles invariant.

- An isometry is an affine image in whose vector representation with respect to a Cartesian coordinate system the matrix A is orthogonal.

- the term "shear along the direction A parallel to the plane B" denotes an affine map which shifts each point of the space along the direction A parallel to the plane B by a distance proportional to the distance of the point from the plane B.

- each additional gap has at least one first additional non-planar surface and a second additional non-planar surface which delimits it from the regions which at least partially absorb the radiation

- the contour of the first additional nonplanar surface after application of the associated affine map can each be at least partially described by the same function z ( x , y ), by which the first non-planar surface of the first gap can be at least partially described, and the contour of the second additional non-planar surface is at least partially complementary to the contour of the first additional non-planar surface, it is achieved that the additional column each have similar imaging properties as the first gap.

- the set of affine mappings which comprises the identity mapping for the first gap and the associated affine mapping for each additional gap can be placed in a sequence in such a way that an affine image generating the sequence exists, such that for each pair of affine maps following each other in the sequence, the affine image of the pair following in the sequence is obtained by concatenating the affine image of the pair preceding the sequence with the sequence-generating affine map. This ensures that the sub-images caused by the individual gaps are in a particularly simple and regular relationship to each other.

- the associated affine map is an isometry.

- the additional gaps can be formed by applying a method, which essentially corresponds to the method used to form the first gap, after a movement of the diaphragm corresponding to the respective isometry has been carried out.

- the sequence of affine images is generated by an isometry, it is further achieved that the formation of all gaps in each case the same movement before application of the applied method for forming a gap method is executed.

- the associated isometry can be described in each case as concatenation of a first isometry and a second isometry, each of the first and second isometries each having either a translation along a coordinate axis or a rotation around one is parallel to a coordinate axis or coincident with a coordinate axis axis.

- each of the first and second isometries may be a rotation about an axis parallel to a coordinate axis or coincident with a coordinate axis.

- the first isometry is in each case a rotation about a respective angle ⁇ about a first axis, which lies in the x - y plane and runs parallel to the y- axis or coincides with the y -axis

- the second isometry each rotation about a respective angle ⁇ about a second axis, which lies in the xz plane and parallel to the z- axis or coincides with the z- axis. It is thereby achieved that the sub-images caused by the gaps adjoin one another at least at a predetermined distance from the y - z plane and result in a consistent overall image there.

- the angle ⁇ can each be 0 °.

- the first axis can coincide with the y- axis. It is thereby achieved that the sub-images caused by the gaps adjoin one another independently of the distance from the yz-plane and result in a consistent overall image.

- the associated affine image is in each case a shear for each additional gap.

- the shear is in each case a shear in the y- direction parallel to the y- z plane. This ensures that the imaging surface is increased irrespective of the distance of the imaging plane to the diaphragm center and the distortions or blurring in the superposition of the partial images caused by the column are particularly low.

- A, B, C and n are constants.

- the constant A may have the value 0, and the constant B may have the value 0.

- the shape of the first non-planar surface corresponds to the shape of the first nonplanar surface of the laid-open publication DE 10 2005 029 674 A1 disclosed aperture.

- each additional gap that the contour of the second additional non-planar surface relative to the contour of the first additional non-planar surface is at least partially in the same position in which the contour of the second non-planar surface is relative to the contour of the first non-planar surface located. This ensures that the mapping properties of the column match and all columns can be formed using the same procedure.

- the first gap has a gap width h (y) which is essentially constant in a direction parallel to the optical axis x.

- the visible in the direction of the beam passage then has a size which is proportional to the expression H 2 y ⁇ f y ⁇ y is. If the gap width h (y) is chosen so that the is constant, beams of equal intensity are imaged with the same imaging quality.

- the width of the column is variable.

- the imaging properties of the diaphragm can be adapted to different situations, in particular to different intensities of the investigated radiation sources.

- the first gap fulfills the ideal hole camera principle only for beam bundles whose directional vectors lie in the xz plane, it is provided in a further embodiment of the invention that the radiation-absorbing regions are arranged rotatably about the optical axis x, so that the Column can be rotated.

- the radiation-absorbing regions are arranged rotatably about the optical axis x, so that the Column can be rotated.

- the building material for the diaphragm all materials are in question, which are able to absorb the radiation emitted by the radiation source effectively.

- these are heavy metals with a high atomic number, for example copper or tungsten.

- plastics with a high hydrogen content for example polyethylene, are suitable.

- the additional gaps can be formed by the same or a similar method as the first gap.

- the column according to the in the German patent application with the file number 10 2007 057 261.3 disclosed methods are formed.

- the invention therefore also provides a method of manufacturing a shutter as described above in which relative movement is performed between a cutting tool capable of cutting along a straight line and a workpiece such that the cutting tool traverses the workpiece a line intersecting a beam path in the diaphragm to be made, wherein the relative movement is repeated at least once, and wherein before each repetition of the relative movement, the workpiece is moved.

- the workpiece is cut along a fixed first direction. Furthermore, it is preferred that a rotational movement of the workpiece about a first axis of rotation, which runs along a second direction perpendicular to the cutting direction of the cutting tool, and at the same time a translational movement of the workpiece along the second direction are performed. Preferably, the rotational movement and the translational movement of the workpiece are linearly coupled.

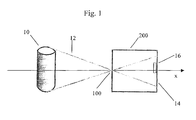

- FIG. 1 illustrates the Lochensekar at an imaging device 200.

- a radiation source 10 for example, a test body, high-energy radiation 12, in particular X-rays or gamma rays, emitted.

- the radiation 12 strikes a diaphragm 100, by which it is limited and directed along an optical axis x according to the Lochtrekos on an imaging region 14.

- the imaging region 14 is typically a projection surface on which an image of the test body 10 is generated.

- a receiving unit 16 which is sensitive to the radiation 12, in particular a detector or a camera.

- the diaphragm 100 comprises the radiation 12 at least partially absorbing regions.

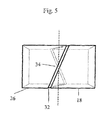

- a first radiation 12 absorbing region 18 is in FIG. 2 shown. It is delimited by a first non-planar surface 20 of a slit or the region 12 of low-absorbing radiation (not shown).

- the position of the Cartesian coordinate system is chosen so that its origin lies on the first non-planar outer surface 20, without limiting the generality.

- the x-axis coincides with the optical axis.

- surface C ⁇ 0; however, C> 0 can also be selected.

- the radiation absorbing portion 18 in this case is a parallelepiped, with respect to the coordinate system symmetrical body of suitable absorbent material (width a, depth b). For hard radiation this is a heavy metal with the highest possible density, for example copper or tungsten.

- the beam paths 22a, b correspond to direction vectors (1, 0, ⁇ aC / 2). For every direction vector (1, 0, z) for which - aC / 2 ⁇ z ⁇ aC / 2, there is exactly one parallel edge on the non-planar surface 20. For each direction vector with non-vanishing y-component, on the other hand the corresponding lines on the non-planar surface 20 are not linear.

- FIGS. 4a, b show first for illustration for two viewing angles, a diaphragm according to published patent application DE 10 2005 029 674 A1 with a single gap 32 and two radiation-absorbing areas 18 and 26.

- a view through the gap 32 in a straight direction is possible only at one point.

- the cleavage direction can optionally be horizontal ( FIG. 4 ) or vertical ( FIG. 5 ) be aligned.

- distances to the object can be estimated on the basis of large-area contours and, if necessary, measured.

- FIG. 6 shows schematically a test arrangement.

- a continuously radiating, powerful x-ray tube 46 generates radiation, which is hidden by an all-round shield, here a lead wall with window 48.

- the radiation passing through the window of the lead wall 48 falls onto an aluminum plate as scattering filter 50.

- the actual test object 10 is arranged between the scattering filter 50 and the diaphragm 100 according to the invention, which is integrated in a shielding wall 30 made of lead.

- an X-ray film or an image storage film (English: phosphor imaging plate) is used in a cassette.

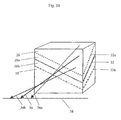

- FIG. 7 shows a perspective view of a panel according to a first embodiment of the present invention.

- the shutter of the present invention also includes additional gaps 32a and 32b defined by first and second additional non-planar surfaces, respectively, from the radiation absorbing regions 28a and 26, and 18 and 28b, respectively. It is, as in FIGS. 8 and 9 in more detail, each of the first additional non-planar surface is tilted relative to the first non-planar surface by an angle ⁇ about an axis parallel to the y-axis and rotated by an angle ⁇ about the z-axis, and the second additional not plane surface is in each case complementary to the first additional non-planar surface.

- the diaphragm has two additional gaps; however, as many additional columns as desired can be added to further enhance the imaging properties of the aperture.

- the spatial position of each further gap preferably results from the spatial position of the adjacent gap by the same isometry.

- FIG. 8 shows a cross-sectional view of the aperture of FIG. 7 in sectional plane A in the direction of view a, with the first gap 32, the additional gaps 32a and 32b and the radiation-absorbing areas 18, 28a, 28b and 26.

- the additional column 32a and 32b are each tilted with respect to the first gap 32 by an angle ⁇ about an axis parallel to the y axis through the receiving unit 16 extending axis, so that the central rays of the column converge at the receiving unit 16.

- the angle ⁇ can be kept so small that distortions due to the oblique incidence on the image surface are negligible and the known approximations for small angles (sin ⁇ ⁇ tan ⁇ ) can be applied.

- FIG. 9 shows a plan view of the central rays of the diaphragm of FIG. 7 in the direction b.

- the central beams 36a, 36b of the additional column are rotated relative to the central beam 36 of the first gap by an angle ⁇ about the z-axis.

- the superimposed floor plans serve only to clarify the alignment and do not relate to the visor body.

- the angle ⁇ can be chosen freely; it determines the distance or overlap of the adjacent partial images.

- FIG. 10 shows a perspective view of the aperture of FIG. 7 with the first gap 32, the additional gaps 32a and 32b, the radiation absorbing areas 18, 28a, 28b and 26 and the central beam 36 of the first gap 32 and the central beams 36a and 36b of the additional gaps 32a and 32b.

- all the beams from a passage direction open exactly onto a horizontal image axis 38, so that a sequence of the partial images caused by the gaps is ensured.

- FIG. 11 shows a perspective view of a panel according to a second embodiment of the present invention.

- This diaphragm also has a first gap 32 and additional gaps 32a and 32b as well as the radiation 12 absorbing regions 18, 28a, 28b and 26.

- C ⁇ 0 is selected; however, C> 0 can also be selected.

- the second embodiment of the present invention differs from the first embodiment in two essential features.

- the axis with respect to which the additional gaps are tilted by the angle ⁇ relative to the first gap coincides in this embodiment with the y-axis.

- no fixed distance is predetermined in this embodiment in which the receiving unit 16 must be arranged relative to the diaphragm.

- FIG. 12 shows a perspective view to illustrate the structure of the aperture of FIG. 11 ,

- the first gap 32 is shown.

- the outline of the panel 100 of the first embodiment is shown for comparison.

- the lines of intersection of the first gap 32 with the outer boundary surfaces of the two diaphragms are shown.

- Aperture 100 ' is truncated at x 0 ⁇ 0 at x coordinate x 0 as compared to aperture 100; on the other hand, it is widened in the direction of higher x-coordinates compared to the stop 100.

- the beam guidance is unchanged from the first embodiment.

- the y-axis comes to lie outside the diaphragm body. This makes it possible to arrange the column tilted relative to each other about the y-axis, without causing the visor body falls apart. This makes it particularly easy to add more columns, and the individual columns can be made narrower. For example, to make a panel according to this second embodiment of the present invention, many columns could be realized by stacking correspondingly shaped panels with wedge-shaped profiles.

- FIG. 13 Fig. 12 shows a z-direction plan view of a shear used in a third embodiment of the present invention. It is a shear in the y direction parallel to the yz plane.

- FIG. 13a shows the unsaved first gap

- FIG. 13b shows the sheared additional gap.

- the shear angle ⁇ is plotted, which forms the sheared x- axis with the unsecured x- axis.

- FIG. 14 shows a perspective view illustrating the construction of a diaphragm according to the third embodiment of the present invention.

- the first gap 32 and an additional, according to the in FIG. 13 Shear sheared gap 32a are shown.

- Limits are set only by the mechanical stability of the visor material and by the need to maintain a sufficient thickness for the shielding layer. Due to the shear, the gaps do not interfere with each other in their course.

- the outline of the bezel 100 of the first embodiment and the bezel 100 'of the second embodiment shown.

- the cut lines of the first gap 32 with the contour of the visor 100 ' are the lines of intersection of the additional gap 32a with the outline of the orifice 100 "and the shear angle ⁇ shown the aperture 100".

- Shear shear shown additional gap 32a finds place in it.

- FIG. 15 is a perspective view of a panel according to a fourth embodiment of the present invention. Again, the first gap 32 and an additional gap 32a are shown, with further gaps being added.

- the bezel according to the fourth embodiment of the present invention consists of two bezels according to the third embodiment of the present invention, which are joined together at their central axes. As a result, a higher wall thickness for particularly high-energy radiation can be achieved.

Landscapes

- Physics & Mathematics (AREA)

- Spectroscopy & Molecular Physics (AREA)

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- High Energy & Nuclear Physics (AREA)

- Measurement Of Radiation (AREA)

- Analysing Materials By The Use Of Radiation (AREA)

- Diaphragms For Cameras (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE200810025109 DE102008025109B4 (de) | 2008-05-22 | 2008-05-22 | Blende für eine bildgebende Einrichtung |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2124231A2 true EP2124231A2 (fr) | 2009-11-25 |

| EP2124231A3 EP2124231A3 (fr) | 2010-06-16 |

Family

ID=40941484

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09160478A Withdrawn EP2124231A3 (fr) | 2008-05-22 | 2009-05-18 | Fentes pour un dispositif d'imagerie |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP2124231A3 (fr) |

| DE (1) | DE102008025109B4 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2542000A (en) * | 2015-09-04 | 2017-03-08 | Secr Defence | Collimator for providing constant collimation effect |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009021750B4 (de) * | 2009-05-12 | 2013-01-17 | BAM Bundesanstalt für Materialforschung und -prüfung | Schwenkbar bewegliche Schlitzblendenvorrichtung |

| EP2482288B1 (fr) | 2011-02-01 | 2013-09-04 | BAM Bundesanstalt für Materialforschung und -prüfung | Dispositif d'imagerie modulaire pour rayonnement hautement énergétique doté d'un diaphragme à fente en forme de surfaces réglées |

| JP6277186B2 (ja) | 2012-07-05 | 2018-02-07 | アメリカン サイエンス アンド エンジニアリング, インコーポレイテッドAmerican Science and Engineering, Inc. | 放射線ビーム生成システムおよび放射線ビーム照射方法 |

| DE102014103833B3 (de) * | 2014-03-20 | 2015-07-09 | Bundesrepublik Deutschland, Vertreten Durch Den Bundesminister Für Wirtschaft Und Energie, Dieser Vertreten Durch Den Präsidenten Der Bundesanstalt Für Materialforschung Und -Prüfung (Bam) | Schlitzblende für Anwendungen in der Radiographie |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1046337A (en) | 1963-05-16 | 1966-10-19 | Industrial Nucleonics Corp | Combined shutter and collimator structure, and radiation gauge incorporating the same |

| DD240091A1 (de) | 1985-08-07 | 1986-10-15 | Akad Wissenschaften Ddr | Lochkamera fuer enrgiereiche quantenstrahlung |

| DE4000507A1 (de) | 1990-01-10 | 1991-07-11 | Philips Patentverwaltung | Anordnung zur untersuchung eines pruefobjekts mit gamma- oder roentgenstrahlung |

| DE69001117T2 (de) | 1989-10-11 | 1993-09-02 | Commissariat Energie Atomique | Geraet zur echtzeitlokalisierung der bestrahlungsquelle. |

| DE19603212C1 (de) | 1996-01-30 | 1997-05-07 | Karlsruhe Forschzent | Gamma-Kamera |

| US6377661B1 (en) | 1999-04-12 | 2002-04-23 | General Electric Company | Radiation imager collimator |

| DE102005029674A1 (de) | 2005-06-20 | 2006-12-28 | BAM Bundesanstalt für Materialforschung und -prüfung | Blende für eine bildgebende Einrichtung |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2653896B1 (fr) * | 1989-11-02 | 1992-01-03 | Informatek Sopha Medical Ste N | Gamma camera equipee d'un cone stenope pour une acquisition de type photographique. |

| DE102007057261B3 (de) | 2007-11-26 | 2009-08-06 | BAM Bundesanstalt für Materialforschung und -prüfung | Vorrichtung und Verfahren zur Herstellung von Schlitzblenden |

-

2008

- 2008-05-22 DE DE200810025109 patent/DE102008025109B4/de not_active Expired - Fee Related

-

2009

- 2009-05-18 EP EP09160478A patent/EP2124231A3/fr not_active Withdrawn

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1046337A (en) | 1963-05-16 | 1966-10-19 | Industrial Nucleonics Corp | Combined shutter and collimator structure, and radiation gauge incorporating the same |

| DD240091A1 (de) | 1985-08-07 | 1986-10-15 | Akad Wissenschaften Ddr | Lochkamera fuer enrgiereiche quantenstrahlung |

| DE69001117T2 (de) | 1989-10-11 | 1993-09-02 | Commissariat Energie Atomique | Geraet zur echtzeitlokalisierung der bestrahlungsquelle. |

| DE4000507A1 (de) | 1990-01-10 | 1991-07-11 | Philips Patentverwaltung | Anordnung zur untersuchung eines pruefobjekts mit gamma- oder roentgenstrahlung |

| DE19603212C1 (de) | 1996-01-30 | 1997-05-07 | Karlsruhe Forschzent | Gamma-Kamera |

| US6377661B1 (en) | 1999-04-12 | 2002-04-23 | General Electric Company | Radiation imager collimator |

| DE102005029674A1 (de) | 2005-06-20 | 2006-12-28 | BAM Bundesanstalt für Materialforschung und -prüfung | Blende für eine bildgebende Einrichtung |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2542000A (en) * | 2015-09-04 | 2017-03-08 | Secr Defence | Collimator for providing constant collimation effect |

| GB2542000B (en) * | 2015-09-04 | 2017-12-06 | Secr Defence | Collimator for providing constant collimation effect |

| CN107949886A (zh) * | 2015-09-04 | 2018-04-20 | 英国国防部 | 用于提供恒定准直效果的准直器 |

| US10102937B2 (en) * | 2015-09-04 | 2018-10-16 | The Secretary Of State For Defence | Collimator for providing constant collimation effect |

| CN107949886B (zh) * | 2015-09-04 | 2020-11-17 | 英国国防部 | 用于提供辐射的准直的准直器和生成扫描辐射束的方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE102008025109A1 (de) | 2009-12-03 |

| EP2124231A3 (fr) | 2010-06-16 |

| DE102008025109B4 (de) | 2010-06-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE112019004433B4 (de) | System und verfahren für röntgenstrahlfluoreszenz mit filterung | |

| DE102005029674B4 (de) | Blende für eine bildgebende Einrichtung | |

| EP1772874B1 (fr) | Diaphragme orienté vers le foyer | |

| DE102010062133B4 (de) | Kollimator für einen Strahlendetektor und Verfahren zur Herstellung eines solchen Kollimators sowie Verfahren zur Herstellung eines Kollimatoren aufweisenden Strahlendetektors | |

| DE69938469T2 (de) | Röntgenstrahlenanalysevorrichtung | |

| EP1324351B1 (fr) | Sytème optique à rayons X avec ouverture dans le focus d'un mirroir à rayons X | |

| DE3689231T2 (de) | Röntgenstrahlquelle. | |

| DE9117302U1 (de) | Vorrichtung zum Steuern von Strahlen von Teilchen, Röntgen- und Gammastrahlen und Anwendungen davon | |

| EP1215482A2 (fr) | Dispositif d'inspection d'objets | |

| DE102008025109B4 (de) | Blende für eine bildgebende Einrichtung | |

| DE102010020610A1 (de) | Strahlendetektor und Verfahren zur Herstellung eines Strahlendetektors | |

| DE102007058986B3 (de) | Streustrahlenraster und Verfahren zur Herstellung | |

| DE3007816A1 (de) | Szintillations-detektor | |

| DE102008061487A1 (de) | Verfahren zur Herstellung eines kammartigen Kollimatorelements für eine Kollimator-Anordnung sowie Kollimatorelement | |

| EP3120364A1 (fr) | Diaphragme à fente pour applications radiographiques | |

| DE10337935A1 (de) | Vorrichtung für die Aufnahme von Strukturdaten eines Objekts | |

| EP0788610B1 (fr) | Spectrometre a rayons x | |

| DE2610751A1 (de) | Vorrichtung zur lokalisation von lichterscheinungen | |

| WO2018220053A1 (fr) | Configuration d'une gamma-caméra comprenant un collimateur rotatif servant à représenter des objets à rayonnement | |

| DE10125454A1 (de) | Gerät zur Röntgenanalyse mit einem Mehrschichtspiegel und einem Ausgangskollimator | |

| DE102009021750B4 (de) | Schwenkbar bewegliche Schlitzblendenvorrichtung | |

| EP2333786B1 (fr) | Diaphragme à fente asymétrique ainsi que dispositif et procédé de sa fabrication | |

| EP2482288B1 (fr) | Dispositif d'imagerie modulaire pour rayonnement hautement énergétique doté d'un diaphragme à fente en forme de surfaces réglées | |

| DE3438466A1 (de) | Strahlungsdetektoranordnung | |

| WO2020260336A1 (fr) | Régulation des paramètres de processus au moyen de la détermination par radiographie à rayons x en ligne de propriétés de matériau lors de la production de bandes métalliques et de tôles |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK TR |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK TR |

|

| 17P | Request for examination filed |

Effective date: 20100914 |

|

| 17Q | First examination report despatched |

Effective date: 20111219 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20141008 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20150219 |