EP2109510B1 - Method and apparatus for winding up metal strips onto a winding mandrel - Google Patents

Method and apparatus for winding up metal strips onto a winding mandrel Download PDFInfo

- Publication number

- EP2109510B1 EP2109510B1 EP07818307.6A EP07818307A EP2109510B1 EP 2109510 B1 EP2109510 B1 EP 2109510B1 EP 07818307 A EP07818307 A EP 07818307A EP 2109510 B1 EP2109510 B1 EP 2109510B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- roller

- strip

- metal strip

- driver

- measuring device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000002184 metal Substances 0.000 title claims description 53

- 238000000034 method Methods 0.000 title claims description 18

- 238000004804 winding Methods 0.000 title description 24

- 238000005259 measurement Methods 0.000 claims description 16

- 238000007598 dipping method Methods 0.000 claims description 4

- 230000001276 controlling effect Effects 0.000 claims description 3

- 230000001105 regulatory effect Effects 0.000 claims description 3

- 230000001133 acceleration Effects 0.000 claims description 2

- 238000005096 rolling process Methods 0.000 description 5

- 238000007664 blowing Methods 0.000 description 4

- 230000005540 biological transmission Effects 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 238000007654 immersion Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

- B21C47/003—Regulation of tension or speed; Braking

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

- B21C47/02—Winding-up or coiling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

- B21C47/02—Winding-up or coiling

- B21C47/04—Winding-up or coiling on or in reels or drums, without using a moving guide

- B21C47/06—Winding-up or coiling on or in reels or drums, without using a moving guide with loaded rollers, bolts, or equivalent means holding the material on the reel or drum

- B21C47/063—Winding-up or coiling on or in reels or drums, without using a moving guide with loaded rollers, bolts, or equivalent means holding the material on the reel or drum with pressure rollers only

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

- B21C47/02—Winding-up or coiling

- B21C47/10—Winding-up or coiling by means of a moving guide

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

- B21C47/34—Feeding or guiding devices not specially adapted to a particular type of apparatus

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

- B21C47/34—Feeding or guiding devices not specially adapted to a particular type of apparatus

- B21C47/3408—Feeding or guiding devices not specially adapted to a particular type of apparatus for monitoring the lateral position of the material

- B21C47/3425—Feeding or guiding devices not specially adapted to a particular type of apparatus for monitoring the lateral position of the material without lateral edge contact

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

- B21C47/34—Feeding or guiding devices not specially adapted to a particular type of apparatus

- B21C47/3433—Feeding or guiding devices not specially adapted to a particular type of apparatus for guiding the leading end of the material, e.g. from or to a coiler

- B21C47/3441—Diverting the leading end, e.g. from main flow to a coiling device

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

- B21C47/34—Feeding or guiding devices not specially adapted to a particular type of apparatus

- B21C47/345—Feeding or guiding devices not specially adapted to a particular type of apparatus for monitoring the tension or advance of the material

Definitions

- the invention relates to a method according to the preamble of claim 1 and a device according to the preamble of claim 6 for winding metal bands on a winding mandrel arranged in a winding mandrel to which the metal strip is fed from a driver having a lower and upper driver role, wherein for guidance a table is provided below the metal strip and above the metal strip, a pivotable band switch and this are arranged close to the winding mandrel then a pivotable shaft flap.

- a method and such a device are known from WO 03/004963 A1 known.

- Known driver has a stationary mounted lower roller and an engageable against this upper roller.

- the engagable upper roller is mounted in an adjustable by means of pressure medium cylinder pivot frame, which is formed of two opposing wings, which are connected in the region of their common pivot axis by a mounted on both sides in the driver frame base.

- the wings of this driver can be adjusted by pressure medium cylinders which can be acted upon separately, with the base interconnecting the wings being designed as a torsion spring.

- One or more of these metering rollers which are pressed against the rolled strip from below, may be between the rolling mills of the finishing train and / or in the rolling direction behind the last stand of the finishing train and / or before a capstan and / or between the capstan and the capstan to be ordered.

- a measuring roller arranged between the blowing apparatus and the reel the obtained measured value can be used to pivot the blowing apparatus and in this way the band run can be regulated during winding onto the reel mandrel.

- a loop lifter which can measure a wedging which is present over the bandwidth due to the longitudinal tension prevailing in a metal band.

- the loop lifter has a looper roll mounted on both sides in a respective pivoting arm.

- the pivot arms are each divided by a joint in a shaft arm and a roller arm and connected to a Schliegerheberwelle.

- the joint deflects a restoring force exerted by the metal band on the looper roll applied from below against the metal band on force gauges arranged on the pivot arms.

- the restoring force corresponds to the longitudinal tension, so that it can be determined from the measured restoring forces.

- the shaft arm and the roller arm are connected to each other via a holding element. Either due to the total longitudinal tension or the determined wedge ratio, for example, the runout and inlet directions designed as rolling mills or drivers can be readjusted, such as the rotational speed or the setting of the rolls.

- the invention has for its object to provide a method and an apparatus of the type mentioned in such a way that an improved tensile measurement of a metal strip in the reel shaft can be achieved, which is intended to regulate the blowing apparatus or driver with such an influence on the tape, that a straight edge metal collar can be achieved.

- the wedging of the tension distribution determined by the strip tension measuring device immersed in the metal strip with a wrap angle in the metal strip is determined from the measured bearing forces of a bearing of the strip tension measuring device.

- a looping angle generated by a roll of the strip tension measuring device dipping into the metal strip can be used.

- the wrapping angle ensures the transmission of force from the metal strip to the roll and from there to the dynamometer integrated in the strip tension measuring device.

- the wrap angle is kept approximately constant by controlling the immersion depth of the roll.

- the wrap angle depends on the stroke of the swivel cylinder or the swivel cylinder and on the diameter of the wound coils.

- the stroke of the at least one pivoting cylinder can be controlled.

- the setpoint can be calculated during the winding process depending on the current coil diameter, the optimal looping and the geometric data.

- To record the stroke can be in the swing cylinder a odometer on or grow on the cylinder;

- the swing-in tension measuring device can be equipped with an angle measurement, so that the stroke of the swing cylinder can be calculated.

- the instantaneous diameter of the coil can be determined from the counted revolutions of the winding mandrel and the thickness of the metal strip.

- a direct measurement of the coil diameter e.g. with a laser-optical measuring device.

- the role of the strip tension measuring device is ceremoniatt before swinging on the speed of the metal strip. Since the roller is pivoted onto the belt during the winding process, pre-accelerating prevents damage to the metal strip due to a later-required acceleration process.

- the drive of the roller can be done mechanically and / or electrically and / or hydraulically.

- An apparatus for solving the problem underlying the invention, in particular for carrying out the method, according to the invention is characterized in that the band-wedge formed as pivotable from above into the metal band Bandzugmess worn and with a switch body is provided, which has a rotatably mounted, at its front end a roller-bearing roller arm, wherein between the switch body and the roller arm, a force-measuring means is arranged, which is technically connected to a control device of the driver.

- the strip tension measuring device according to the invention thus simultaneously fulfills the classic band softening function.

- the function of the strip tension measuring device as a simultaneous band-pass filter is preferably supported by the fact that at least one front section of the table following the lower roller of the driver below the metal band is designed as a pivoting table. This is pivotable counterclockwise about the axis of the lower drive roller.

- the switch body connects a rear-side pivot arm with a front-side pivot arm of the strip tension measuring device.

- the switch body takes on the torsion load as a connection between the swivel arm on the drive side with the swivel arm on the operating side, by a single-sided operation of the belt tension measuring device by only one rear or drive side swivel cylinder would arise.

- a driven turnout roller is advantageously arranged in the axis of rotation of the strip tension measuring device that receives the drivably mounted roller, the metal strap can be protected from damage when it is guided on the way from the lower roller of the driver to the next roller of the subsequent coiler shaft ,

- a variant of the invention provides that the strip tension measuring device is arranged with the roller arm to the mandrel pointing integrated into the upper shaft flap.

- the strip tension measuring device is arranged with the roller arm to the mandrel pointing integrated into the upper shaft flap.

- the front roller of the strip tension measuring device would connect to a reaching to the first pressure roller of the winding mandrel shaft flap and the free space to the upper roller of the driver would be filled with a conventional switch.

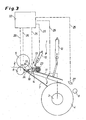

- the metal strip 2 is fed to the winding mandrel 3 by a blowing apparatus or driver, of which only the upper and lower drive rollers 5, 6 are shown. From the lower drive roller 6 is followed by the winding mandrel 3 below the metal strip 2, a table 7 at. The beginning or the tip of the thus-fed metal strip 2 is received by a first, the winding mandrel 3 associated pressure roller 8, the distributed distributed over the circumference further such roles.

- a band switch 9 which rests in the waiting position for tape recording on the upper drive roller 5.

- the band switch 9 is pivoted by a cylinder 10 which engages with its piston rod to a pivot arm of the band switch 9.

- the reel shaft 1 is closed at the top by a guided from the band switch 9 to the winding mandrel 3 shaft flap 11.

- a cylinder 12 is articulated to this.

- a strip tension measuring device 13 which at the same time fulfills the band softening function.

- This consists of a rear or drive side pivot arm 14 and a front-side pivot arm 14, of which in Fig. 2 the rear / drive side pivot arm can be seen.

- the two pivot arms 14 are by a torsion load receiving turnout body 15 (see. Fig. 4 ) connected with each other.

- it has a roller arm 16, in whose front end a driven roller 17 is mounted.

- the roller arm 16 is rotatably supported by a hinge 18. In order to avoid tilting due to gravity, the roller arm 16 is held in position by a retaining element 19.

- This can be controlled as a result of the measurement, for example, by pivoting the upper and / or lower drive roller 5, 6 or parallel pivoting both roles or by specifying different closing forces on the drive and operating side that arise on the winding mandrel 3 a straight edge coil 4 can.

- the strip tension measuring device 13 is formed at its rear end in the tape running direction, away from the roller 17 with a provided in its axis of rotation switch point 23, as in the Fig. 2 and 3 shown as a cross section in the region of the pivot arm 7 through the pin of the switch roller 23.

- the reel shaft 1 is closed at the top by a pivotable by means of the cylinder 12 shaft flap 11.

- the below the metal strip 2 from the lower drive roller 6 to the mandrel 3 extending, the metal strip 2 conductive table 7 is formed at least at its front end with a pivotable about the axis of the lower drive roller 6 counterclockwise pivoting table 24.

- Fig. 3 which shows the operating position shortly before the end of a reeling operation for winding the metal strip 2 to a finished coil 4

- the wrap angle that forms the metal strip 2 due to the dipping roller 17 of the strip tension measuring device 13.

- different measured signals 25 or control signals 26 are indicated by dashed lines, which enter the control device 22 or depart from it to pivot means of the upper and lower drive rollers 5, 6 (see the dashed lines 26).

- the parameters which are essential for determining and, if necessary, maintaining an optimum wrap angle during the entire winding process are determined, for example, by detection the stroke of the swivel cylinder or the swivel cylinder 10 of the strip tension measuring device 13, wherein the / the cylinder are equipped with a displacement meter, determined by an angle measurement of the strip tension measuring device 13 and the current diameter of the coil 4.

- This diameter can be determined from the counted revolutions of the mandrel 3 (cf the dotted line 25 emanating therefrom) and the strip thickness.

- a direct measurement of the diameter of the coil 4 is possible, as with an indicated laser-optical measuring means 27.

- a measurement signal from the strip tension measurement in the reel shaft of a driver control can also be done in the combination strip tension measuring device / band switch by the combination strip tension measuring device / shaft cap.

- the in the Fig. 2 and 3 shown strip tension measuring device 13 would then be arranged with its role 17 to the winding mandrel 3 integrated into the shaft flap 11, ie, over the line AA of Fig. 2 mirrored.

- the space then free from the upper drive roller 5 to the strip tension measuring device 13 could in this option be combined with a conventional band switch 9 (cf. Fig. 1 ) filled or bridged.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Winding, Rewinding, Material Storage Devices (AREA)

- Controlling Rewinding, Feeding, Winding, Or Abnormalities Of Webs (AREA)

Description

Die Erfindung betrifft ein Verfahren gemäß Oberbegriff des Anspruchs 1 und eine Vorrichtung gemäß Oberbegriff des Anspruchs 6 zum Aufwickeln von Metallbändern auf einen in einem Haspelschacht angeordneten Wickeldorn, dem das Metallband von einem eine untere und obere Treiberrolle aufweisenden Treiber zugeleitet wird, wobei zur Führung ein Tisch unterhalb des Metallbandes vorgesehen ist und oberhalb des Metallbandes eine schwenkbare Bandweiche sowie sich dieser bis nahe zum Wickeldorn anschließend eine schwenkbare Schachtklappe angeordnet sind. Ein solches Verfahren und eine solche Vorrichtung sind aus der

Ein durch die

Die anstellbare obere Walze ist in einem mittels Druckmittelzylinder verstellbaren Schwenkrahmen gelagert, der aus zwei einander gegenüber liegenden Schwingen gebildet wird, die im Bereich ihrer gemeinsamen Schwenkachse durch eine beidseitig im Treiberrahmen gelagerte Basis verbunden sind. Die Schwingen dieses Treibers sind durch jeweils separat beaufschlagbare Druckmittelzylinder verstellbar, wobei die die Schwingen miteinander verbindende Basis als Torsionsfeder ausgebildet ist.A through the

The engagable upper roller is mounted in an adjustable by means of pressure medium cylinder pivot frame, which is formed of two opposing wings, which are connected in the region of their common pivot axis by a mounted on both sides in the driver frame base. The wings of this driver can be adjusted by pressure medium cylinders which can be acted upon separately, with the base interconnecting the wings being designed as a torsion spring.

Es lassen sich hier durch Einleitung unterschiedlicher Anstellkräfte bei relativ geringer Differenzkraft der Druckmittelzylinder unterschiedliche Schwenkwinkel der Schwingen und damit der anstellbaren oberen Walze erreichen. Denn durch Verschwenken der oberen Walze kann die vom Treiber ausgeübte Zugkraft auf das Band beeinflusst und auf diese Weise eine Zugverteilung eingestellt werden.It can be achieved by introducing different Anstellkräfte at relatively low differential force of the pressure medium cylinder different swing angle of the wings and thus the adjuster upper roller. Because by pivoting the upper roller, the force exerted by the driver pulling force can be influenced on the band and set in this way a train distribution.

Aus der

Eine oder mehrere dieser Messrollen, die von unten gegen das Walzband angedrückt werden, können zwischen den Walzgerüsten der Fertigstraße und/oder in Walzrichtung hinter dem letzten Walzgerüst der Fertigstraße und/oder vor einem Treibapparat für eine Haspel und/oder zwischen dem Treibapparat und der Haspel angeordnet werden. Bei einer zwischen dem Treibapparat und der Haspel angeordneten Messrolle kann der erhaltene Messwert zum Verschwenken des Treibapparates verwendet und auf diese Weise der Bandlauf beim Aufwickeln auf den Haspeldom geregelt werden.One or more of these metering rollers, which are pressed against the rolled strip from below, may be between the rolling mills of the finishing train and / or in the rolling direction behind the last stand of the finishing train and / or before a capstan and / or between the capstan and the capstan to be ordered. In a measuring roller arranged between the blowing apparatus and the reel, the obtained measured value can be used to pivot the blowing apparatus and in this way the band run can be regulated during winding onto the reel mandrel.

Durch die

Der Erfindung liegt die Aufgabe zugrunde, ein Verfahren und eine Vorrichtung der eingangs genannten Art so weiterzubilden, dass sich eine verbesserte Zugmessung eines Metallbandes im Haspelschacht erreichen lässt, die dazu dienen soll, den Treibapparat bzw. Treiber mit einer solchen Beeinflussung des Bandlaufs zu regeln, dass sich ein kantengerades Metallbund erreichen lässt.The invention has for its object to provide a method and an apparatus of the type mentioned in such a way that an improved tensile measurement of a metal strip in the reel shaft can be achieved, which is intended to regulate the blowing apparatus or driver with such an influence on the tape, that a straight edge metal collar can be achieved.

Diese Aufgabe wird mit einem Verfahren erfindungsgemäß dadurch gelöst, dass die vom Treiber auf das Metallband ausgeübte Längszugkraft zur Steuerung des Bandlaufs durch den Treiber mittels einer im Haspelschacht von oben in das Metallband eintauchenden Bandzugmesseinrichtung ermittelt und das Messsignal einer Treiberregelung zugeleitet wird. Durch das erfindungsgemäße Einschwenken der Bandzugmesseinrichtung von oben auf das Metallband kann insbesondere auch noch am Bandende ein optimaler Umschlingungswinkel eingehalten werden. Dies wäre bei einem Einschwenken der Bandzugmesseinrichtung von unten nicht möglich, da in diesem Fall der Umschlingungswinkel durch die oberhalb des Metallbandes benötigte Bandweiche einschließlich Schachtklappe stark eingeschränkt und so klein wird, dass am Bandende keine sichere Messung mehr möglich ist. Die Messung am Bandende ist aber gerade wichtig, weil hier die Bandführung durch den nicht mehr vorhandenen Bandzug der Fertigstaffel der Walzstraße besonders schwierig ist.This object is achieved with a method according to the invention in that the force exerted by the driver on the metal strip Längszugkraft for controlling the tape run by the driver by means of a reel shaft from above immersed in the metal strip Bandzugmesseinrichtung and the measurement signal is fed to a driver control. By pivoting the strip tension measuring device according to the invention from the top onto the metal strip, an optimum wrap angle can be maintained even at the end of the strip, in particular. This would not be possible with a pivoting of the strip tension measuring device from below, since in this case the wrap angle is severely limited by the required above the metal strip band switch including shaft flap and so small that no reliable measurement is possible at the end of the tape. However, the measurement at the end of the tape is just important because here the tape guide is particularly difficult due to the no longer present strip tension of the finishing scale of the rolling mill.

Es wird erfindungsgemäß vorgeschlagen, dass die aufgrund des im Metallband herrschenden Längszuges über die Bandbreite vorliegende, von der mit einem Umschlingungswinkel in das Metallband eintauchenden Bandzugmesseinrichtung ermittelte Keiligkeit der Zugverteilung aus den gemessenen Lagerkräften einer Lagerung der Bandzugmesseinrichtung bestimmt wird.According to the invention, it is proposed that the wedging of the tension distribution determined by the strip tension measuring device immersed in the metal strip with a wrap angle in the metal strip is determined from the measured bearing forces of a bearing of the strip tension measuring device.

Hierzu kann nach einer bevorzugten Ausführung der Erfindung zur direkten oder indirekten Lagerkraftmessung ein von einer in das Metallband eintauchenden Rolle der Bandzugmesseinrichtung erzeugter Umschlingungswinkel herangezogen werden. Der Umschlingungswinkel stellt die Kraftübertragung von dem Metallband auf die Rolle und von dieser auf den in der Bandzugmesseinrichtung integrierten Kraftmesser sicher.For this purpose, according to a preferred embodiment of the invention for direct or indirect bearing force measurement, a looping angle generated by a roll of the strip tension measuring device dipping into the metal strip can be used. The wrapping angle ensures the transmission of force from the metal strip to the roll and from there to the dynamometer integrated in the strip tension measuring device.

Zur Betätigung der Bandzugmesseinrichtung ist zumindest ein Zylinder erforderlich, nach einem Vorschlag der Erfindung ein an einem hinterseitigen Schwenkarm angreifender Schwenkzylinder mit Hubregelung. Alternativ können es zwei Schwenkzylinder sein. Eine andere Möglichkeit zur Betätigung der Bandzugmesseinrichtung besteht darin, die Bandzugmesseinrichtung in einem U-förmigen Rahmen vorzusehen, an den ein Zylinder in der Symmetrieachse des Rahmens angreift.To actuate the Bandzugmesseinrichtung at least one cylinder is required, according to a proposal of the invention an attacking on a rear-side swivel arm swivel cylinder with stroke control. Alternatively, it may be two swing cylinders. Another way to operate the Bandzugmesseinrichtung is to provide the Bandzugmesseinrichtung in a U-shaped frame, which is engaged by a cylinder in the axis of symmetry of the frame.

Es empfiehlt sich hierbei, dass der Umschlingungswinkel durch Regelung der Eintauchtiefe der Rolle annähernd konstant gehalten wird. Der Umschlingungswinkel hängt vom Hub des Schwenkzylinders bzw. der Schwenkzylinder und vom Durchmesser des aufgewickelten Coils ab. Um während des gesamten Wickelprozesses eine optimale Umschlingung einzuhalten, lässt sich der Hub des mindestens einen Schwenkzylinders regeln. Der Sollwert kann während des Wickelprozesses abhängig vom momentanen Coil-Durchmesser, der optimalen Umschlingung und den geometrischen Daten berechnet werden. Zur Erfassung des Hubes lässt sich in den Schwenkzylinder ein Wegmesser ein- oder an den Zylinder anbauen; optional kann die einschwenkbare Bandzugmesseinrichtung mit einer Winkelmessung ausgerüstet werden, so dass sich der Hub des Schwenkzylinders berechnen lässt. Der momentane Durchmesser des Coils kann aus den gezählten Umdrehungen des Wickeldorns und der Dicke des Metallbandes bestimmt werden. Alternativ bietet sich auch eine direkte Messung des Coil-Durchmessers an, z.B. mit einem laseroptischen Messmittel.It is recommended that the wrap angle is kept approximately constant by controlling the immersion depth of the roll. The wrap angle depends on the stroke of the swivel cylinder or the swivel cylinder and on the diameter of the wound coils. In order to maintain an optimal looping throughout the winding process, the stroke of the at least one pivoting cylinder can be controlled. The setpoint can be calculated during the winding process depending on the current coil diameter, the optimal looping and the geometric data. To record the stroke can be in the swing cylinder a odometer on or grow on the cylinder; Optionally, the swing-in tension measuring device can be equipped with an angle measurement, so that the stroke of the swing cylinder can be calculated. The instantaneous diameter of the coil can be determined from the counted revolutions of the winding mandrel and the thickness of the metal strip. Alternatively, a direct measurement of the coil diameter, e.g. with a laser-optical measuring device.

Nach einer weiteren vorteilhaften Ausgestaltung der Erfindung wird die Rolle der Bandzugmesseinrichtung vor dem Einschwenken auf die Geschwindigkeit des Metallbandes vorbeschleunigt. Da die Rolle während des Wickelprozesses auf das Band geschwenkt wird, lässt sich durch das Vorbeschleunigen eine Beschädigung des Metallbandes durch einen später ansonsten erforderlichen Beschleunigungsvorgang vermeiden. Der Antrieb der Rolle kann mechanisch und/oder elektrisch und/oder hydraulisch erfolgen.According to a further advantageous embodiment of the invention, the role of the strip tension measuring device is vorbeschleunigt before swinging on the speed of the metal strip. Since the roller is pivoted onto the belt during the winding process, pre-accelerating prevents damage to the metal strip due to a later-required acceleration process. The drive of the roller can be done mechanically and / or electrically and / or hydraulically.

Eine Vorrichtung zur Lösung der der Erfindung zugrunde liegenden Aufgabe, insbesondere zum Durchführen des Verfahrens, ist erfindungsgemäß dadurch gekennzeichnet, dass die Bandweiche als von oben in das Metallband einschwenkbare Bandzugmesseinrichtung ausgebildet und mit einem Weichenkörper versehen ist, der einen drehbar gelagerten, an seinem vorderen Ende eine Rolle tragenden Rollenarm aufweist, wobei zwischen dem Weichenkörper und dem Rollenarm ein Kraftmessmittel angeordnet ist, das signaltechnisch mit einer Regeleinrichtung des Treibers verbunden ist. Die erfindungsgemäße Bandzugmesseinrichtung erfüllt somit gleichzeitig die klassische Bandweichenfunktion. Aus der Außerbetriebsposition, d.h. der abgehobenen Wartestellung, schwenkt nämlich die gesamte Bandzugmesseinrichtung entgegen dem Uhrzeigersinn nach unten in die in das einlaufende Metallband eintauchende Betriebsstellung und führt bei damit gleichzeitig aktivierter Messung das Metallband zum nachfolgenden Wickeldorn.An apparatus for solving the problem underlying the invention, in particular for carrying out the method, according to the invention is characterized in that the band-wedge formed as pivotable from above into the metal band Bandzugmesseinrichtung and with a switch body is provided, which has a rotatably mounted, at its front end a roller-bearing roller arm, wherein between the switch body and the roller arm, a force-measuring means is arranged, which is technically connected to a control device of the driver. The strip tension measuring device according to the invention thus simultaneously fulfills the classic band softening function. From the non-operating position, ie the lifted standby position, the entire Bandzugmesseinrichtung pivots counterclockwise downwards into the operating position immersed in the incoming metal strip and leads at the same time activated measurement the metal strip to the subsequent winding mandrel.

Die Funktion der Bandzugmesseinrichtung als gleichzeitige Bandweiche wird vorzugsweise dadurch unterstützt, dass zumindest ein Vorderabschnitt des sich der unteren Rolle des Treibers unterhalb des Metallbandes anschließenden Tisches als Schwenktisch ausgebildet ist. Dieser ist entgegen dem Uhrzeigersinn um die Achse der unteren Treiberrolle verschwenkbar.The function of the strip tension measuring device as a simultaneous band-pass filter is preferably supported by the fact that at least one front section of the table following the lower roller of the driver below the metal band is designed as a pivoting table. This is pivotable counterclockwise about the axis of the lower drive roller.

Nach einer vorteilhaften Ausführung der Erfindung verbindet der Weichenkörper einen hinterseitigen Schwenkarm mit einem vorderseitigen Schwenkarm der Bandzugmesseinrichtung. Bei nur einem Schwenkzylinder, der hinterseitig und somit antriebsseitig angebracht wäre, nimmt der Weichenkörper als Verbindung zwischen dem Schwenkarm auf der Antriebsseite mit dem Schwenkarm auf der Bedienungsseite die Torsionsbelastung auf, die durch eine einseitige Betätigung der Bandzugmesseinrichtung durch nur einen hinter- bzw. antriebsseitigen Schwenkzylinder entstehen würde.According to an advantageous embodiment of the invention, the switch body connects a rear-side pivot arm with a front-side pivot arm of the strip tension measuring device. With only one swivel cylinder, which would be mounted on the rear side and thus on the drive side, the switch body takes on the torsion load as a connection between the swivel arm on the drive side with the swivel arm on the operating side, by a single-sided operation of the belt tension measuring device by only one rear or drive side swivel cylinder would arise.

Wenn vorteilhaft in der von dem die antreibbar gelagerte Rolle aufnehmenden Rollenarm entfernten Drehachse der Bandzugmesseinrichtung eine angetriebene Weichenrolle angeordnet ist, lässt sich das Metallband vor Beschädigungen schützten, wenn es auf dem Weg von der unteren Rolle des Treibers zur nächsten Rolle des sich anschließenden Haspelschachts geführt wird.If a driven turnout roller is advantageously arranged in the axis of rotation of the strip tension measuring device that receives the drivably mounted roller, the metal strap can be protected from damage when it is guided on the way from the lower roller of the driver to the next roller of the subsequent coiler shaft ,

Eine Variante der Erfindung sieht vor, dass die Bandzugmesseinrichtung mit dem Rollenarm zum Wickeldorn weisend in die obere Schachtklappe integriert angeordnet ist. Bei dieser Anordnung liegt eine Kombination aus Bandzugmesseinrichtung und Schachtklappe vor. Der vorderen Rolle der Bandzugmesseinrichtung würde sich eine bis zur ersten Andrückrolle des Wickeldorns reichende Schachtklappe anschließen und der freie Raum zur oberen Rolle des Treibers hin würde mit einer konventionellen Weiche ausgefüllt werden.A variant of the invention provides that the strip tension measuring device is arranged with the roller arm to the mandrel pointing integrated into the upper shaft flap. In this arrangement, there is a combination of Bandzugmesseinrichtung and manhole cover. The front roller of the strip tension measuring device would connect to a reaching to the first pressure roller of the winding mandrel shaft flap and the free space to the upper roller of the driver would be filled with a conventional switch.

Weitere Merkmale und Einzelheiten der Erfindung ergeben sich aus den Ansprüchen und der nachfolgenden Beschreibung eines in den Zeichnungen dargestellten Ausführungsbeispiels der Erfindung. Es zeigen:

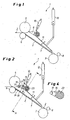

- Fig. 1

- in einer schematischen Darstellung eine Seitenansicht eines konventionellen, zum Stand der Technik zählenden Haspelschachtes;

- Fg. 2

- in einer schematischen Darstellung eine Seitenansicht eines Haspelschachtes mit einer von oben in das Metallband einschwenkbaren, gleichzeitig eine Bandweichenfunktion erfüllenden Bandzugmesseinrichtung, die sich in der von dem Metallband abgehobenen Außerbetriebsposition befindet;

- Fig. 3

- den Gegenstand der

Fig. 2 mit der in die Mess- bzw. Betriebsposition eingeschwenkten Bandzugmesseinrichtung, kurz vor dem Ende eines Aufwickelvorgangs; und - Fig. 4

- als Einzelheit einen Querschnitt durch eine in der Bandzugmesseinrichtung gelagerte Weichenrolle.

- Fig. 1

- in a schematic representation of a side view of a conventional, counting to the prior art reel shaft;

- Fig. 2

- in a schematic representation of a side view of a reel shaft with a swing-in from above into the metal band, while a band softening function fulfilling Bandzugmesseinrichtung located in the lifted off the metal band off-mode position;

- Fig. 3

- the object of

Fig. 2 with the tension measuring device pivoted into the measuring or operating position, shortly before the end of a winding process; and - Fig. 4

- as a detail, a cross section through a mounted in the Bandzugmesseinrichtung points role.

Ein Haspelschacht 1, wie in

Oberhalb des Metallbandes 2 befindet sich eine Bandweiche 9, die in der Warteposition zur Bandaufnahme an der oberen Treiberrolle 5 anliegt. Die Bandweiche 9 wird von einem Zylinder 10 verschwenkt, der mit seiner Kolbenstange an einen Schwenkarm der Bandweiche 9 angreift. Der Haspelschacht 1 wird nach oben hin durch eine von der Bandweiche 9 bis zum Wickeldorn 3 herangeführte Schachtklappe 11 abgeschlossen. Zum Verschwenken der Schachtklappe 11 ist an diese ein Zylinder 12 angelenkt.Above the

Bei der in den

Sobald die Bandzugmesseinrichtung 13 von oben in das Metallband 2 einschwenkt und in dieses mit seiner Rolle 17 unter Bildung eines Umschlingungswinkels eintaucht, wird über die Rolle 17 eine Kraft aufgebracht, die den Rollenarm 16 im Uhrzeigersinn beaufschlagt. Das Drehen des Rollenarms im Uhrzeigersinn wird allerdings von einem Kraftmesser 20 verhindert, der vielmehr für eine Abstützung des Rollenarms 16 sorgt, eine in der Kraftachse 21 der Abstützung erzeugte Kraft ermittelt und als Messsignal an eine Regeleinrichtung 22 (vgl.

Die Bandzugmesseinrichtung 13 ist an ihrem in Bandlaufrichtung hinteren, von der Rolle 17 entfernten Ende mit einer in ihrer Drehachse vorgesehenen Weichenrolle 23 ausgebildet, wie in den

Der

In jedem Fall ist es möglich, ein Messsignal aus der Bandzugmessung im Haspelschacht einer Treiberregelung zur Verfügung zu stellen. Dies kann alternativ zu der dargestellten Ausführung in der Kombination Bandzugmesseinrichtung/Bandweiche auch durch die Kombination Bandzugmesseinrichtung/Schachtkappe erfolgen. Die in den

- 11

- Haspelschachtreel slot

- 22

- Metallbandmetal band

- 33

- Wickeldornmandrel

- 44

- Bund/CoilFederal / Coil

- 55

- obere Treiberrolleupper driver role

- 66

- untere Treiberrollelower driver role

- 77

- Tisch (Leittisch)Table (control table)

- 88th

- Andrückrollecapstan

- 99

- Bandweichebandpass filter

- 1010

- Zylindercylinder

- 1111

- Schachtklappebay door

- 1212

- Zylindercylinder

- 1313

- Bandzugmesseinrichtungstrip tension measuring device

- 1414

- Schwenkarmswivel arm

- 1515

- Weichenkörpersoft body

- 1616

- Rollenarmroller arm

- 1717

- Rollerole

- 1818

- Gelenkjoint

- 1919

- Halteelementretaining element

- 2020

- Kraftmesserdynamometer

- 2121

- Kraftachseforce axis

- 2222

- Treiber-RegeleinrichtungDriver control device

- 2323

- Weichenrollesoft roll

- 2424

- SchwenktischRotary table

- 2525

- Messsignalmeasuring signal

- 2626

- Messsignalmeasuring signal

- 2727

- laseroptisches Messmittellaser-optical measuring device

Claims (12)

- Method of coiling metal strips (2) on a coiling mandrel (3), which is arranged in a coiler shaft (1) and to which the metal strip is fed by a driver having a lower and an upper driver roller (5, 6), wherein a table (7) is provided below the metal strip (2) for guidance and a strip diverter as well as a pivotable shaft flap (11), which adjoins as far as the vicinity of the coiling mandrel, are arranged above the metal strip, characterised in that the longitudinal tension force, which is exerted on the metal strip (2) by the driver, for controlling the strip running through the driver is detected by means of a strip tension measuring device (13) dipping from above into the metal strip (2) in the coiler shaft (1) and the measurement signal is fed to a driver regulating device (22).

- Method according to claim 1, characterised in that the wedge angle of the tension distribution is determined from the measured bearing forces of bearing means of the strip tension measuring device (13).

- Method according to claim 1 or 2, characterised in that a looping angle produced by a roller (17) dipping into the metal strip (2) in the case of inward pivotation of the strip tension measuring device (13) is utilised for direct or indirect bearing force measurement.

- Method according to claim 3, characterised in that the looping angle is kept approximately constant for regulation of the dipping-in depth of the roller (17).

- Method according to claim 3 or 4, characterised in that the roller (17) is subject to pre-acceleration to the speed of the metal strip (2) prior to inward pivotation.

- Device for coiling metal strips (2) on a coiling mandrel (3), which is arranged in a coiler shaft (1) and to which the metal strip is fed by a driver having a lower and an upper driver roller (5, 6), wherein a table (7) is provided below the metal strip (2) for guidance and a strip diverter as well as a pivotable shaft flap (11), which adjoins this as far as the vicinity of the coiling mandrel, are arranged above the metal strip, particularly for carrying out the method according to claim 1, characterised in that the strip diverter is constructed as a strip tension measuring device (13) pivotable from above into the metal strip (2) and is provided with a diverter body (15), which comprises a rotatably mounted roller arm (16) carrying a roller (17) at its front end, wherein arranged between the diverter body (15) and the roller arm (16) is force measuring means (20) in signal connection with a regulating device (22) of the driver.

- Device according to claim 6, characterised in that the diverter body (15) connects a rear-side pivot arm (14) with a front-side pivot arm (14) of the strip tension measuring device (13).

- Device according to claim 7, characterised by at least one pivot cylinder (10), which acts on the rear-side pivot arm (14), with stroke regulation.

- Device according to any one of claims 6 to 8, characterised in that the roller (17) mounted in the roller arm (16) is drivable.

- Device according to any one of claims 6 to 9, characterised in that a driven diverter roller (23) is arranged at the rotational axis, which is remote from the roller arm (16), of the strip tension measuring device (13).

- Device according to any one of claims 6 to 10, characterised in that at least one front section of the table (7), which adjoins the lower driver roller (6) below the metal strip (2), is constructed as a pivot table (24).

- Device according to any one of claims 6 to 11, characterised in that the strip tension measuring device (13) together with the roller arm (16) is arranged to be integrated in the upper shaft flap (11) to face the coiling mandrel (3).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102006045608 | 2006-09-25 | ||

| PCT/EP2007/008217 WO2008037395A1 (en) | 2006-09-25 | 2007-09-21 | Method and apparatus for winding up metal strips onto a winding mandrel |

| DE102007045425A DE102007045425A1 (en) | 2006-09-25 | 2007-09-21 | Method and device for winding metal strips on a winding mandrel |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2109510A1 EP2109510A1 (en) | 2009-10-21 |

| EP2109510B1 true EP2109510B1 (en) | 2014-02-12 |

Family

ID=39185155

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07818307.6A Active EP2109510B1 (en) | 2006-09-25 | 2007-09-21 | Method and apparatus for winding up metal strips onto a winding mandrel |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US20100025514A1 (en) |

| EP (1) | EP2109510B1 (en) |

| JP (1) | JP2010504216A (en) |

| KR (1) | KR101071117B1 (en) |

| CN (1) | CN101516539B (en) |

| BR (1) | BRPI0716770B1 (en) |

| CA (1) | CA2664263C (en) |

| DE (1) | DE102007045425A1 (en) |

| RU (1) | RU2391167C1 (en) |

| WO (1) | WO2008037395A1 (en) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009058875A1 (en) * | 2009-12-18 | 2011-07-07 | SMS Siemag AG, 40237 | A reel device and method for operating a reel device |

| KR101421814B1 (en) * | 2012-11-02 | 2014-07-22 | 주식회사 포스코 | Guiding apparatus for winding strip |

| DE102012224351A1 (en) | 2012-12-21 | 2014-06-26 | Sms Siemag Ag | Method and device for winding a metal strip |

| US9908137B2 (en) | 2013-11-14 | 2018-03-06 | Illinois Tool Works Inc. | Fluid application device having a modular non-contact nozzle for applying fluid to an article |

| US9718083B2 (en) | 2013-11-14 | 2017-08-01 | Illinois Tool Works Inc. | Fluid application device having a modular nozzle assembly for applying fluid to an article |

| US9932704B2 (en) * | 2013-11-22 | 2018-04-03 | Illinois Tool Works Inc. | Fluid application device, strand engagement device and method of controlling the same |

| CN103743953B (en) * | 2013-12-29 | 2017-01-04 | 中国计量学院 | Twin metal strip resistance servo-actuated synchronization continuous measurement system |

| MX2016006380A (en) * | 2015-05-18 | 2016-11-17 | Danieli Off Mecc | Tensioning unit for a rolling apparatus. |

| PL226814B1 (en) * | 2015-05-29 | 2017-09-29 | Przedsiębiorstwo Concept Stal B&S Lejman Spółka Jawna | Sheet rolling machine |

| CN107774728A (en) * | 2016-08-31 | 2018-03-09 | 扬中凯悦铜材有限公司 | Copper bar drawing winds integrated apparatus |

| CN109650123A (en) * | 2019-02-27 | 2019-04-19 | 中冶赛迪工程技术股份有限公司 | A kind of strip tape threading apparatus and method |

| CA3168206A1 (en) * | 2020-01-22 | 2021-07-29 | Novelis Inc. | Sensing and offsetting the force of events in a coil forming operation |

| EP4019158B1 (en) * | 2020-12-23 | 2023-11-01 | Primetals Technologies Austria GmbH | Reel device for large thickness range of metal strips |

Family Cites Families (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS51127988A (en) * | 1975-04-30 | 1976-11-08 | Ishikawajima Harima Heavy Ind Co Ltd | Tension control device having looper and this looper |

| JPS5865674A (en) * | 1981-10-16 | 1983-04-19 | Ricoh Co Ltd | Printer |

| JPS60231516A (en) | 1984-04-28 | 1985-11-18 | Sumitomo Metal Ind Ltd | Coiler having looper mechanism |

| DE3507251A1 (en) * | 1985-03-01 | 1986-09-04 | SMS Schloemann-Siemag AG, 4000 Düsseldorf | DRIVER FOR ROLLER TAPE |

| GB8608494D0 (en) * | 1986-04-08 | 1986-05-14 | Davy Mckee Sheffield | Strip guiding for downcoilers |

| JPH01109314U (en) * | 1988-01-20 | 1989-07-24 | ||

| SE461298B (en) * | 1988-06-02 | 1990-01-29 | Asea Brown Boveri | PLANET METERS FOR ROLLED BANDS |

| CN2198987Y (en) * | 1994-08-23 | 1995-05-31 | 陈平 | Band coiling device for steel band-coiled type pressure container |

| DE19520709A1 (en) * | 1995-06-09 | 1996-12-12 | Schloemann Siemag Ag | Drivers for rolled strips |

| JPH10137846A (en) * | 1996-11-06 | 1998-05-26 | Mitsubishi Heavy Ind Ltd | Band steel coiler for hot rolling equipment |

| DE19704447A1 (en) * | 1997-02-06 | 1998-08-13 | Schloemann Siemag Ag | Flatness measuring roller |

| DE19818207C2 (en) * | 1998-04-23 | 2000-05-31 | Schloemann Siemag Ag | Steckel hot rolling mill |

| US6039283A (en) * | 1998-05-19 | 2000-03-21 | Hylsa S.A. De C.V. | Thin strip coiling system |

| US6146411A (en) * | 1998-12-24 | 2000-11-14 | Alsius Corporation | Cooling system for indwelling heat exchange catheter |

| US6321052B1 (en) * | 1999-09-08 | 2001-11-20 | Fuji Xerox Co., Ltd. | Method and apparatus for correcting running state and tension for an endless belt in an image-forming apparatus |

| DE19953524A1 (en) * | 1999-11-05 | 2001-05-10 | Sms Demag Ag | Loop lifter |

| US6722087B1 (en) * | 2000-09-21 | 2004-04-20 | Mic Industries | Building panel and panel crimping machine |

| DE10131850B4 (en) * | 2001-06-30 | 2013-04-25 | Sms Siemag Aktiengesellschaft | Thin strip reel with flatness measuring roll |

| FI114391B (en) * | 2002-04-30 | 2004-10-15 | Pesmel Oy | Wrapping and diaphragm wrapping apparatus comprising a circumferential structure |

| DE10258499A1 (en) * | 2002-12-14 | 2004-07-01 | Sms Demag Ag | Deflection device of a reel system for reeling tapes |

-

2007

- 2007-09-21 BR BRPI0716770-9A patent/BRPI0716770B1/en active IP Right Grant

- 2007-09-21 US US12/442,715 patent/US20100025514A1/en not_active Abandoned

- 2007-09-21 CA CA2664263A patent/CA2664263C/en not_active Expired - Fee Related

- 2007-09-21 CN CN2007800356368A patent/CN101516539B/en active Active

- 2007-09-21 JP JP2009528648A patent/JP2010504216A/en active Pending

- 2007-09-21 WO PCT/EP2007/008217 patent/WO2008037395A1/en active Application Filing

- 2007-09-21 KR KR1020097003037A patent/KR101071117B1/en active IP Right Grant

- 2007-09-21 DE DE102007045425A patent/DE102007045425A1/en not_active Withdrawn

- 2007-09-21 RU RU2009115695/02A patent/RU2391167C1/en active

- 2007-09-21 EP EP07818307.6A patent/EP2109510B1/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| BRPI0716770B1 (en) | 2019-03-26 |

| CN101516539A (en) | 2009-08-26 |

| EP2109510A1 (en) | 2009-10-21 |

| US20100025514A1 (en) | 2010-02-04 |

| BRPI0716770A2 (en) | 2013-09-17 |

| WO2008037395A1 (en) | 2008-04-03 |

| JP2010504216A (en) | 2010-02-12 |

| CA2664263C (en) | 2011-04-19 |

| RU2391167C1 (en) | 2010-06-10 |

| CN101516539B (en) | 2012-02-15 |

| CA2664263A1 (en) | 2008-04-03 |

| KR101071117B1 (en) | 2011-10-07 |

| DE102007045425A1 (en) | 2008-04-17 |

| KR20090031622A (en) | 2009-03-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2109510B1 (en) | Method and apparatus for winding up metal strips onto a winding mandrel | |

| EP2069088B1 (en) | Method and device for winding metal strips onto a coiling mandrel | |

| DE2618901C2 (en) | Device for strip tension control in a continuous rolling mill | |

| EP3584016B1 (en) | Wear reduction in coil box rollers | |

| DE10131850B4 (en) | Thin strip reel with flatness measuring roll | |

| EP1784266B1 (en) | Rolling mill for rolling a metallic strip | |

| EP1278606B1 (en) | Method and device for reeling up in the proper position a hot-rolled strip in a reeling installation | |

| EP1908534B1 (en) | Rolling mill and method for flexible cold or hot one-way or reverse rolling of a metal strip | |

| EP1097754B1 (en) | Loop lifter | |

| EP3917694A1 (en) | Changing the effective contour of a running surface of a working roll during the hot rolling of rolling stock in a roll stand to form a rolled strip | |

| EP2624977A1 (en) | Driver for a steel strip coiling installation | |

| EP1763410B1 (en) | Method and device for reducing vibrations in a steckel mill | |

| DE2911881A1 (en) | Sling lifter | |

| DE102013207188A1 (en) | Apparatus and method for thornless winding a metal strip | |

| EP0817688A1 (en) | Strip winder | |

| WO2010094506A2 (en) | Strip coiler for starting and finishing to coil metal strips | |

| DE2600784C3 (en) | Process for rolling hot strip and hot strip mill for carrying out the process | |

| EP3307448B1 (en) | Method and device for controlling a parameter of a rolled stock | |

| EP2637807B1 (en) | Rolling mill for rolling a metal strip | |

| AT510468B1 (en) | FLOW FOOT FOR AN ESPECIALLY METALLIC TAPE | |

| EP2745948A1 (en) | Coiling device with reel shaft which can be bent back | |

| DE1995821U (en) | DEVICE FOR WINDING RAIL-SHAPED MATERIALS. | |

| DE102011089744A1 (en) | Speed measuring device for hot-rolled strip speed measurement in intermediate scaffold region, has magnet rotatably arranged at roll-forehead-final side, and sensor arranged in stationary manner with magnet set opposite to holding element | |

| DE29511051U1 (en) | Pulling machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20090427 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20130920 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 651898 Country of ref document: AT Kind code of ref document: T Effective date: 20140215 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502007012760 Country of ref document: DE Effective date: 20140327 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20140212 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140212 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140612 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140212 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140212 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140212 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140212 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140212 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140612 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140212 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140212 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140212 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140212 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502007012760 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140212 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140212 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20141113 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502007012760 Country of ref document: DE Effective date: 20141113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140212 Ref country code: LU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140921 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20140921 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140212 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20150529 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140930 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140930 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140921 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502007012760 Country of ref document: DE Representative=s name: HEMMERICH & KOLLEGEN, DE Ref country code: DE Ref legal event code: R081 Ref document number: 502007012760 Country of ref document: DE Owner name: SMS GROUP GMBH, DE Free format text: FORMER OWNER: SMS SIEMAG AG, 40237 DUESSELDORF, DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140921 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140212 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140513 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20070921 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140212 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230707 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20230921 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20230927 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240918 Year of fee payment: 18 |