EP2067533B2 - Vibrateur pour un appareil de fonçage vibratoire - Google Patents

Vibrateur pour un appareil de fonçage vibratoire Download PDFInfo

- Publication number

- EP2067533B2 EP2067533B2 EP08000543.2A EP08000543A EP2067533B2 EP 2067533 B2 EP2067533 B2 EP 2067533B2 EP 08000543 A EP08000543 A EP 08000543A EP 2067533 B2 EP2067533 B2 EP 2067533B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- vibrator

- sensors

- module

- accordance

- unbalanced masses

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000001133 acceleration Effects 0.000 claims description 17

- 230000003068 static effect Effects 0.000 claims description 12

- 230000001939 inductive effect Effects 0.000 claims description 6

- 239000000463 material Substances 0.000 claims description 4

- 230000000007 visual effect Effects 0.000 claims description 3

- 230000001105 regulatory effect Effects 0.000 claims 1

- 238000011156 evaluation Methods 0.000 description 5

- 230000001965 increasing effect Effects 0.000 description 3

- 238000010276 construction Methods 0.000 description 2

- 238000001514 detection method Methods 0.000 description 2

- 239000002689 soil Substances 0.000 description 2

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B06—GENERATING OR TRANSMITTING MECHANICAL VIBRATIONS IN GENERAL

- B06B—METHODS OR APPARATUS FOR GENERATING OR TRANSMITTING MECHANICAL VIBRATIONS OF INFRASONIC, SONIC, OR ULTRASONIC FREQUENCY, e.g. FOR PERFORMING MECHANICAL WORK IN GENERAL

- B06B1/00—Methods or apparatus for generating mechanical vibrations of infrasonic, sonic, or ultrasonic frequency

- B06B1/10—Methods or apparatus for generating mechanical vibrations of infrasonic, sonic, or ultrasonic frequency making use of mechanical energy

- B06B1/16—Methods or apparatus for generating mechanical vibrations of infrasonic, sonic, or ultrasonic frequency making use of mechanical energy operating with systems involving rotary unbalanced masses

- B06B1/161—Adjustable systems, i.e. where amplitude or direction of frequency of vibration can be varied

- B06B1/166—Where the phase-angle of masses mounted on counter-rotating shafts can be varied, e.g. variation of the vibration phase

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D7/00—Methods or apparatus for placing sheet pile bulkheads, piles, mouldpipes, or other moulds

- E02D7/18—Placing by vibrating

Definitions

- the invention relates to a vibration generator according to the preamble of claim 1.

- the invention further relates to a vibratory pile driver according to claim 6.

- vibrators are used to bring objects such as profiles into the ground or to pull them out of the ground or to compact soil material.

- the soil is stimulated by vibration and thus reaches a "pseudo-liquid" state.

- the vibration is characterized by a linear movement and is generated by pairwise counter-rotating imbalances within a Vibratorgetriebes.

- Vibration generators are characterized by the rotating unbalance and the maximum speed. Such a vibration generator is eg in EP 0 926 300 A1 disclosed.

- the vibration generators are linear vibration exciters whose centrifugal force is generated by rotating imbalances. These vibration exciters move at a variable speed.

- the size of the imbalance is also called "static moment".

- the course of the velocity of the linear vibration exciter corresponds to a periodically recurring function, for example a sine function, but it can also take other forms. For a sinusoidal course of the velocity, the following applies: If the unbalance center of gravity is in the direction of movement or perpendicular thereto, the angular acceleration of the imbalances and all the associated rotating parts is 0. Maximum values of the angular acceleration occur when the imbalances relative to the direction of movement are approximately 45, 135, 225 or 315 degrees are deflected.

- the invention aims to remedy this situation.

- the invention is based on the object to provide a vibration exciter, which allows a reduction in the indexed by changing vibration speeds loads of machine elements in operation. According to the invention, this object is solved by the features of the characterizing part of patent claim 1.

- a vibration exciter is created, which allows a reduction in the indicated by changing vibration speeds loads of machine elements in operation.

- sensors for detecting the relative position of the imbalance masses to each other and for detecting the acceleration of the vibrator.

- the sensors preferably include inductive sensors, acceleration sensors and / or rotary encoders. Such sensors have proven to be durable and robust.

- the sensors are connected to an evaluation unit, which compares the measured values recorded by the sensors with stored maximum values. This allows the detection of load peaks.

- the evaluation unit preferably determines the currently applied static torque on the basis of the measured values determined by the sensors.

- the evaluation unit is connected to an audible and / or visual warning device.

- a device for controlling the vibration generator is arranged, which is connected to the evaluation unit. In this way, automatic regulation of the vibration generator as a function of the detected measured values of the vibration generator is made possible.

- the means for changing the relative rotational position of the rotatable imbalance masses to each other via the control device can be controlled. This allows a direct control of the static torque of the vibrator.

- the evaluation unit advantageously has a programmable logic controller (PLC). This allows flexible control of the vibration generator.

- PLC programmable logic controller

- the invention is further based on the object to provide a Vibratoryramm réelle that allows a reduction in the indicated by changing vibration speeds of the vibrator loads of machine elements in operation. According to the invention, this object is solved by the features of patent claim 6.

- a vibratory pile driver is provided, which allows a reduction in the indicated by changing vibration velocities of the vibrator loads of machine elements in operation.

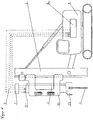

- the vibration ramming device chosen as an exemplary embodiment consists essentially of a carrier device 1, on which a vibrator (vibrator) 3 is arranged so as to be vertically displaceable via a broker 2.

- the vibration generator 3 comprises a housing 31, which is surrounded by a hood 30. On the hood 30, a clamping tongs 37 for receiving pile material 4 is arranged.

- the hood 30 serves to guide the vibrator 3 and transmits the static force of the leader 2 to the vibrator 3.

- the vibrator 3 generates via rotating imbalances 3311, 3321, 3331, 3511, 3521, 3531, a vibration which via the clamping forceps 33 on the Rammgut 4 is transmitted.

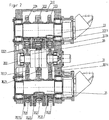

- the vibrator 3 is designed as a vibrator gearbox ( FIG. 2 ). It consists essentially of a housing 31 in which gears 331, 332, 333, 351, 352, 353 provided with shafts 33, 35 are rotatably mounted.

- the gears 331, 332, 333, 351, 352, 353 are each provided with unbalanced masses 3311, 3321, 3331, 3511, 3521, 3531, wherein the gears of both shafts 3, 5 via gears 3613, 3614 of the rotor shaft 361 of a pivot motor 36 with each other are engaged.

- the gears 331, 3321, 3331, 3511, 3521, 3531 provided with unbalanced masses 331, 332, 333, 351, 352, 353 are adjustable relative to each other via the pivot motor 36 in its rotational position, whereby the resulting imbalance or the resulting static moment is adjustable.

- Such Vibratorgetriebe with rotatably mounted imbalance masses that are adjustable in relative phase position the skilled person for example from the DE 20 2007 005 283 U1 known.

- the vibrator 3 is opposite to the gears 331, 332, 333, 351, 352, 353 provided on the inside of the housing 31 each with two parallel to the circumference of the gears spaced from each other arranged inductive sensors 310.

- the inductive sensors 310 enable the detection of the angular acceleration of the rotating imbalance masses 3311, 3321, 3331, 3511, 3521, 3531.

- the time offset of the imbalance masses 3311, 3321, 3331, 3511, 3521, 3531 can furthermore be used to determine their relative position to one another.

- an acceleration sensor 311 is arranged on the housing 31 of the vibration generator 3.

- a programmable logic controller (PLC) 7 is arranged, which further calculated on the basis of frequency and time offset of the imbalance masses to each other applied static moment.

- PLC programmable logic controller

- a controller 8 is arranged, which is connected via lines 6 to the PLC 7.

- the controller 8 is set up in such a way that it calculates an admissible angular acceleration of the rotating parts of the vibration generator 3 from the static torque determined by the SPS 7 and the known moment of inertia of the rotating parts and the acceleration data determined by the sensor 311.

- the installation of an optical and / or acoustic signal in the operator's stand of the carrier device is possible in order to inform the operator of exceeding permissible acceleration values.

- the adjustment of the resulting imbalance / the resulting static torque can be done in this case on the operator by appropriate control of the swing motor within the vibrator 3.

Landscapes

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Mining & Mineral Resources (AREA)

- Paleontology (AREA)

- Civil Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Structural Engineering (AREA)

- Mechanical Engineering (AREA)

- Apparatuses For Generation Of Mechanical Vibrations (AREA)

- Measurement Of Mechanical Vibrations Or Ultrasonic Waves (AREA)

Claims (6)

- Vibrateur à mettre en oeuvre dans un appareil de fonçage vibratoire, comprenant une transmission de vibrations agencée dans un carter, comprenant des masselottes en rotation agencées sur au moins deux arbres, sachant qu'à l'intérieur du carter sont agencés des moyens permettant de modifier les positions de rotation relatives des masselottes, caractérisé en ce qu'à l'intérieur du carter sont agencés des capteurs (310,311) servant à saisir la position des masselottes (3311, 3321, 3331, 3511, 3521, 3531) les unes par rapport aux autres, et que des capteurs sont prévus pour saisir l'accélération du vibrateur, et en ce qu'est prévu un module (7) servant à déterminer l'accélération angulaire des masselottes en rotation (3311, 3321, 3331, 3511, 3521, 3531) sur la base des valeurs de mesure saisies par les capteurs (310, 311), sachant que ces capteurs (310, 311) sont reliés au module (7) qui compare les valeurs de mesure saisies par les capteurs (310, 311) avec des valeurs maximales en mémoire et qui est relié à un équipement agencé servant à réguler le vibrateur, équipement qui permet d'exciter les moyens (36) servant à modifier les positions de rotation relatives des masselottes rotatives (3311, 3321, 3331, 3511, 3521, 3531).

- Vibrateur selon la revendication 1, caractérisé en ce que les capteurs (310, 311) comprennent des capteurs et/ou encodeurs rotatifs inductifs.

- Vibrateur selon l'une des revendications 1 à 2, caractérisé en ce que le module (7) détermine le moment statique ponctuel sur la base des valeurs de mesure saisies par les capteurs (310, 311).

- Vibrateur selon l'une des revendications 1 à 3, caractérisé en ce que le module (7) est relié à un équipement avertisseur sonore et / ou visuel.

- Vibrateur selon l'une des revendications 1 à 4, caractérisé en ce que le module (7) présente un automate programmable industriel (API).

- Appareil de fonçage vibratoire destiné à enfoncer des éléments de fonçage dans le sol ou à les en extraire, ainsi qu'à compacter du matériau constitutif du sol, comprenant un vibrateur (3) selon l'une des revendications 1 à 5.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP08000543.2A EP2067533B2 (fr) | 2007-12-06 | 2008-01-12 | Vibrateur pour un appareil de fonçage vibratoire |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP07025254 | 2007-12-06 | ||

| EP08000543.2A EP2067533B2 (fr) | 2007-12-06 | 2008-01-12 | Vibrateur pour un appareil de fonçage vibratoire |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2067533A1 EP2067533A1 (fr) | 2009-06-10 |

| EP2067533B1 EP2067533B1 (fr) | 2013-09-25 |

| EP2067533B2 true EP2067533B2 (fr) | 2016-12-07 |

Family

ID=39415437

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08000543.2A Active EP2067533B2 (fr) | 2007-12-06 | 2008-01-12 | Vibrateur pour un appareil de fonçage vibratoire |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US20090146514A1 (fr) |

| EP (1) | EP2067533B2 (fr) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ATE531462T1 (de) * | 2009-06-26 | 2011-11-15 | Anlagentech Baumasch Ind | Schwingungserreger |

| DE102010010037B4 (de) * | 2010-03-03 | 2019-10-31 | Bomag Gmbh | Stufenlos verstellbarer Schwingungserreger |

| RU2672118C1 (ru) * | 2015-04-17 | 2018-11-12 | Юнттан Ой | Способ забивки свай |

| DE102017001877A1 (de) * | 2017-02-27 | 2018-08-30 | Liebherr-Werk Nenzing Gmbh | Verfahren zum Erkennen von Hindernissen beim Betrieb einer Vibrationsramme |

| KR20210149820A (ko) * | 2019-04-12 | 2021-12-09 | 가부시끼가이샤 사따께 | 체분리 장치의 운전 감시 시스템 |

Family Cites Families (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3744322A (en) * | 1970-12-07 | 1973-07-10 | Space Res Corp | Angular velocity sensors |

| DE2442367A1 (de) * | 1974-09-04 | 1976-03-18 | Tracto Technik | Hydraulisch angetriebener vibrator |

| US4143719A (en) * | 1976-02-27 | 1979-03-13 | Kabushiki Kaisha Komatsu Seisakusho | Multi-vibro pile hammer |

| US4211121A (en) * | 1976-09-01 | 1980-07-08 | Fmc Corporation | Vibrator with eccentric weights |

| US4113034A (en) * | 1977-06-20 | 1978-09-12 | Raygo, Inc. | Uniaxial variable vibratory force generator |

| DE3043719A1 (de) * | 1980-11-20 | 1982-06-24 | Wacker-Werke Gmbh & Co Kg, 8077 Reichertshofen | Schwingungserreger fuer bodenverdichtungsgeraete |

| US4766771A (en) * | 1984-11-15 | 1988-08-30 | Outboard Marine Corporation | Shaking apparatus |

| US4793196A (en) * | 1987-03-24 | 1988-12-27 | Key Technology, Inc. | Gear coupled, counter-rotating vibratory drive assembly |

| US4819740A (en) * | 1987-11-16 | 1989-04-11 | Vulcan Iron Works Inc. | Vibratory hammer/extractor |

| JP2729969B2 (ja) * | 1990-03-29 | 1998-03-18 | 株式会社高橋エンジニアリング | 杭打ち装置 |

| US5177386A (en) * | 1990-08-30 | 1993-01-05 | Kencho Kobe Co., Ltd. | Vibration generator adjustable during operation |

| FR2674594B1 (fr) * | 1991-03-28 | 1993-06-04 | Acb | Dispositif pour compenser une force vibratoire ou un couple vibratoire subi par un corps. |

| FR2692523B1 (fr) * | 1992-06-19 | 1994-10-07 | Procedes Tech Construction | Dispositif pour la commande d'un vibrateur à moment variable. |

| DE4301368A1 (de) * | 1992-07-03 | 1994-01-05 | Gedib Ingbuero Innovation | Vorrichtung und Verfahren zur Schwingungserregung |

| AU692479B2 (en) * | 1993-11-30 | 1998-06-11 | Sakai Heavy Industries, Ltd. | Vibrating mechanism and apparatus for generating vibrations for a vibration compacting roller with a variable amplitude |

| DE4425905A1 (de) * | 1994-07-21 | 1996-01-25 | Bald Hubert | Vorrichtung und Verfahren zur Kompensation von Querschwingungen an Unwuchtvibratoren mit vorgegebener Schwingrichtung |

| DE19507466C2 (de) * | 1995-03-03 | 1999-07-29 | Braun Paul W | Vorrichtung zur Bestimmung einer Positionsänderung |

| DE19636268C2 (de) * | 1996-09-06 | 1998-07-16 | Hofmann Werkstatt Technik | Verfahren zum Eindrehen eines in einer Auswuchtmaschine drehgelagerten und mittels eines Antriebs antreibbaren Rotors, insbesondere Kraftfahrzeugrades, in Ausgleichspositionen zweier Ausgleichsebenen für einen dynamischen Unwuchtmassenausgleich |

| FR2772805B1 (fr) * | 1997-12-24 | 2000-02-25 | Procedes Tech Const | Dispositif pour la commande asservie de l'amplitude des vibrations d'un vibrateur a moment variable |

| NL1008635C2 (nl) * | 1998-03-19 | 1999-09-21 | Ice B V | Trilinrichting en werkwijze voor het trillend aandrijven van een voorwerp. |

| US6098447A (en) * | 1998-10-16 | 2000-08-08 | Frederick Engineering Co. | Dynamic force measuring instrument for foundation and casing |

| DE10038206C2 (de) * | 2000-08-04 | 2002-09-26 | Wacker Werke Kg | Regelbarer Schwingungserreger |

| US20030082002A1 (en) * | 2001-10-31 | 2003-05-01 | Potts Dean R. | Variable vibratory mechanism |

| US6769838B2 (en) * | 2001-10-31 | 2004-08-03 | Caterpillar Paving Products Inc | Variable vibratory mechanism |

| JP2007163244A (ja) * | 2005-12-13 | 2007-06-28 | Epson Toyocom Corp | 加速度センサ素子、加速度センサ |

| JP2008047194A (ja) * | 2006-08-11 | 2008-02-28 | Fujitsu Ltd | バランス修正装置 |

| DE202007005283U1 (de) * | 2007-03-07 | 2007-07-12 | Abi Gmbh | Schwingungserreger |

-

2008

- 2008-01-12 EP EP08000543.2A patent/EP2067533B2/fr active Active

- 2008-12-05 US US12/315,718 patent/US20090146514A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| EP2067533B1 (fr) | 2013-09-25 |

| EP2067533A1 (fr) | 2009-06-10 |

| US20090146514A1 (en) | 2009-06-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2085149B2 (fr) | Vibrateur pour un appareil de fonçage vibratoire | |

| EP3491192B1 (fr) | Rouleau de compactage du sol comprenant un dispositif de détection sur la garniture du rouleau et procédé de détermination de la rigidité du sol | |

| EP2067533B2 (fr) | Vibrateur pour un appareil de fonçage vibratoire | |

| EP2085148B1 (fr) | Vibrateur pour un appareil de fonçage vibratoire | |

| DE102015006398B3 (de) | Bodenverdichtung mit einem Baggeranbauverdichter | |

| EP2791423B1 (fr) | Dispositif permettant de détecter le mouvement du rouleau d'un compacteur de sol | |

| DE102006008266B4 (de) | Verfahren und Vorrichtung zum Messen von Bodenparametern mittels Verdichtungsmaschinen | |

| EP3102920B1 (fr) | Machine de vibration | |

| DE112010000670B4 (de) | System und Verfahren zum Steuern einer Oberflächenverdichtung einer Walzmaschine mit Vibrationsverdichtungswalze | |

| EP2928611B1 (fr) | Procédé de réglage d'entraînement et système d'entraînement fonctionnant selon ce procédé | |

| EP2627826B1 (fr) | Méthode pour la détermination de la rigidité et/ou de l'amortissement d'un domaine d'une solidité | |

| DE102010060843B4 (de) | Verfahren und Vorrichtung zum Messen von Bodenparametern mittels Verdichtungsmaschinen | |

| EP2105214A1 (fr) | Dispositif de production de vibrations | |

| CN107347251A (zh) | 用于压实机的振动设备 | |

| DE10019806A1 (de) | Bodenverdichtungsvorrichtung mit Schwingungsdetektion | |

| WO2008128619A1 (fr) | Générateur de vibrations pour dispositif de compactage du sol | |

| EP2781269A1 (fr) | Générateur de vibrations, notamment pour une machine de construction | |

| WO2013107886A1 (fr) | Élément roulant et procédé de détection | |

| EP2392413B1 (fr) | Marteaux à vibration | |

| EP3693090A1 (fr) | Tamiseur réglable et procede d'utilisation d'un tamiseur réglable | |

| DE102010006254A1 (de) | Vorrichtung und Verfahren zum Überwachen rotierender Maschinenelemente | |

| DE3508357A1 (de) | Verfahren zum dynamischen auswuchten gegenueber dem schwerpunkt symmetrischer rotationsmaschinen im montierten zustand | |

| DE10345591B3 (de) | Verfahren und Einrichtung zum Erfassen von unwuchtabhängigen Bewegungserscheinungen bei einer Wäschetrommel | |

| DE202008017313U1 (de) | Schwingungserzeuger für Vibrationsrammgerät | |

| EP1930505A1 (fr) | Compacteur à plaque |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20081014 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| AKX | Designation fees paid |

Designated state(s): AT DE FR GB NL |

|

| 17Q | First examination report despatched |

Effective date: 20100211 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20130522 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: HEICHEL, CHRISTIAN Inventor name: KLEIBL, ALBRECHT |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT DE FR GB NL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 633502 Country of ref document: AT Kind code of ref document: T Effective date: 20131015 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502008010704 Country of ref document: DE Effective date: 20131121 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 502008010704 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: BAUER MASCHINEN GMBH Effective date: 20140624 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 502008010704 Country of ref document: DE Effective date: 20140624 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20140112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140112 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20161207 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT DE FR GB NL |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 502008010704 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230513 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20240123 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20240118 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20231218 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20240123 Year of fee payment: 17 |